Three level electric jar for bearing ball silk bar

A technology of ball screw and electric cylinder, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of electric cylinder design inconvenience, self-locking, and small installation size, so as to save axial installation space and improve work efficiency. Efficiency, the effect of preventing backlash under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

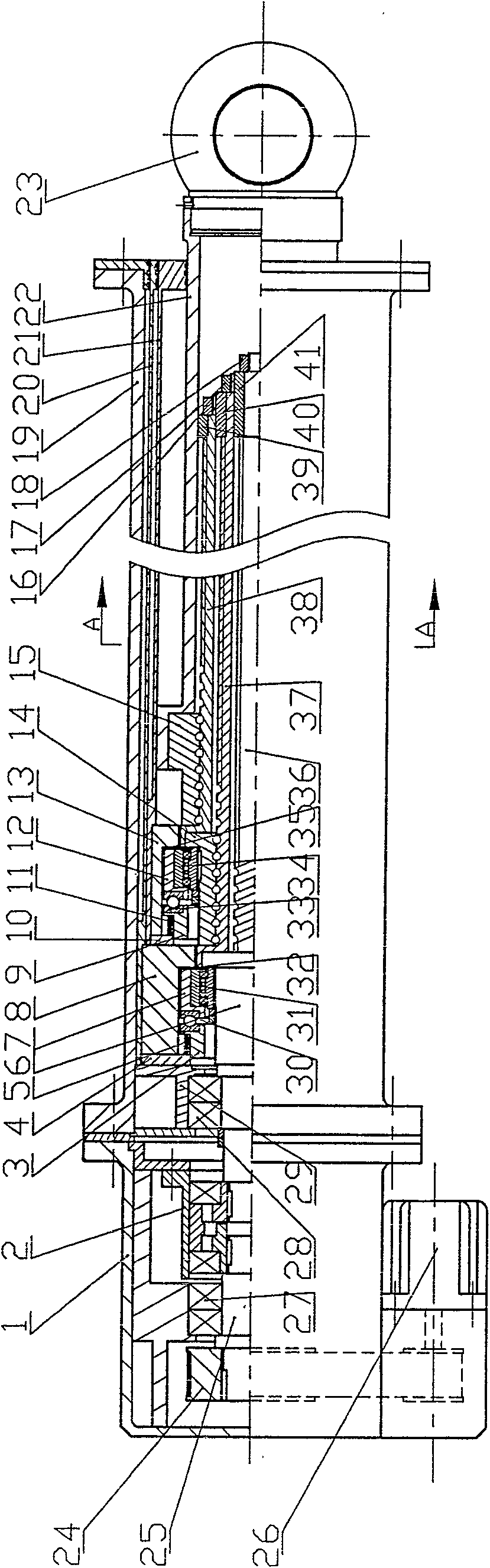

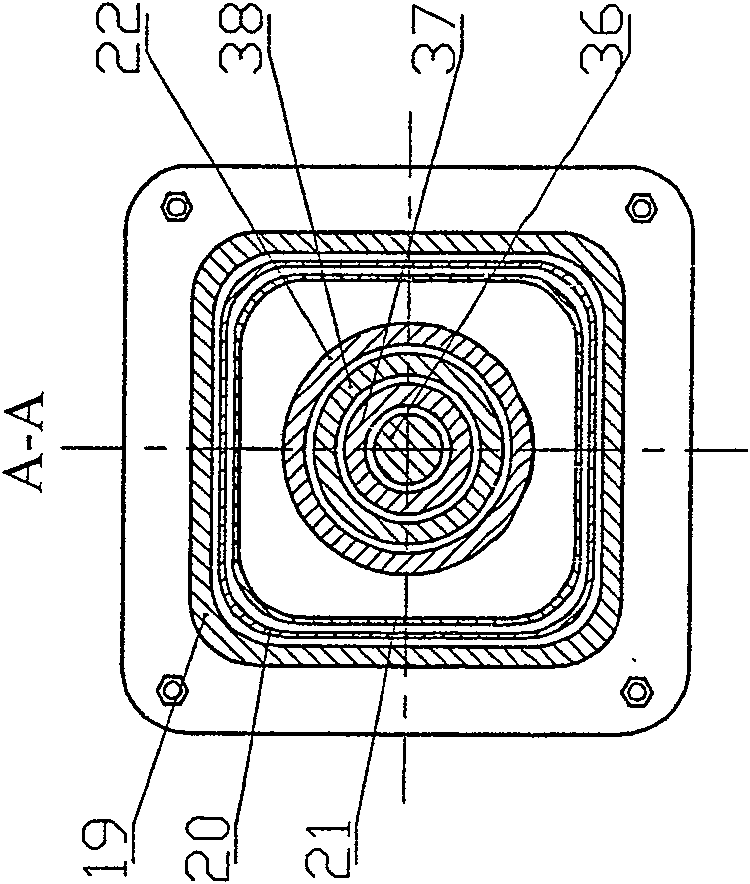

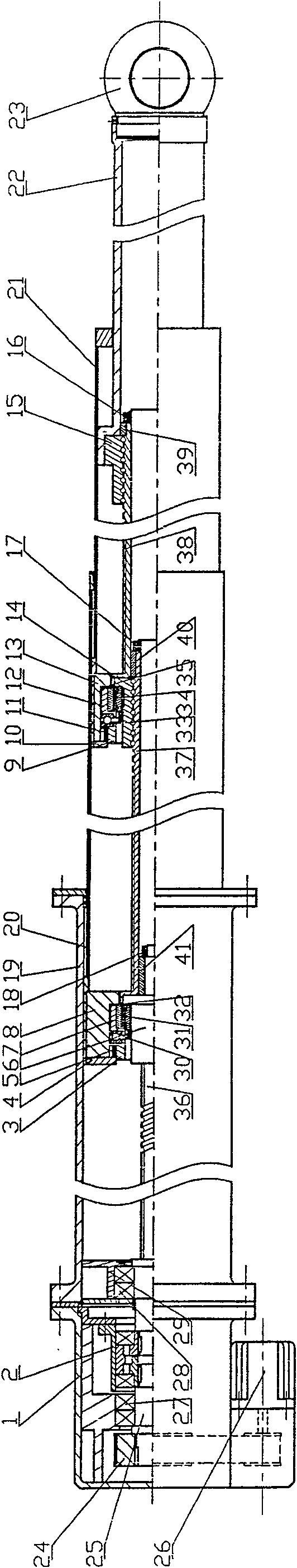

[0014] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes installing the first-stage nut 6 on the helical groove of the first-stage screw mandrel 36, and the end of the first-stage screw mandrel 36 is equipped with a shaft-end stopper 41, and is fastened by the shaft-end nut 18. The inner ring of the overrunning clutch 31 is fixed on the first stage nut 6, the outer ring of the one-way overrunning clutch 31 is fixed with the sleeve 7, and the thrust ball bearing 30 is installed on the sleeve 7, and the other side of the thrust ball bearing 30 is installed On the slider 3, the slider 3 is covered with a spring 5, the spring 5 is pressed by the slider 3 and the cylinder stopper 4, and the cylinder stopper 4 and the middle block 8 are fixedly installed on the first-stage inner cylinder 20 , the sleeve 7 and the middle block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com