Fabricated concrete overhead ground mounting structure and mounting method

An installation structure and prefabricated technology, applied in the direction of floors, building structures, local raised floors, etc., can solve the problems of poor flatness, pollution of the environment, low efficiency, etc., and achieve the effect of fast and efficient installation and improvement of construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

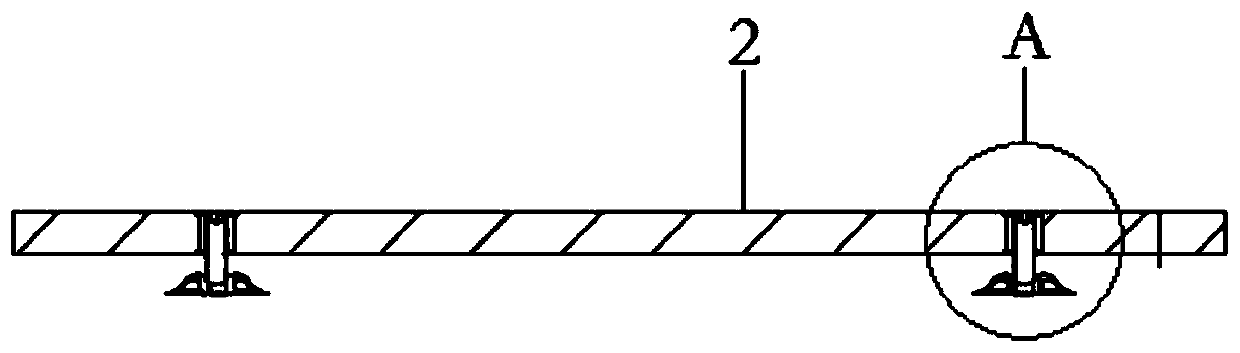

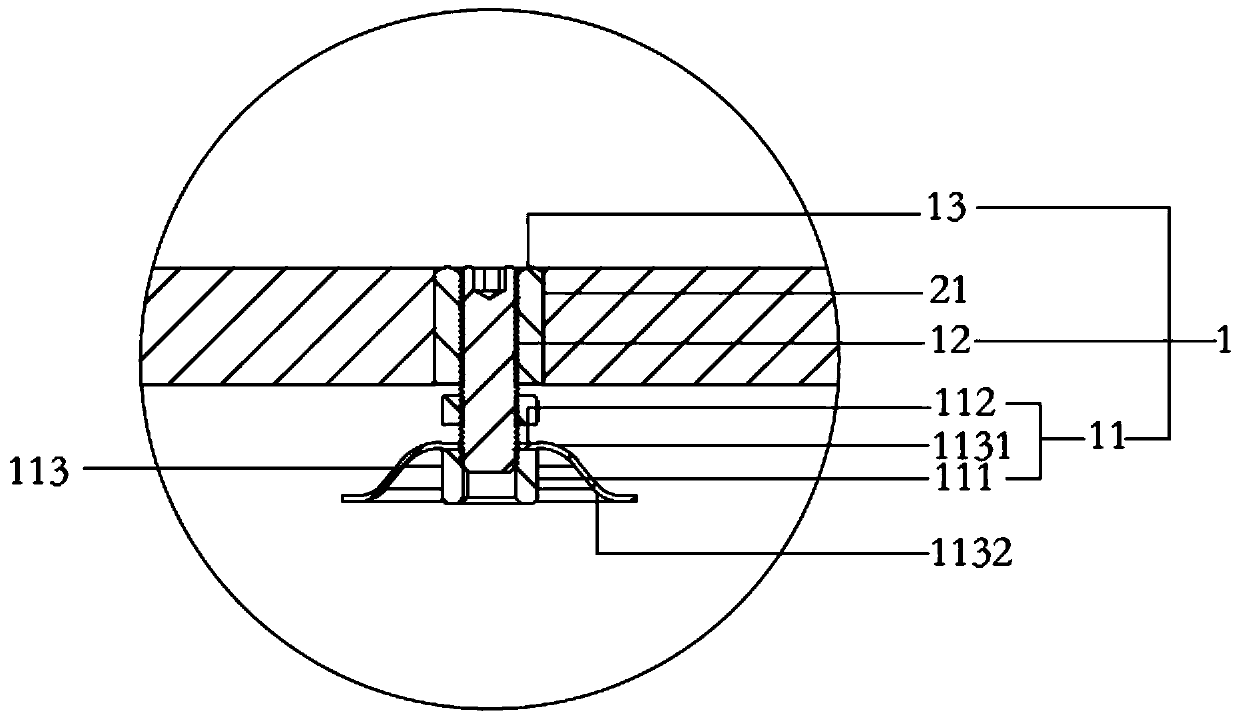

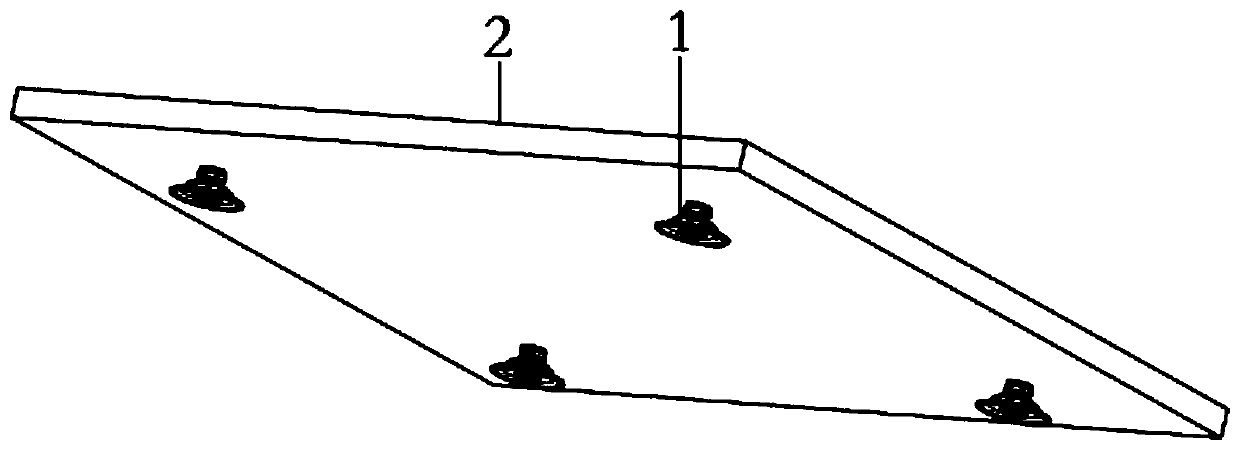

[0034] see Figure 1 to Figure 3 , the figure shows a prefabricated concrete overhead ground installation structure provided by Embodiment 1 of the present invention. First, a leveling layer is provided, which includes a plurality of support mechanisms 1, and the support mechanism 1 includes footings 11, support columns 12 and Positioning sleeve 13, a plurality of footings 11 are fixedly installed on the ground, and footing 11 comprises base post 111 and balance board 112, and balance board 112 is fixedly installed on the base post 111, and the bottom of base post 111 and the bottom of balance board 112 They are all in contact with the ground, the bottom end of the support column 12 is fixedly installed on the base column 111, and the top end of the support column 12 is fixedly fitted with a positioning sleeve 13, and the lower surface of the concrete plate 2 is provided with a plurality of positioning grooves 21. The positions of the positioning grooves 21 correspond to the p...

Embodiment 2

