Off-line assembling device for foundation bolts and adjustment method thereof

A technology of anchor bolts and assembly devices, which is applied in the direction of basic structure engineering, construction, building construction, etc., can solve the problems of anchor bolt offset and accuracy cannot be guaranteed, and achieve saving of fixing materials, ensuring consistent elevation, make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

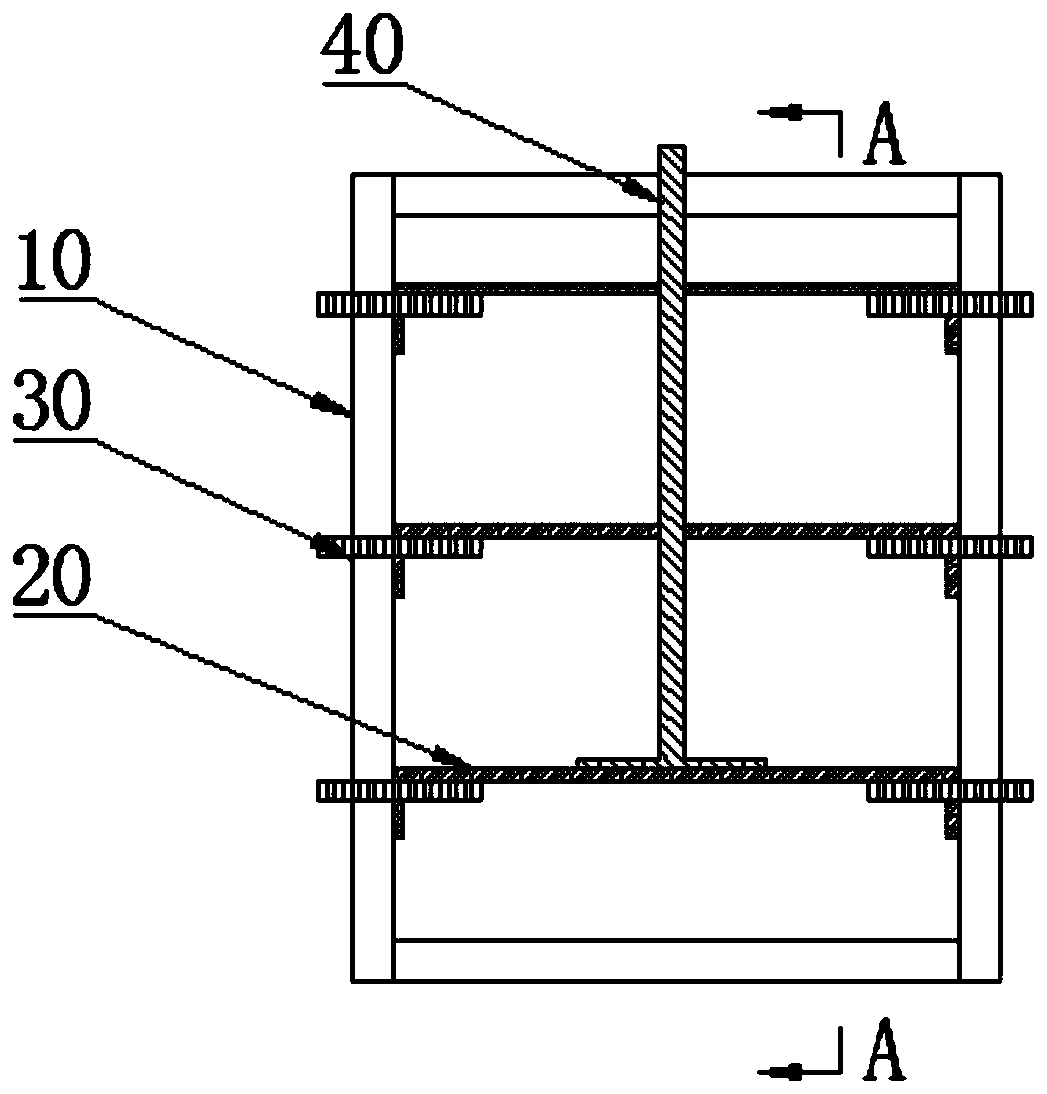

