Three-phase flat wire motor stator winding

A motor stator and three-phase winding technology, which is applied to the shape/style/structure of the winding conductors, and can solve the problems of poor mass production and manufacturing process of flat wire motor stator windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

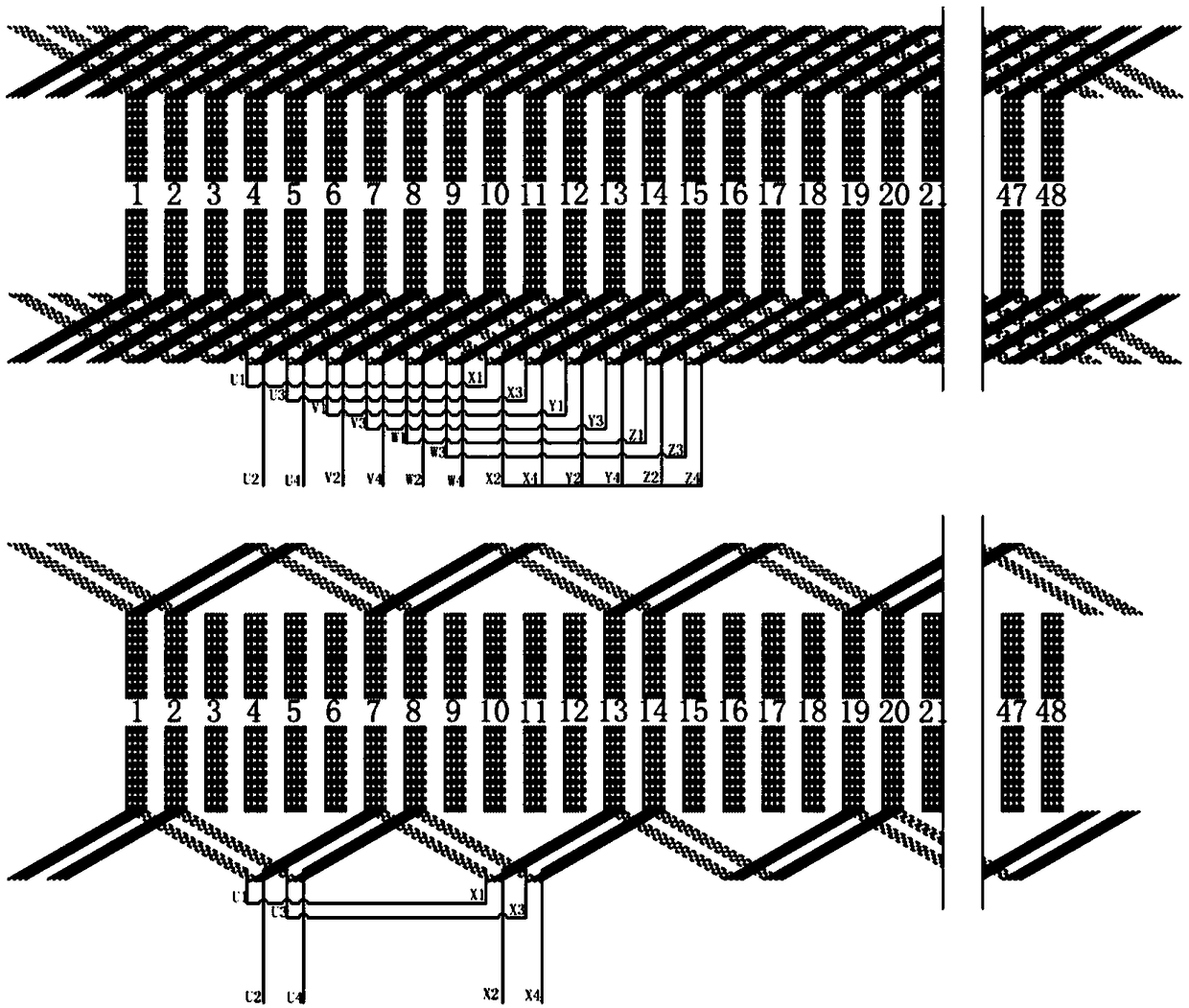

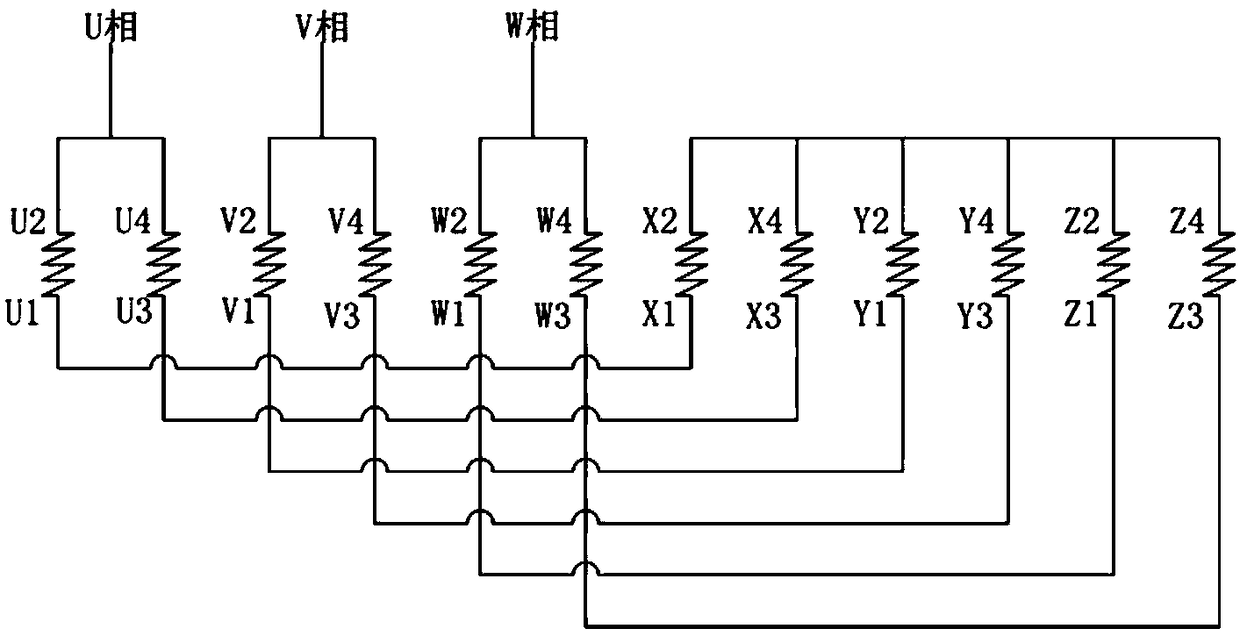

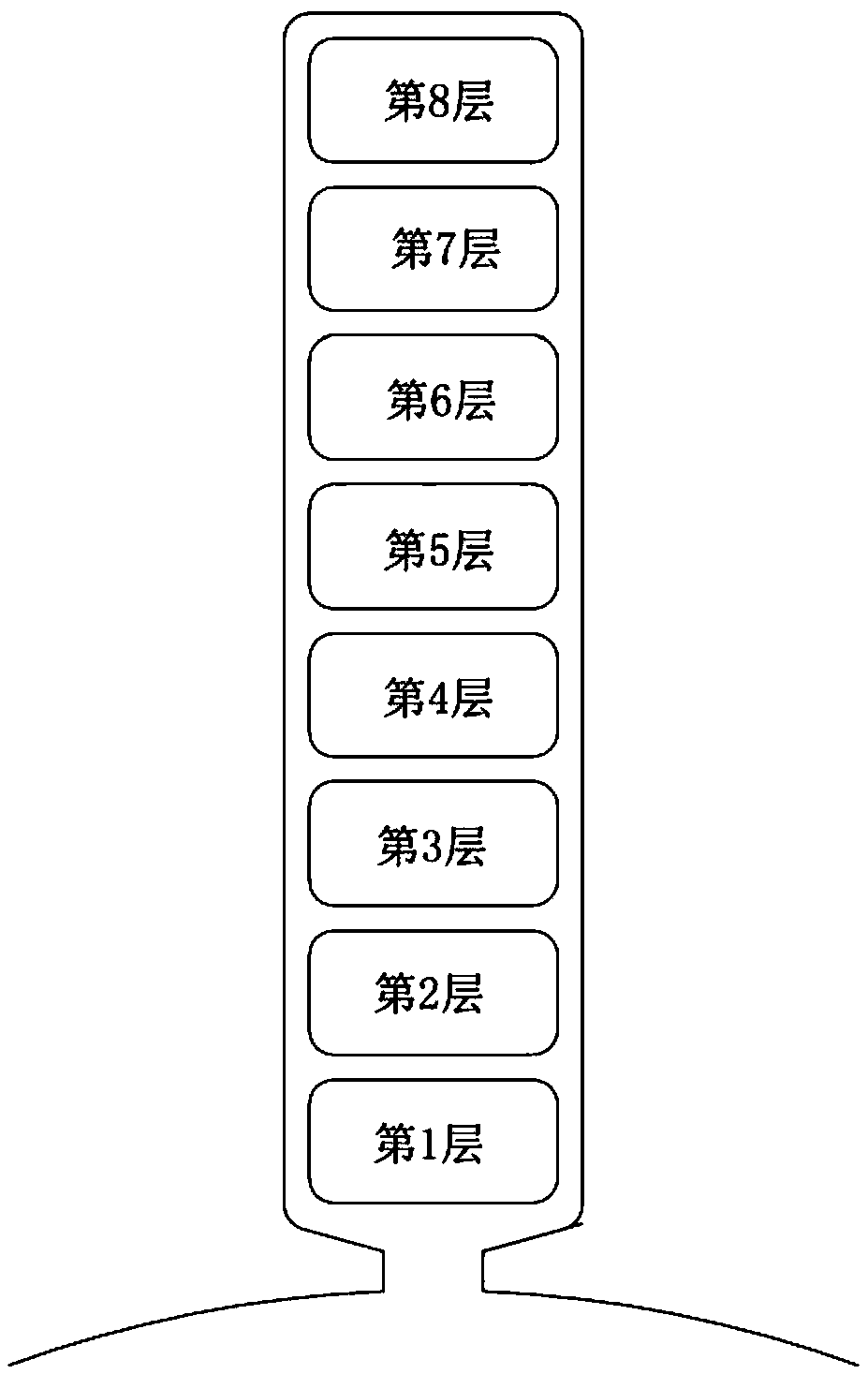

[0040] Such as Figure 1 to Figure 6As shown, the present invention provides a three-phase flat wire motor stator winding. The motor stator includes 8 poles and 48 rectangular stator slots at equal intervals. The number of conductors in each rectangular stator slot is 8 layers, and there are three phases in total. Winding structure, that is, U-phase winding structure, V-phase winding structure and W-phase winding structure, each phase winding structure has two branches and the two branches are connected in series, each phase winding structure includes insertion side 1 and welding side 6, welding Side 6 is equipped with power lead wires, the pitch of insertion side 1 is equal and the pitch is 6, the winding structure of each phase is U-shaped wire, the inner layer of the three-phase flat wire motor stator winding leads to the series lead wire, and the three-phase flat wire motor stator The outer layer of the winding leads to the power lead-out line and the star-point connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com