Ejector with enclosed cylinder structure

A technology of catapult and cylinder, which is applied in the direction of launch/drag transmission, etc., can solve the problems of sealing difficulty of open-type catapult cylinder, increase structural weight, reduce reliability, etc., achieve higher take-off weight, lower production cost, and reduce structural parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

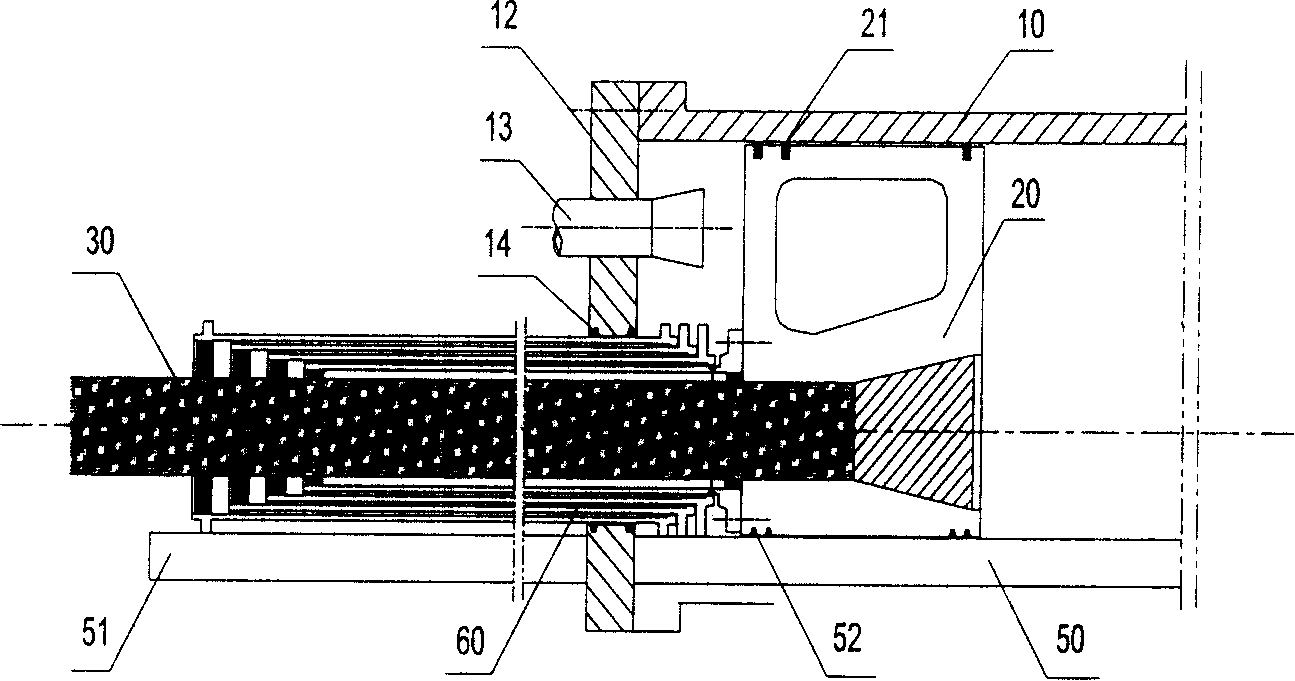

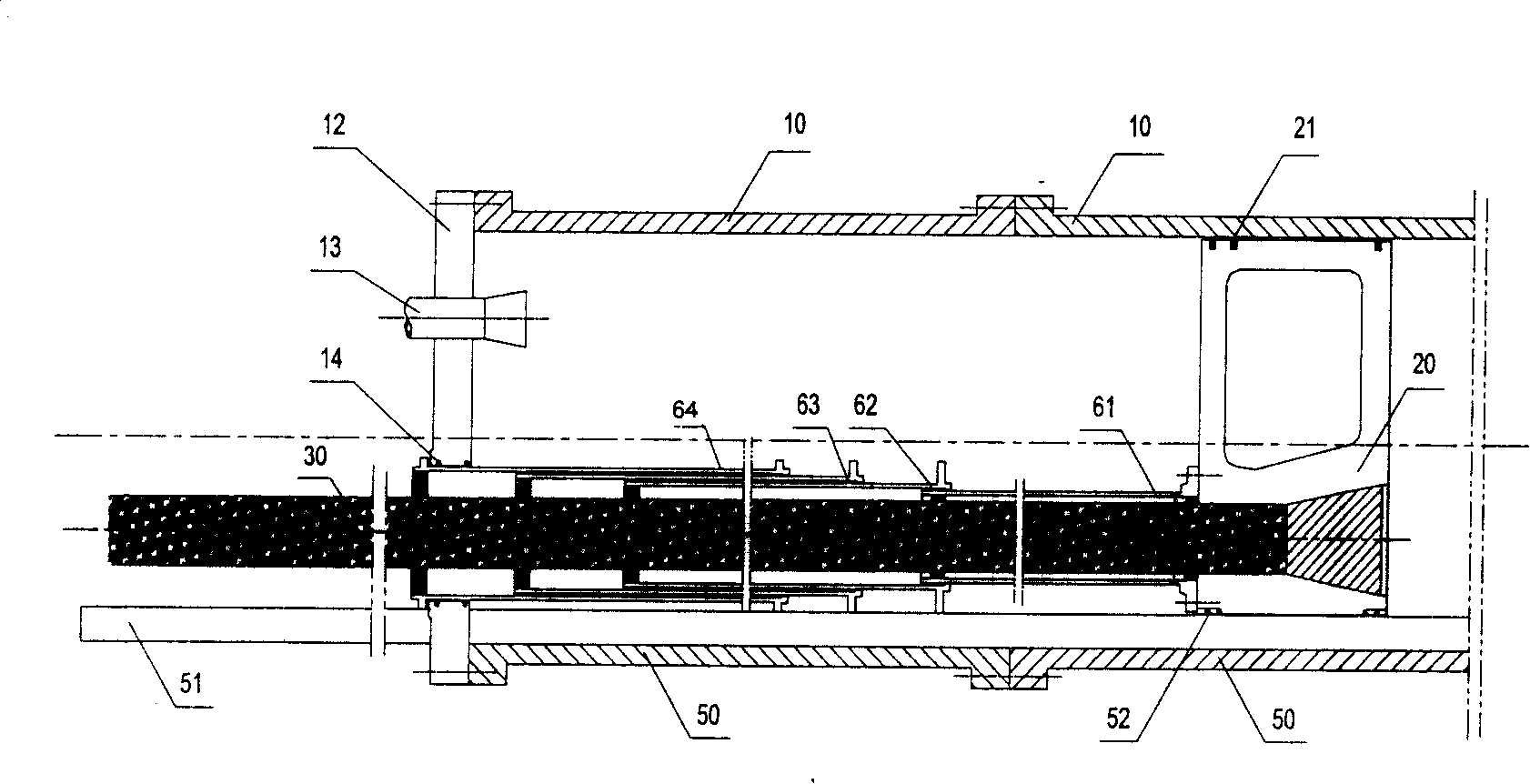

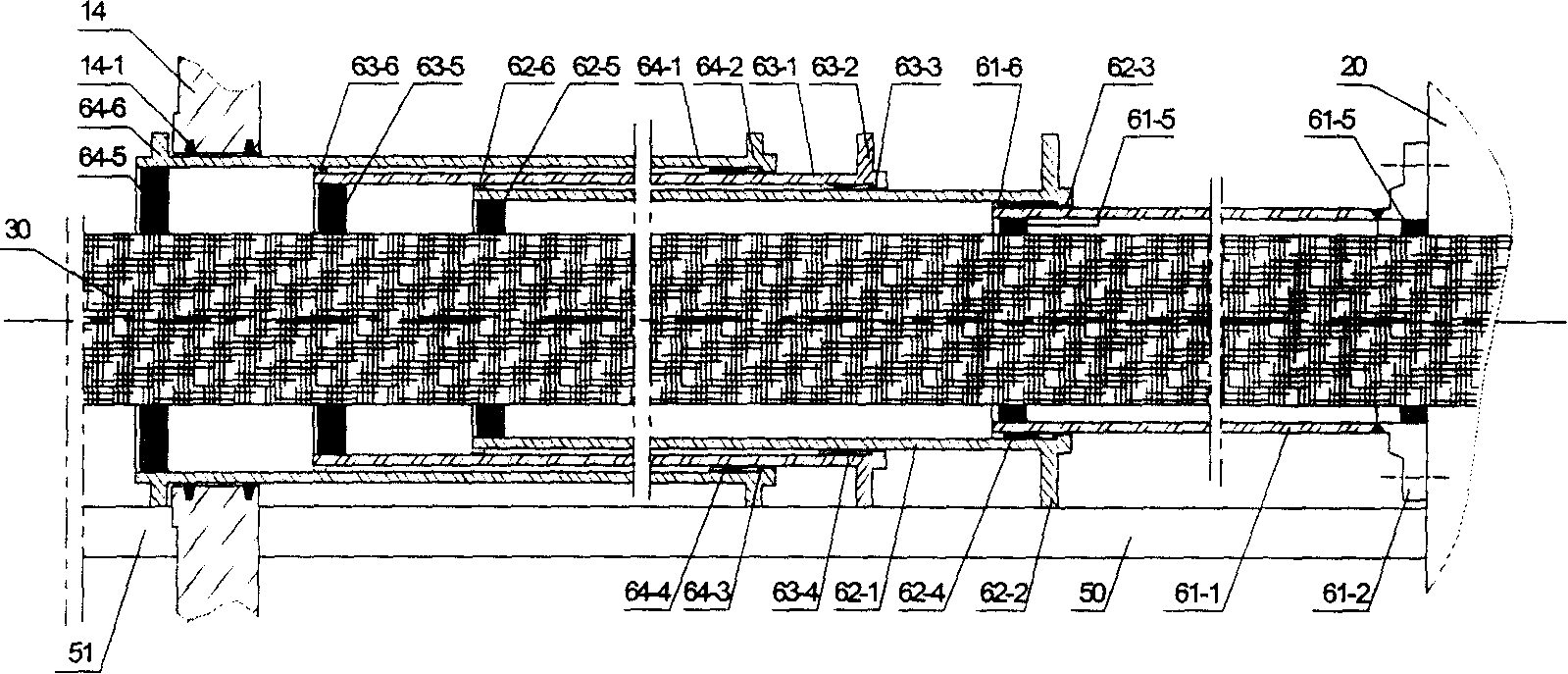

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. Refer to figure 1 , The present invention is used for ejection aircraft, and mainly consists of ejection cylinder 10, cylinder head 12, piston 20, high-strength steel cable 30 and telescopic sealing device 60. The ejection cylinder 10, the cylinder head 12, the piston 20 and the telescopic sealing device 60 constitute a closed space. The ejection power gas is injected into the ejection cylinder 10 through the ejection control valve and the intake valve 13 and acts on the piston 20 to push the piston 20 forward. The core of the high-strength steel cable 30 connecting the piston 20 and the reciprocating car is a steel wire. The strength of the steel cable can reach 1970~2170MPa, which is much higher than that of the steel structure. For example, the minimum breaking force of a steel cable with a diameter of 60mm can reach 4,000KN, which is about 4 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com