An end face sealing structure of a fuel pump shaft tail

A technology for end face seals and fuel pumps, which is applied to engine seals, pump components, and rotary piston/oscillating piston pump components, etc. It can solve problems such as cumbersome assembly, high weight of the gear pump housing, and large installation space , to achieve the effect of simplifying the seal structure of the shaft end face, shortening the axial installation space and reducing the weight of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

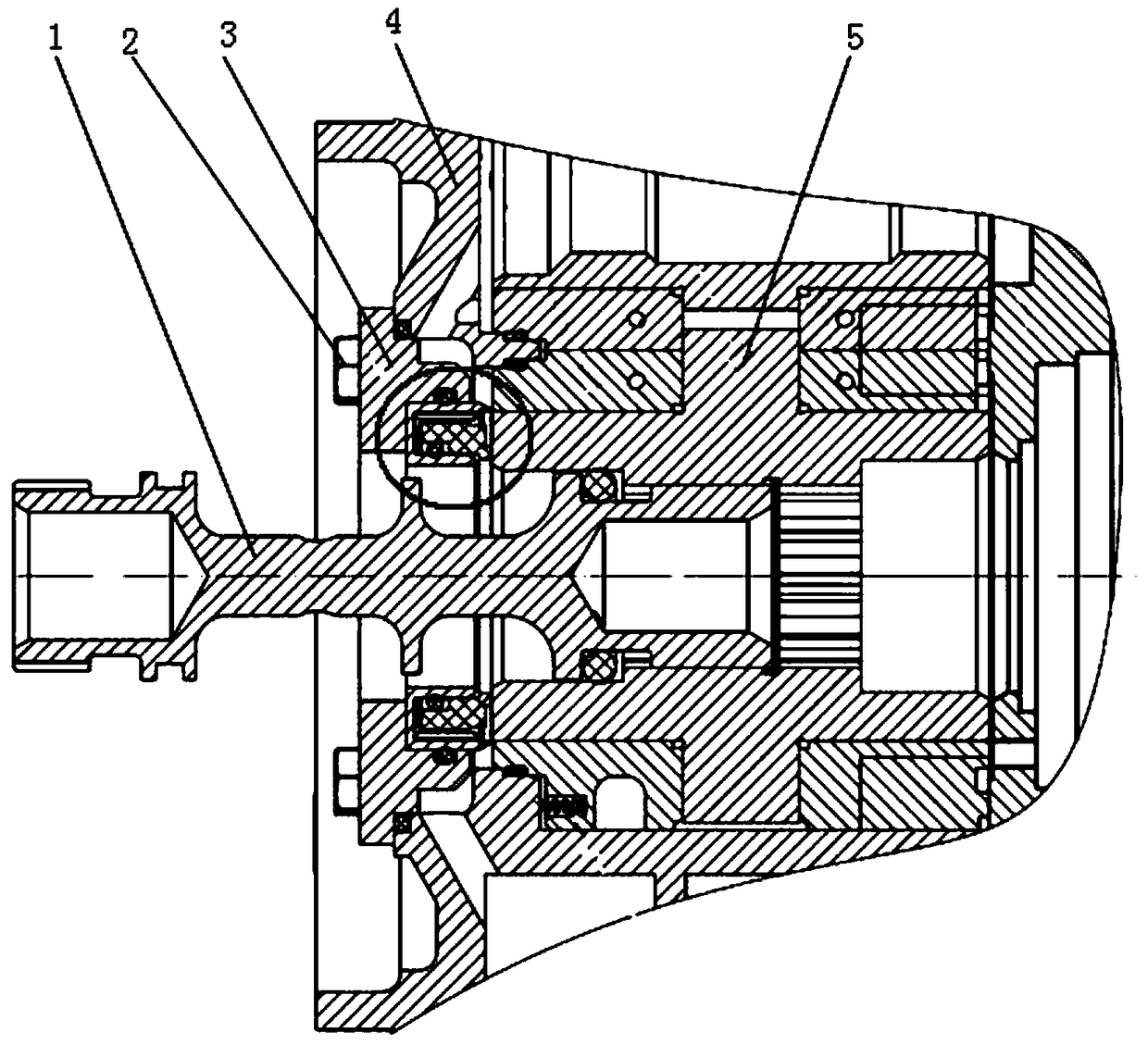

[0018] The invention relates to an end face sealing structure of a shaft tail of a fuel gear pump, and the fuel pump is used for an aero-engine;

