Crossed roller bearing and speed reducer

A cross-roller and reducer technology, applied in the field of bearings, can solve the problems that the inner ring cannot be processed with continuous tooth shape, the NN type reducer cannot be used, and the continuous tooth shape cannot be processed, and achieves compact structure, cost saving, The effect of reducing the axial installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

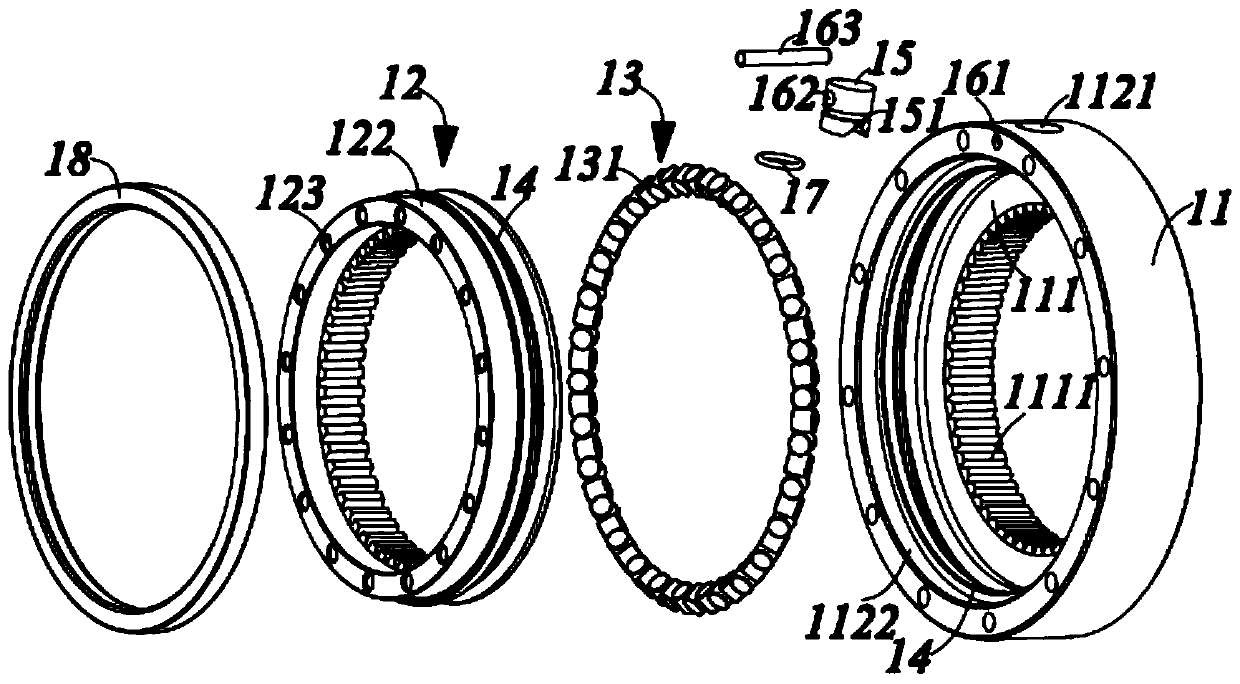

[0026] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to Figure 1 to Figure 9 Shown is a preferred embodiment of the present invention. However, it should be noted that these embodiments do not limit the present invention, and any functional, method, or structural equivalent transformations or substitutions made by those skilled in the art based on these embodiments fall within the protection scope of the present invention.

