Automatic feeding, positioning, conveying and press-fitting system for stator end cover

A technology of automatic feeding and stator end cover, applied in the manufacture of stator/rotor bodies, electromechanical devices, electric components, etc., can solve the problems of large manpower, unable to guarantee product qualification rate, no automatic positioning and pressing, etc., to save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

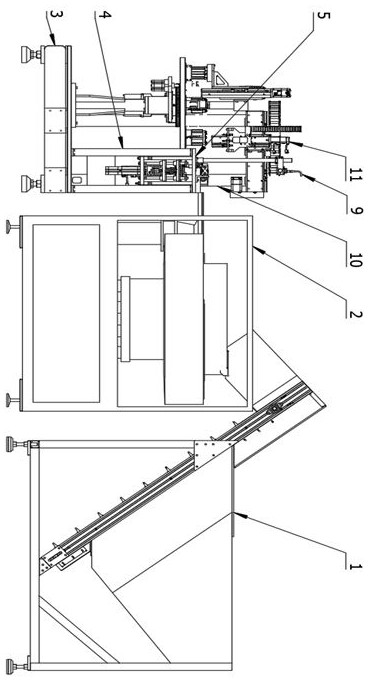

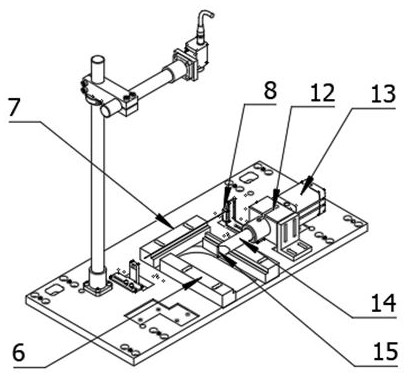

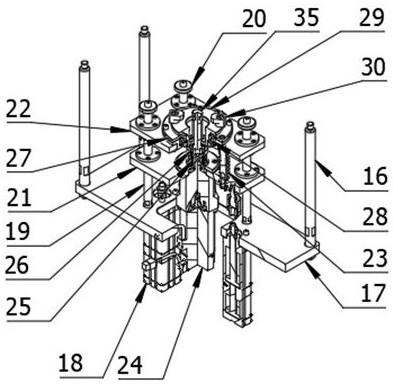

[0018] refer to Figure 1-Figure 6 . A stator end cover automatic feeding, positioning, conveying and pressing system, a column 4 is set up on the frame base 3 to support the upper plate 5, side beams 10 are also provided on the side of the frame base 3 to support and fix the transfer module manipulator 11, and the frame base 3 A turntable mechanism is arranged on the top; an end cover pressing mechanism is arranged on the turntable mechanism; a side positioning block 6, a front positioning block 7, a photoelectric switch 8 and a blocking guide block 12 are set at corresponding positions on the upper plate 5; A visual system 9 is established; a blocking cylinder 13 is provided on the side of the blocking guide block 12, and a latch 14 is arranged inside the blocking guiding block 12, and a blocking chamfer 15 is provided on the latch 14; the cylinder rod of the blocking cylinder 13 is fixedly connected with the latch 14; It is fixedly connected with the jacking and rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com