Patents

Literature

92results about How to "Beautiful texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin Rejuvenation Cream

ActiveUS20080153757A1Reduce rateInhibition formationCosmetic preparationsBiocideWrinkle skinSkin complexion

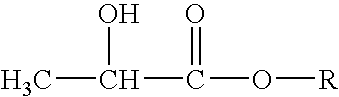

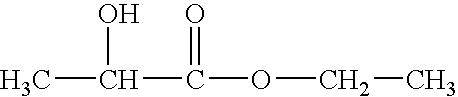

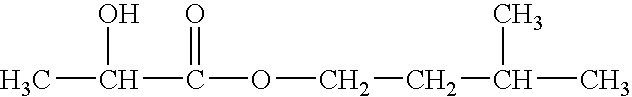

The subject invention relates to a skin cream that can be used to moisturize and rejuvenate skin that has been damaged by exposure to sunlight or which has simply been affected over the years by intrinsic aging. It can also be used to slow the rate of photo-induced aging to maintain beautiful skin tone and texture over the years. It inhibits the formation of wrinkles and in some cases reduces the depth of existing wrinkles or eliminates them entirely. In some cases, the skin cream of this invention also lightens age spots and other types of blemishes associated with aging. This invention is based upon the discovery that alkyl lactates, such as ethyl lactate, can be used to improve the penetration of active ingredients in skin care formulations deep into lower layers of the skin tissue. For instance, ethyl lactate can be included in aqueous based skin creams, such as oil in water emulsions, to deliver active ingredients deep into the skin structure. Ethyl lactate is particularly desirable for utilization in conjunction with ascorbic acid (Vitamin C) containing skin cream formulations. This is beneficial because the overall effectiveness of skin creams that utilize ascorbic acid as an active ingredient is contingent upon delivery of the ascorbic acid through the outer layers of the stratum corneum and viable epidermis and into the dermis layer of the skin structure. The present invention more specifically discloses a topical formulation comprising about 1 weight percent to about 20 weight percent ascorbic acid, about 1 weight percent to about 10 weight percent of an amino acid selected from the group consisting of phenylalanine and tyrosine, about 0.5 weight percent to about 5 weight percent of a non-toxic zinc salt, about 0.01 weight percent to about 20 weight percent of an alkyl lactate, wherein the alkyl group in the alkyl lactate contains from 2 to about 12 carbon atoms, and a pharmaceutically acceptable carrier.

