Multiple-row angular contact antifriction bearing, particularly for mounting the bevel pinion shaft in a motor vehicle rear axle differential

A technology for rolling bearings and automobile rear axles, which is applied to rolling contact bearings, roller bearings, shafts and bearings, etc., and can solve problems such as increasing axial installation space, increasing manufacturing costs, and raceway wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

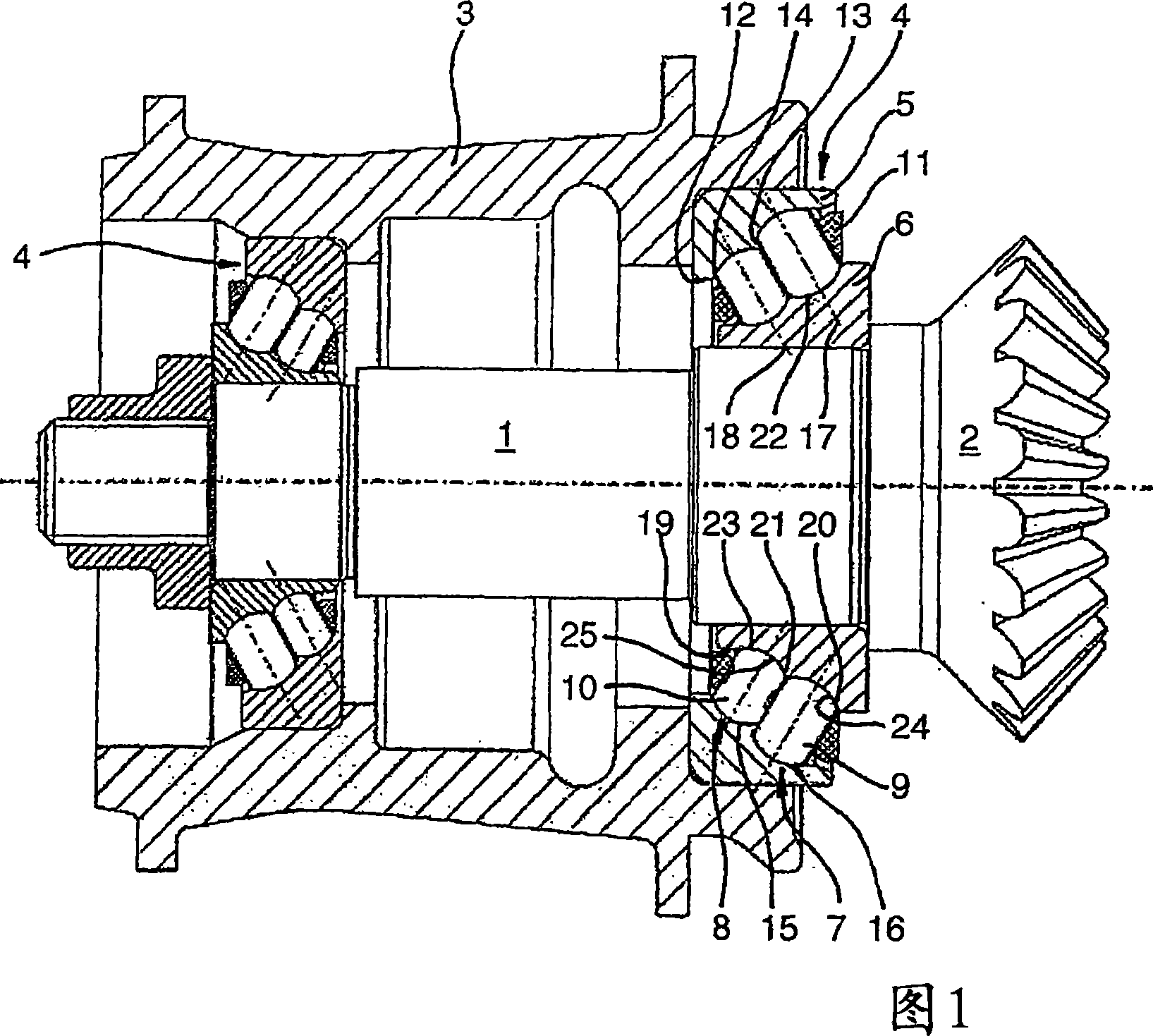

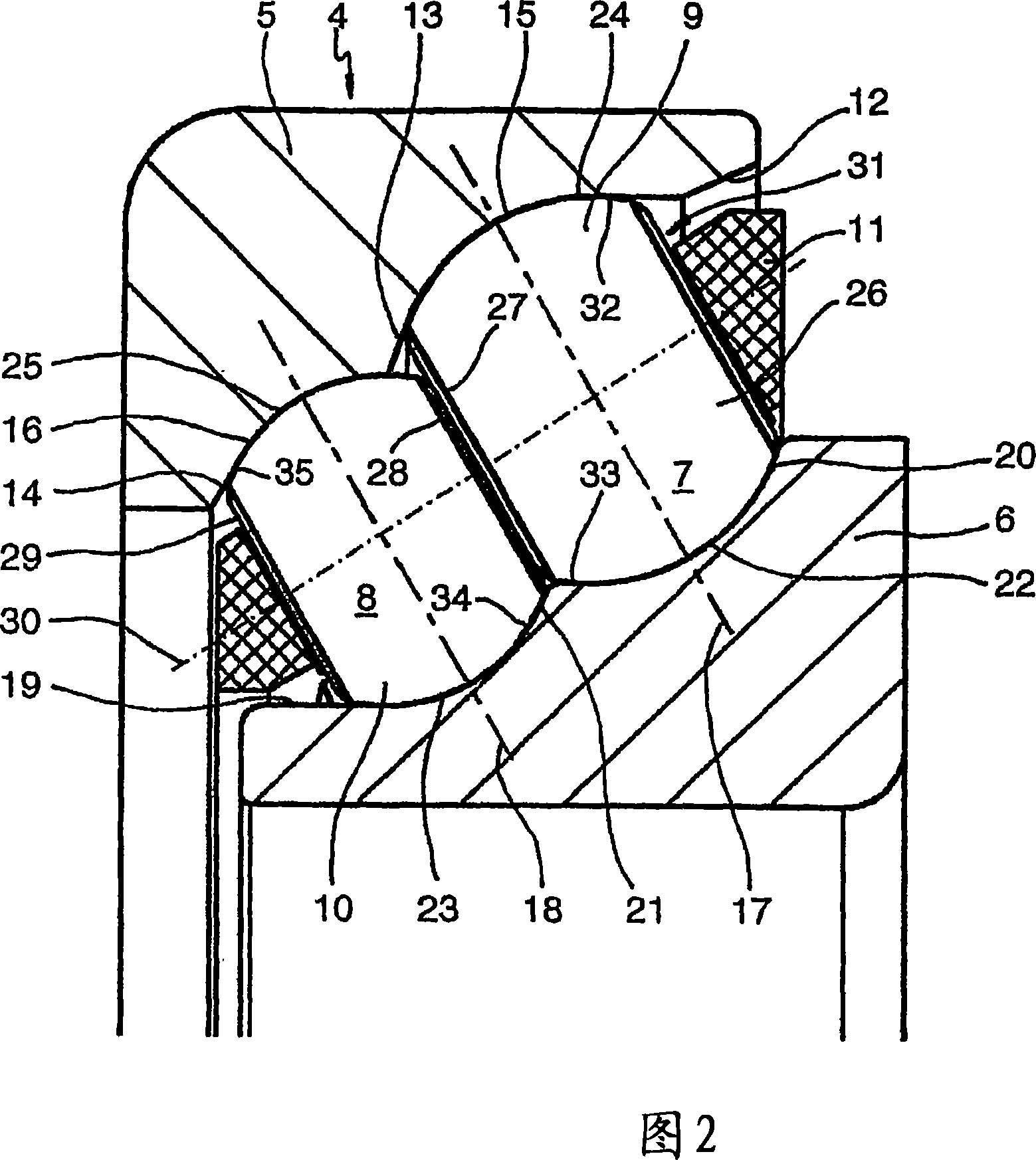

