An automatic opening and feeding device for a toothpaste filling machine

A technology of filling machine and toothpaste, which is applied in the field of automatic bag opening and feeding device, can solve the problems of simple structure of the feeding end of the hose, affecting the automatic production efficiency of toothpaste, and the cleanliness of toothpaste production, so as to achieve a smooth bag cutting process, Improve bag cutting efficiency and set novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

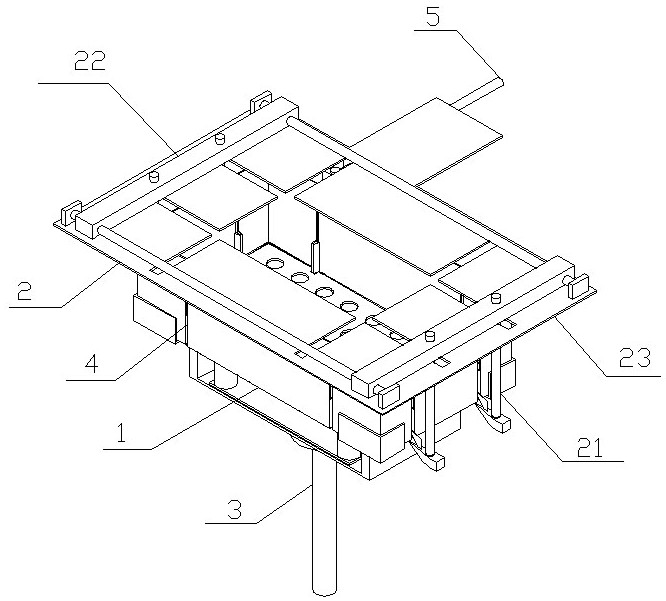

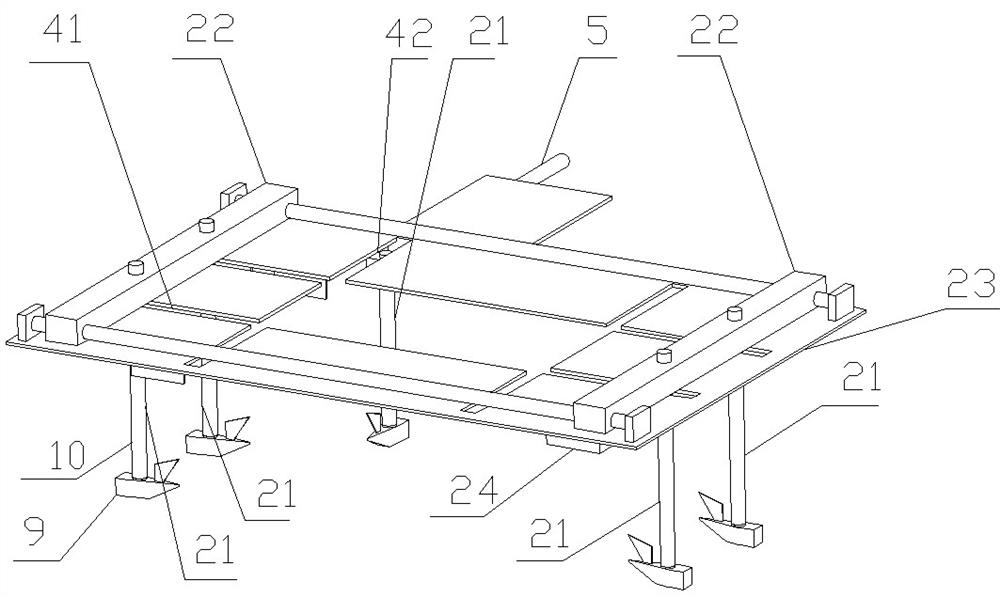

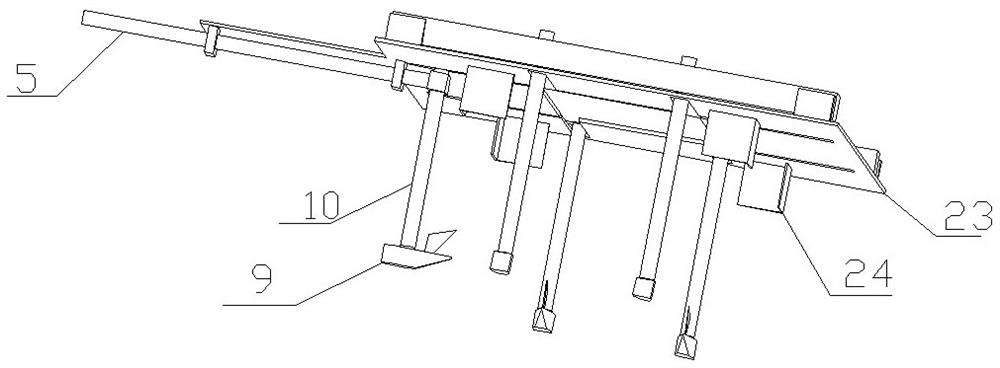

[0021] like Figure 1 to Figure 6 The shown automatic bag opening and feeding device of a toothpaste filling machine includes a box body 1, a bag cutting device 2 and a bag suction device 3; There are a plurality of vertical guide grooves 4, and the box body 1 is arranged on the top of the suction bag device 3, and is used to hold toothpaste tubes covered with aseptic packaging bags outside; the bag cutting device 2 is covered on the outer periphery of the box body 1, and is To cut the aseptic packaging bag; the suction bag device 3 is used to transport the toothpaste tube to the feeding position of the toothpaste filling machine, and at the same time absorb the packaging bag cut by the bag cutting device 2 to complete an automatic feeding The bag cutting device 2 includes a cutter assembly 21, a slide bar 22 and a support plate 23; wherein the support plate 23 is covered on the top of the box body 1, and the bottom of the support plate 23 is provided with four brackets for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com