Owner:LUNAM LABS

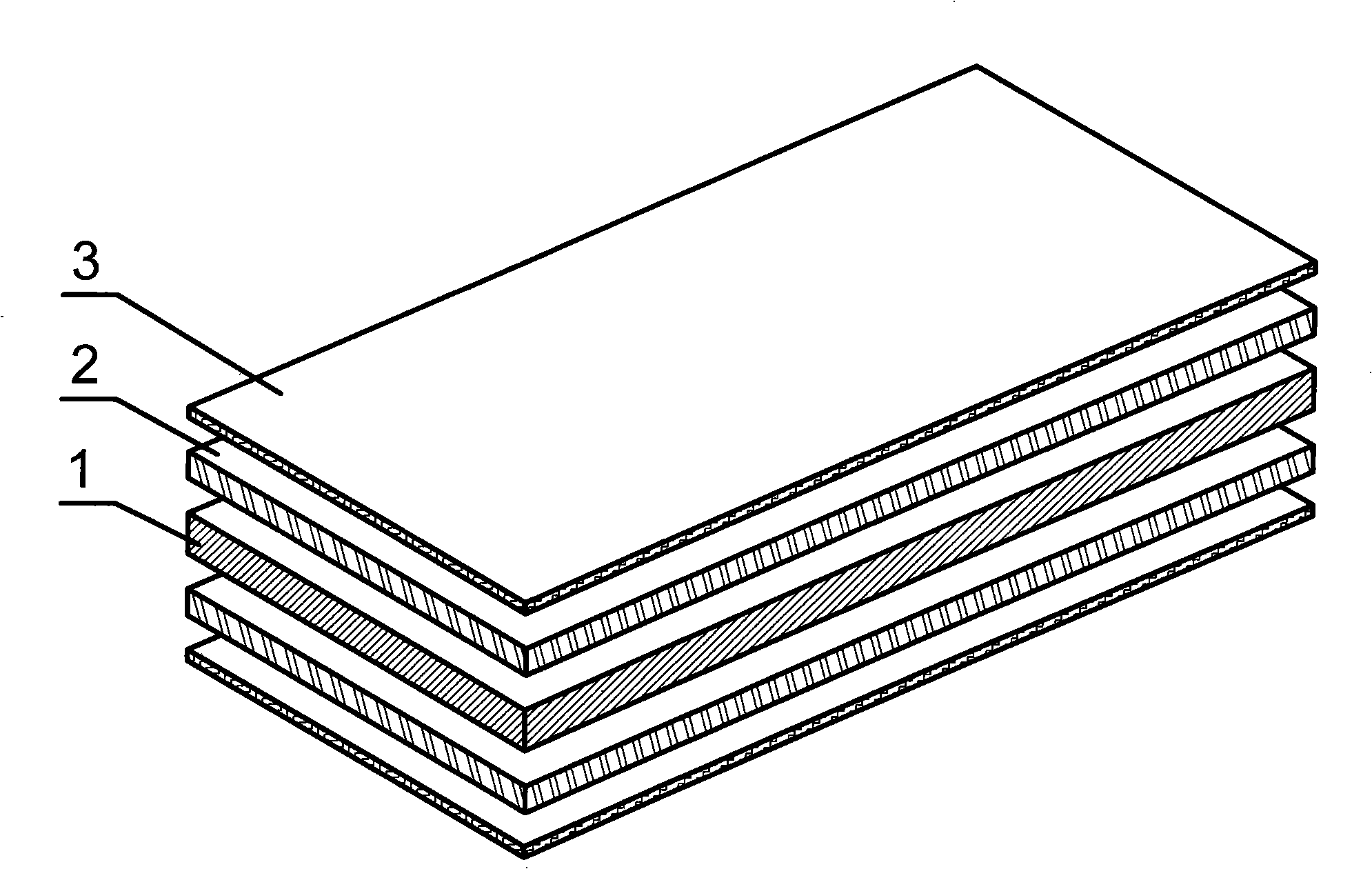

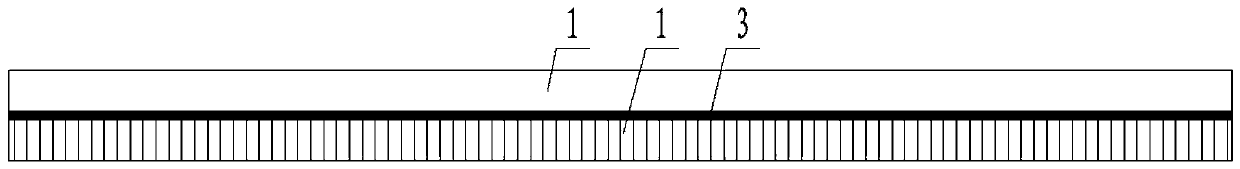

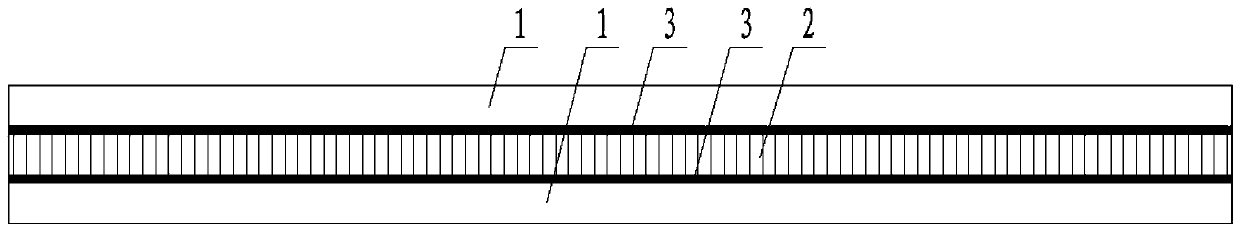

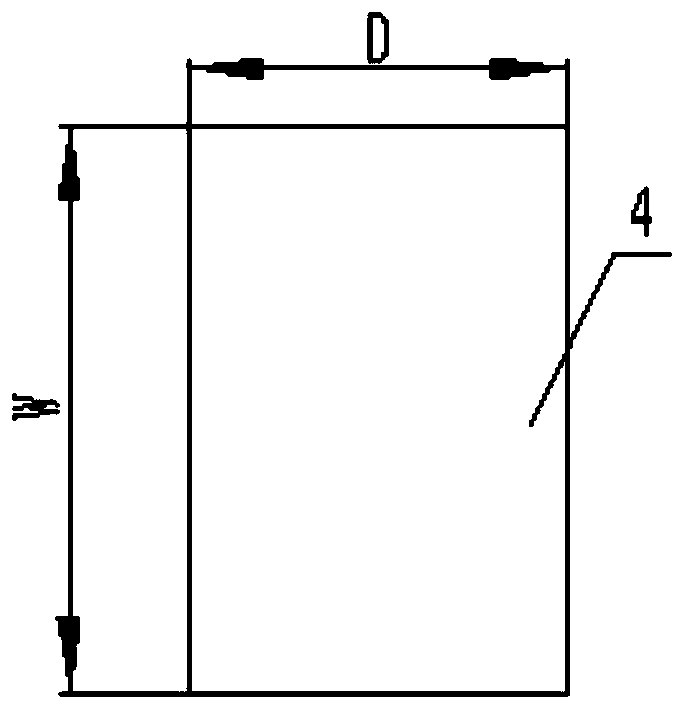

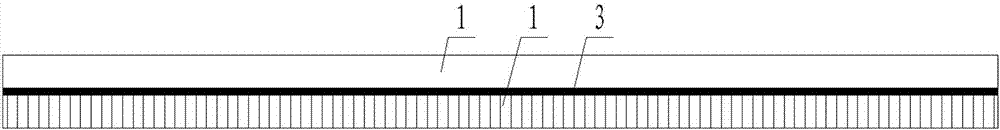

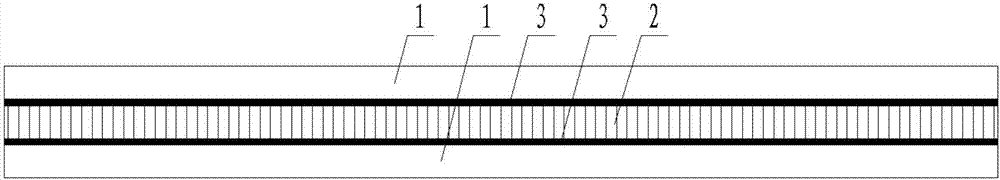

Flexible decorative facing brick and production process thereof

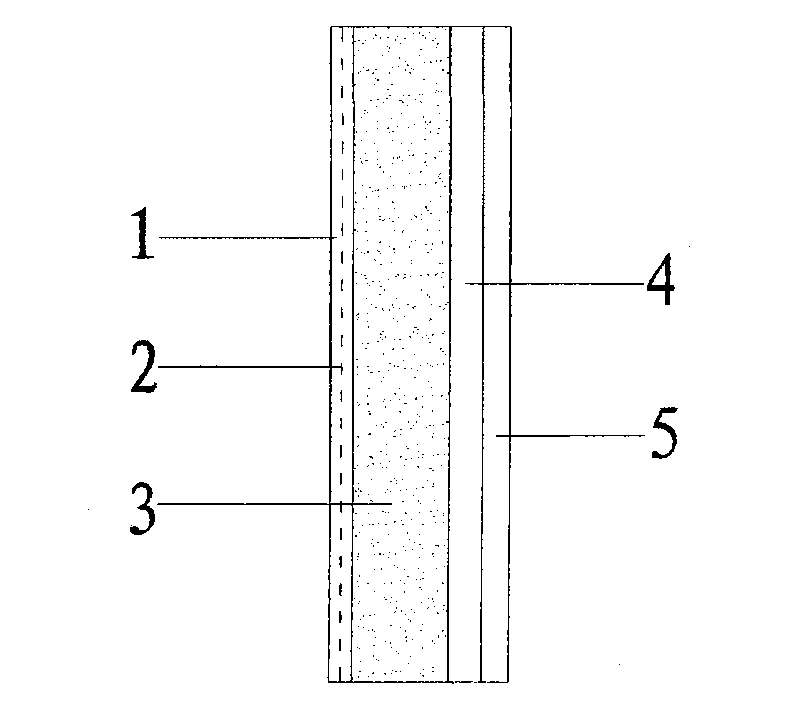

The invention provides a flexible decorative facing brick. By adopting a sheet as a basic-layer matrix body 1, polymer color-sand glue material on the matrix body as a brick body 2 and transparent paint as a brick-surface protection layer 3, the flexible decorative facing brick is produced through the processes of scraping, coating, baking, spraying and cutting. A production process comprises: manufacturing a sheet matrix body in advance for later use; washing, screening and drying natural color sand; weighing 55 to 65 percent of natural color sand and 35 to 45 percent of polymer latex in a weight ratio, putting the two into a kettle for preparing the polymer color-sand glue material, stirring uniformly and producing the polymer color-sand glue material for later use; introducing the sheet matrix body onto a gathering platform of a production line for the flexible decorative facing brick, adding the polymer color-sand glue material, performing scraping-coating, pressing, knurling and block division, sending the obtained product into the production line for dewatering and drying; spraying the transparent paint serving as the brick-surface protection layer; and cutting and packaging the obtained product according to size. The decorative facing brick manufactured by the method has the advantages of good elasticity and flexibility, and the production process is high in manufacturing efficiency and saves energy.

Owner:烟台同化防水保温工程有限公司

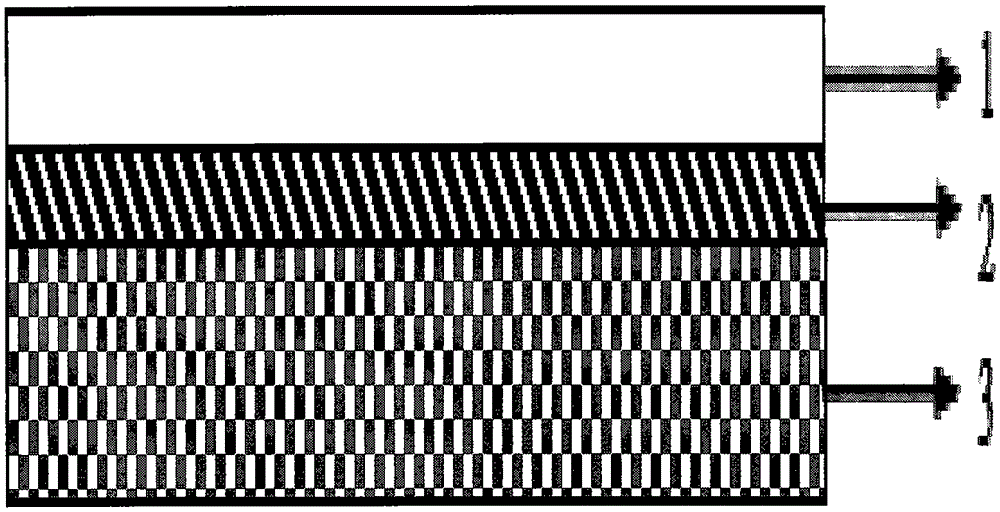

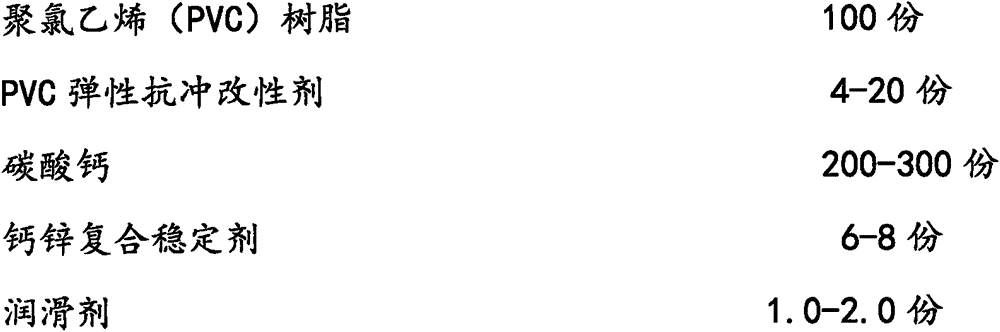

Novel PVC board and manufacturing method thereof

ActiveCN105295256ASimple processReduce production processConstruction materialCovering/liningsKnurlingPolyvinyl chloride

The invention provides a novel PVC (polyvinyl chloride) board and a manufacturing method thereof. The novel PVC board comprises a PVC transparent wearing layer, a PVC simulation pattern film layer and a PVC bottom layer from top to bottom, wherein the PVC bottom layer contains a PVC elastic anti-shock modifier; the PVC bottom layer, the PVC simulation pattern film layer and the PVC transparent wearing layer are together arranged between a first roller and a second roller, a composite layer is formed via rolling depression, and the composite layer is further treated to form the PVC board. By adopting the manufacturing method, production processes are reduced, the production efficiency is improved, the PVC board is firmer, and lines and knurling patterns are clearer and more attractive.

Owner:TAIZHOU HUALI PLASTIC

Formula of PE (Poly Ethylene) wood plastic composite material of imitation wood grain surface and manufacture process thereof

ActiveCN101962484APreserve surface protection effectImprove mechanical propertiesFiberPlastic materials

The invention discloses a formula of a PE (Poly Ethylene) wood plastic composite material for an imitating wood grain surface, which comprises a master batch I and a master batch II, wherein the master batch I is a primary color material and comprises an HDPE (High-Density Polyethylene) returned material I, recycled leftover plant fiber powder and an auxiliary material I; and the master batch II is a dispersed color material and comprises an HDPE returned material II, recycled leftover plant fiber powder and an auxiliary material II. The melt index of the master batch I is less than that of the master batch II. The invention also provides a manufacture process of the PE wood plastic composite material for the imitating wood grain surface. The natural imitating wood grain surface is directly formed by adopting the formula and the process during the production without carrying out surface machining; and the manufactured wood plastic material is not subjected to the removal of the surface skinning layer, thus the surface protection effect of a skinning layer is remained.

Owner:ZHEJIANG ZHONGYUAN FENGYE PIPES

Method for preparing plastic biologic packing material of even adulterated powder

InactiveCN101092486AIncreased maximum amount addedImprove the effect of addingSustainable biological treatmentBiological water/sewage treatmentAdhesiveInjection moulding

This invention discloses a method for preparing uniformly powder-doped plastic biofiller. The method comprises: placing plastic granular matrix in a stirring kettle, heating or spraying liquid adhesive so that the surface of plastic granular matrix has viscosity, adding powder, stirring, adhering powder to the surface of plastic granular matrix, adding coupling agent and wetting agent, placing in an injection molding machine, and injection-molding to obtain uniformly powder-doped plastic biofiller. The obtained uniformly powder-doped plastic biofiller has such advantages as high uniformity, good appearance, and high powder doping amount, high processability, no dust, no environmental pollution and no harm to operator's health.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of salix mongolica dyed hard wood

ActiveCN101623893AWide range of usesSolve the shortageDrying solid materials with heatWood treatment detailsVolumetric Mass DensityPulp and paper industry

The invention relates to a manufacturing method of salix mongolica dyed hard wood, using salix mongolica as raw material to manufacture dimensional lumber with density being 0.8-1.1 and expanding the application range thereof; the implementation process comprises the followings steps: (1) manufacturing salix mongolica strips into flat and peeled salix mongolica strands by a laminating method; (2) washing the strands with circulating water and bleaching; (3) drying the strands to water content of 20%-25%; (4) dying the strands; (5) using modified phenol gum for gumming the strands; (6) drying the strands to water content of 12%-15% after gumming; (7) using a cold pressing method to compact the compositive blank in a die with using unit pressure being 550-650kg / cm<2>; (8) causing the blank to be glued and solidified into integral salix mongolica dyed hard wood at the temperature of 140 DEG C to 145 DEG C; (9) processing and reforming the salix mongolica dyed hard wood into acceptable products with uniform specification. The invention provides a new hard wood for woodwork industry.

