Ceramic tile concrete composite board wall surface leveling and supporting device

A supporting device and composite panel technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems of large hollowness, unevenness of tile-concrete composite panels, and easy breakage, so as to improve construction efficiency and fast and efficient installation , Solve the effect of a large sense of emptiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

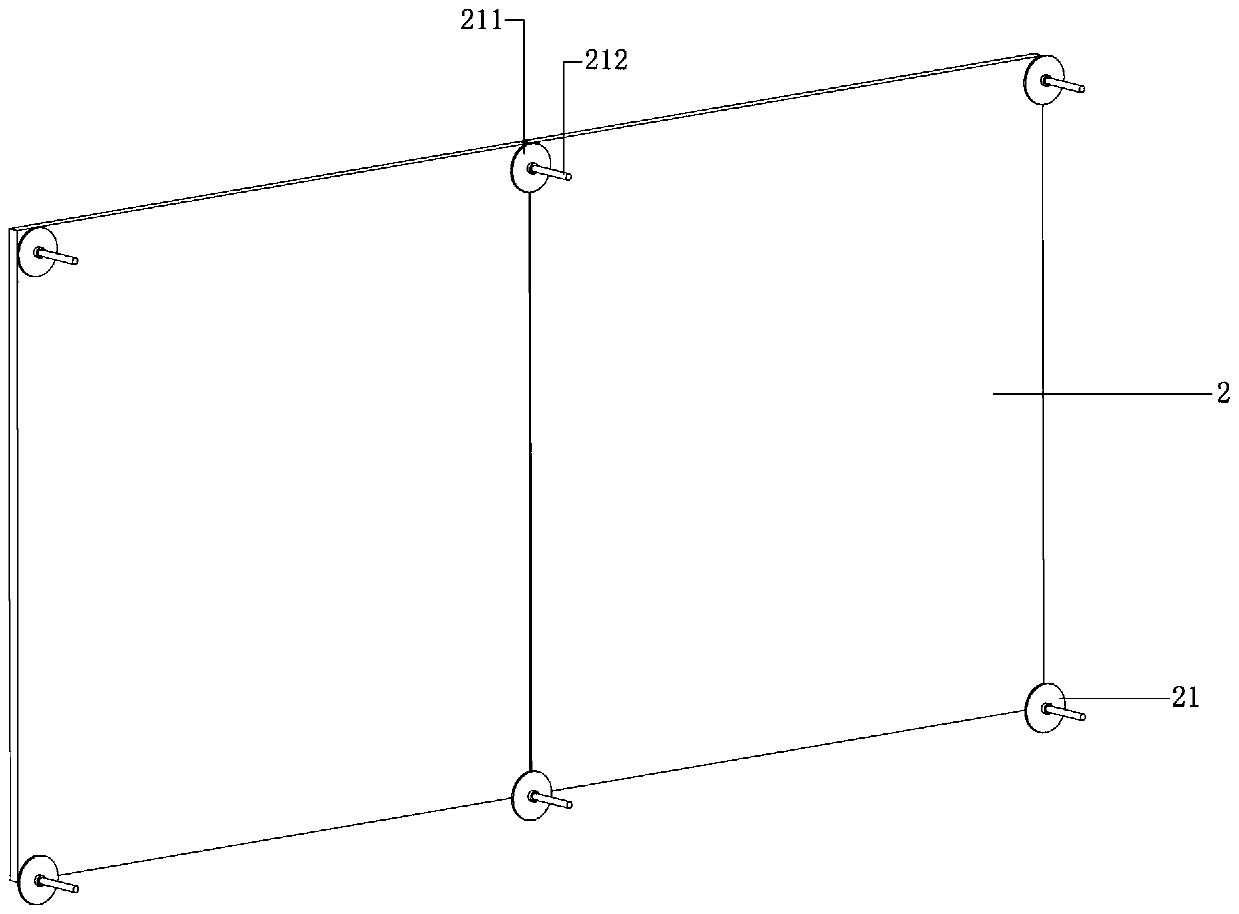

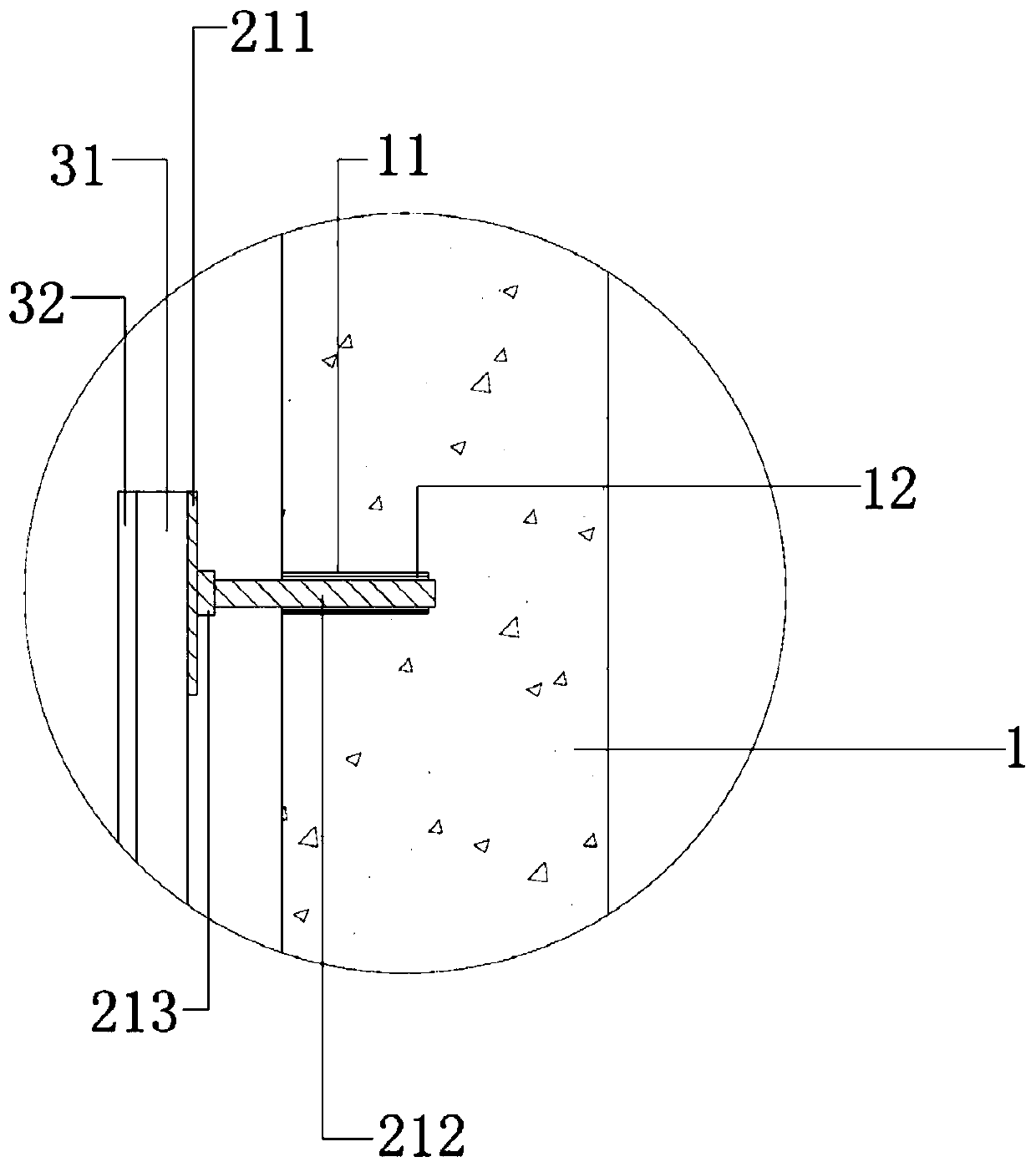

[0026] see Figure 1 to Figure 2 , the figure shows a tiled concrete composite board wall leveling and supporting device provided by Embodiment 1 of the present invention, which includes several tiled concrete composite boards 2 dry-hanging on the wall 1, and the tiled concrete composite board 2 includes The concrete base 31 and the ceramic tiles 32 fixed on the concrete base 31, the tile concrete composite board 2 is a rectangular board body, and the four corners of the tile concrete composite board 2 are connected to the wall 1 through the leveling support part 21, and the leveling support part 21 includes a circular chassis 211 and a connecting shaft 212, the connecting shaft 212 is fixedly connected to the center of the circular chassis 211, the circular chassis 211 is fixedly connected to the inner side of the corner of the ceramic tile concrete composite board 2, and the connecting shaft 212 is fixedly inserted into the wall In the connection hole 11 preset on the body 1...

Embodiment 2

[0033] see Figure 1 to Figure 2 , the figure shows a ceramic tile concrete composite board wall leveling and supporting device provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The bottom end of the connecting shaft 212 has a circular base plate 213 fixedly connected to the center of the circular chassis 211 . Through the setting of the above structure, the reinforcement effect on the bottom end of the connecting shaft can be realized, and the stability of the corner support can be further improved.

[0034] combine Figure 1 to Figure 2 As shown, the wall leveling and supporting device of a tiled concrete composite board described in the above embodiment is mainly realized by the following construction methods:

[0035] S1: Drill out the connection hole 11 at the corresponding position on the wall 1 with an electric hammer, and knock in the iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com