[0044] see Figure 1 to Figure 3 , the figure shows a prefabricated concrete overhead ground installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Support mechanism 1 Including footing 11, support column 12 and positioning sleeve 13, a plurality of footings 11 are fixedly installed on the ground, the bottom end of support column 12 is fixedly installed on the base column 111, and the top end of support column 12 is fixedly fitted with a positioning sleeve The barrel 13 and the lower surface of the concrete board 2 are provided with a plurality of positioning grooves 21, the positions of the plurality of positioning grooves 21 correspond to the positions of the plurality of support mechanisms 1, the positioning sleeve 13 is detachably positioned in the positioning groove 21, and the positioning sleeve 13 The inner wall of the inne...

Embodiment 3

[0046] see Figure 1 to Figure 3 , the figure shows a prefabricated concrete overhead ground installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: footing 11 It includes a base column 111 and a balance board 112, the balance board 112 is fixedly installed on the base column 111, the bottom of the base column 111 and the balance board 112 are all in contact with the ground, and a reinforcement is installed between the base column 111 and the balance board 112 The reinforcing plate is ring-shaped, and it is set on the base column 111. At the same time, the side wall of the reinforcing plate is an arc surface, which matches the shape of the side wall of the balance plate 112. At the same time, in order to adapt to the small deformation of the balance plate 112 under the action of pressure, A rubber ring can be pasted on the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com