Owner:ERDOS CITY HUALIN SALIX TECH CO LTD

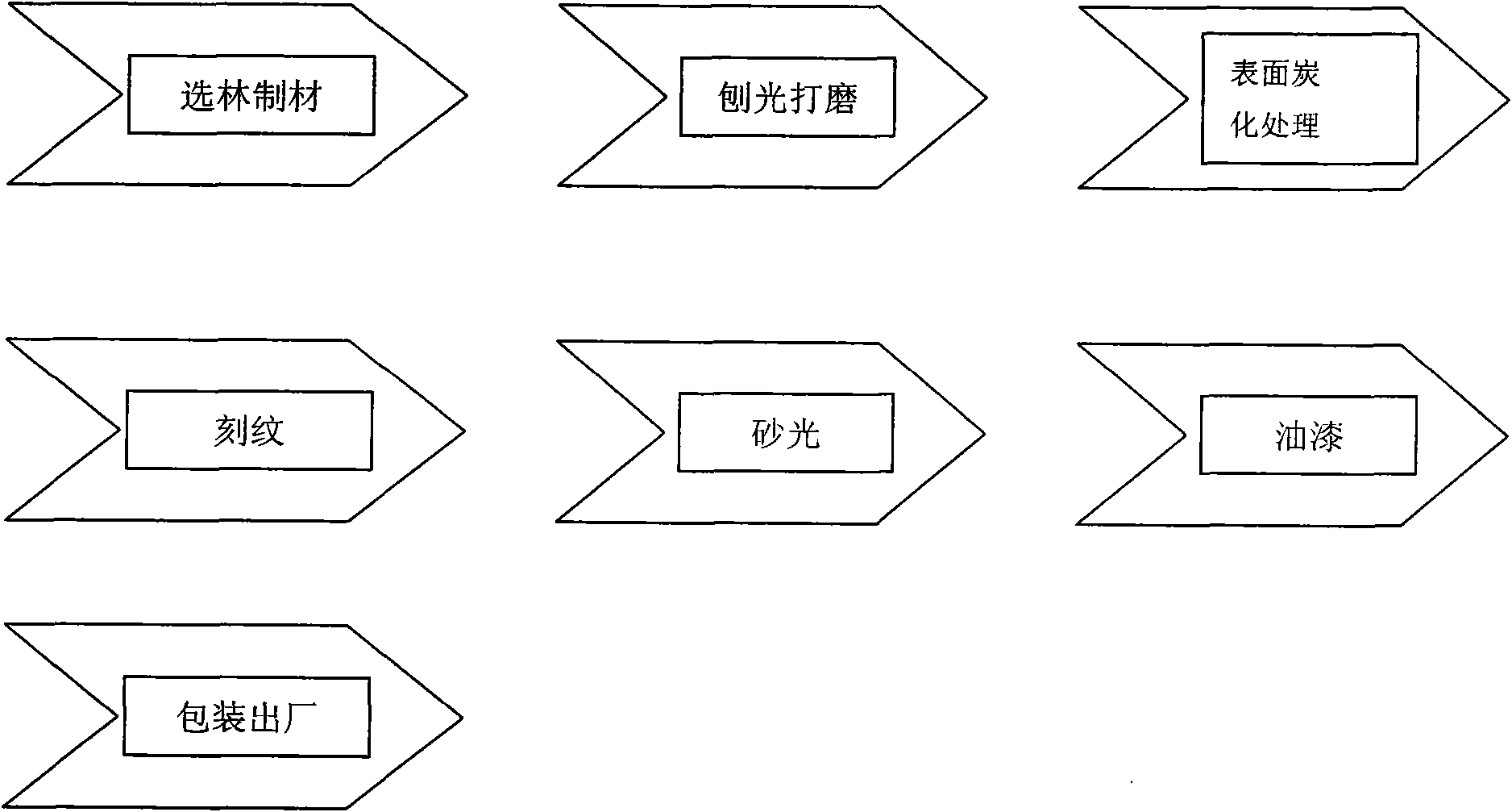

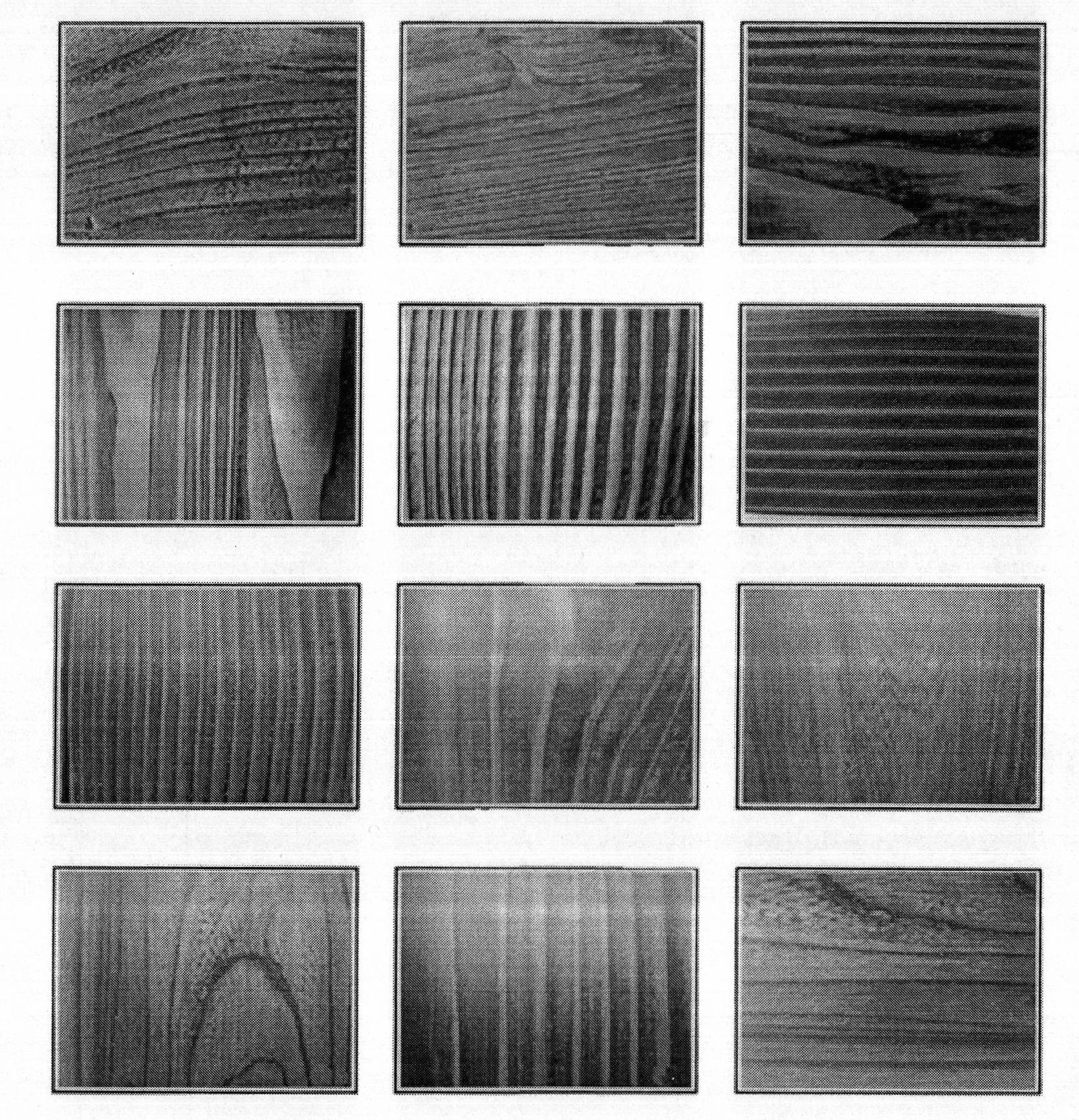

Manufacture method of solid wood and solid wood composite baking floor

The invention discloses a manufacture method of a solid wood and a solid wood composite baking floor, aiming at providing a manufacture method for utilizing solid wood floor blank with the levels of B, C and D or utilizing the blank of the solid wood composite floor to manufacture the solid wood and solid wood composite baking floor with low cost, beautiful texture and good decorative effect. The manufacturing method comprises the following steps: arranging tongue-and-groove boards on the floor blank, baking the surface of porous plates of the floor, and carrying out surface treatment and surface coating treatment. The invention uses carbonized effect generated by flame baking so as to mask the defects of the surfaces of inferior materials, and is beneficial to different sparse and compact materials which are natural to the wood after fiber drawing treatment, thus presenting rugged wood texture and leading the whole floor to be very beautiful; the decorative effect is distinctive and very novel, the applications are extreme wide, various quality indexes can reach or exceed the indexes of existing similar products, so that the value of the inferior wood with the levels of B, C and D is greatly improved, therefore, the manufacturing method has great economical and social benefits.