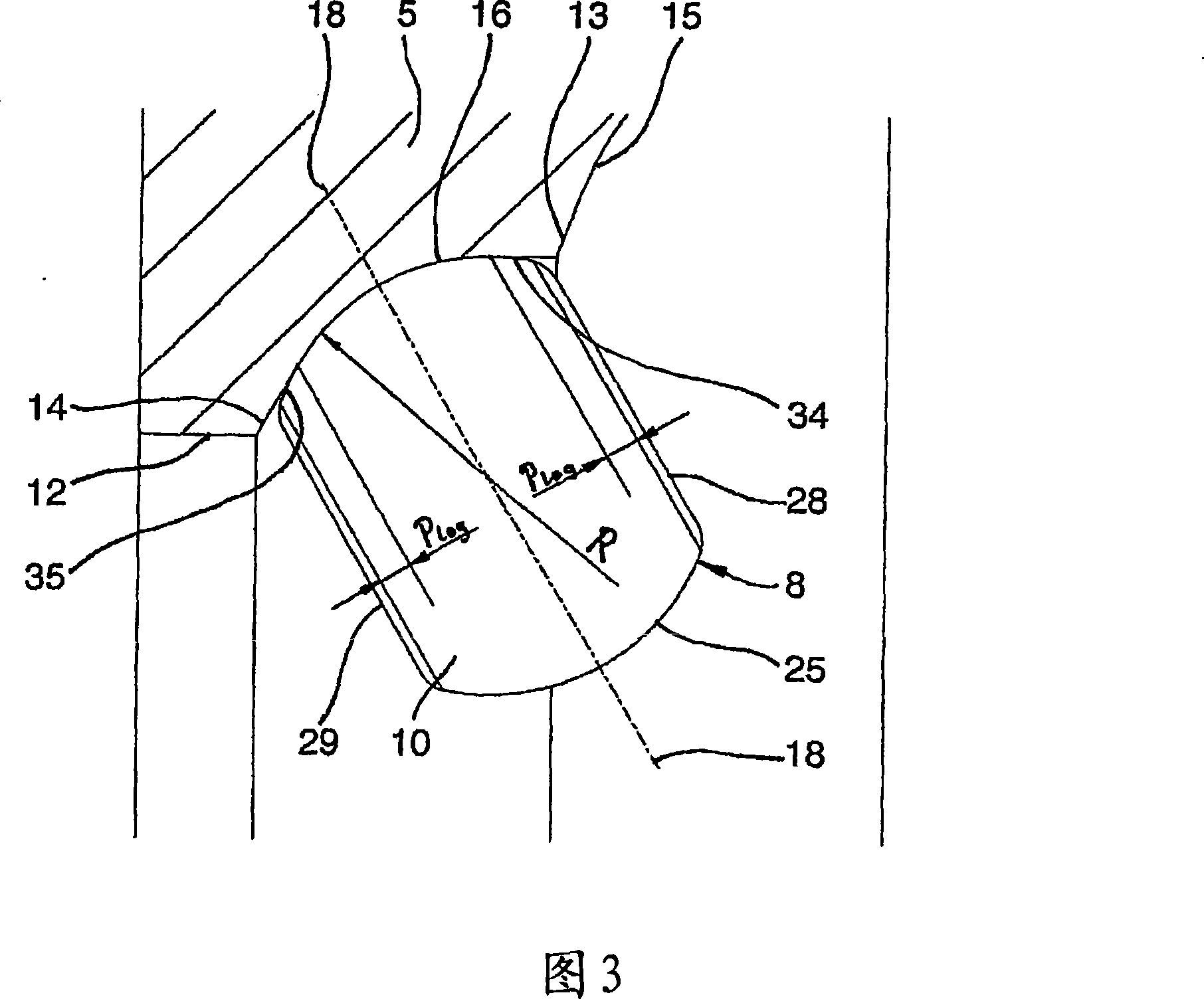

[0019] A part of the rear axle differential of the vehicle can be seen clearly from FIG. 1 , with which the engine torque can be transmitted to the on the drive shaft of the car. The bevel gear shaft 1 is fixed here in the housing 3 of the rear axle differential via two spaced-apart angular contact roller bearings 4 arranged opposite each other, which each substantially comprise an outer bearing ring 5 and An inner bearing ring 6 and a plurality of rolling elements 9 , 10 arranged next to each other in two rows 7 , 8 between the respective bearing rings 5 , 6 , which are held at uniform distances in the circumferential direction by a bearing cage 11 . In this case, the inner sides 12 of the outer bearing rings 5 of the two angular contact rolling bearings 4 are formed with two adjacent raceways 15 , 16 delimited on one side by a shoulder 13 , 14 , which are in contact with the inner bearings. On the outer side 19 of the ring 5 two adjacent raceways 22 , 23 which are like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com