Device and method for picking up, deforming and depositing a thin glass pane

A glass plate and thin glass technology, applied in glass forming, glass reshaping, chemical instruments and methods, etc., can solve problems that are difficult to automate, cannot achieve accuracy, and the robot arm cannot determine the thin glass plate accurately enough The ideal position of the chip and other issues can be improved to achieve the effect of improving edge flushness and small manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

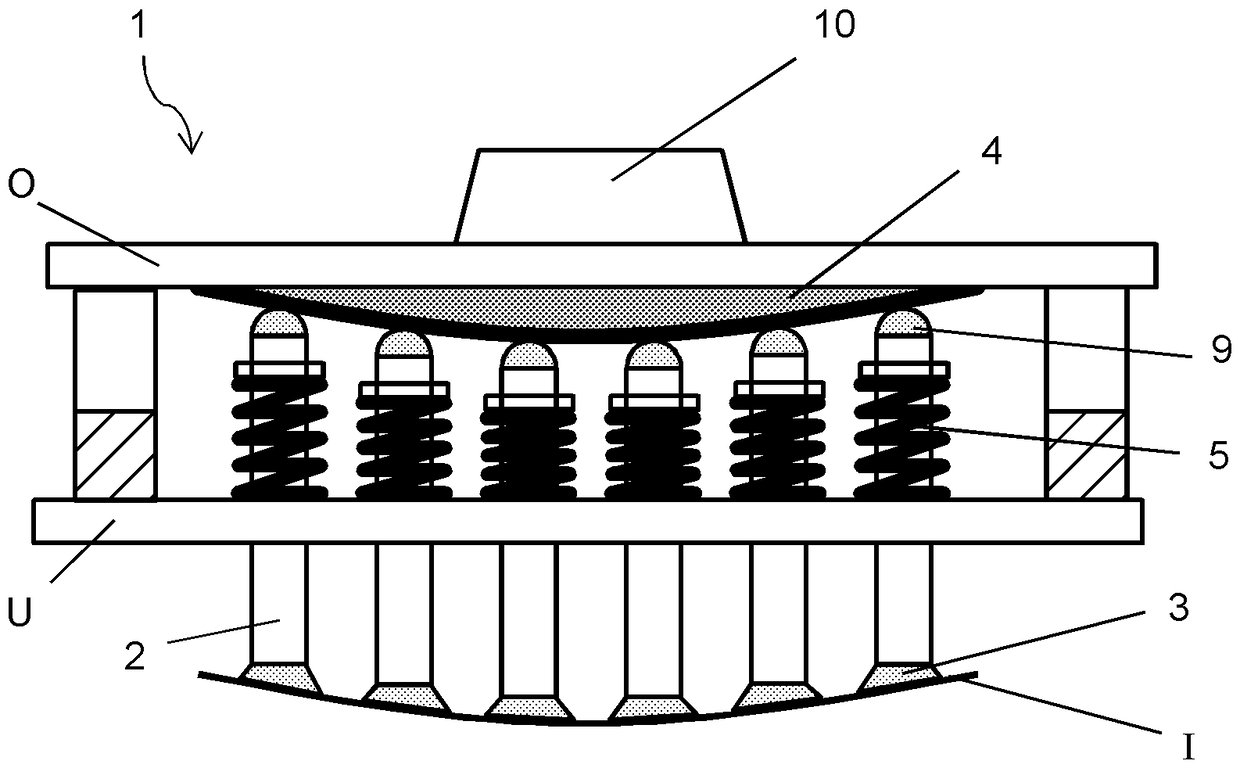

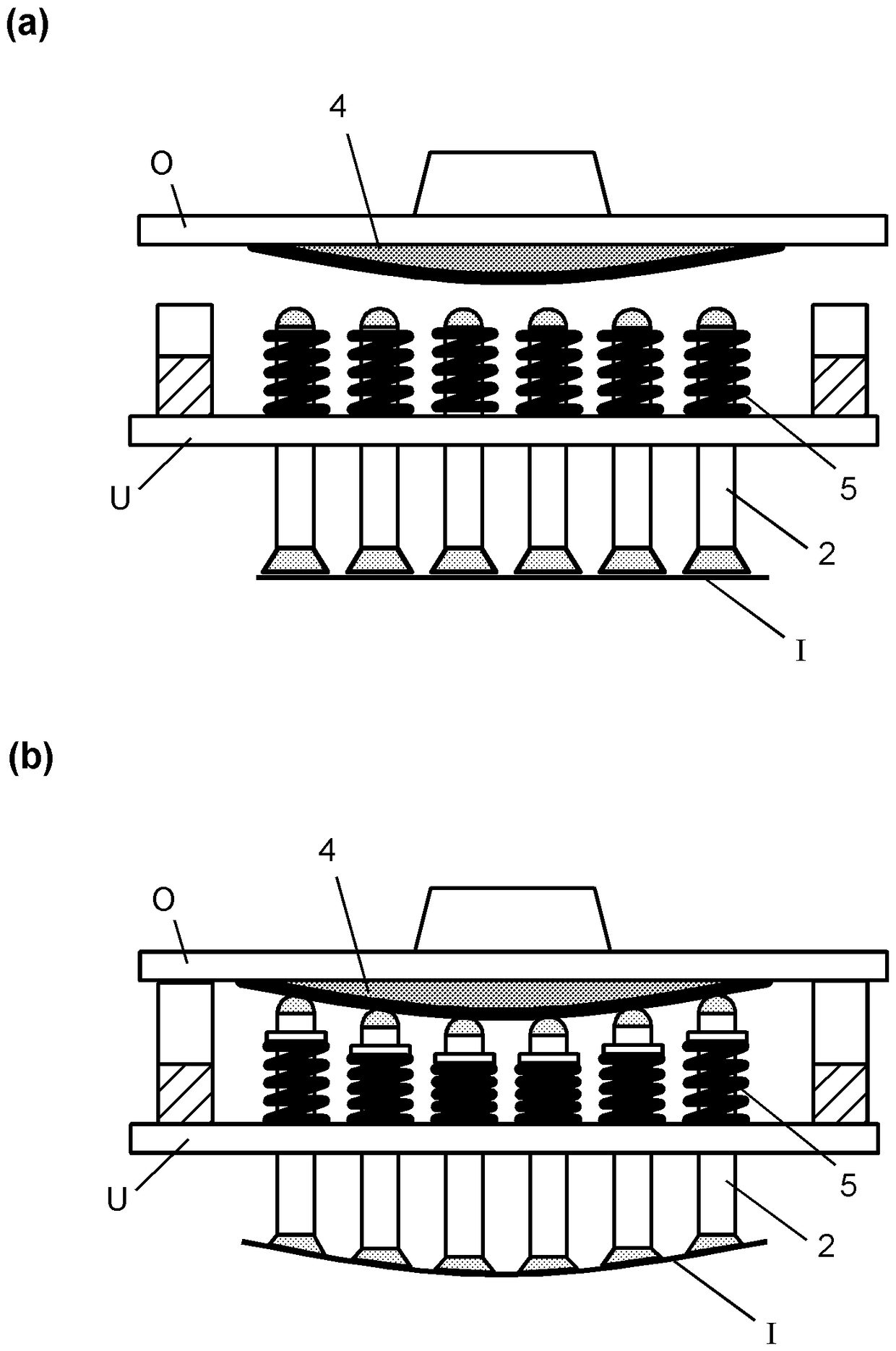

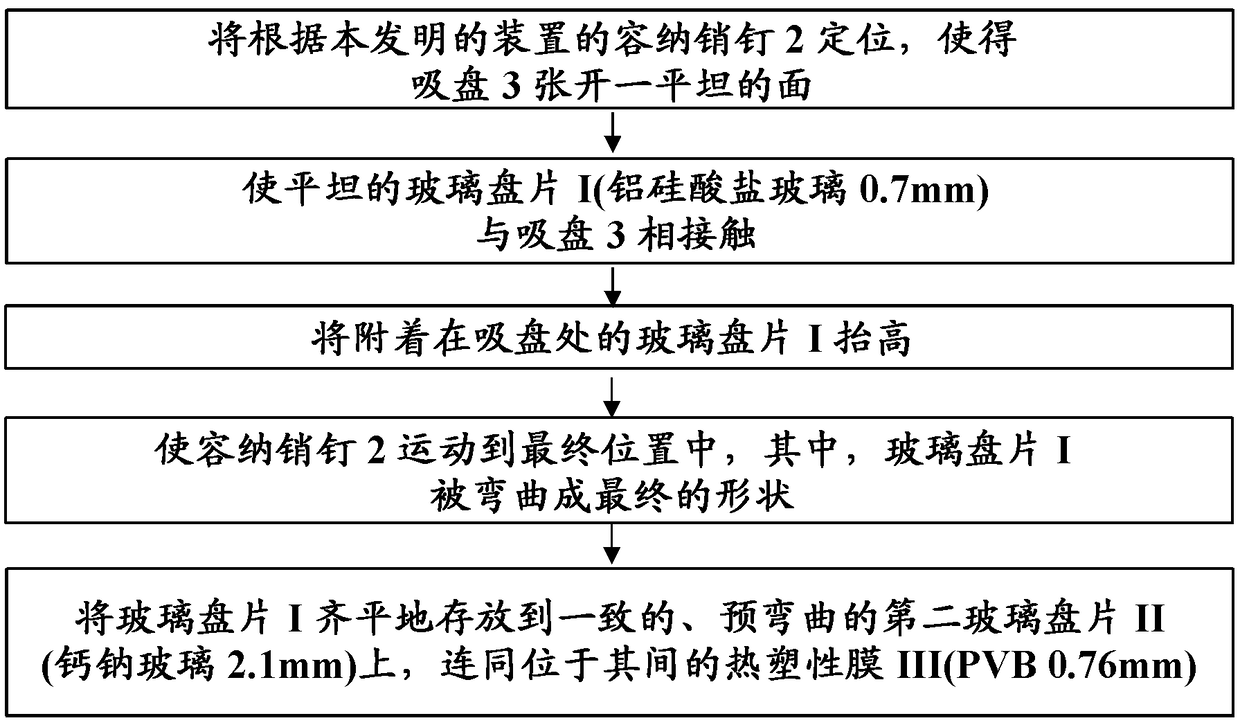

[0051] figure 1A first variant of the first design of the device according to the invention for receiving, deforming and storing thin glass disks is shown. The device comprises a frame 1 with a top side O and a bottom side U. The top side of the frame 1 is connected to a robot arm 10 by means of which the frame 1 can be moved. The underside U of the frame 1 is equipped with receiving pins 2 which are guided through bore holes in the cover of the underside U. Inside the frame there is an associated spring 5 for each receiving pin 2 which is tensioned between the cover of the frame 1 and the flange on the receiving pin and presses the receiving pin upwards into the frame 1 . On the top side O of the machine frame 1 a model mold 4 is fixed. The former mold 4 is, for example, a hollow mold made of steel with a downwardly directed surface, the curvature of which corresponds to the desired curvature of the glass disk 1 which is to be accommodated and strained with the device. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com