Cleanable press machine

一种冲压装置、清洁位置的技术,应用在冲压装置领域,达到简化清洁过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

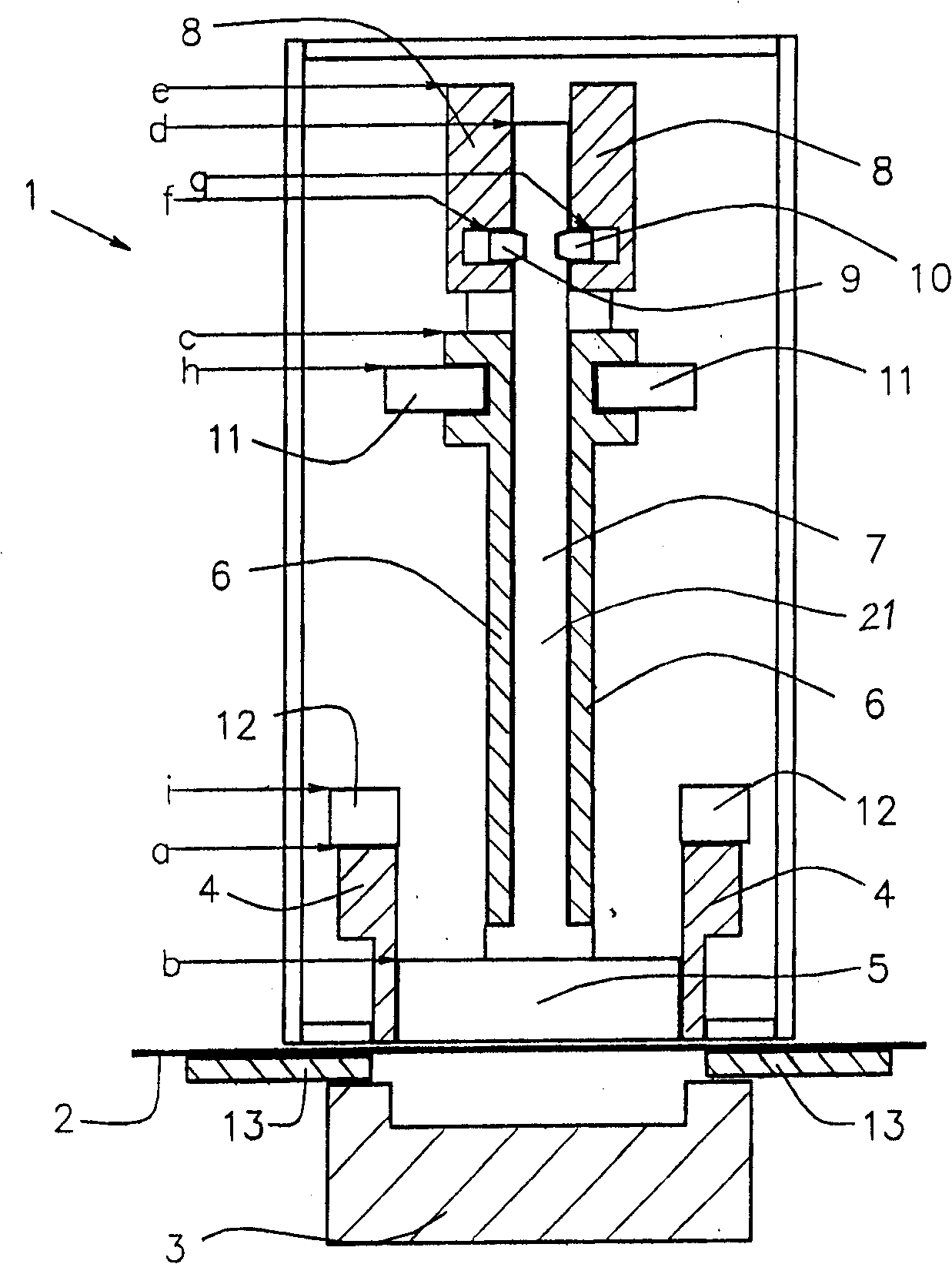

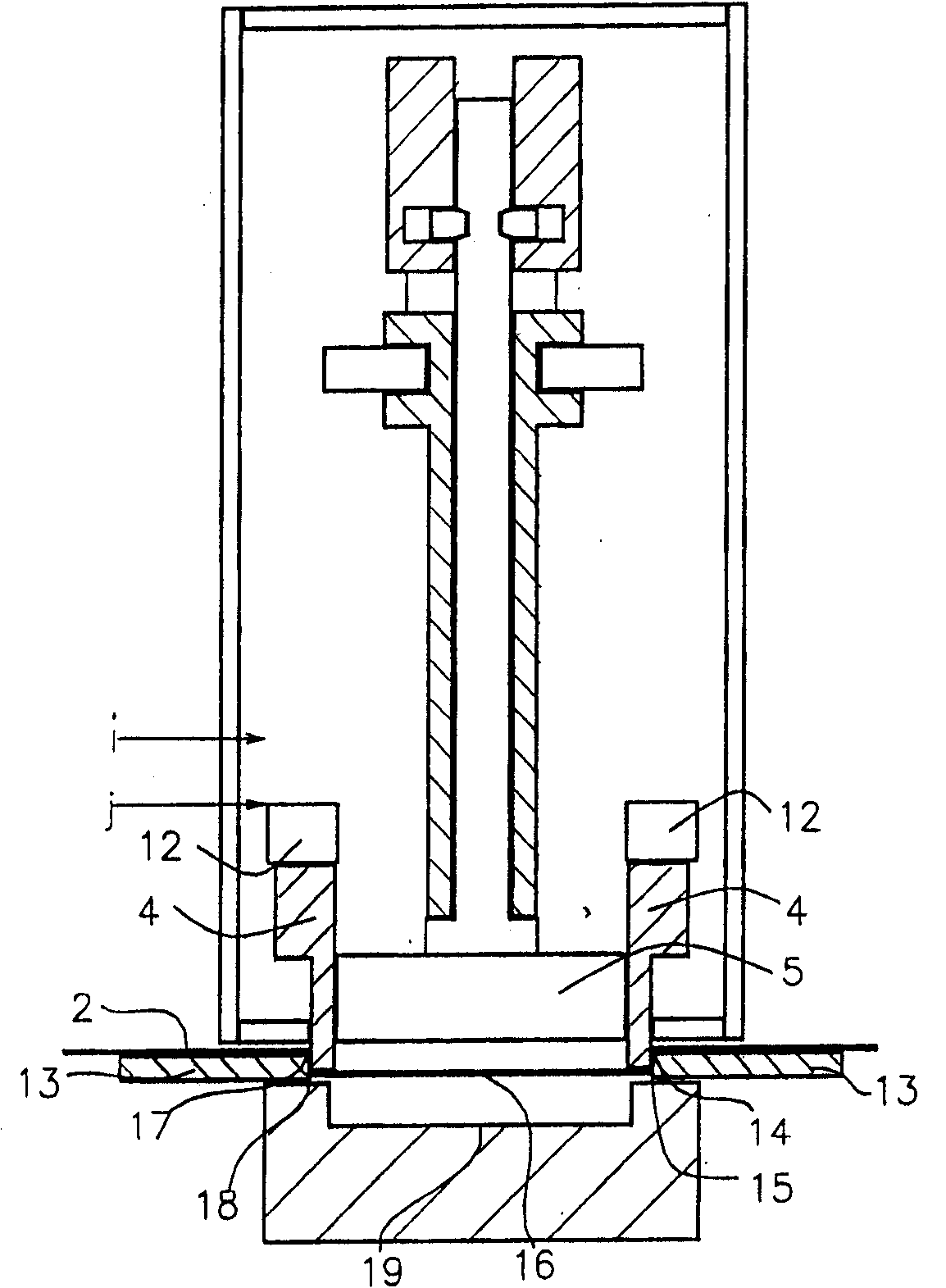

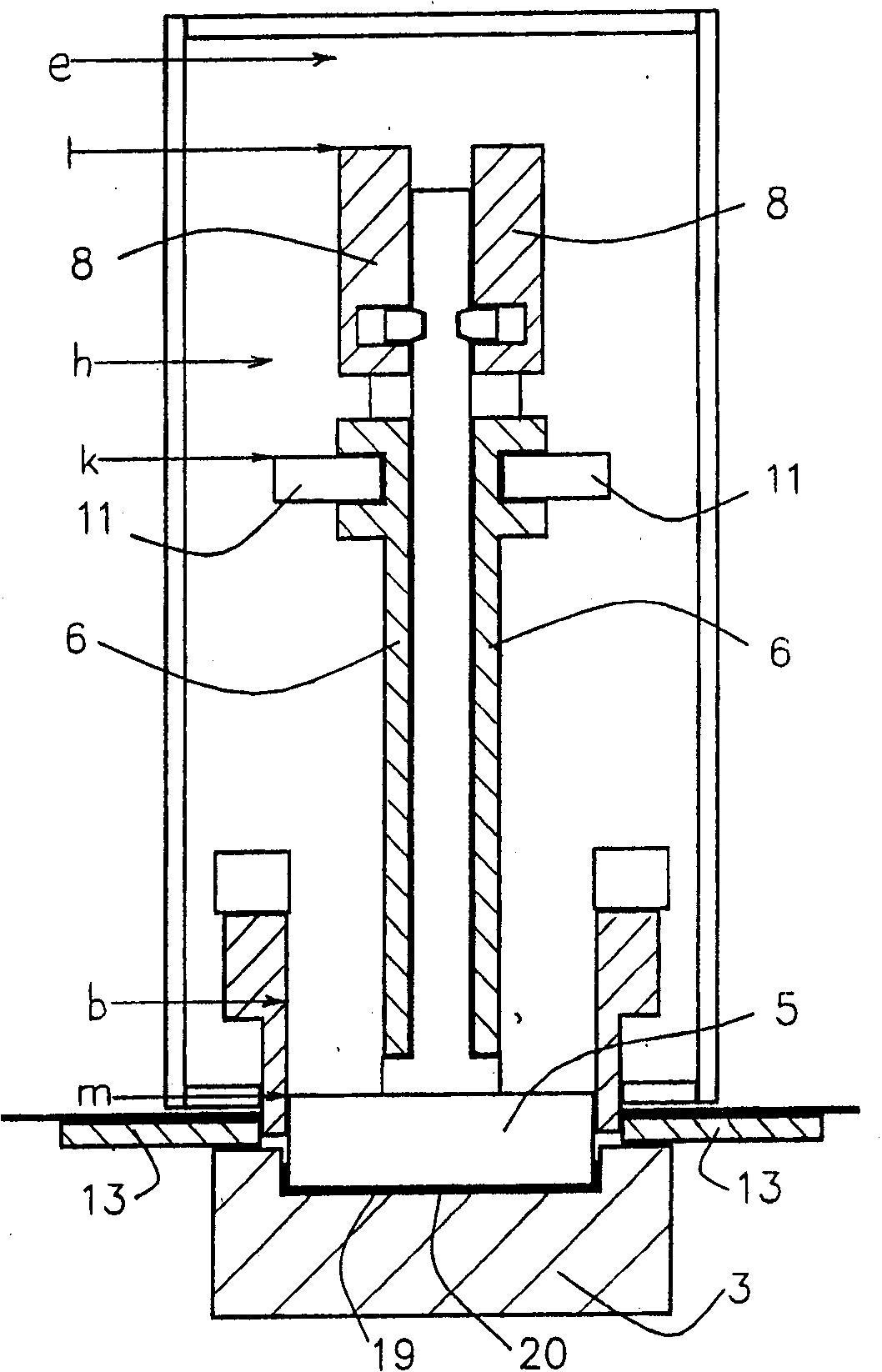

[0015] In order to describe the advantages of the present invention in detail, it should first be Figures 1 to 3 The procedure in stamping and forming a container bottom for a beverage container is described. then press Figure 4 Instructions clean. For the sake of simplicity, only the essential parts of the stamping device 1 necessary for the description of the invention are shown schematically. As mentioned above, the following description refers only to the bottom of the container. However, these embodiments are also suitable for the top cap, which is usually punched out in a second such punching device in a plant for producing beverage cartons.

[0016] figure 1 The stamping device is shown in the working position directly before stamping. A punching belt 2 made of cardboard composite material is located between a bending mandrel 3 and the punching device 1 . The bending mandrel 3 , the drawing sleeve 13 and the stamping device 1 are axially aligned with one another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com