Method for preparing titanium steel cladding board with thin coating

A composite board and thin cladding technology, which is applied in temperature control, metal rolling, manufacturing tools, etc., can solve problems such as warping of composite boards and affecting the shape of composite boards, achieve good board shape, avoid buckling, and save The effect of investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

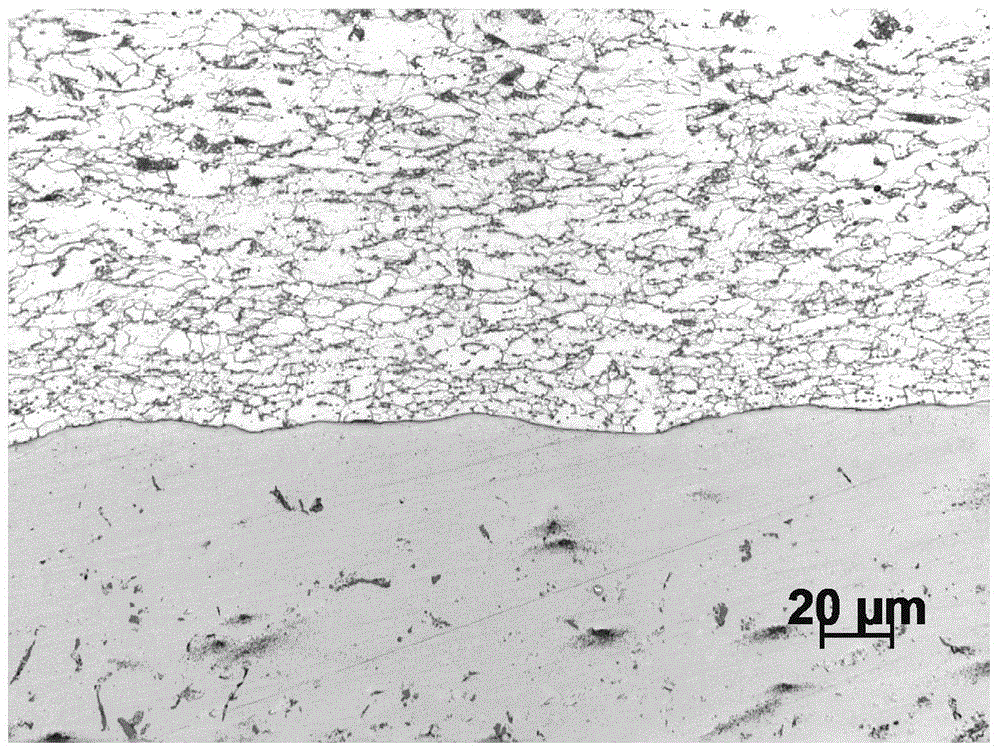

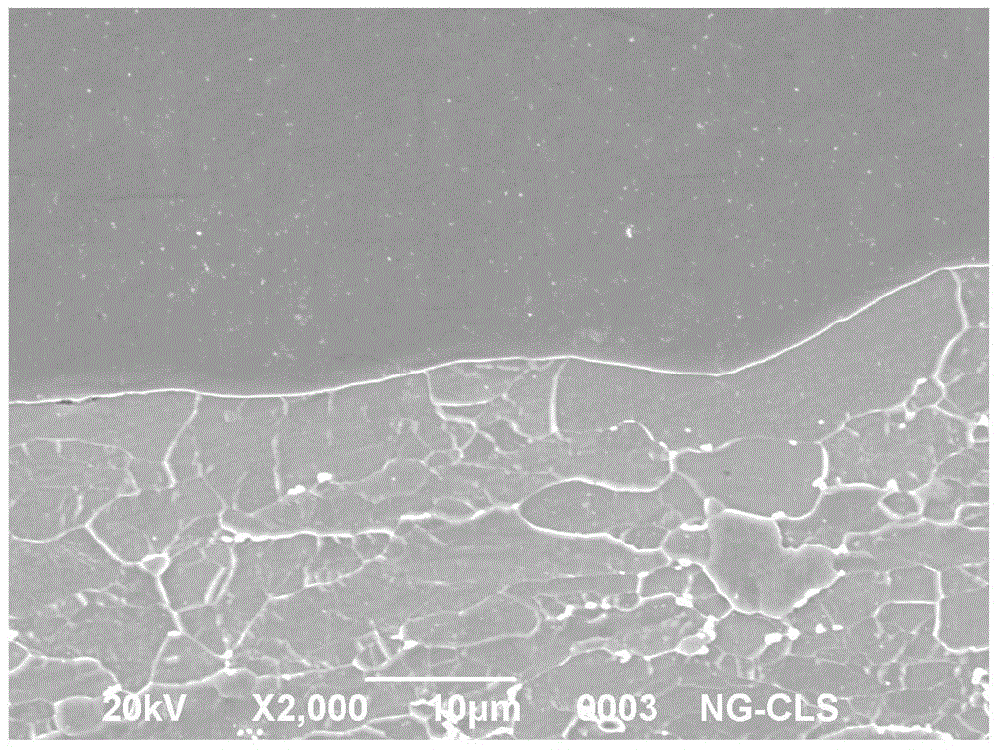

[0024] The cladding layer is TA1, the base layer is Q235B titanium steel explosive composite billet, wherein the thickness of the titanium layer of TA1 is 3mm, the thickness of Q235B steel plate is 30mm, and the total thickness is 33mm;

[0025] Perform surface treatment on the selected TA1 / Q235B billet, remove the sediment and other impurities on the upper and lower surfaces of the composite billet, and clean the burrs around the composite billet at the same time;

[0026] Put the cleaned TA1 / Q235B composite billet in a walking heating furnace for heating, keep the titanium layer at the top and the steel plate at the bottom during heating, and the burners opened during the heating process are all burners on the lower side of the furnace. The steel loaded at the end of the furnace enters the preheating section, the temperature of the preheating section is 450~550°C, and the preheating time is 50 minutes; then enters the heating section, the temperature of the heating section is...

Embodiment 2

[0031] The cladding layer is TA2, the base layer is Q235B titanium steel explosive composite billet, wherein the thickness of the titanium layer of TA2 is 3mm, the thickness of the Q235B steel plate is 45mm, and the total thickness is 48mm;

