Four-stage ball screw double-electric-cylinder

A ball screw and electric cylinder technology, applied in the field of mechanical transmission, can solve the problems of increasing the weight and difficulty of the cylinder block, and achieve the effect of saving radial and axial installation dimensions and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

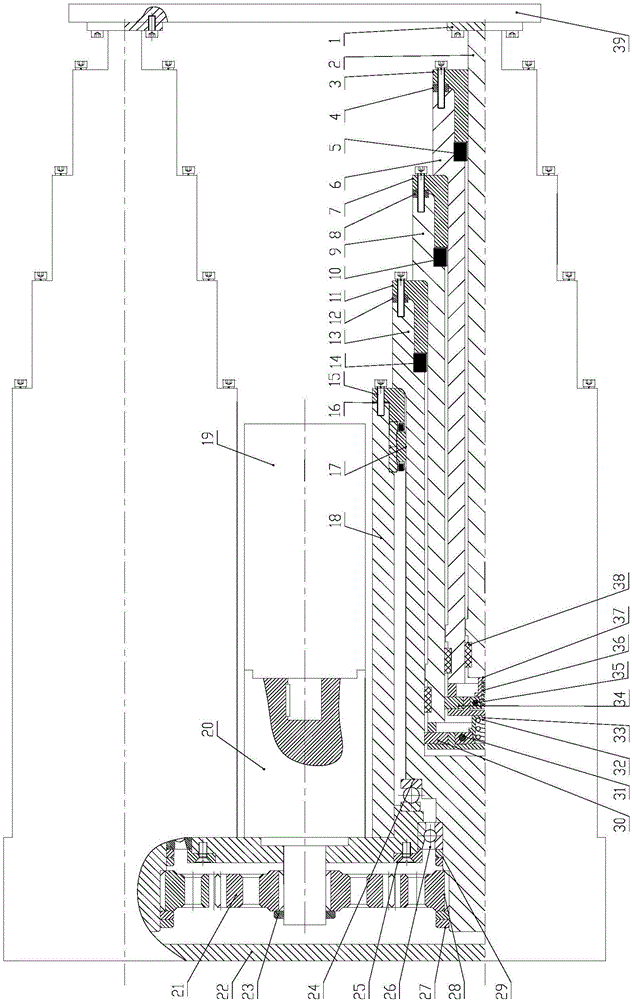

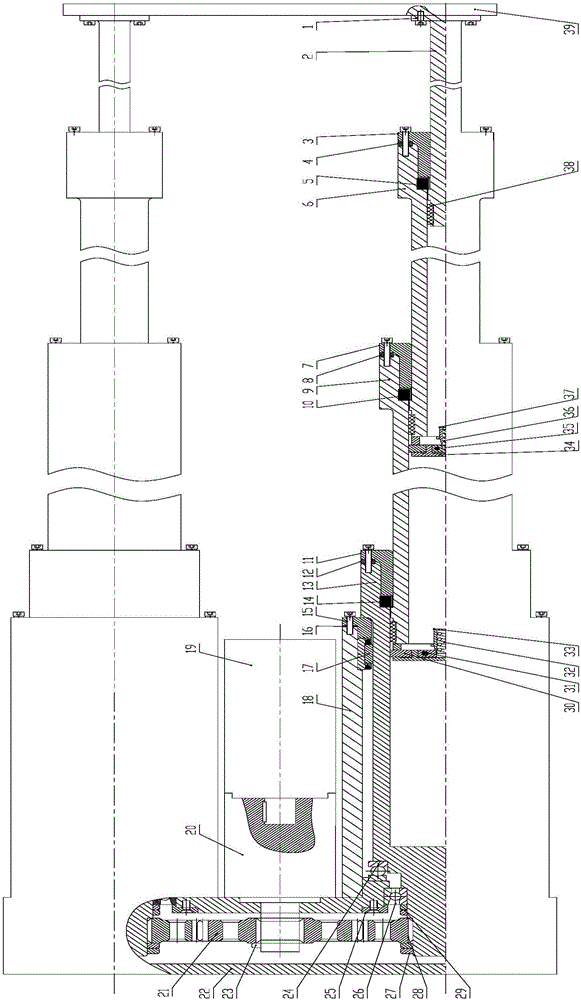

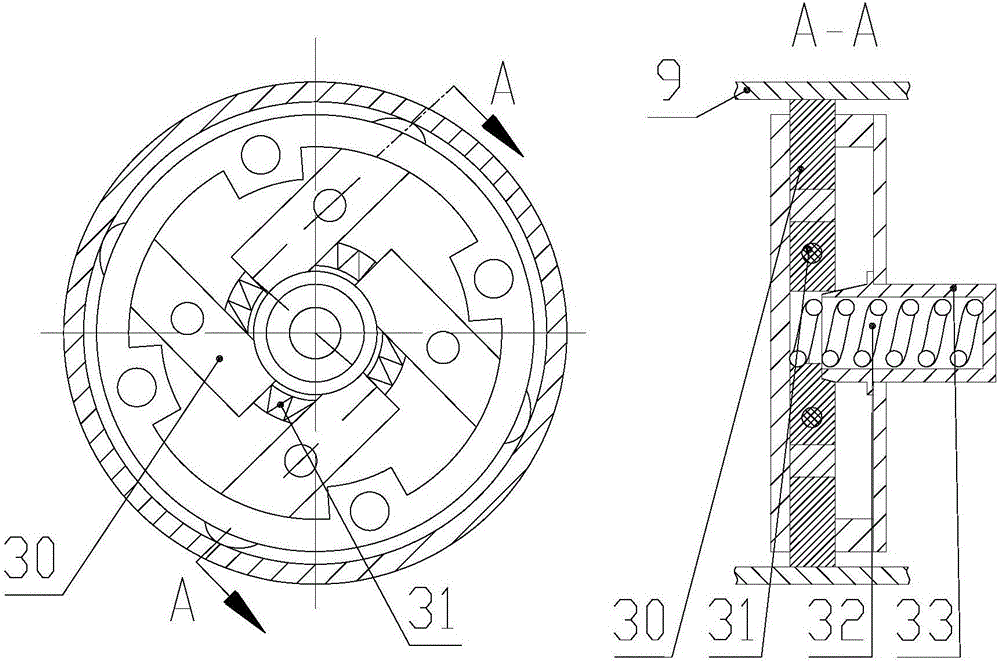

[0013] The invention will be further described below in conjunction with the accompanying drawings and examples.

[0014] The servo motor (19) drives the main gear (21) installed in the gear box (22) and the tail gear (28) of the master cylinder (13) to rotate through the reducer (20) fixed on the gear box (22) , an angular contact ball bearing (26) is installed at the end of the main cylinder (13), the inner ring of the bearing is connected with the main cylinder (13) and locked with the No. 2 lock nut 27, and the outer ring is embedded in the gear box (22), Then use the pressure plate (25) to stop, the end face of the tail of the main cylinder (13) fits the end face of the gear box (22) through the thrust ball bearing (24), the outer cylinder (18) is fixedly connected with the gear box (22), and the front end The inner wall is equipped with a needle roller bearing (17) without an inner ring, and the inner wall of the bearing is in contact with the master cylinder (13), and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com