Front-wheel-drive vehicle gearbox

A technology of automobile transmission and front wheel drive, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of enlarging the space of the engine room, reducing the rigidity, reducing the service life of the gearbox, etc., and achieve a comfortable driving environment , increase the degree of coincidence, reduce the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

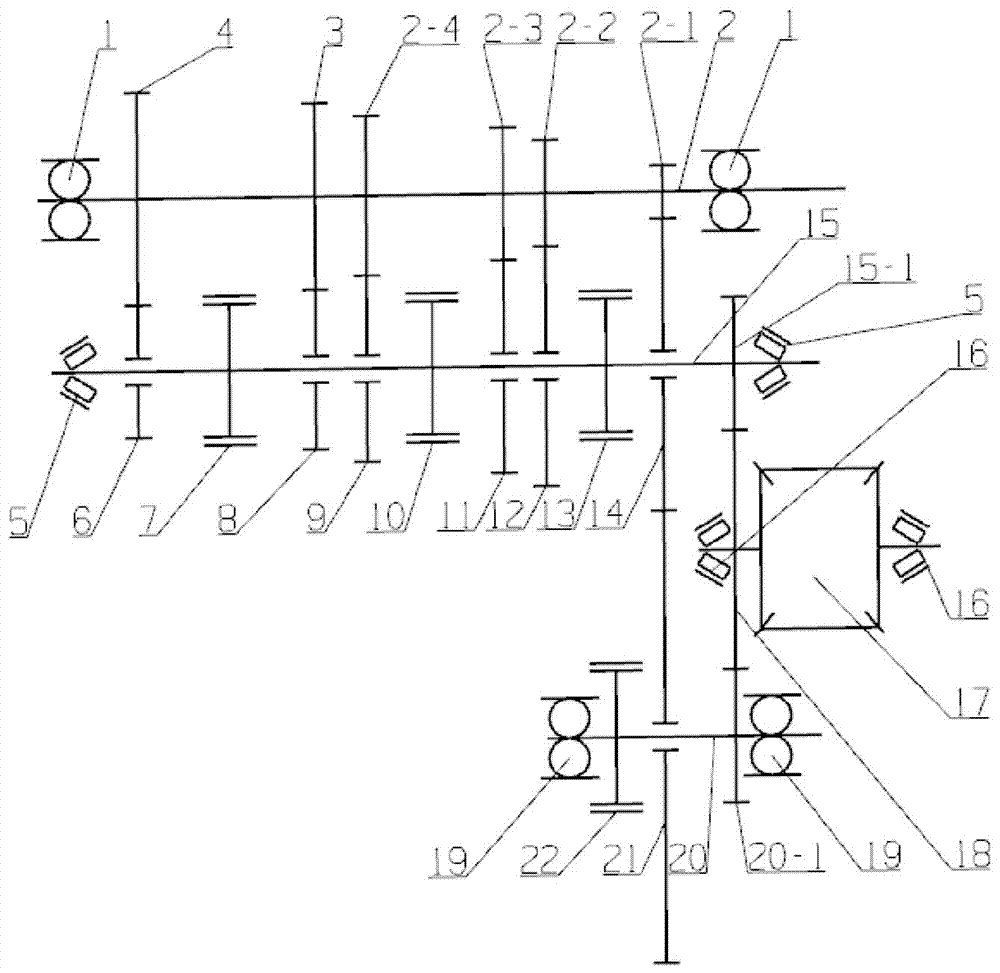

[0026] see figure 1 , a kind of embodiment of front-wheel-drive automobile transmission, front-wheel-drive automobile transmission, comprises transmission mechanism, shift mechanism, and described transmission mechanism comprises input shaft 2, output shaft 15, reverse gear shaft 20 that are arranged parallel to each other. Both ends of the input shaft 2 are respectively interference fitted with the input shaft bearing 1, and the input shaft 2 is supported in the transmission housing (not shown) through the input shaft bearing 1. The interference connection structure is simple, the centering is good, and the bearing capacity is high , It can work reliably under variable load and impact load, and it is not necessary to cut keyways on the input shaft to weaken the strength of the input shaft 2. The input end of the input shaft 2 is provided with a spline f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com