Owner:张高荣

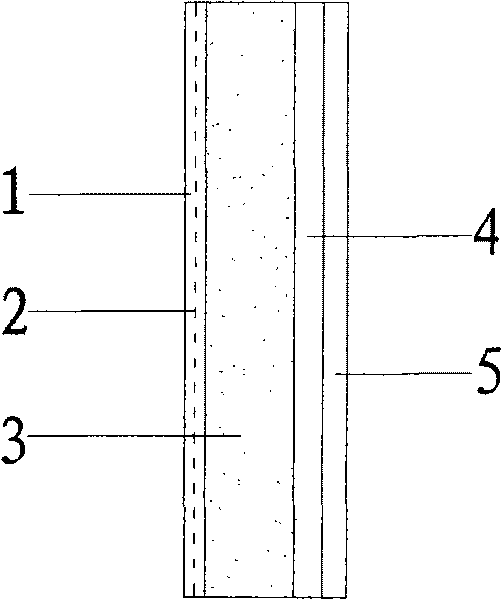

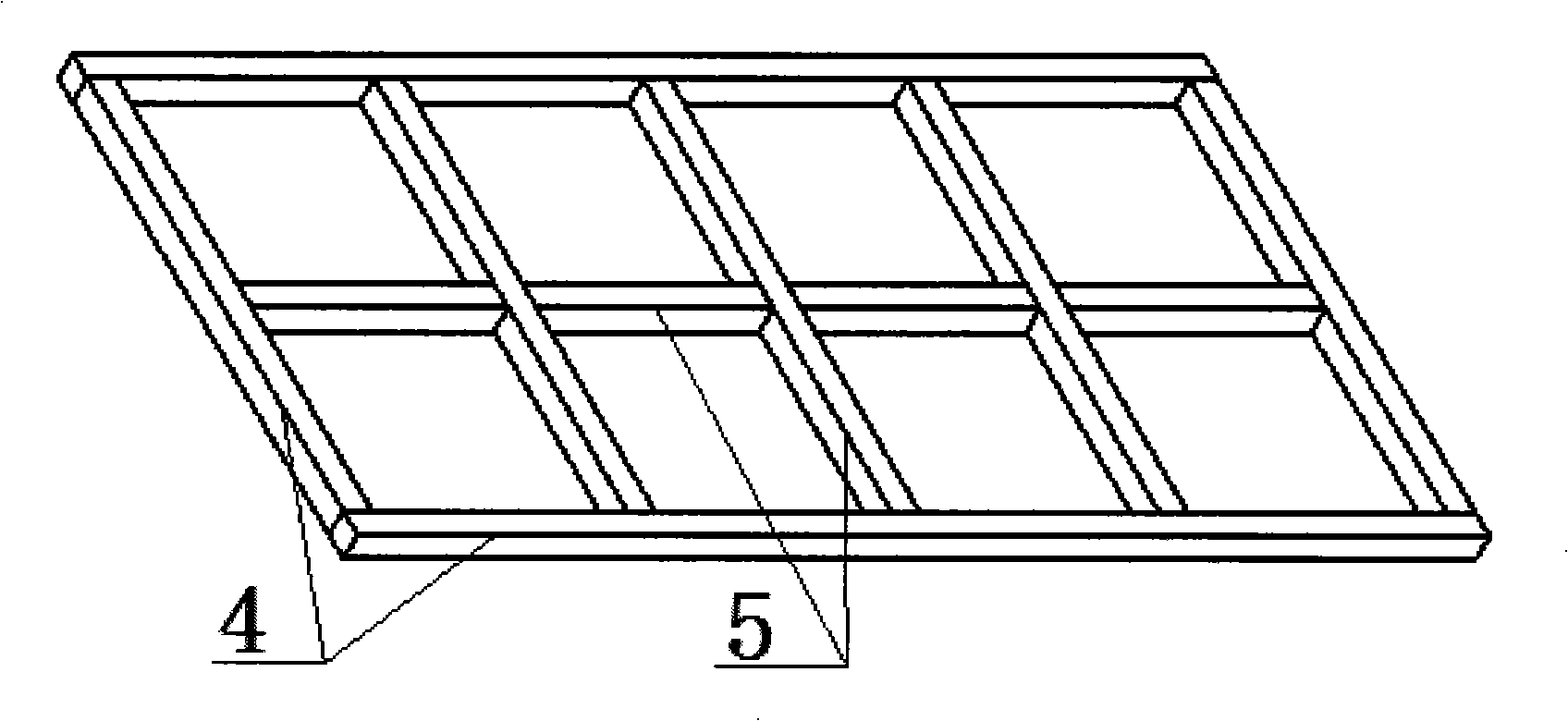

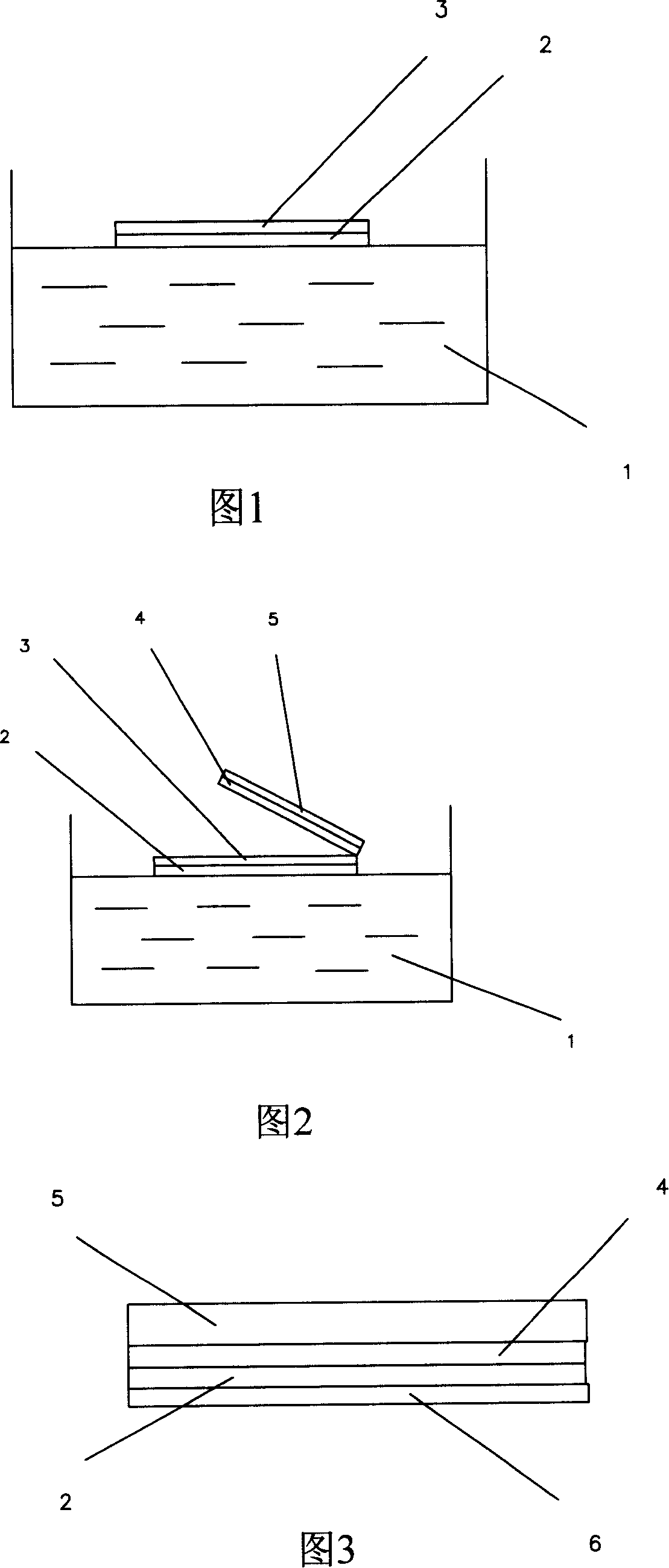

Solid wooden composite door and method for making the same

InactiveCN101343975AVarious shapesReduce consumptionDecorative surface effectsLayered productsNatural resourceSolid wood

The invention discloses a solid wood composite door and a manufacturing method thereof. The solid wood composite door comprises a door framework (1), mould boards (2) symmetrically arranged on the bottom surface and the surface of the door framework (1), and decorative boards (3) arranged on the mould boards (2); compared with the traditional solid wood door, the invention has the advantages that the consumption of wood is reduced, precious natural resources are saved, the manufacture cost is reduced, the phenomenon of contortion or deformation or rip is not easy to occur during the use of the solid wood composite door, the texture of the solid wood composite door is natural and artistic, the hardness degree of the painting surface is high, the wear resistance and the anti-yellowing property are good, the adhesive force of oil paint is strong, the transparency of the painting surface is high, and the environmental protection performance is good.

Owner:湖州世友门业有限公司

Microlite PVC foam floor

The invention relates to a microlite PVC (Poly Vinyl Chloride) foam floor and belongs to the technical field of chemical building materials. The microlite PVC foam floor is prepared from the following raw materials in parts by weight: 100-150 parts of PVC, 200-300 parts of microlite powder, 0.5-0.7 part of stabilizer, 0.6-1.0 part of foaming agent, 0.2-0.3 part of plasticizer, 0.5-0.7 part of lubricant and 0.5-0.7 part of flame retardant. The microlite PVC foam floor is extrusion-molded by using a plastic extruding machine; the obtained microlite PVC foam floor is low in density, wear-resistant, impact-resistant, high in elastic strength, natural in texture, and beautiful and elegant; the microlite PVC foam floor is also environment-friendly, non-toxic, tasteless and formaldehyde-free; the microlite PVC foam floor is further waterproof, damp-proof, skid-proof, wear-resistant, corrosion-resistant, fire-resistant, and recyclable.

