Microlite PVC foam floor

A technology of microcrystalline stone and floor, applied in the field of floor and microcrystalline PVC foamed floor, can solve the problems of short life, low product strength, chemical toxicity, etc., and achieve high elastic strength, low density and natural texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

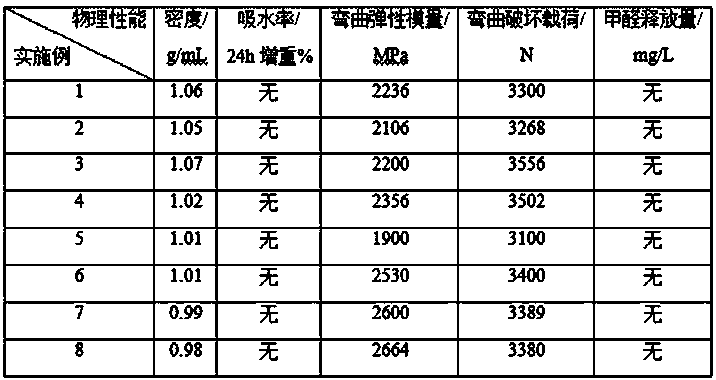

Examples

Embodiment 1

[0030] A kind of microcrystalline stone PVC foam floor, is made up of the raw material of following parts by weight:

[0031] 100 parts of PVC5 type, 200 parts of microcrystalline stone powder, 0.5 parts of stabilizer, 0.6 parts of foaming agent, 0.2 parts of plasticizer, 0.5 parts of lubricant and 0.5 parts of flame retardant.

[0032] The particle size of the microcrystalline powder is 600 mesh.

[0033] The stabilizer is a calcium-zinc composite stabilizer.

[0034] The blowing agent is azodicarbonamide ADC.

[0035] Described plasticizer is DBP.

[0036] Described lubricant is paraffin.

[0037] The flame retardant is chlorinated polyethylene CPE135A.

Embodiment 2

[0039] A kind of microcrystalline stone PVC foam floor, is made up of the raw material of following parts by weight:

[0040] 110 parts of PVC5 type, 210 parts of microcrystalline stone powder, 0.55 parts of stabilizer, 0.62 parts of foaming agent, 0.24 parts of plasticizer, 0.56 parts of lubricant, and 0.52 parts of flame retardant.

[0041] The particle size of the microcrystalline powder is 400 mesh.

[0042] The stabilizer is a calcium-zinc composite stabilizer.

[0043] The foaming agent is DPT.

[0044] Described plasticizer is epoxidized soybean oil.

[0045] The lubricant is oxidized polyethylene wax.

[0046] The flame retardant is tricresyl phosphite.

Embodiment 3

[0048] A kind of microcrystalline stone PVC foam floor, is made up of the raw material of following parts by weight:

[0049] 126 parts of PVC5 type, 250 parts of microcrystalline stone powder, 0.6 parts of stabilizer, 0.78 parts of foaming agent, 0.28 parts of plasticizer, 0.66 parts of lubricant, and 0.65 parts of flame retardant.

[0050] The particle size of the microcrystalline powder is 600 mesh.

[0051] The stabilizer is a calcium-zinc composite stabilizer.

[0052] The blowing agent is azodicarbonamide ADC.

[0053] Described plasticizer is DBP.

[0054] Described lubricant is paraffin.

[0055] The flame retardant is tricresyl phosphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com