[0019] Such as figure 1 As shown, the sealing structure described is a dynamic and static ring sealing structure including the static ring assembly 3 and the sealing end face 16 of the fuel pump driving gear 5; Assembled on the gear pump casing 4;

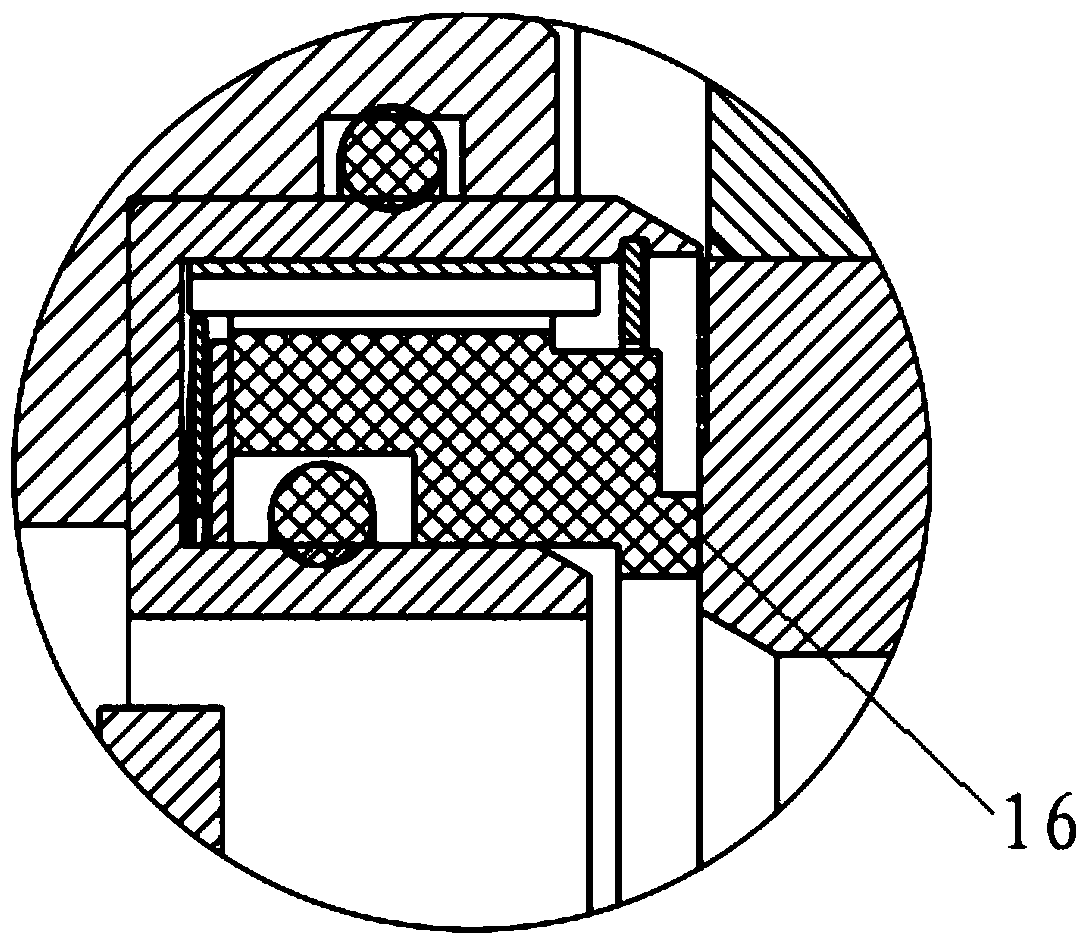

[0020] Such as figure 2 As shown, the static ring assembly includes a static ring 8, an end cover 6, a static ring seat 14, an anti-rotation block 11, a retaining ring 10, a wave spring 13, an adjusting washer 12, and O-rings 7 and 9; the end cover 6 and the static The ring seat 14 is fixedly connected and sealed with an O-ring 7. The static ring seat 14 is a ring and has a concave cross-section. The side wall inside the concave shape is welded with an anti-rotation block 11, and a wave spring is sequentially installed inside the concave shape. (13), adjusting gasket 12, O-shaped sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com