Owner:HENAN LEISEN IND

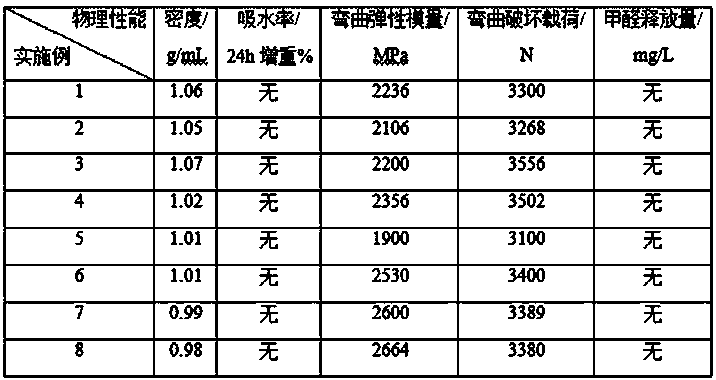

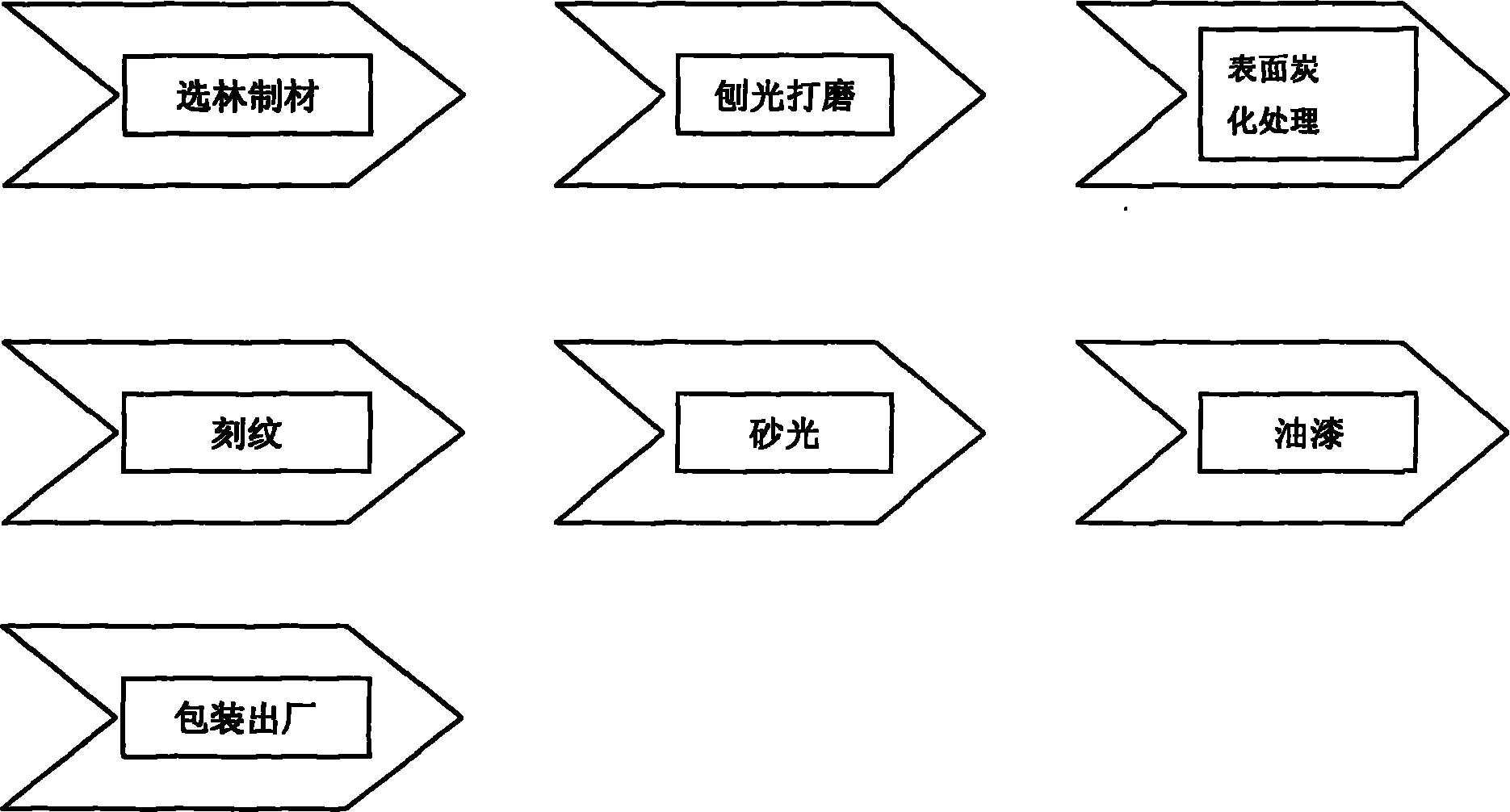

Production process of antique engraving wood

ActiveCN101767510AImprove natureGood dimensional stabilitySpecial ornamental structuresFiberStrong acids

The invention relates to a production process of an antique engraving wood, which is characterized by comprising the following steps of: carrying out surface carbonizing treatment of on wood by using flame wherein the surface of the wood is not on open fire; and grinding the wood which is subjected to the surface carbonizing treatment. The process carries out the surface carbonizing treatment to the same extent by the property difference of early wood and late wood which are formed in the process of wood growth so that wood fibers of the early wood and the late wood generate destructive effects to the different extent, highlight texture characteristics of the wood and endow classic texture quality characteristics to the wood, and moreover the wood has higher dimension stability, corrosionresistant performance, weathering performance and anti-pollution performance without destroying the mechanical performance of the wood. Strong acid solutions are not required in the process of preparation, requirements for equipment and operators are low, and products can be used for decorative boards, furniture, bearing beams and other landscape engineering and are suitable for large-scale mass production.

Owner:OUYANG FURUI JIANGSU WOOD IND CO LTD

High-strength automobile hub and preparation method thereof

InactiveCN108277395AHigh strengthImprove corrosion resistanceFoundry mouldsFoundry coresManganeseAlloy

The invention discloses a high-strength automobile hub and a preparation method thereof. The automobile hub is made of an alloy. The alloy comprises, by mass percent, 3%-12% of silicon, 0.1%-5% of carbon, 0.01%-3% of copper, 1%-10% of manganese, 1.2% or less of calcium, 0.1%-8% of chrome, 3.5% or less of iron, 5%-18% of zinc oxide, 0.001%-0.5% of phosphorus, 0.01%-1% of nickel, 0.001%-0.3% of molybdenum, 0.005%-0.8% of tungsten, 0.0001%-0.5% of lead, 0.001%-0.3% of strontium, 1%-15% of magnesium borate, 0.2%-10% of potassium titanate and the balance aluminum. During smelting, the components are taken and, by weight percent, put into a smelting furnace to be subjected to smelting and deslagging, and then by means of refining, standing, pouring, pressurizing, cooling and demolding, the automobile hub is obtained. According to the high-strength automobile hub and the preparation method thereof, the components are scientific and reasonable, the formula is simple, the preparation process iseasy to implement, and the obtained hub is high in strength, resistant to corrosion, impact and abrasion, good in heat resistance, long in service life and good in casting performance. The preparation process is simple and easy to operate, the energy consumption is low, the production efficiency is high, and the high-strength automobile hub is suitable for being produced on a large scale.

Owner:TIANJIN XUANZE METAL PROD

Method for manufacturing wood grain and marble glass

The invention discloses a manufacturing method for glass with wood grain or marble grain and is divided into the steps, a. undercoating, wherein, the glass is coated with an amount of polishing oil specially used by the transparent class to increase adhesive of a transfer printing layer to the glass, after coating, the glass is dried in a drier for 20-50 minutes in a temperature ranging from 70-80 DEG C and then cooled to ambient temperature; b. activating transfer printing film, wherein, water-carrying transfer printing film is laid on the water surface in a transfer printing water tank with an image layer upside and the surface of the image is evenly coated with activator; c. water-carrying transfer printing; d. arranging; e. drying; f. printing colored paint, wherein, color paint is coated on the transfer printing surface and then is oven dried or dried naturally and last sides and uncoated surface of the glass are cleaned. The method for manufacturing glass with wood grain and marble grain has low cost and simple technique.

Owner:刘松坡

Artificial wood finishing container floor and manufacturing process thereof

InactiveCN101284593ASolve material defectsBeautiful textureBio-packagingLarge containersWood finishingAdhesive

The invention discloses a container floor with artificial wood facing. The container floor comprises a surface layer and a middle layer; wherein, the surface layer is covered on the middle layer, the surface layer is made of artificial wood, the middle layer is pressed by a drying wood veneer or a bamboo veneer and at least one face of the middle layer is attached with an artificial wood layer. The container floor with artificial wood facing of the invention has the production process that: firstly, the drying wood veneer or the bamboo veneer is carried out assembly, pre-pressing and hot pressing by using phenolic resin as adhesive, the thermally pressed product is used as the middle layer after sanded through fixed thickness; secondly, the artificial wood is pressed and attached on single surface or double surfaces of the middle layer to be as the surface layer of the container floor; sanding, trimming and edge milling are carried out based on requirements after got pressing, thus obtaining the finished product of the container floor. The container floor with artificial wood facing of the invention has another production process that the artificial wood is taken as a face layer and a bottom layer of the container floor, the drying wood veneer or the bamboo veneer is taken as the middle layer, assembly, pre-pressing and hot pressing is carried out by using phenolic resin as the adhesive, the thermally pressed product is sanded through fixed thickness, trimmed and edge-milled, thus obtaining the finished product of the container floor.

