Pitched roof construction technology

A construction technique and technology of sloping roofs, applied in the direction of roofs, roof coverings, building roofs, etc., can solve the problems of pre-embedded steel bars that are easy to be skewed, shifted, affect the closing surface, affect the smoothness of the water strips, and the flatness of the hanging tiles. Achieve the effects of flexible construction, easy pouring and surface closing, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

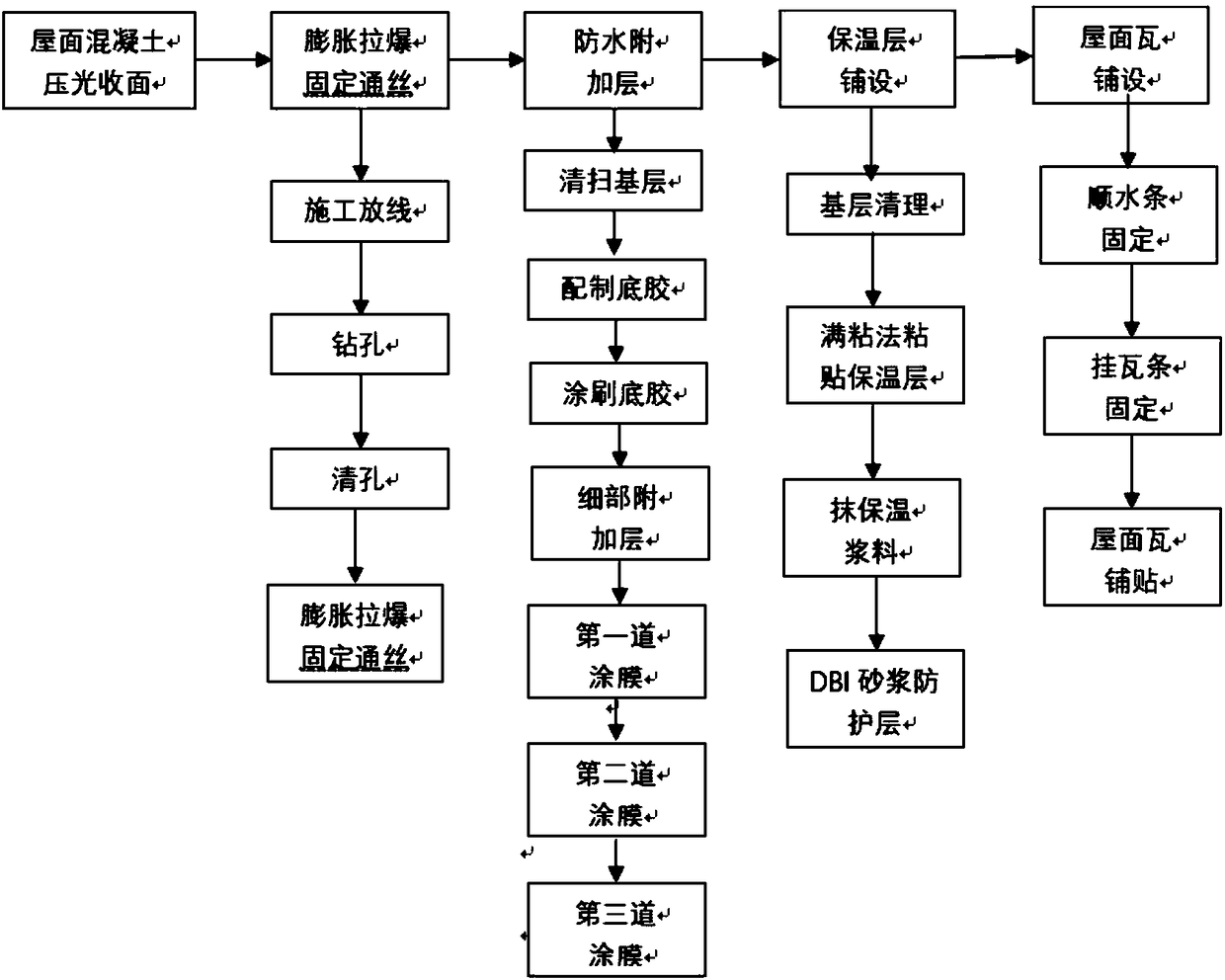

[0053] figure 1 The flow chart of the sloping roof construction technology that the embodiment of the present invention provides; figure 1 As shown, the slope roof construction technology provided by Embodiment 1 of the present invention includes the following steps:

[0054] a) The roof concrete is calendered and finished, and the wire is installed to pull the blast;

[0055] b) Make a waterproof additional layer and scrape three coating films;

[0056] c) Paste the insulation board, and apply the insulation slurry layer and the DBI mortar protection layer;

[0057] d) The water strip is fixed by double nuts and the through wire, and the tile strip and the water strip are fixed;

[0058] e) Laying of roof tiles.

[0059] Specifically, the installation method of the wire pull blast is: after the roof garbage is cleaned up, the wire pull blast is installed by setting out the wires. The vertical and horizontal spacing of the wires are both 600mm, and the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com