Flexible decorative facing brick and production process thereof

A face brick, flexible technology, applied in covering/lining, architecture, building structure, etc., can solve the problems of smashing people, high energy consumption, heavy weight, etc., and achieve the effect of low cost, beautiful texture and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the present invention in detail, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples. However, the embodiments should not be interpreted in a limiting manner.

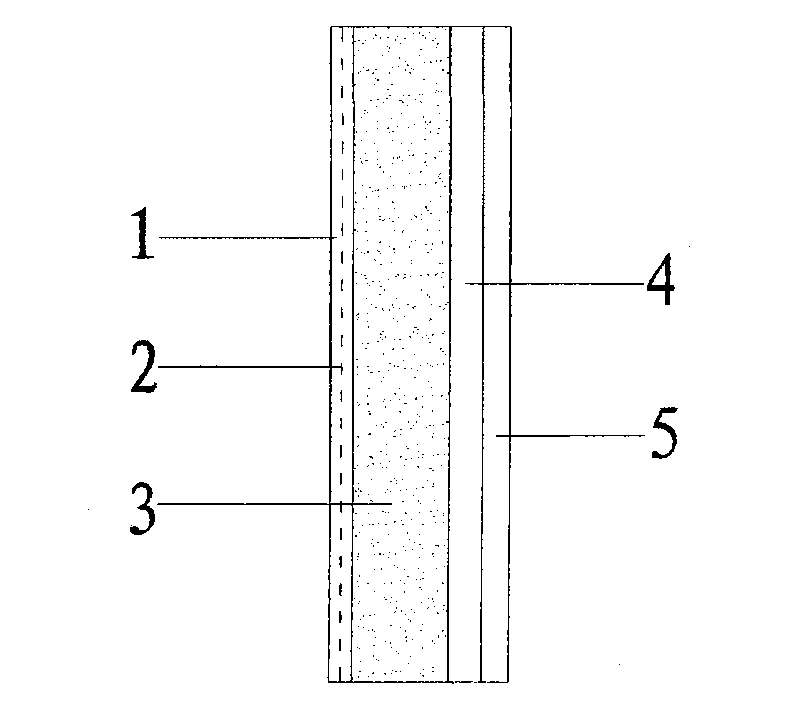

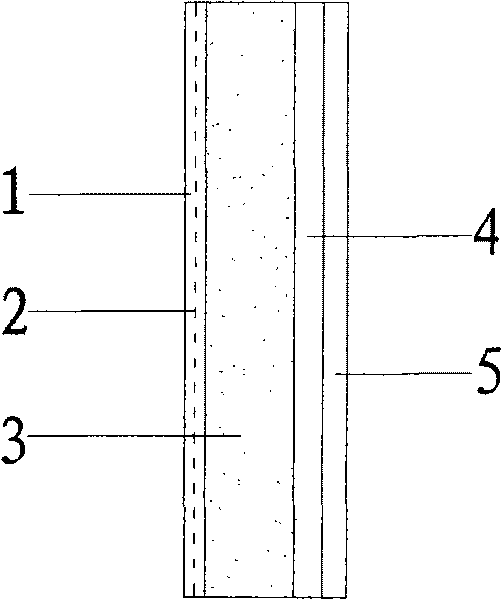

[0026] Depend on figure 1 It can be seen that the flexible decorative tile of the present invention is based on the polymer cement sheet as the base carcass 1, the sheet contains non-woven fabric 2, the polymer colored sand glue on it is the body 3 of the brick, and the transparent coating is The brick surface protection layer 4, the outermost water-soluble glue is the antifouling film layer 5 on the brick surface, which is made through the processes of scraping, baking, spraying, rolling and cutting.

[0027] The specific production process of the above-mentioned flexible decorative tiles is as follows:

[0028] 1. Stir the adhesive and inorganic powder evenly in a ratio of 1:1.5~2, press them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com