[0032] Perform surface treatment on the selected TA2 / Q235B blank, remove the sediment and other impurities on the upper and lower surfaces of the composite blank, and clean the burrs around the composite blank;

[0033] Put the cleaned TA2 / Q235B composite billet in a walking heating furnace for heating, keep the titanium layer on the top and the steel plate on the bottom during heating, and the burners opened during the heating process are all burners on the lower side of the furnace. The steel loaded at the end of the furnace enters the preheating section. The temperature of the preheating section is controlled at 450~550°C, and the preheating time is 55 minutes. Then it enters the heating section. The temperature of the heating section i...

Embodiment 3

[0038] The cladding layer is TA2, the base layer is Q345B titanium steel explosive composite billet, wherein the thickness of the titanium layer of TA2 is 6mm, the thickness of Q345B steel plate is 60mm, and the total thickness is 66mm;

[0039] Perform surface treatment on the selected TA2 / Q345B blank, remove the sediment and other impurities on the upper and lower surfaces of the composite blank, and clean the burrs around the composite blank;

[0040] Put the cleaned TA2 / Q345B composite billet in the walking heating furnace for heating, keep the titanium layer on the top and the steel plate on the bottom when heating, and the burners opened during the heating process are all the burners on the lower side of the furnace. The steel loaded at the end of the furnace enters the preheating section, the temperature of the preheating section is 450~550°C, and the preheating time is 65 minutes; then it enters the heating section, the temperature of the heating section is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com