Beam-slab structure for marine environment and building method thereof

A beam-slab structure and marine environment technology, applied in structural elements, building structures, floor slabs, etc., can solve the problems of easy corrosion of internal truss steel bars, inability to combine seawater and sea sand concrete, etc., to reduce material transportation costs and achieve good economy. Effective, high-durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further introduced below in combination with specific implementation methods and accompanying drawings.

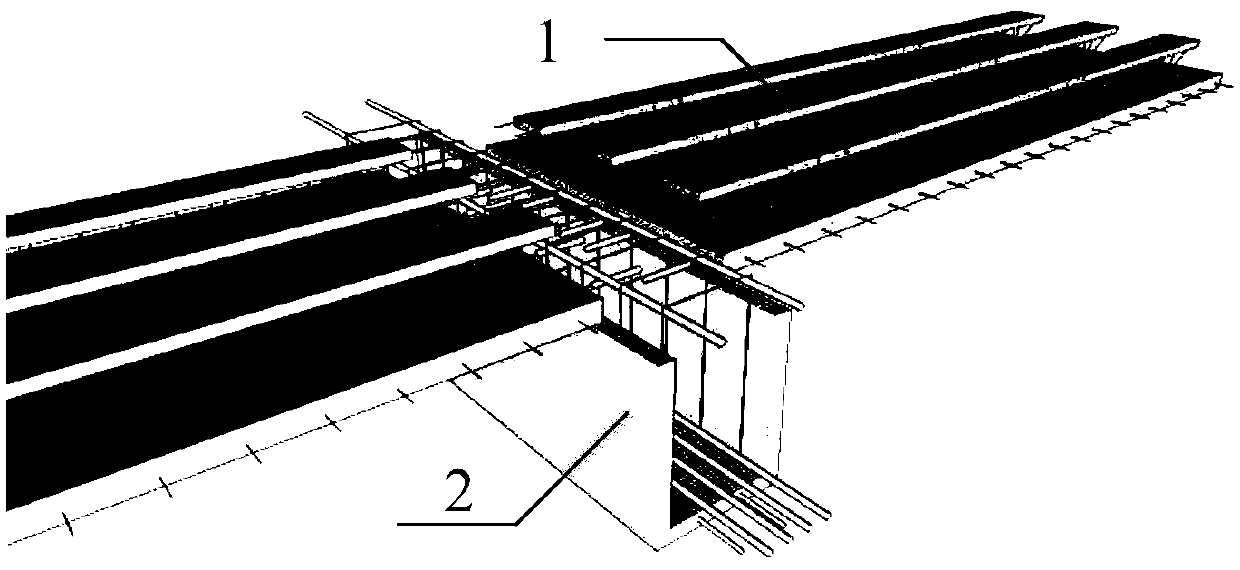

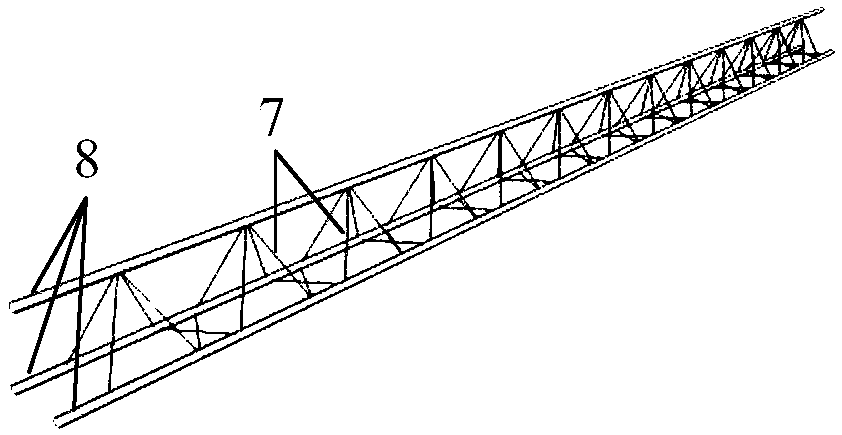

[0038] This specific embodiment discloses a new type of beam-slab structure facing the marine environment, such as figure 1 and Figure 7 As shown, it includes a prefabricated UHPC formwork composite beam 2 and a prefabricated FRP truss composite slab 1; wherein, the prefabricated UHPC formwork composite beam 2 includes a U-shaped UHPC formwork 14, and the U-shaped UHPC formwork 14 is provided with a beam bottom Prestressed FRP tendons 18 in the formwork, U-shaped UHPC formwork 14 is provided with FRP stirrups 16 in the U-shaped area, FRP stirrups 16 are provided with FRP vertical bars 17, and the bottom of FRP stirrups 16 is provided with FRP Tensile longitudinal reinforcement 15; prefabricated FRP reinforcement truss laminated slab 1 includes FRP reinforcement truss, the bottom of the FRP reinforcement truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com