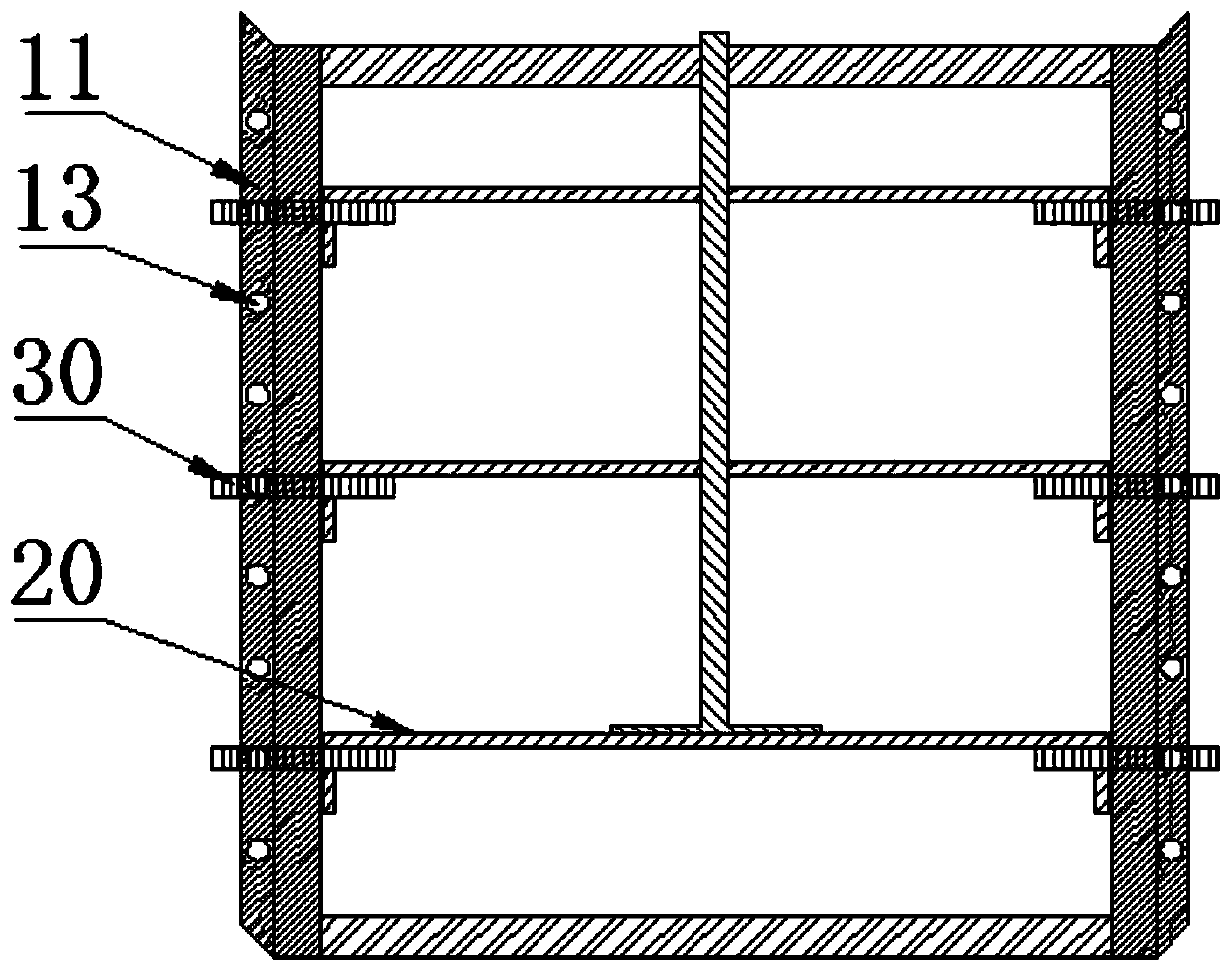

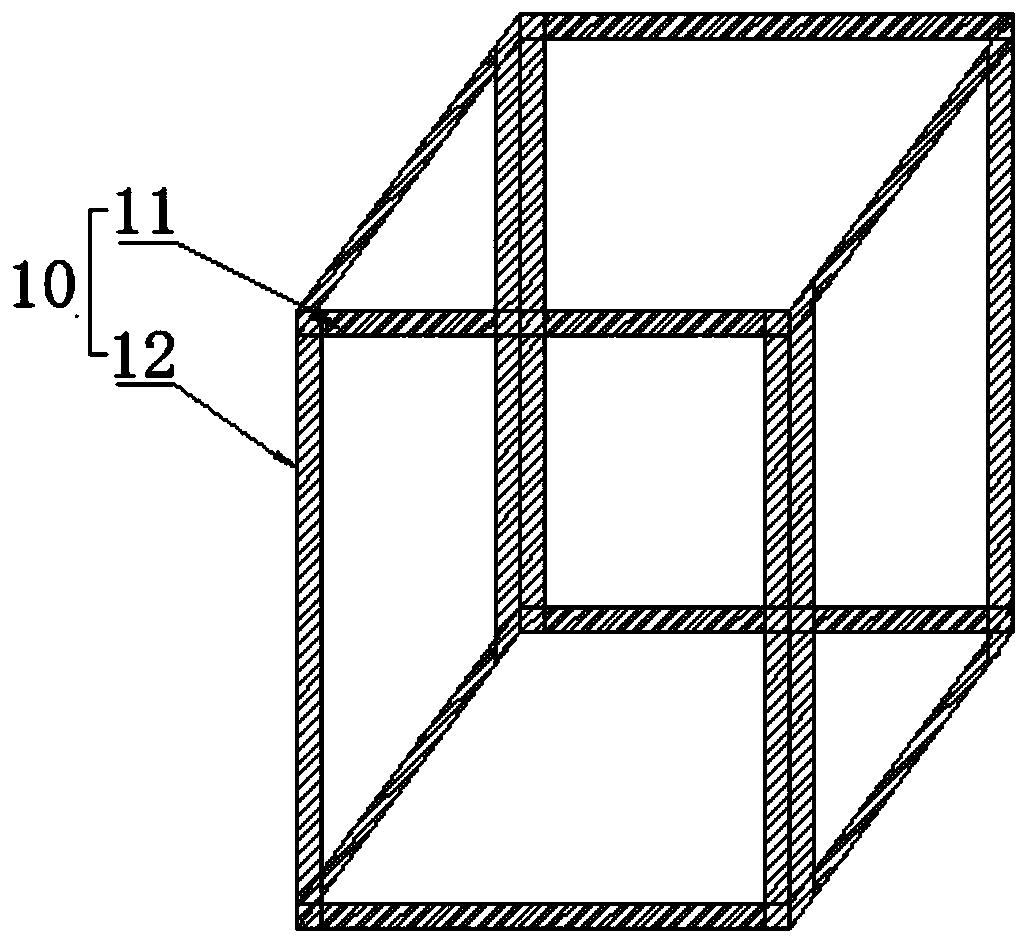

[0036] An embodiment of the present invention is an off-line assembly device for anchor bolts, such as Figure 1-2 As shown, it includes a fixed part 10, a positioning part 20 and an adjustable part 30. The positioning part 20 is embedded in the fixed part 10 and placed above the adjustable part 30. There are several sets of first through holes inside the positioning part 10. 22 , the anchor bolt 40 is arranged vertically through the first through hole 22 , and the positioning part 20 is arranged perpendicular to the fixed part 10 and arranged parallel to the adjustable part 30 . The adjustable part 30 is arranged perpendicular to the vertical axis of the fixed part 10 , and the adjustable part 30 is detachably connected to the fixed part 10 , and the adjustable part 30 is fixedly installed horizontally through the fixed part 10 and the adjustable part 20 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com