Owner:MAOYOU WOOD

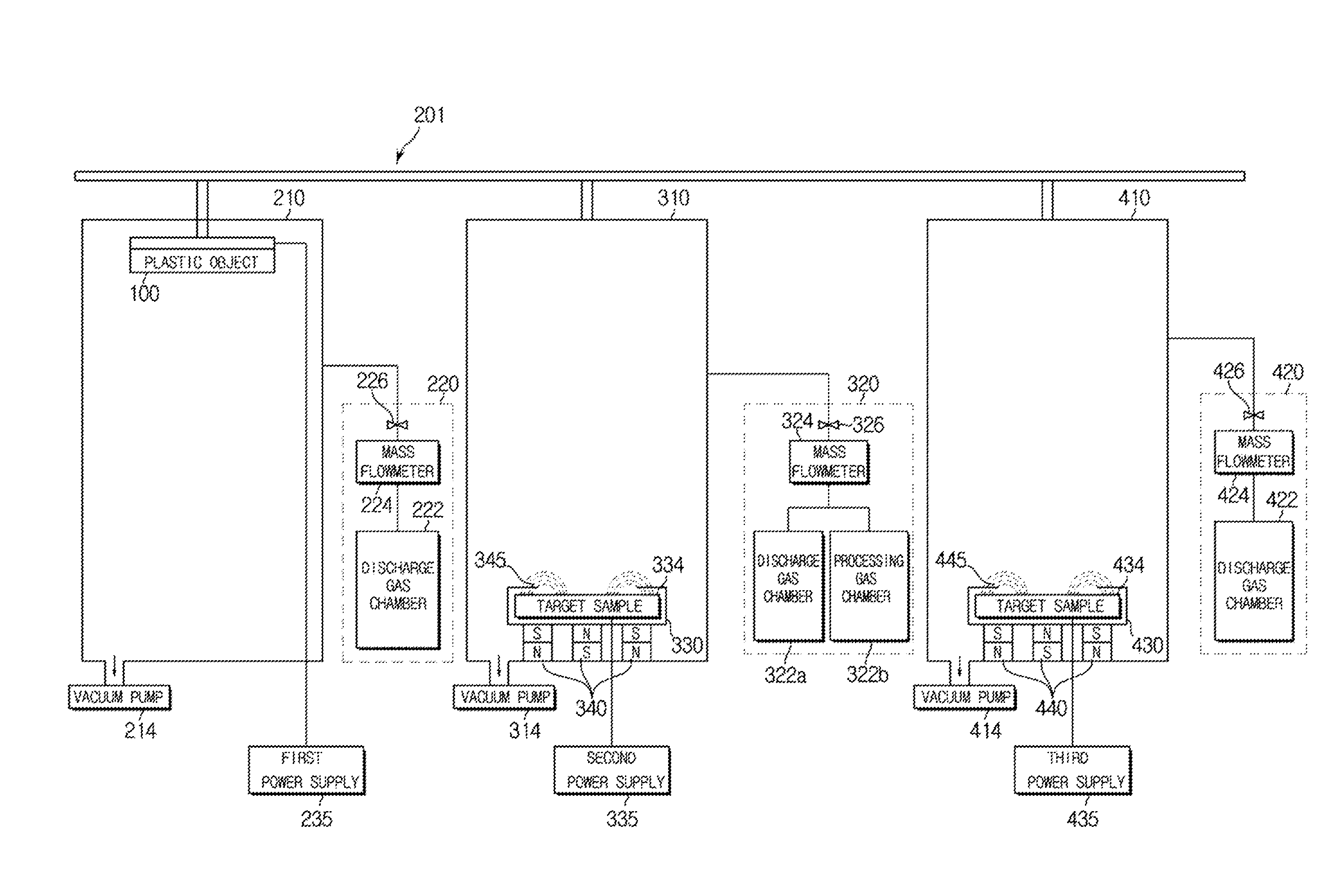

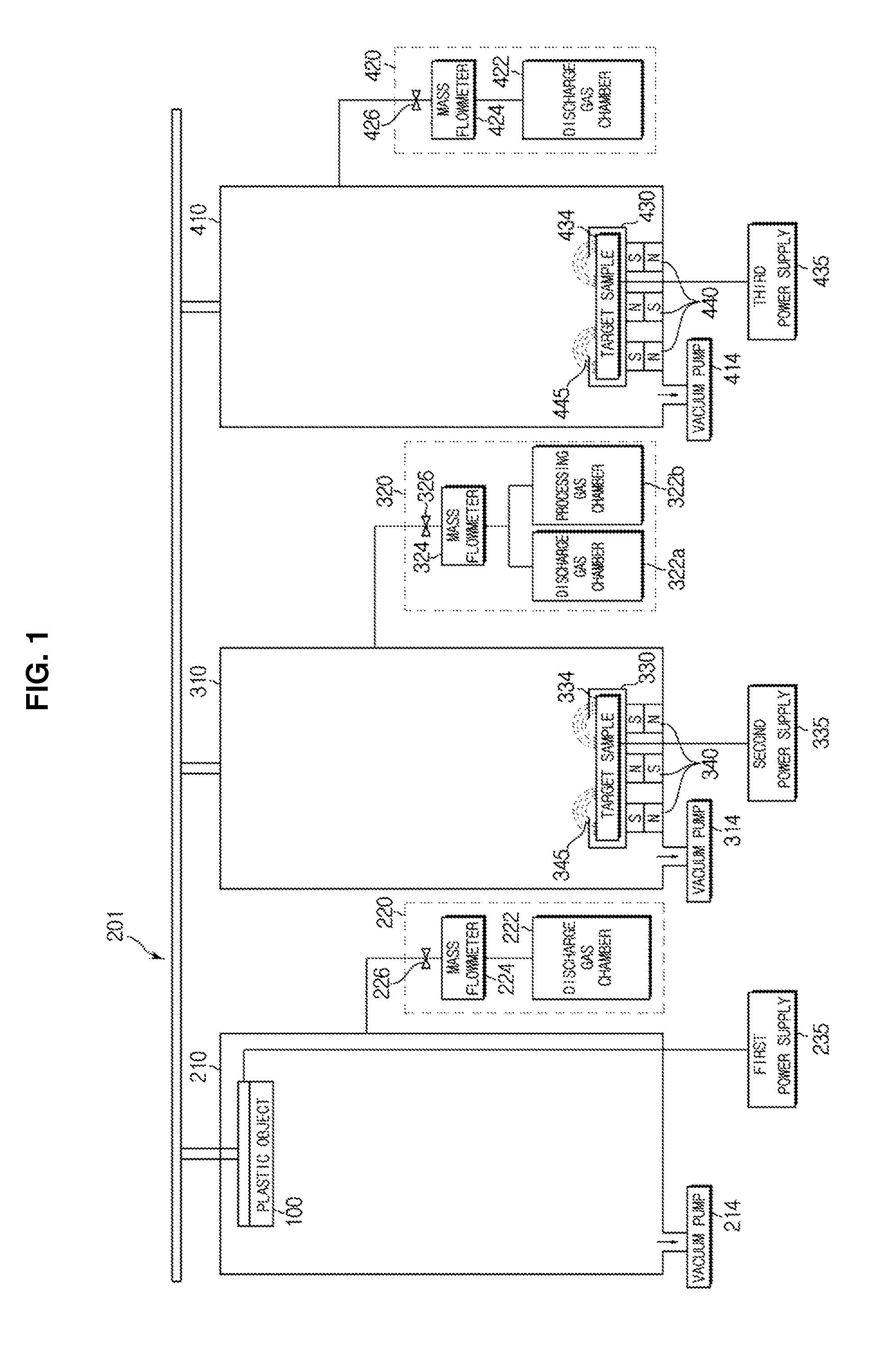

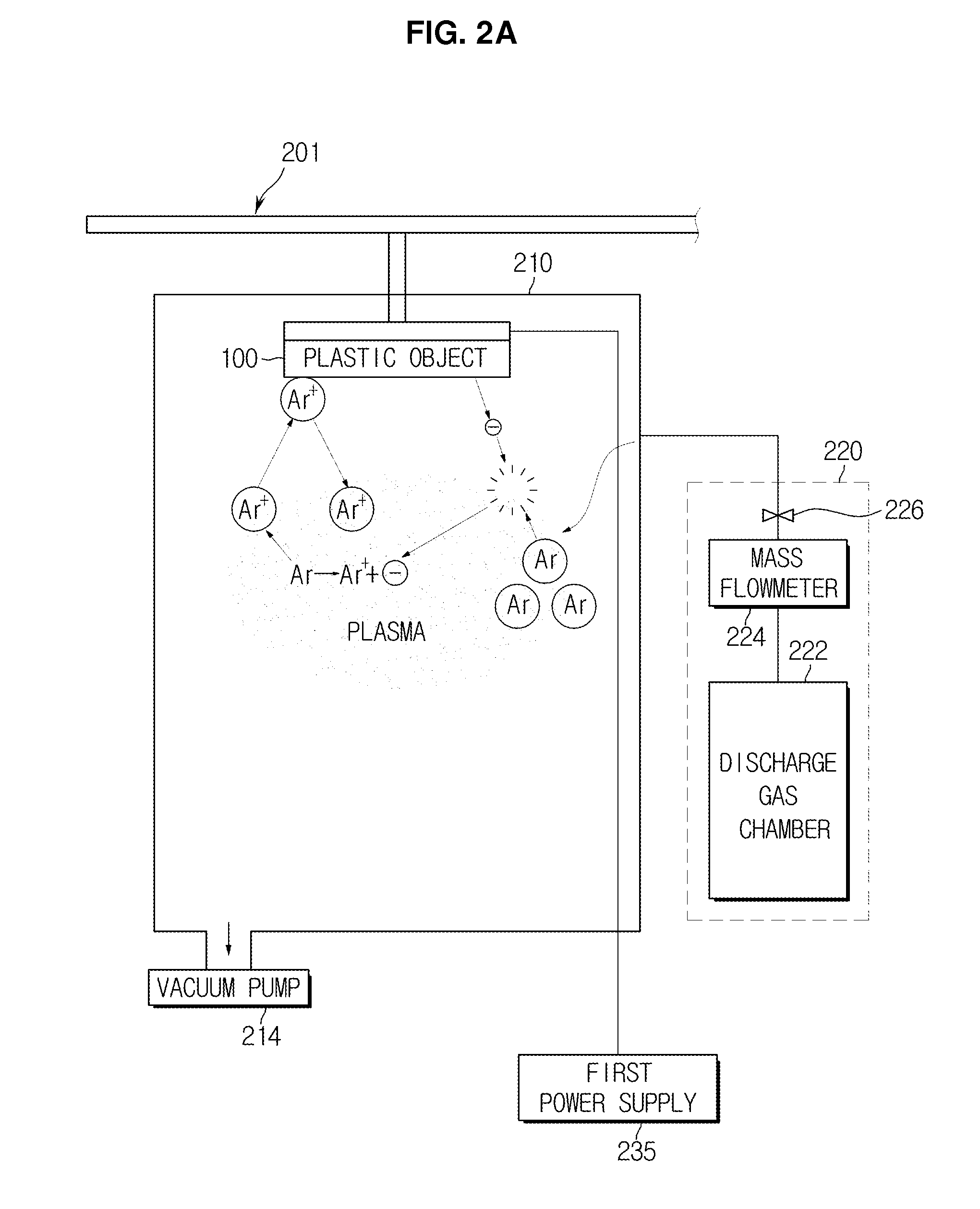

Method of manufacturing multi-layer thin film, member including the same and electronic product including the same

