Bottle and closure assembly with locking elements

A cap assembly and capping technology, which is applied in the direction of caps, closures, bottle/container caps, etc., and can solve problems such as untightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

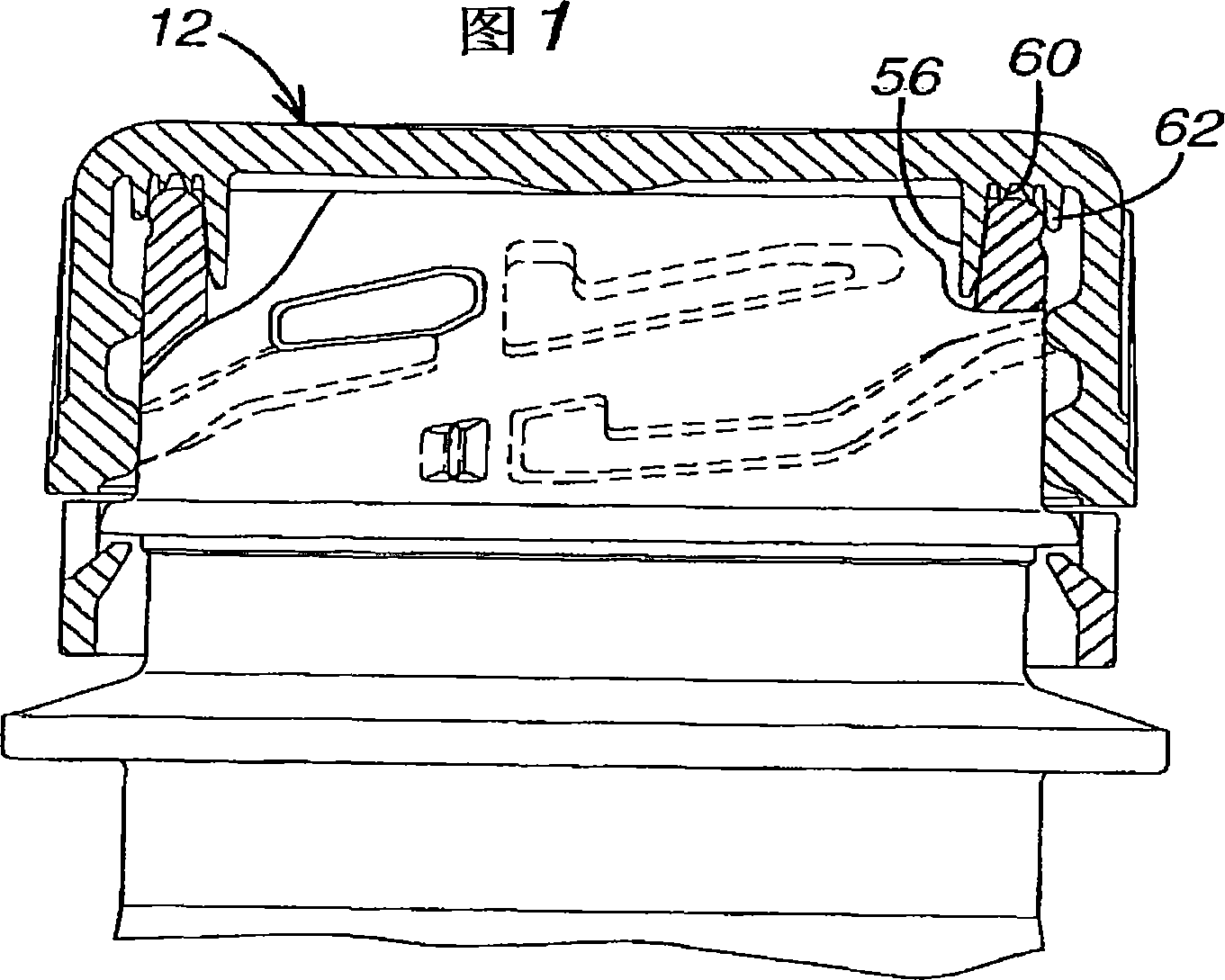

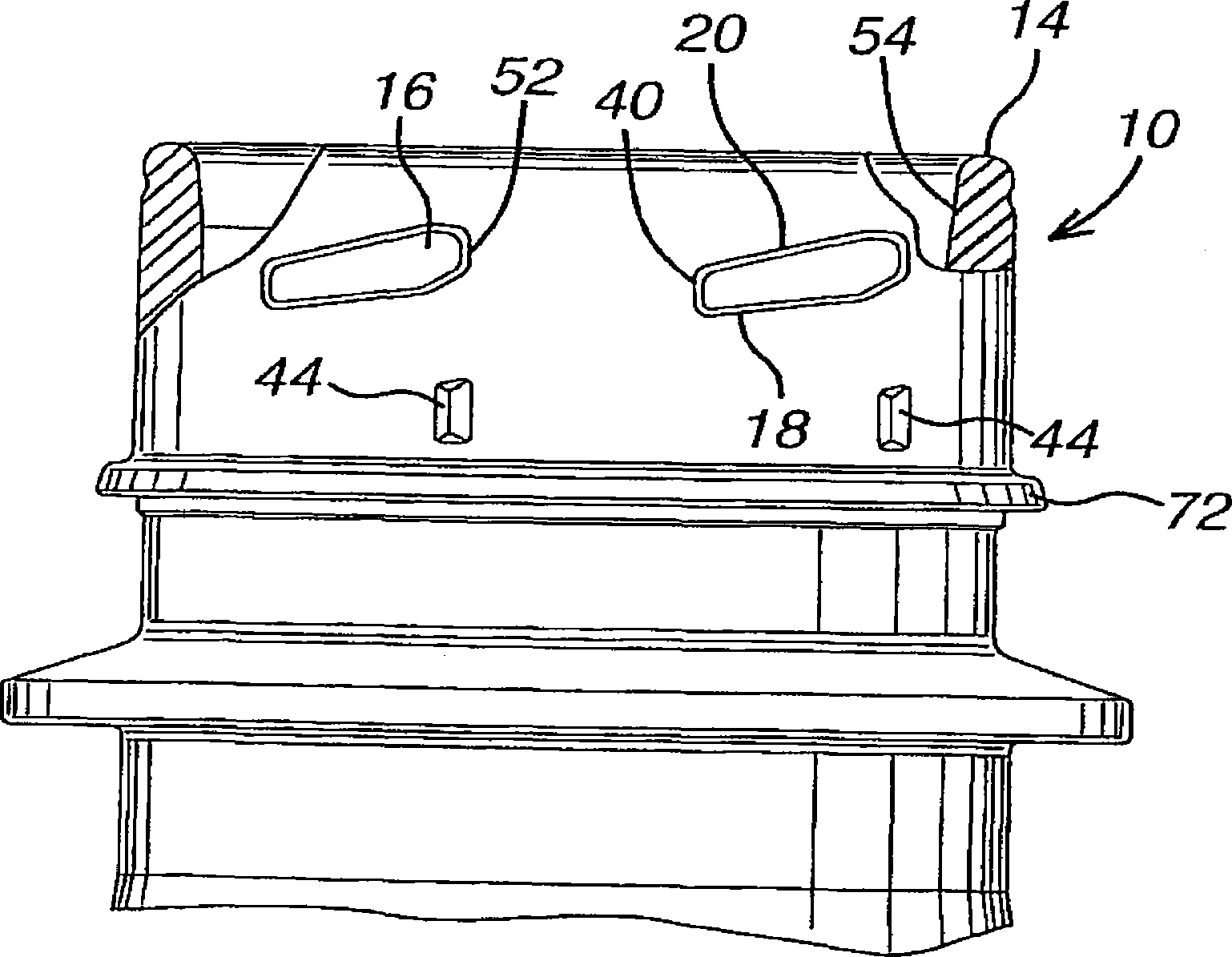

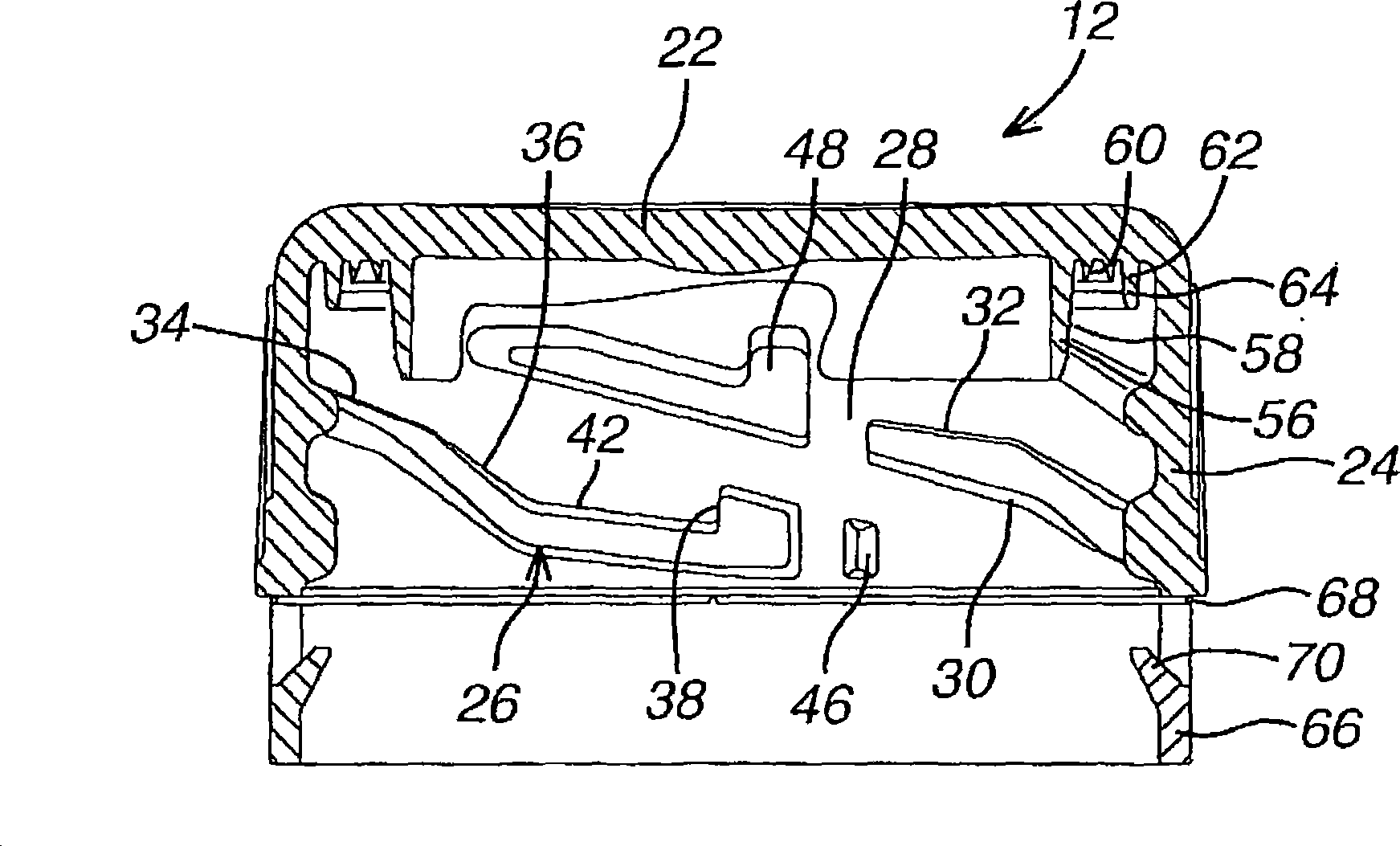

[0086] Please refer to Figure 1 and figure 2 , the present embodiment is a container closure assembly especially for carbonated beverage containers. The main features of this assembly are similar to those described and claimed in International Patent Applications WO95 / 05322, WO97 / 21602 and WO99 / 19228, the entire contents of which are hereby incorporated by reference. However, it is important to point out that the threads provided on the cap and neck of the present invention are reversed compared to the cap assemblies described in those applications. That is, the assembly detailed in the earlier patent application has a short threaded section at the closure skirt and a longer threaded section at the neck. However, the present invention provides a short threaded section at the neck and a longer threaded section at the closure skirt.

[0087] The assembly of this embodiment includes a container neck 10 and a closure 12 for a carbonated beverage container. Both the container ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com