Drilling verticality monitoring and deviation rectifying method along with drilling process

A process monitoring and verticality technology, applied in measurement, drilling equipment, directional drilling, etc., can solve problems such as the inability to monitor the verticality of the borehole in real time, the inability to rectify the deviation independently, and the quality of the pile that affects the construction efficiency, so as to improve the quality of the hole. and construction efficiency, avoiding multiple shutdowns for adjustment, and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

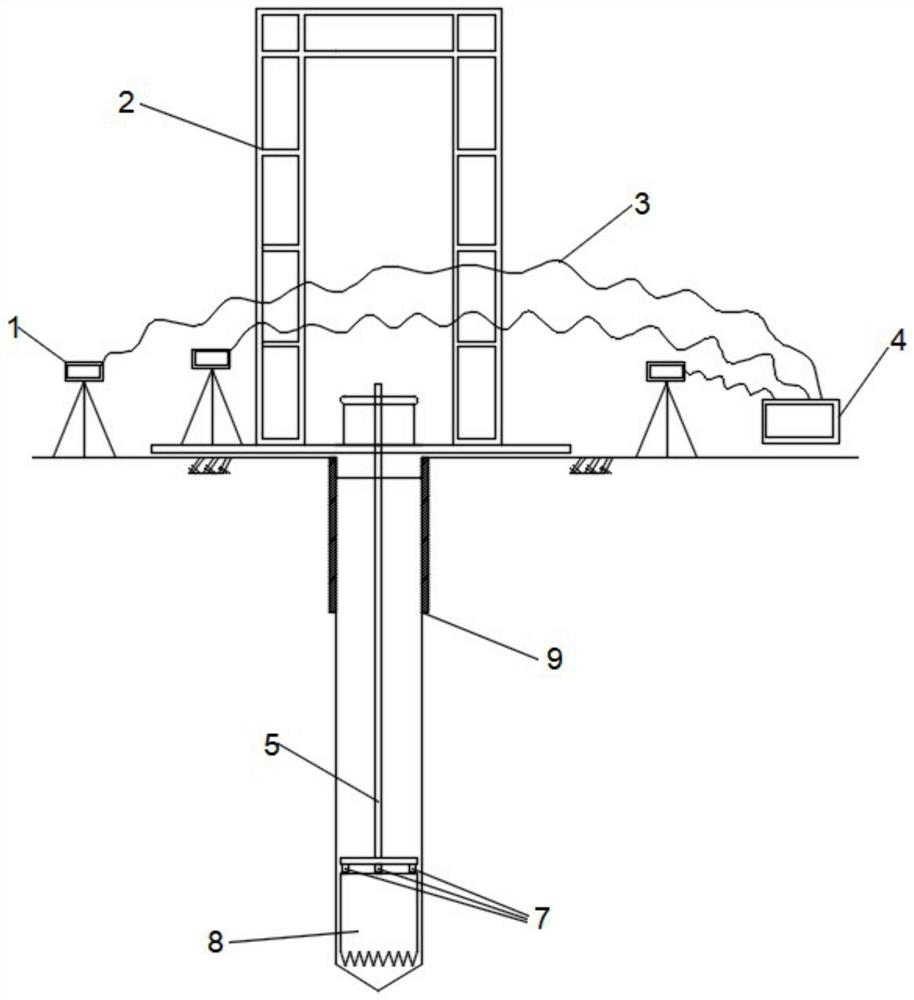

[0032] Such as Figure 1-4 As shown, the embodiment of the present invention provides a method for monitoring the verticality of the borehole and correcting the deviation during the drilling process, including the following steps:

[0033] S1. Drilling machine in place

[0034] After confirming the drilling position, move the drilling machine to the construction position;