InactiveUS20140355183A1High surface hardnessBeautiful textureSynthetic resin layered productsVacuum evaporation coatingHardnessOptoelectronics

A method of manufacturing a multi-layer thin film is provided. The method includes modifying a surface of a plastic object by plasma treatment, depositing at least one hardness-enhancing layer on the plastic object, and depositing a color layer on the hardness-enhancing layer. The method may further include depositing a protective layer on the color layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Production method for whole bamboo or bamboo-wood composite veneer and floor laminated board

InactiveCN105058540ABeautiful textureRaise the gradeFlat articlesDomestic articlesBamboo culmOriented strand board

The invention belongs to the field of manufacturing processes of composite artificial boards, and particularly relates to a production method for a whole bamboo or bamboo-wood composite veneer and a floor laminated board. The composite veneer and the floor laminated board comprise full bamboo, large bamboo sheets used for bamboo-wood composition and large wood sheets, and the large wood sheets are doped in the large bamboo sheets, drying is carried out after glue is applied, and a novel whole bamboo or bamboo-wood composite oriented strand board is pressed; then bonding and transverse saw changing are carried out to form the whole bamboo or bamboo-wood composite veneer and the floor laminated board. The whole bamboo or bamboo-wood composite veneer and the floor laminated board are not a simple LV1 board, and the LV1 board is changed into a novel product in a sawn manner in the longitudinal direction; the appearance is attractive in line, and the grade is higher; the adaptability to different parts made of bamboo species, wood, bamboo culms and wood culms is higher, the quality is stable, the strength is even, and the material variability is small; and the composite veneer and the floor laminated board are most ideal structure materials for replacing raw wood and bamboos, and have the beneficial effects of being high in raw material using rate and flat in board face.

Owner:云南永利发林业有限公司

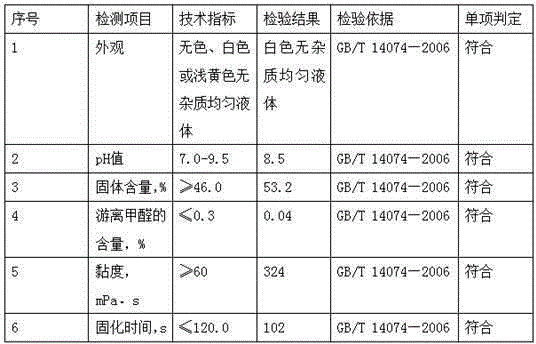

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

Unglazed ceramic product with natural cracks and production process of unglazed ceramic product

The invention relates to the technical field of ceramic manufacturing, in particular to an unglazed ceramic product with natural cracks and a production process of the unglazed ceramic product. A ceramic body of the unglazed ceramic product with the natural cracks comprises the following raw materials: red earth, feldspar, black clay, quartz, spodumene, kaolin and ferric oxide. According to the unglazed ceramic product with the natural cracks, glaze water decoration is absent on the surface and the rough body is exposed, natural cracking is formed on the surface of the ceramic body, crack lines go deeply into the ceramic body, a corrosion-like effect is realized, and the texture effect is attractive; during production of the unglazed ceramic product with the natural cracks, natural cracking is caused on the surface of the ceramic body due to different shrinkage inside and outside, the cracks do not penetrate the ceramic body, and normal use of the ceramic product is not affected. One brand-new ceramic decoration method is provided by means of the unglazed ceramic product with the natural cracks and has positive meaning and positive economic benefit for pushing development of the ceramic products.

Owner:福建省德化县恒昇陶瓷有限公司

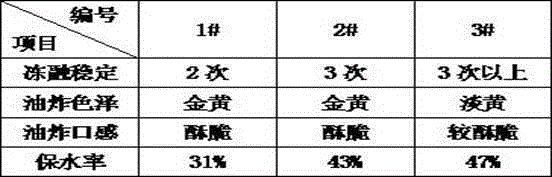

Deep frying coating powder and making process thereof

InactiveCN105285943AImprove stabilityHigh transparencyFood preservationFood ingredient as mouthfeel improving agentFreeze thawingAcetic anhydride

The invention discloses deep frying coating powder, comprising the following components according to the following proportion: cassava starch acetate: corn starch acetate=2:8-8:2. The invention also discloses a making process of the deep frying coating powder. The making process comprises the following steps: taking cassava native starch and corn native starch as raw materials, subjecting the raw materials to activating treatment, adding acetic anhydride, and subjecting the obtained product to washing, dehydration, drying, grinding and screening to obtain the cassava starch acetate and the corn starch acetate. The mixture of the cassava starch acetate and the corn starch acetate is the deep frying coating powder. With the adoption of the deep frying coating powder disclosed in the invention, the water-retaining property of a product is greatly improved, the freeze-thaw stability of the product is improved, and the shelf-life is prolonged. The layering of the product is enhanced, and the taste of the product is enriched. A film forming property is improved, and juice of the product can not easily loss during deep frying.

Owner:FUJIAN BESTSTARCH CREATMATERIAL CO LTD

Ecological type paulownia wood wall plate manufacturing method

InactiveCN104608212AReduce pollutionAbundant raw materialsLaminationLamination apparatusPaulowniaDecomposition

The invention relates to an ecological type paulownia wood wall plate manufacturing method. The method effectively solves the problems that paulownia logging residues and processing residues generated through paulownia wood processing enterprises cannot be machined and utilized effectively due to small specifications and thus are wasted. According to the method, the wall plate is obtained with the paulownia wood of the small specification serving as core materials and high-quality paulownia wood veneer serving as veneering, and antitarnish processing and softening processing are conducted on the selected high-quality paulownia wood; the high-quality paulownia wood is sliced to manufacture the veneer; the paulownia wood veneer is dried; wood making and drying are conducted on the undersized logs of the paulownia logging residues; normalization wood making is conducted, next finger joint integration plate making is conducted, and thickness decomposition, sanding, gluing, veneering and hot pressing are conducted on paulownia wood finger joint plates; sanding is conducted on the veneering plates, and step-shaped tongue-and-grooves are machined on the two sides of the veneering plates in the width direction; transparent coating is conducted. According to the method, raw materials are rich, the machining method is simple, the method is easy to operate, low in cost, good in product quality, free of cracking, free of damage caused by worms, capable of insulating sound, resistant to rot, straight in texture and attractive, and resources are saved.

Method for preparing artificial quartz stones by using kaolin desliming tailings

InactiveCN101961883AHigh strengthImprove corrosion resistanceCeramic shaping apparatusKaolin clayEngineering

The invention discloses a method for preparing artificial quartz stones by using kaolin desliming tailings, which relates to building decoration materials and comprises the following steps of: stirring unsaturated resin and colorants, adding the kaolin desliming tailings, natural river sand and silicon dioxide powder, performing stirring, adding an accelerator, a coupling agent and a curing agent, performing stirring and injecting the mixture into a mould; feeding the mould into a vacuum box for vacuumizing, pressing and forming the mixture and performing curing and heating; and performing cooling de-molding to remove the mould, performing polishing and finally cutting the molded mixture into standard artificial quartz stone slabs, wherein artificial quartz stones are made from the following raw materials in percentage by mass: 12 to 65 percent of natural river sand of 10 to 120 meshes, 15 to 35 percent of natural river sand of larger than 120 to 1,500 meshes, 5 to 15 percent of silicon dioxide powder, 0.1 to 19 percent of unsaturated resin, 0.1 to 5 percent of accelerator, 0.1 to 3 percent of coupling agent, 0.1 to 5 percent of curing agent and 0 to 5 percent of colorant. The method reduces initial investment, and is convenient to operate, easy to implement, simple and reasonable; and the products have the natural veins, stripes and rich colors of marbles, also have the hardness of the quartz stones and are suitable for industrialization.

Owner:XIAMEN UNIV

Antibacterial flame-retardant textile producing method

InactiveCN105369602AGood antibacterial effectImprove waterproof performanceVegetal fibresSurface patternWax

The invention discloses an antibacterial flame-retardant textile producing method. The antibacterial flame-retardant textile producing method is characterized by specifically including the following steps that (1) nano silver sol is prepared; (2) a waterproof flame retardant is prepared; (3) a sol impregnation liquid is prepared; (4) textile processing is performed. Adopted Shengma fibers have good impregnation effect, the photocatalytic property and the bacteriostasis of textiles are improved, the processed textiles have the best waterproof effect, durability and flame retardance, and the wax ingredient in the textiles enable obtained fabrics to be fine, natural and attractive in surface pattern.

