Jaw seals for container closure assemblies

A cap assembly and container technology, which is applied to bottle/container caps, capping containers with caps, sealing caps, etc. It can solve the problems that the caps of containers are not easy to be tightened by users, and it is not easy to tighten them, so as to improve the sealing effect, Set novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

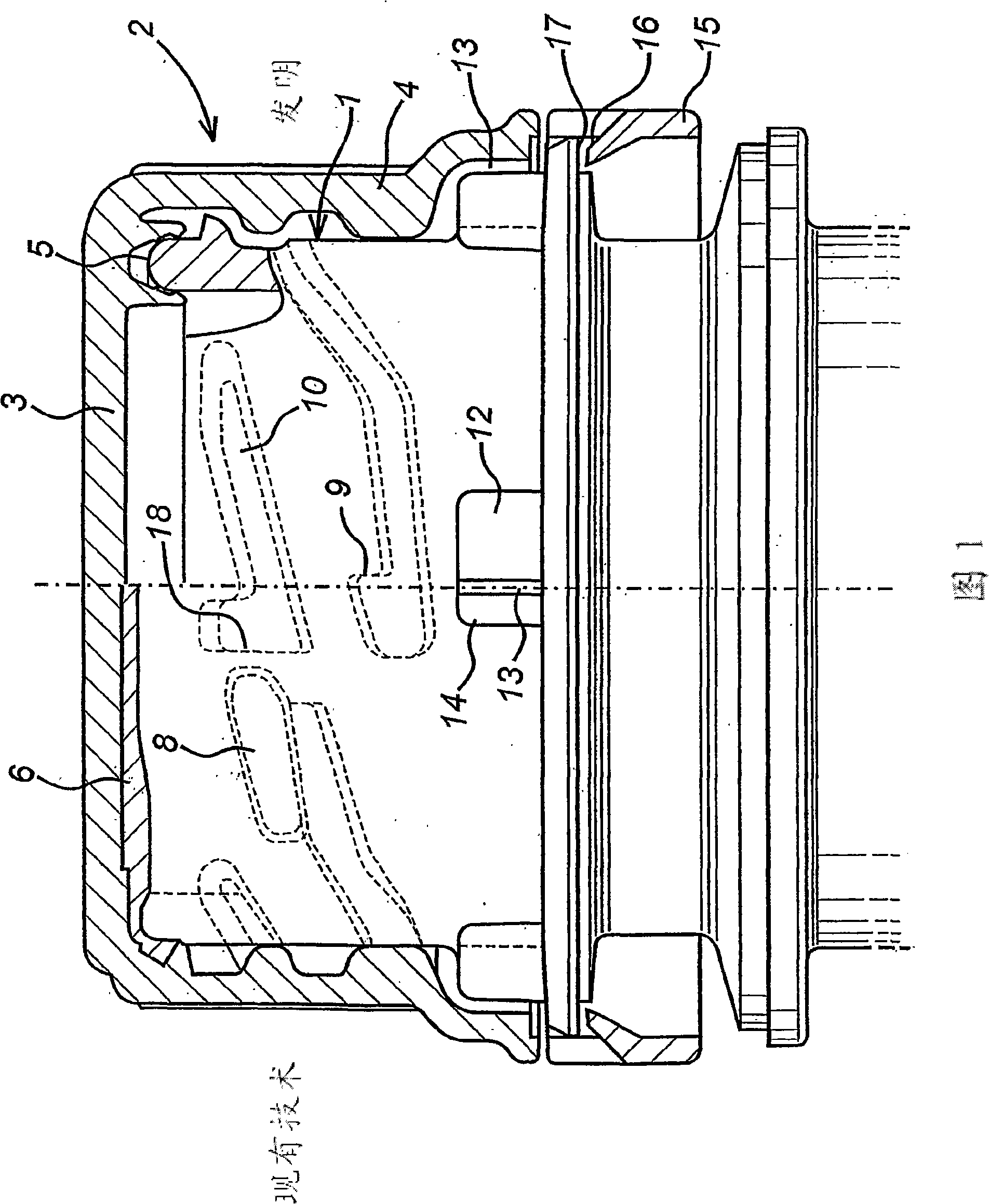

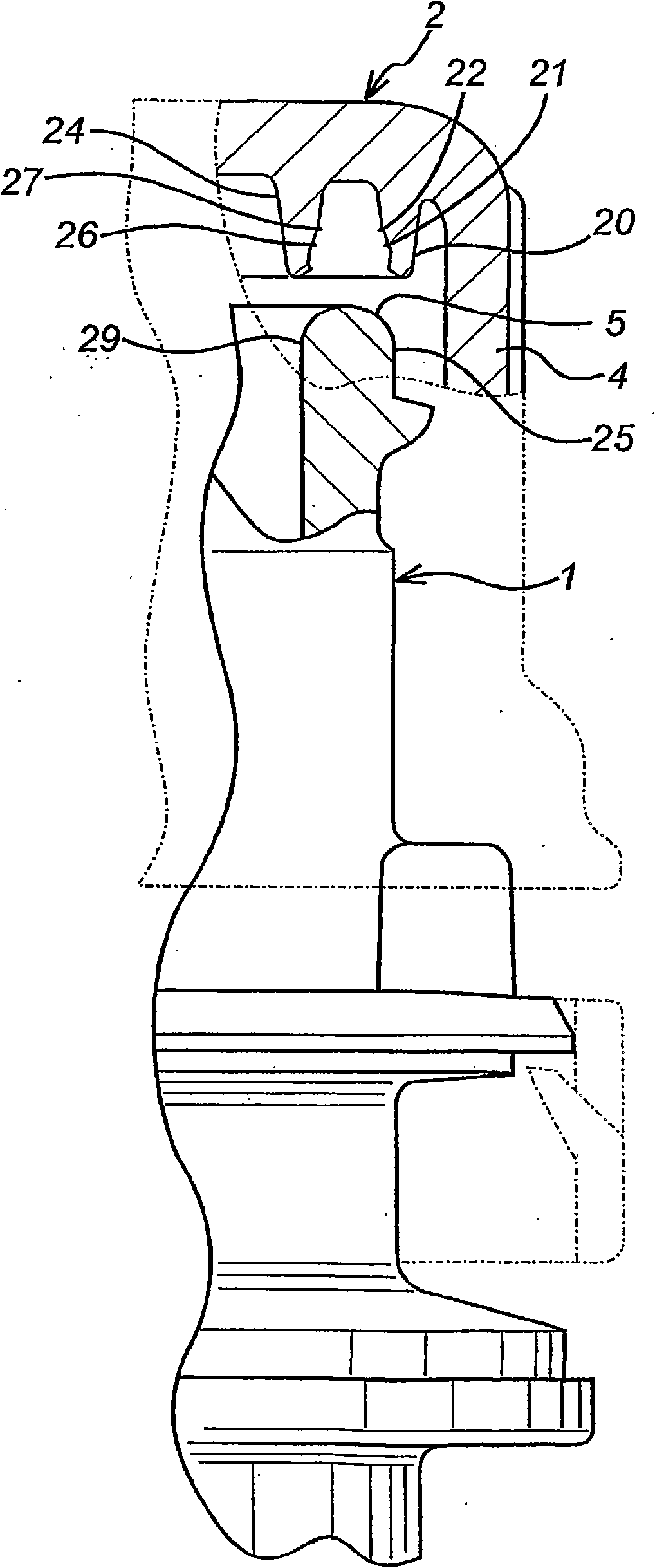

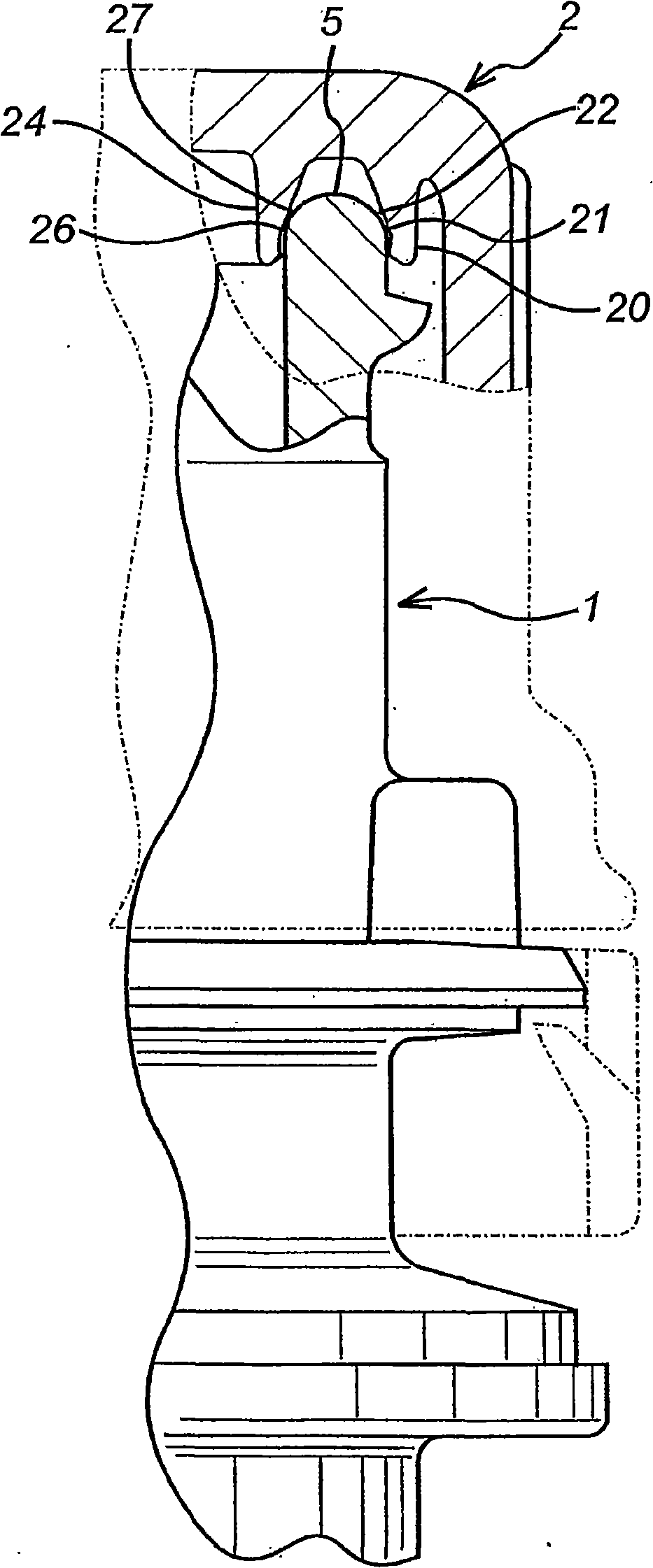

[0058] Referring to Fig. 1, the container closure assembly includes a container neck 1 and a container closure 2, the container closure 2 is provided with a base 3 and a peripheral skirt 4 provided with threads, and the terminal of the container neck 1 is a smooth Lip 5. As shown in the "Prior Art" section on the left side of Figure 1, in prior art container closure assemblies, the lip 5 and resilient gasket 6 form a compression seal.

[0059] The container neck 1 is injection molded from polyethylene terephthalate (PET), and the container cover 2 is integrally injection molded from polyethylene. As disclosed in detail in the European patent application EP-A-1446332, the container neck 1 and the container closure 2 are respectively provided with integrally formed, fast-rotating, large-pitch angle thread lines with pressure safety features. European patent application EP-A-1446332 The entire content of the application is incorporated by reference.

[0060] As shown by the dot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com