Valve and assembly method

A technology of valve sleeves and valve holes, which is applied in valve devices, transportation and packaging, valve operation/release devices, etc., can solve problems such as increasing manufacturing costs, achieve low cost, reduce logistics costs, and improve logistics quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

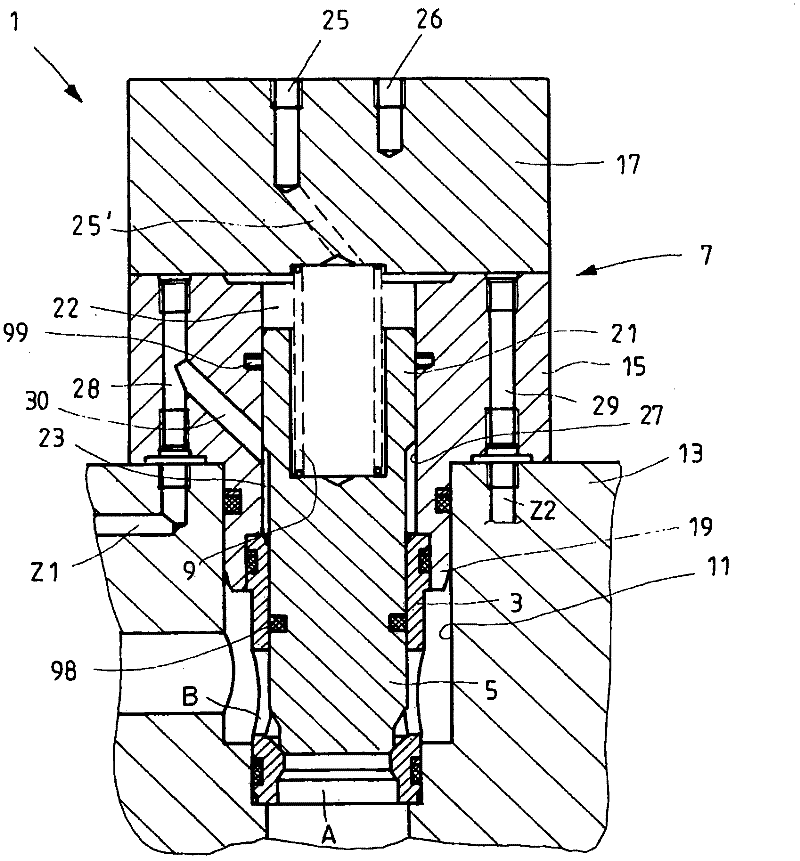

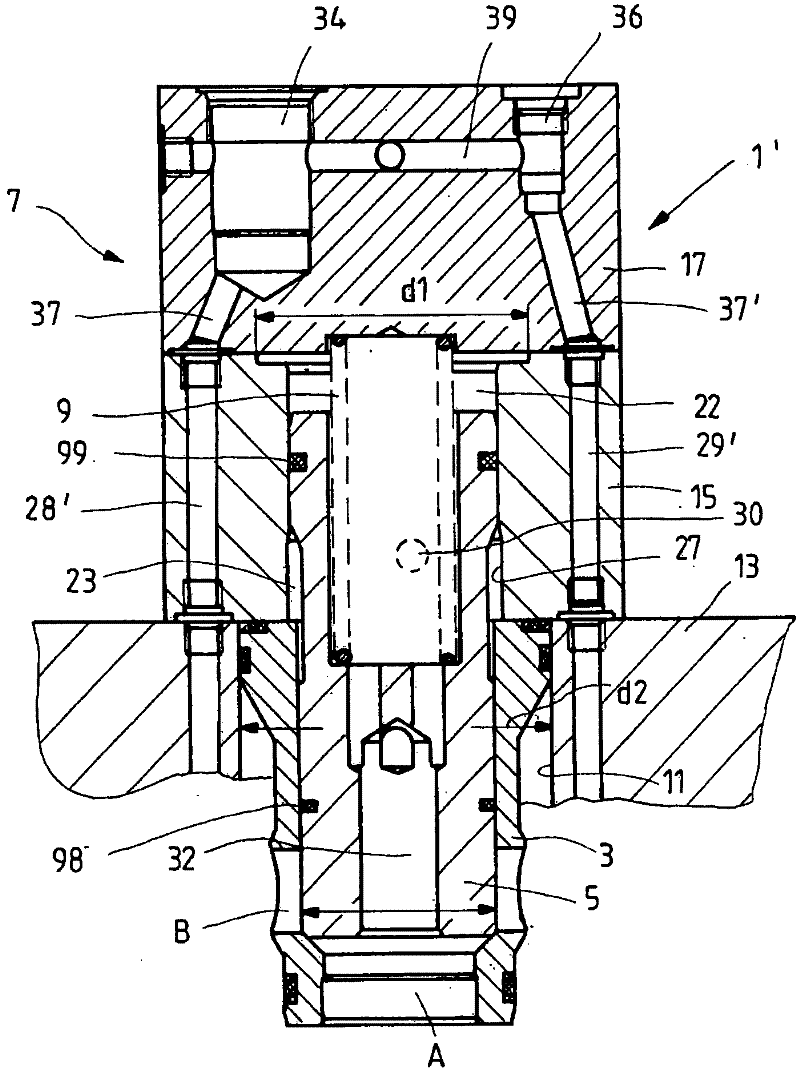

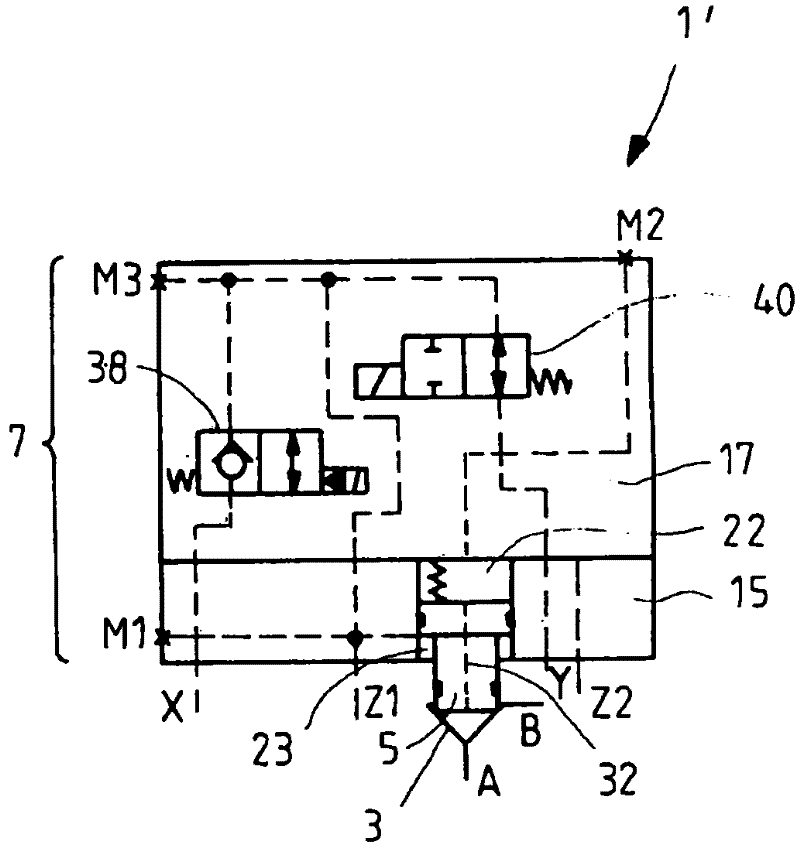

[0028] figure 1 A valve 1 applied in the hydraulic field is shown, to be precise a 2 / 2-way valve adjustable by means of an operating piston, also called an active logic valve. The valve 1 comprises a valve sleeve 3 , a valve piston 5 inserted into the valve sleeve 3 , a valve cover 7 and a spring 9 arranged between the valve piston 5 and the valve cover 7 . The valve sleeve 3 with the valve piston 5 located therein is inserted into the valve bore 11 of the control block 13 . In the control block 13 there are channels for the load connections A, B and the control connections X, Y (not shown), Z1 , Z2 of the valve 1 . The valve cover 7 is screwed onto the control block 13 above the valve hole 11 . The arrangement of the control interfaces X, Y, Z1, Z2 and the valve hole 11 complies with the German Industrial Standard DIN ISO 7368.

[0029] The valve is broadly divided into a main stage and an operating stage. The main stage is formed by a valve piston 5 inserted into the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com