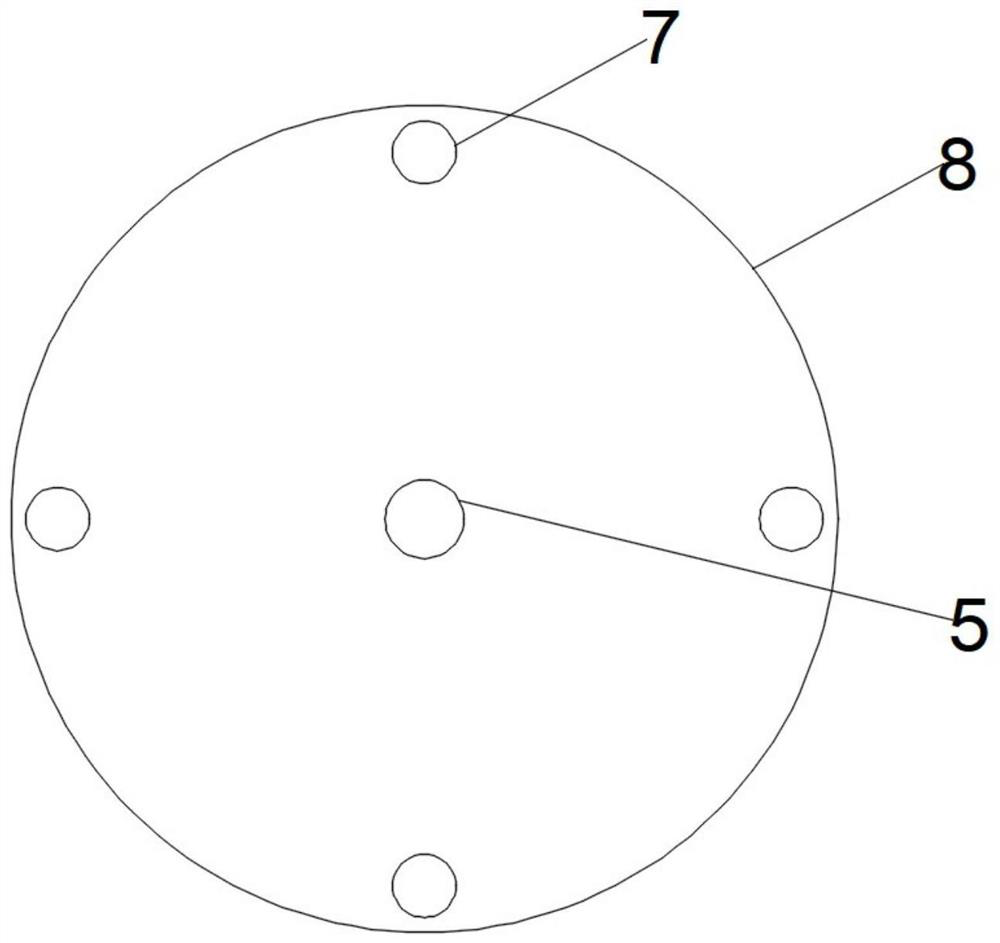

[0035] S2. Install verticality monitoring system and drill bit correction system

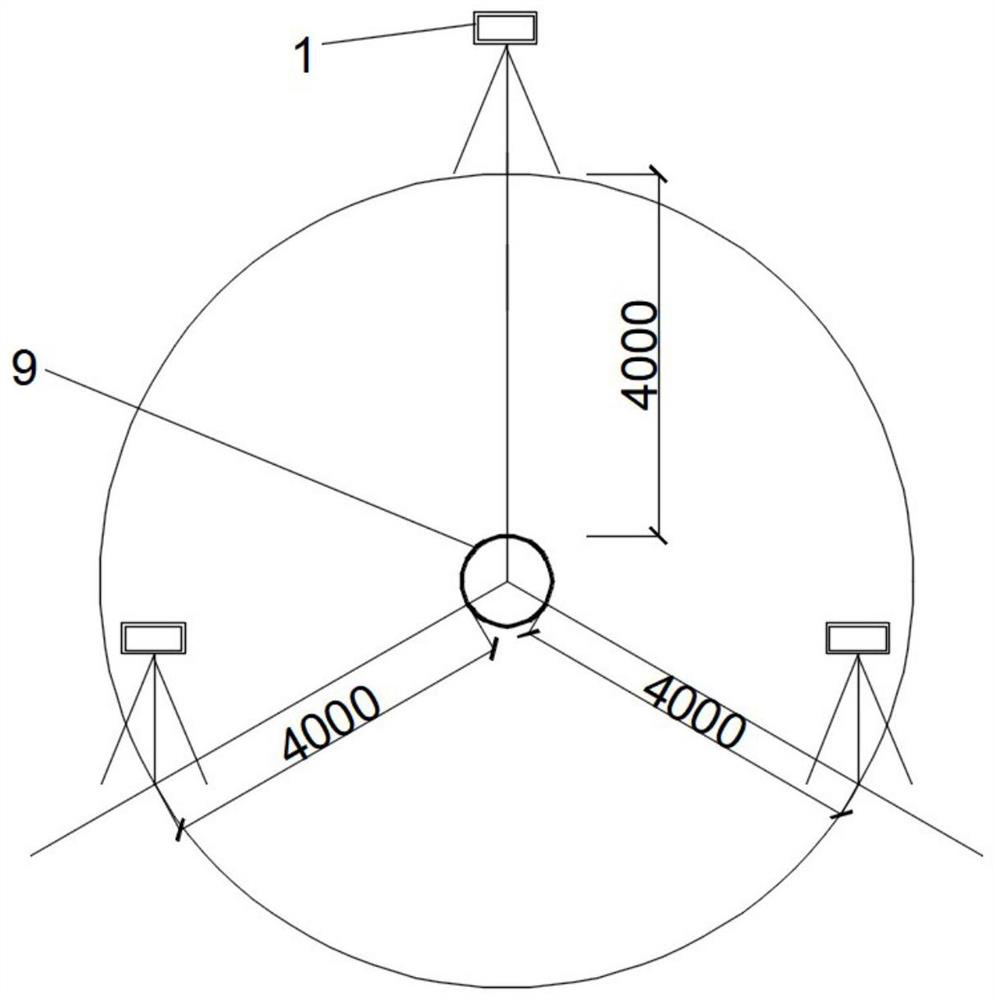

[0036] First place the verticality sensor inside the drill bit of the drilling rig and fix it, and arrange three positioning transmitter receivers on the ground around the drill hole. The three positioning transmitter receivers are placed in a circular array on the ground with the drill hole as the center of the circle. And the distance between the three positioning transmitter receivers and the central axis of the drilling is 4000mm, and the three positioning transmitter receivers are connected to the computer terminal thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com