Conductive slip ring capable of being used for oil pumping unit balancing unit

A conductive slip ring, conductive connection technology, applied in circuits, current collectors, electrical components, etc., can solve problems such as the inability to meet actual needs, size and installation method limitations, to reduce the axial installation space, facilitate transformation, disassembly and assembly handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

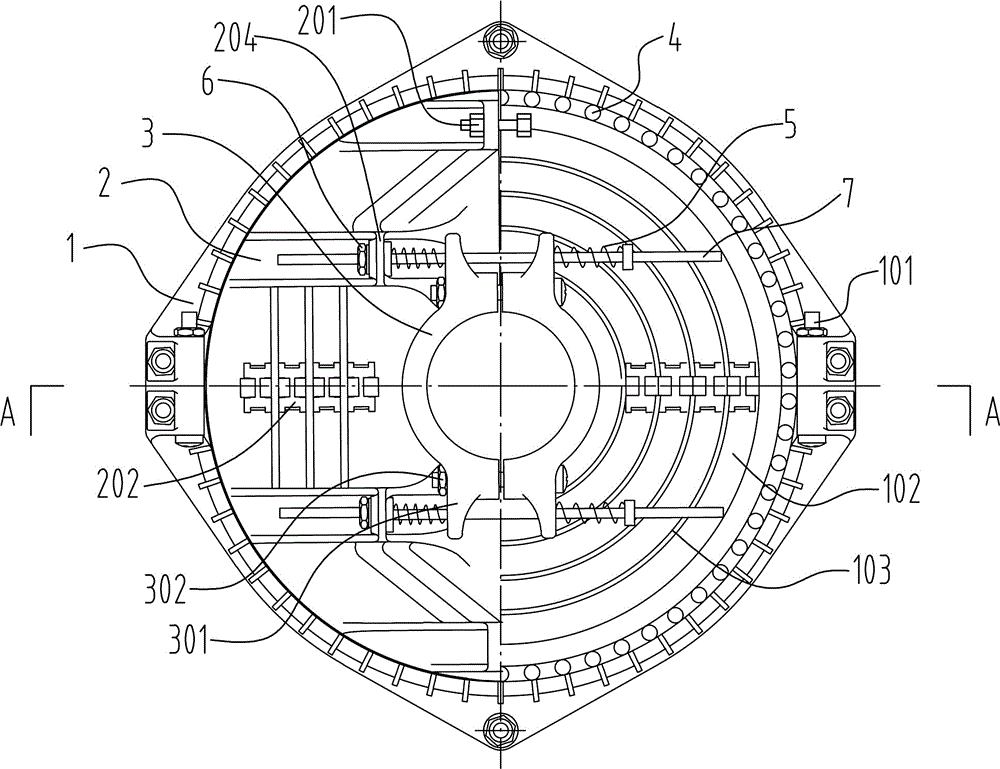

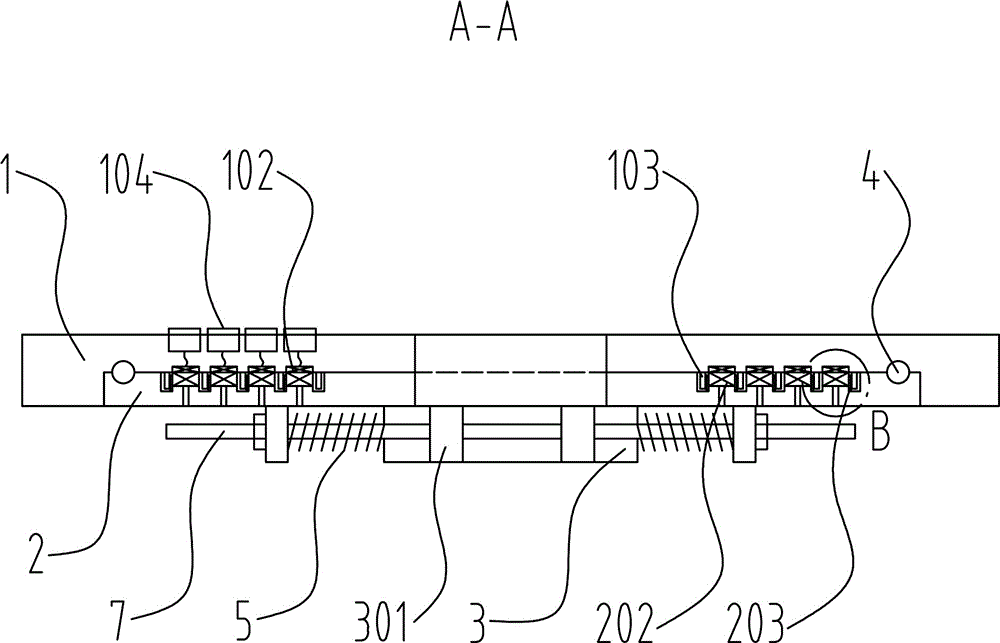

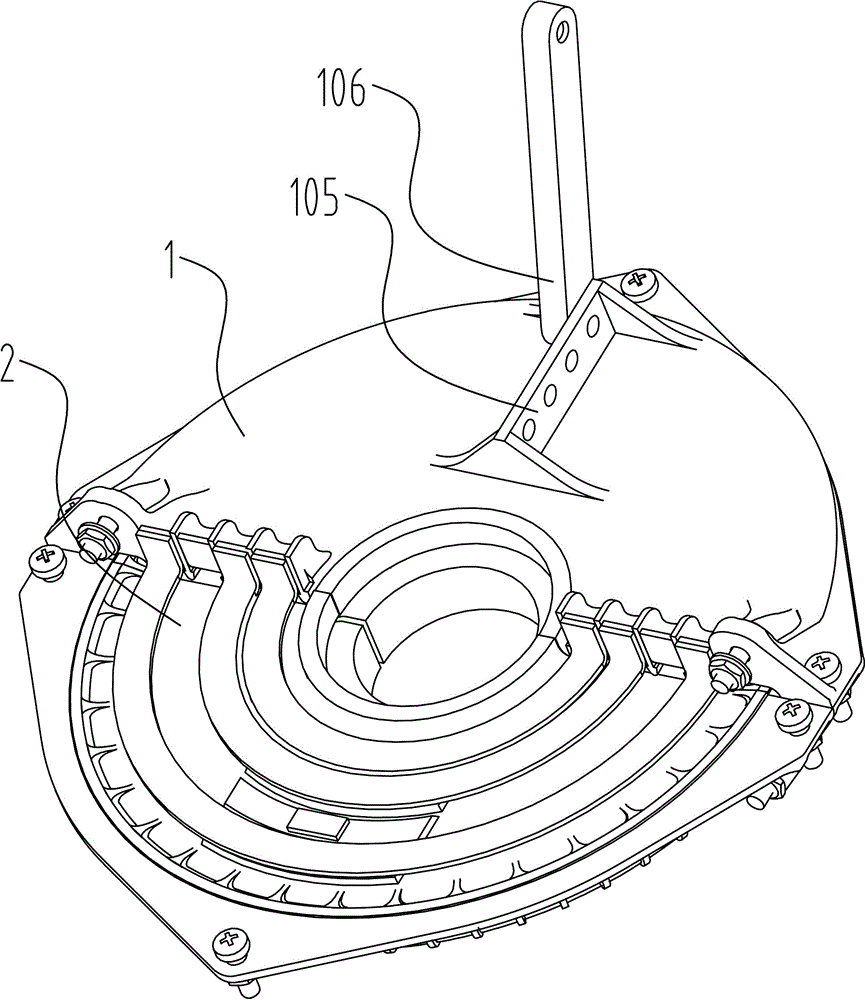

[0032] Such as Figure 1~6 Among them, a conductive slip ring, including:

[0033] The fixed disk 1 is used to connect with the fixed component and connect with the electric input;

[0034] Rotary disk 2, the rotary disk 2 is rotatably installed in the fixed disk 1, the conductive connection between the rotary disk 2 and the fixed disk 1, and the rotary disk 2 is connected to the electrical output;

[0035] The shaft fixing ring 3 is used for fixed connection with the rotating parts, and the shaft fixing ring 3 is connected with the rotary disk 2 . Based on this structure, by adopting a disk-shaped structure, the thickness of the entire conductive slip ring in this example is less than 1 / 3 of the diameter. Therefore, it is convenient to be installed at the position of the output shaft 15 between the reducer 8 and the crank 9, occupies a small space, and is convenient for modifying existing equipment.

[0036] The preferred solution is as Figure 1~3 Among them, a concave c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com