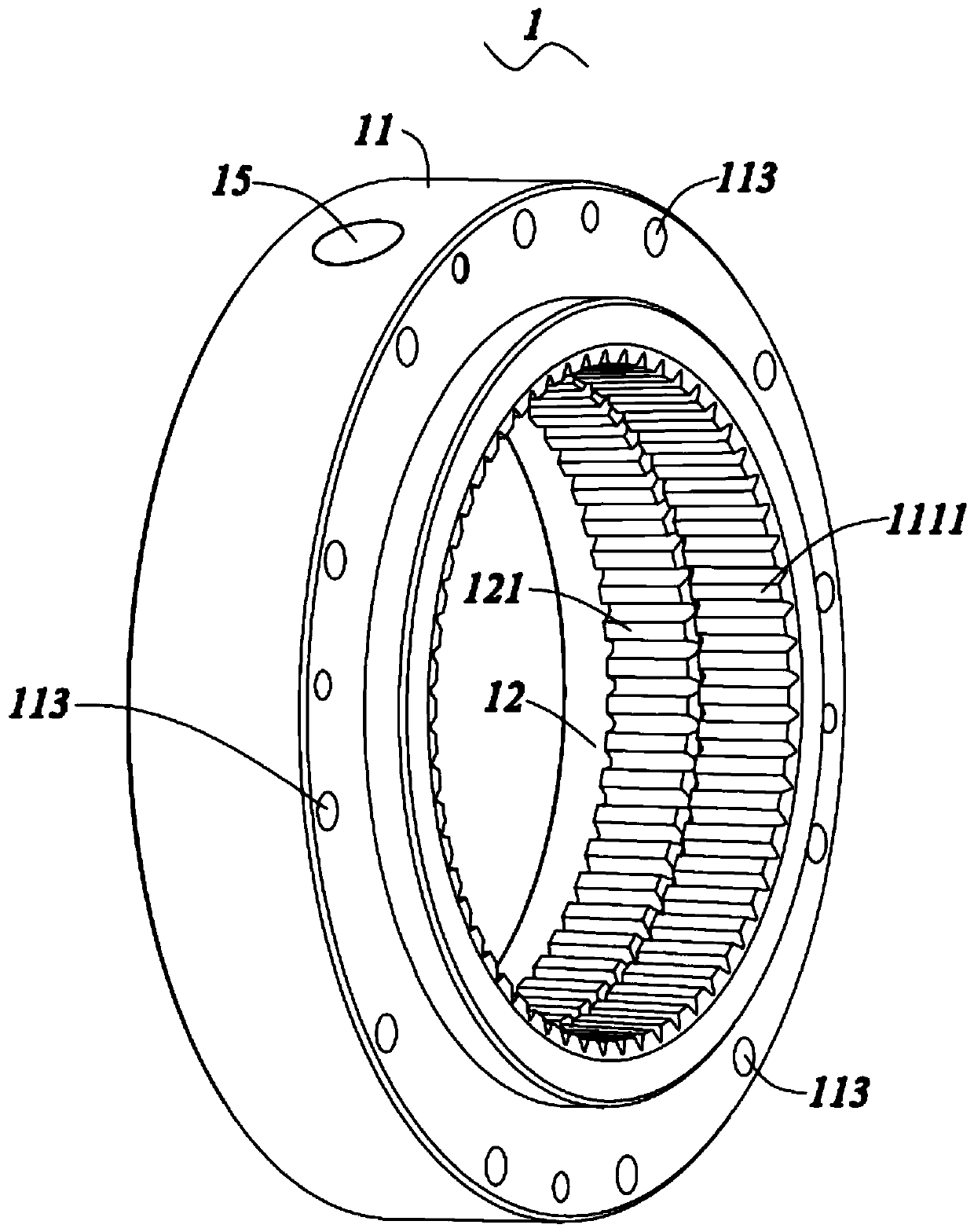

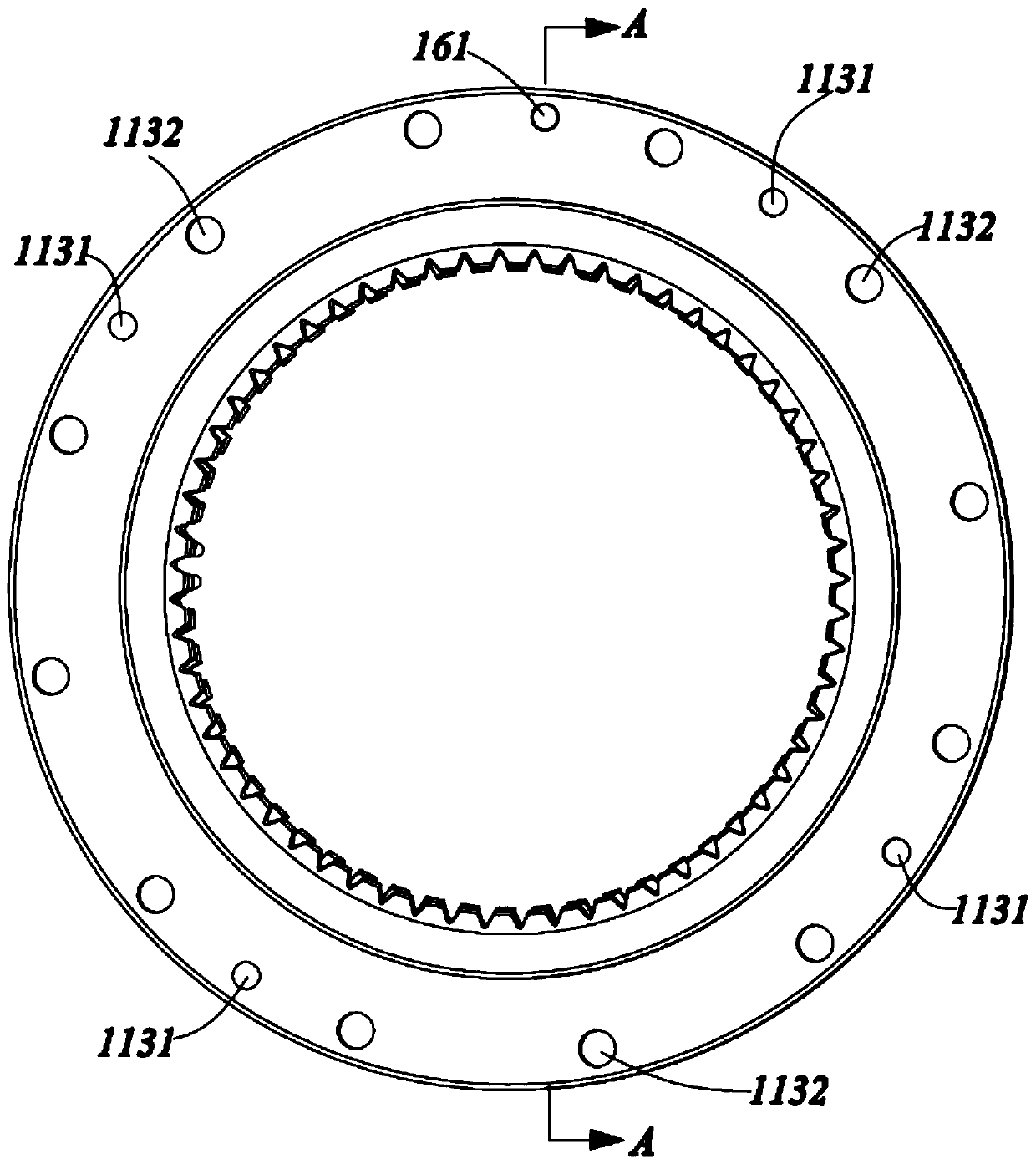

[0027] Please refer to Figure 1 to Figure 5 As shown, the present invention provides a cross roller bearing 1 , including an outer ring bearing 11 , an inner ring bearing 12 , and a rolling assembly 13 arranged between the outer ring bearing 11 and the inner ring bearing 12 .

[0028] The outer ring bearing 11 has a first outer ring 111 and a second outer ring 112 arranged coaxially along its axial direction, and the inner diameter of the first outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com