Construction method for dry sticking of large wall bricks for interior decoration

A construction method and interior decoration technology, applied in covering/lining, construction, building structure, etc., can solve problems such as falling off, easy hollowing of wall bricks and wall base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

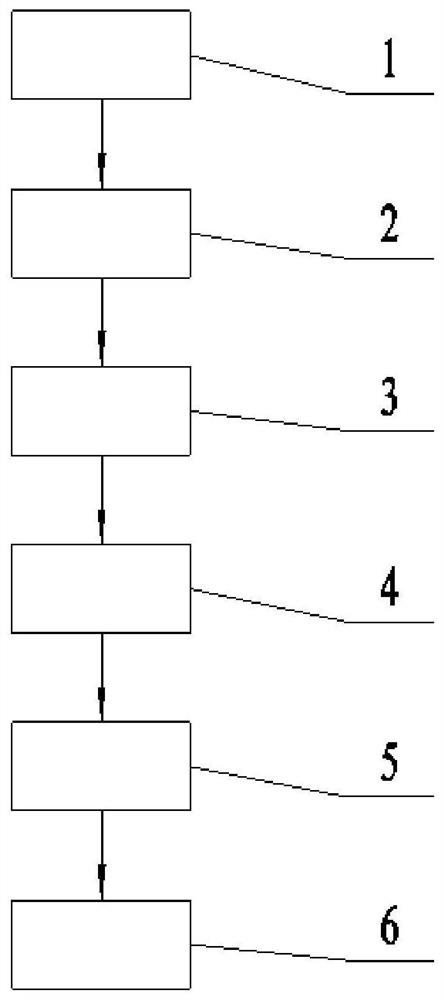

[0038] In this embodiment, a construction method of dry pasting large wall tiles for interior decoration, such as figure 1 shown, including the following steps:

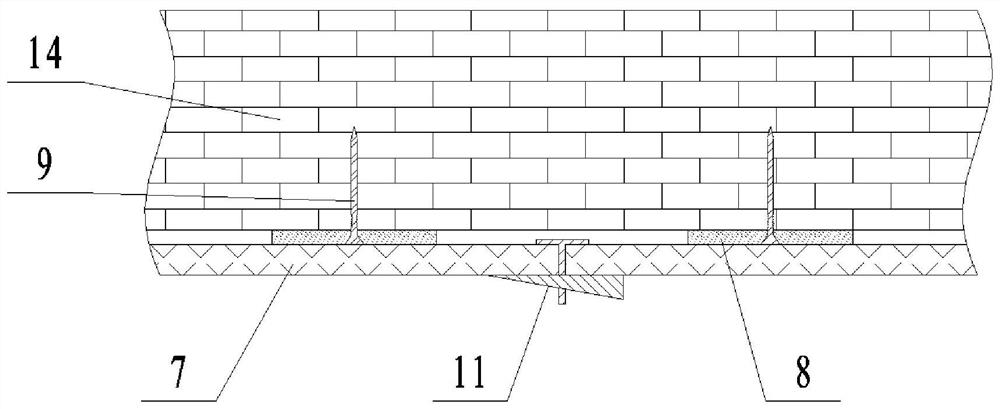

[0039] Step 1: Construction preparation 1: Prepare wall bricks 7, dry glue 8, anchor nails 9 and typesetting drawings, clean the surface impurities of the wall base 14, and paint the wall mortar;

[0040] Step 2: Typesetting and positioning of wall tiles 2: typesetting and marking lines on the surface of the base layer 14 of the wall according to the typesetting drawings, determine the pasting position of each wall tile 7, and arrange the module of the wall tile 7;

[0041] Step 3: Anchor nail installation 3: Arrange dry paste points 10 on the pasting position of each wall brick 7 in the wall, and install an anchor nail 9 at each dry paste point 10 to ensure that the installation position of the anchor nail 9 is consistent with the dry paste point 10. The position of the sticking point 10 is consistent; apply the dr...

Embodiment 2

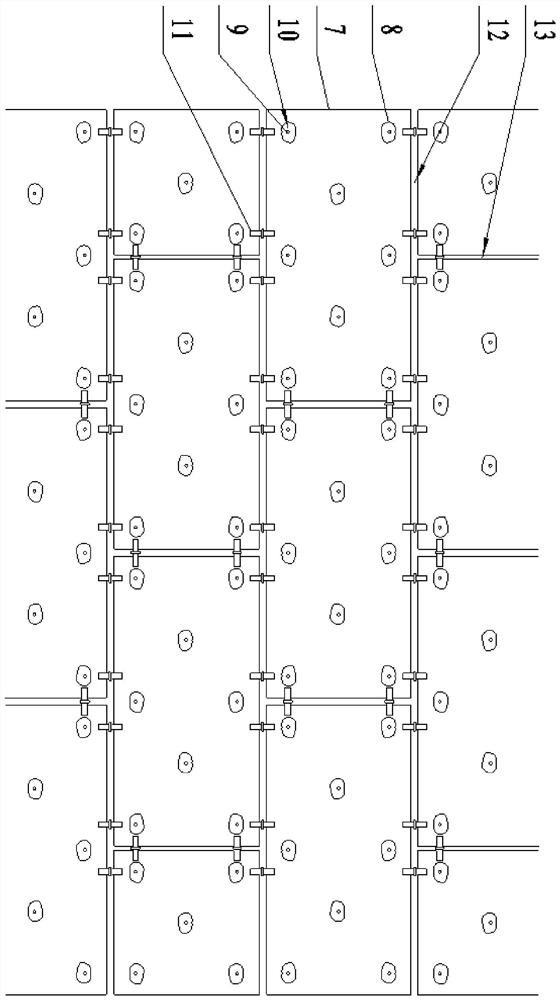

[0047] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, as figure 2 As shown, in step 3, the above-mentioned wall tile 7 is rectangular, and its size is preferably 600mm*1200mm. The number of the above-mentioned dry pasting points 10 arranged on the sticking position of each above-mentioned wall tile 7 is eight, of which six above-mentioned dry The sticking points 10 form two rectangular structures, which are located at the peripheral positions of the above-mentioned wall tiles 7, and the remaining two above-mentioned dry sticking points 10 are respectively located at the intersections of the diagonal lines of the two rectangular structures, and the eight above-mentioned dry sticking points evenly arranged Point 10 ensures that the above-mentioned wall tiles 7 are firmly pasted as a whole, so that the above-mentioned wall tiles 7 can be firmly dry- pasted on the above-mentioned wall base layer 14 .

[0048] As another specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com