Profiling steel plate - bamboo slab rubber combining floor and manufacturing method thereof

A technology of profiled steel plates and combined floor slabs, which is applied to floor slabs, building components, buildings, etc., can solve the problems of bamboo stagnation and has not been widely used in the field of building structures, etc., and achieve the effects of comprehensive cost reduction, beautiful appearance, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

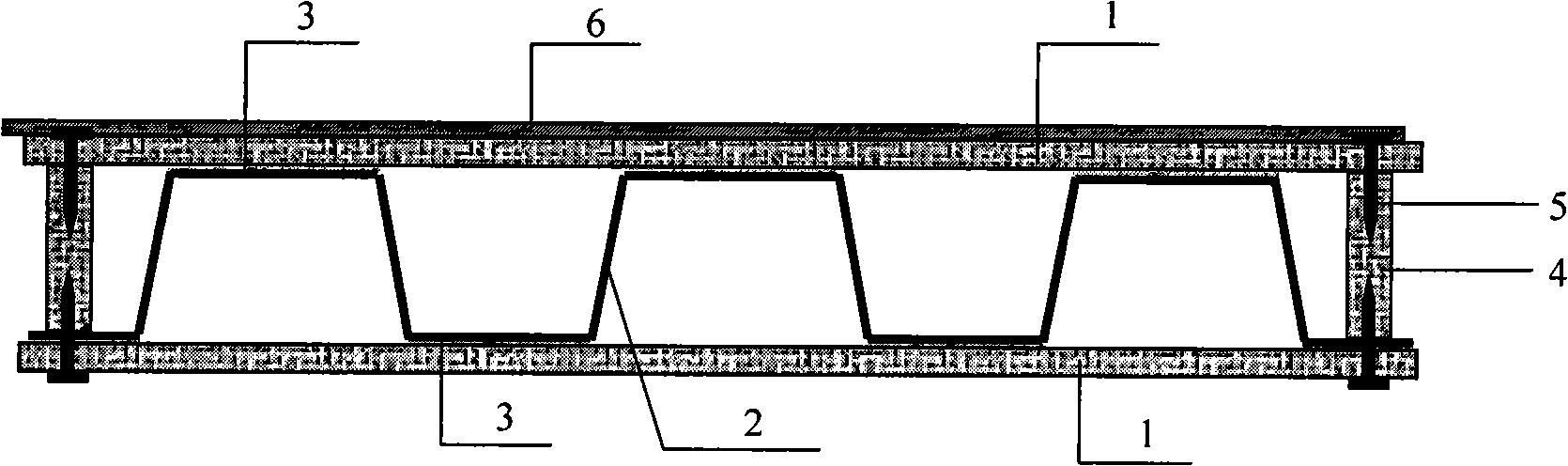

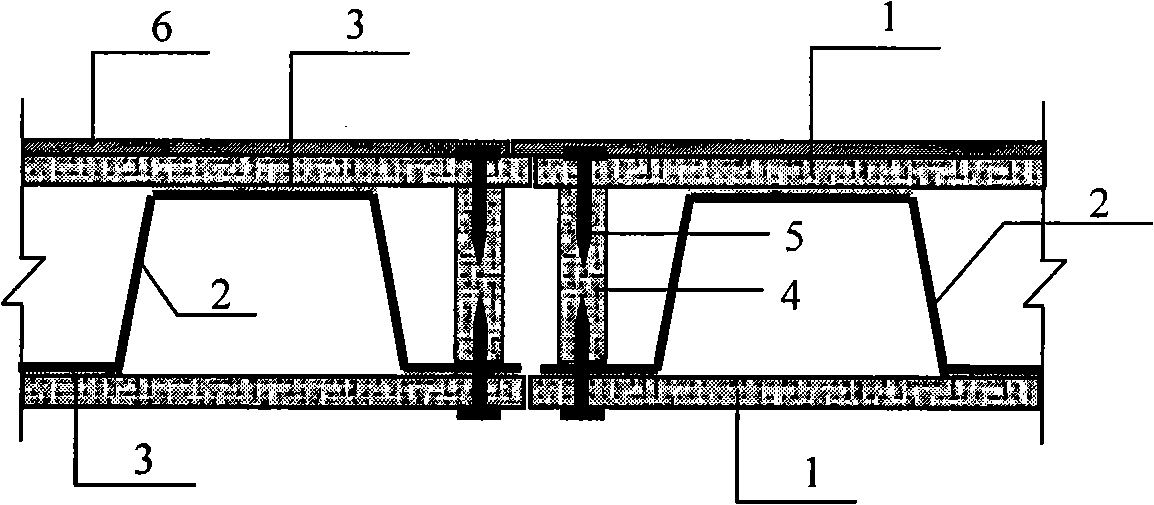

[0019] refer to figure 1 , remove the galvanized layer on the pasting surface of the profiled steel plate (2), then perform sandblasting, and finally clean it with acetone, and polish the pasting surface of the bamboo plywood (1), then also clean it with acetone. In order to improve the buckling strength of the steel plate, the plate type with oblique ribs can be selected. Spread the structural glue (3) evenly on the surface of the treated steel plate, the glue amount is 250-300g / m 2 , laminated immediately after gluing. Stand bamboo slats (4) between the upper and lower bamboo plywood around the profiled steel plate, and fix with pegs (5). Pressurization and curing are carried out afterwards, the pressurization time is 2 days, and the curing time is 7 days. According to different needs, one end of the profiled steel plate-bamboo plywood composite board can be sealed with bamboo strips, and benzene board particles can be filled from the other end to improve the thermal insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com