Clutch device

A clutch device and clutch technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as time-consuming, large rotating mass, etc., and achieve the effects of avoiding waste, small installation space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

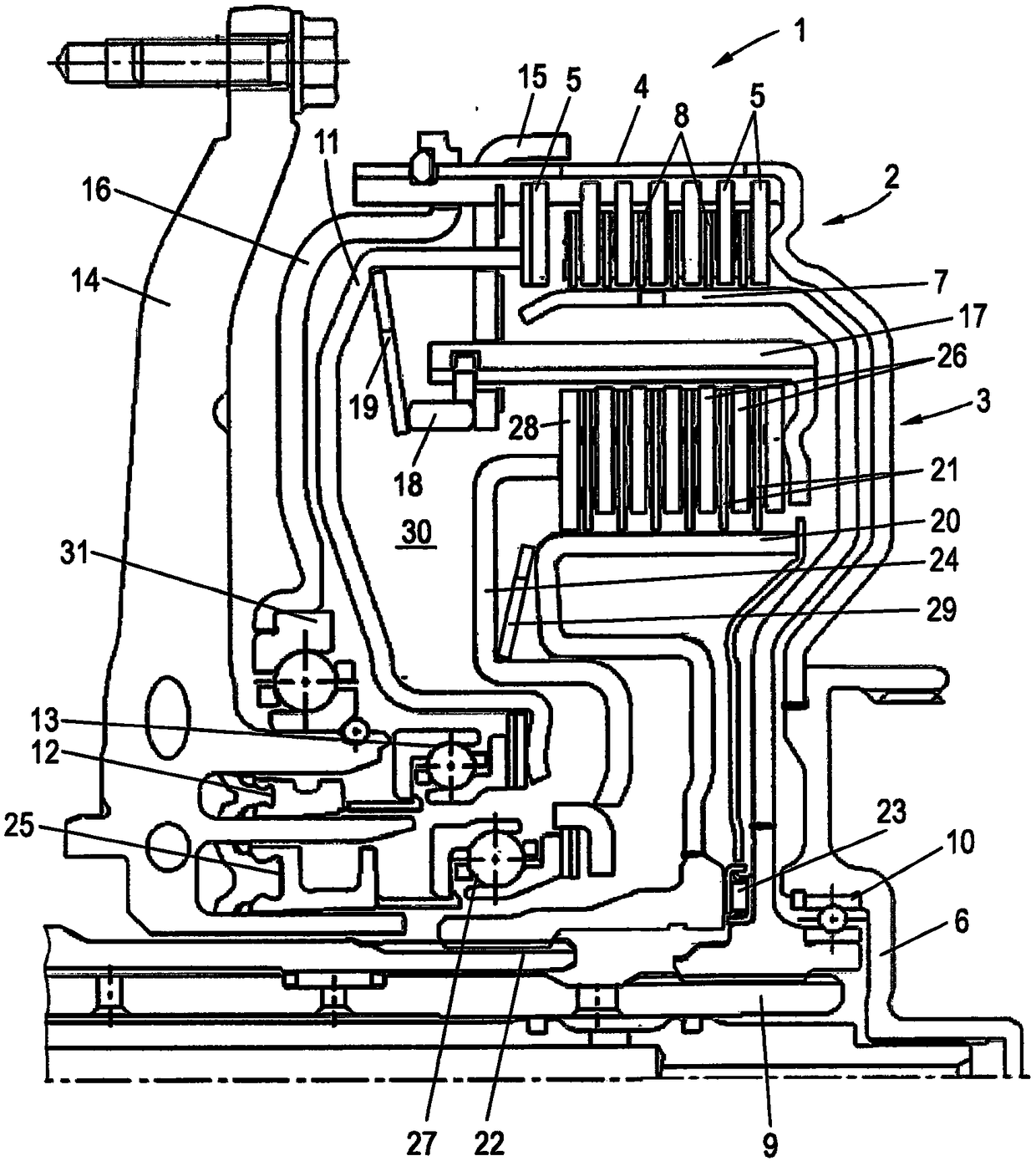

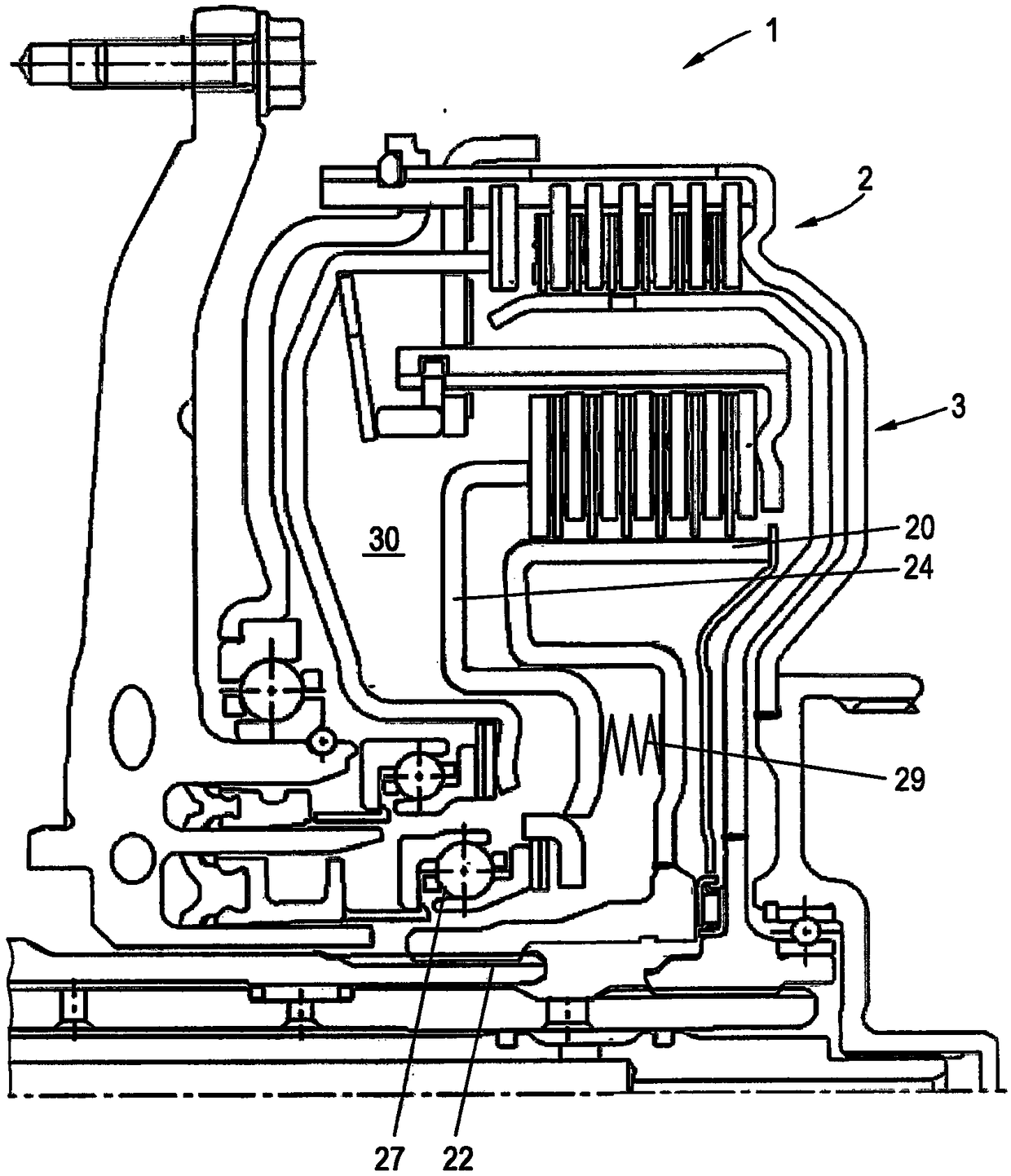

[0021] figure 1 A clutch arrangement 1 according to the invention is shown comprising two subclutches 2 , 3 disposed radially within one another, wherein subclutch 2 is generally referred to as K1 and subclutch 3 is generally referred to as K2 .

[0022] The sub-clutch 2 comprises an outer plate carrier 4 having an outer plate 5, typically a steel plate, arranged thereon. In the exemplary embodiment shown, the outer plate carrier 4 is arranged on a drive element 6 (for example a motor output shaft) and is thus actively driven, for example by an internal combustion engine.

[0023] The sub-clutch 2 also includes an inner plate support 7 on which a plurality of inner plates 8 are arranged, usually friction plates provided with friction linings on both sides. In the exemplary embodiment shown, the inner disc carrier 7 is connected to an output element 9 , for example a transmission shaft or hub or the like leading to the transmission input. The inner disc carrier is decoupled f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com