Owner:QINGDAO XINRUNTU NURSERY STOCK SPECIALIZED COOP

Wood composite flooring needle, hardwood tree rift sawing plaga surfacing material decorative sheet and production method

The invention provides a wood composite floor coniferous and broadleaf tree walk cutting lining decorative sheet and producing method. The decorative sheet is composed of peeler log veneer as core material and scientific wood sliced diameter-cut veneer which is sticked to the surface of the core material. The said method comprises a process of producing the scientific wood and a process of compression cementing using scientific wood sliced diameter-cut veneer as facing. On compressing, the method uses plastic film isolation and multilayer overlap compression. The batch products are obtained by applying pressure for one time. The invention can obtain true wood composite floor coniferous and broadleaf tree walk cutting lining decorative sheet with uniform and beautiful texture. The log of common diameter class is used to extend the range of sorting. The sliced scientific wood veneer is used, so that the quality raw material utilization factor is high and increased by tens times than using direct saw cutting plate. The said invention fundamentally solves the economical efficiency of the said products and makes the products suitable for the social consumption level.

Owner:马新闻

Producing method of impact resistant solid wood composite floor

InactiveCN109623992ABeautiful textureFull colorCovering/liningsPolyureas/polyurethane adhesivesSolid woodPolyvinyl acetate

The invention provides a producing method of an impact resistant solid wood composite floor. The producing method comprises the steps of 1, dyeing, wherein the end portions of veneers are selectivelysealed by adopting two-component polyurethane rubber, wood pipe holes are partly closed, and curing is conducted for 4-6 h at normal temperature; 2, steeping, wherein the veneers are placed in a vacuum steeping tank containing steeping liquid to be subjected to pressurized steeping, the preparing method of the steeping liquid comprises the steps that 90-150 parts by mass of polyurethane polyamineepichlorohydrin, 1-3 parts by mass of a penetrating agent, 1-3 parts by mass of an additive are mixed evenly, and the pH is adjusted to 7.5; 3, curing; 4, gluing, wherein a two-component polyurethaneresin adhesive is adopted to glue the veneers, the adhesive is prepared by adopting 100 parts by mass of polyisocyanates and 10-70 parts by mass of polyvinyl acetate emulsion as double components, adopting 1-10 parts by mass of rosin as an adhesion improving agent, and adding 1-10 parts by mass of phthalic acid ester as a defoaming agent; 5, painting.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for manufacturing Chengni inkstone

InactiveCN103864400ATake advantage ofSolid textureInk standsClaywaresEngineeringManufacturing engineering

The invention discloses a method for manufacturing Chengni inkstone. The method comprises the following twenty-two process steps: selecting a stone, breaking the stone, ball-milling, cleaning, drying in the shade, corroding, forming, pressurizing, designing, shoveling the blank, carving, finely grinding, drying, roasting, finishing, drying finely, cooking in rice vinegar, fine and accurate grinding in water, maintaining, polishing, checking and packaging. The inkstone manufactured by the method is excellent in service performance and ink rising is easy.

Owner:惠东存

Permeable decorative strip and method for manufacturing same

The invention relates to the technical field of indoor decorative materials, in particular to a permeable decorative bar and a manufacturing method thereof. In the invention, a novel rubber compound prescription is used, color master batches are added in the rubber compound, the materials in an extruder are heated and pressurized, so that the decorative bar is shaped continuously by an extrusion mould in the flow state, and finally wood texture integrated with a substrate is formed on the penetrating decorative bar; the wood texture not only is low in the cost, but also has good decorative effect, in particular, the decorative patterns are characterized in wear resistance during processing and use.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

A green bamboo-wood composite board and its processing technology

The invention discloses a greenness-reserved bamboo-wood composite board. The greenness-reserved bamboo-wood composite board is of a single-face structure or a double-face structure. Each single-face structure is formed by bonding a greenness-reserved bamboo board and a refined wood board with glue. Each double-face structure is formed by bonding two greenness-reserved bamboo boards and a refined wood board with glue, wherein the refined wood board is arranged between the two greenness-reserved bamboo boards. The outer surface of each greenness-reserved bamboo board is a bamboo greenness face, and a layer of natural bamboo greenness is maintained on each bamboo greenness face. The greenness-reserved bamboo-wood composite board maintains original high hardness, high strength, good wear resistance and good corrosion resistance of the greenness-reserved bamboo board(s), and bamboo greenness of the greenness-reserved bamboo board(s) is reserved. The invention further discloses a processing technology of the greenness-reserved bamboo-wood composite board. The processing technology comprises the steps of selecting materials, conducting sawing-off, removing outer joints, removing inner joints, forming openings, conducting softening, conducting flattening, removing yellowness with the thickness fixed, conducting cooling for shaping, conducting drying at the low temperature, bonding the greenness-reserved bamboo board(s) with the refined wood board to form a greenness-reserved bamboo-wood composite board unit, conducting splicing, and bonding the greenness-reserved bamboo-wood composite board units to form the greenness-reserved bamboo-wood composite board. In the processing technological process, moso bamboo is softened, and no pollution is generated; in the drying process, the greenness-reserved bamboo boards are not deformed or cracked; and each bamboo greenness face maintains high hardness, flatness and smoothness.

Owner:浙江德长竹木有限公司

Greenness-reserved bamboo-wood composite board and processing technology thereof

The invention discloses a greenness-reserved bamboo-wood composite board. The greenness-reserved bamboo-wood composite board is of a single-face structure or a double-face structure. Each single-face structure is formed by bonding a greenness-reserved bamboo board and a refined wood board with glue. Each double-face structure is formed by bonding two greenness-reserved bamboo boards and a refined wood board with glue, wherein the refined wood board is arranged between the two greenness-reserved bamboo boards. The outer surface of each greenness-reserved bamboo board is a bamboo greenness face, and a layer of natural bamboo greenness is maintained on each bamboo greenness face. The greenness-reserved bamboo-wood composite board maintains original high hardness, high strength, good wear resistance and good corrosion resistance of the greenness-reserved bamboo board(s), and bamboo greenness of the greenness-reserved bamboo board(s) is reserved. The invention further discloses a processing technology of the greenness-reserved bamboo-wood composite board. The processing technology comprises the steps of selecting materials, conducting sawing-off, removing outer joints, removing inner joints, forming openings, conducting softening, conducting flattening, removing yellowness with the thickness fixed, conducting cooling for shaping, conducting drying at the low temperature, bonding the greenness-reserved bamboo board(s) with the refined wood board to form a greenness-reserved bamboo-wood composite board unit, conducting splicing, and bonding the greenness-reserved bamboo-wood composite board units to form the greenness-reserved bamboo-wood composite board. In the processing technological process, moso bamboo is softened, and no pollution is generated; in the drying process, the greenness-reserved bamboo boards are not deformed or cracked; and each bamboo greenness face maintains high hardness, flatness and smoothness.

Owner:浙江德长竹木有限公司

Preparing method for carbonized wood

InactiveCN105382901AEquilibrium moisture content decreasedLow hygroscopicityWood charring/burningWater vaporKiln

The invention discloses a preparing method for carbonized wood. The preparing method includes the following steps that southern pine wood is placed into a drying kiln, the temperature in the kiln is increased to 100 DEG C at the speed of 15-25 DEG C / min and increased to 140 DEG C at the speed of 4-8 DEG C / h, during temperature rising, steam is sprayed in a spot manner intermittently, and therefore the water content of the wood is reduced to 1-4%; the temperature is increased to 190-212 DEG C, and heat preservation is conducted for 1-3 hours; then the temperature is reduced to be lower than 100 DEG C, steam is used for replacing air to be fully charged into the whole drying kiln, so that the water content of the wood is increased to 6-10%, after stabilization is achieved, the temperature is reduced for cooling, and therefore the carbonized wood is prepared. The preparing method is a technology used for producing carbonized wood and is specially used for development of southern pines, stability and corrosion resistance of the prepared carbonized wood are greatly improved, texture is attractive and elegant, and decoration performance is good.

Owner:GUILIN RONGTONG TECH CO LTD

Water-wiping-resistant artificial leather and preparation method thereof

The invention relates to the technical field of artificial leather and provides water-wiping-resistant artificial leather and a preparation method thereof. The water-wiping-resistant artificial leather and the preparation method thereof are used for solving the problem in the prior art that the artificial leather is not resistant to water wiping and is poor in air-permeable effect. The water-wiping-resistant artificial leather comprises a base fabric layer, an adhesive layer, a foam layer and a polyurethane surface layer, wherein the adhesive layer, the foam layer and the polyurethane surface layer are sequentially arranged on the base fabric layer; an air-permeable and water-tight coating is arranged between the foam layer and the polyurethane surface layer and comprises the following raw materials in parts by weight: 60-80 parts of polyurethane, 20-40 parts of dimethylformamide, 10-15 parts of leveling agent, 10-20 parts of colored slurry and 100-120 parts of hydrogen peroxide.

Owner:FUJIAN LONGSHANG MICROFIBER

Artificial leather suitable for low-pressure injection molding and preparation method thereof

InactiveCN108166270AImprove qualityEasy to moveTextiles and paperPlasticizerInjection molding process

The invention discloses an artificial leather suitable for low-pressure injection molding and a preparation method thereof, which belong to the technical field of leathers. The artificial leather comprises a base fabric layer, a bonding layer, a foaming layer, a compact layer and a surface treatment layer, wherein the base fabric layer is prepared by adopting weft knitting double jersey; the thickness of the compact layer is larger than the thickness of the surface treatment layer, and accounts for 41 percent to 50 percent of the thickness of the whole artificial leather; in raw materials of the compact layer, the dosage of a plasticizer accounts for 35.7 percent to 40.2 percent of the sum of the raw materials; in raw materials of the foaming layer, the dosage of the plasticizer accounts for 35.9 percent to 42.7 percent of the sum of the raw materials. The artificial leather provided by the invention solves the problems of folds, short mold, reduction printing, shiny sharp corners andsharp corner bursting of an existing artificial leather occurred during a low-pressure injection molding process of high-complexity workpieces.

Owner:广西鑫深科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com