Process for distributing ceramic micro-powder bricks

A micro-powder brick and cloth technology, applied in the field of architectural ceramics, can solve the problems of dull patterns, lack of rigidity, and lack of three-dimensional effect, and achieve the effect of natural texture, rich color, and clear layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

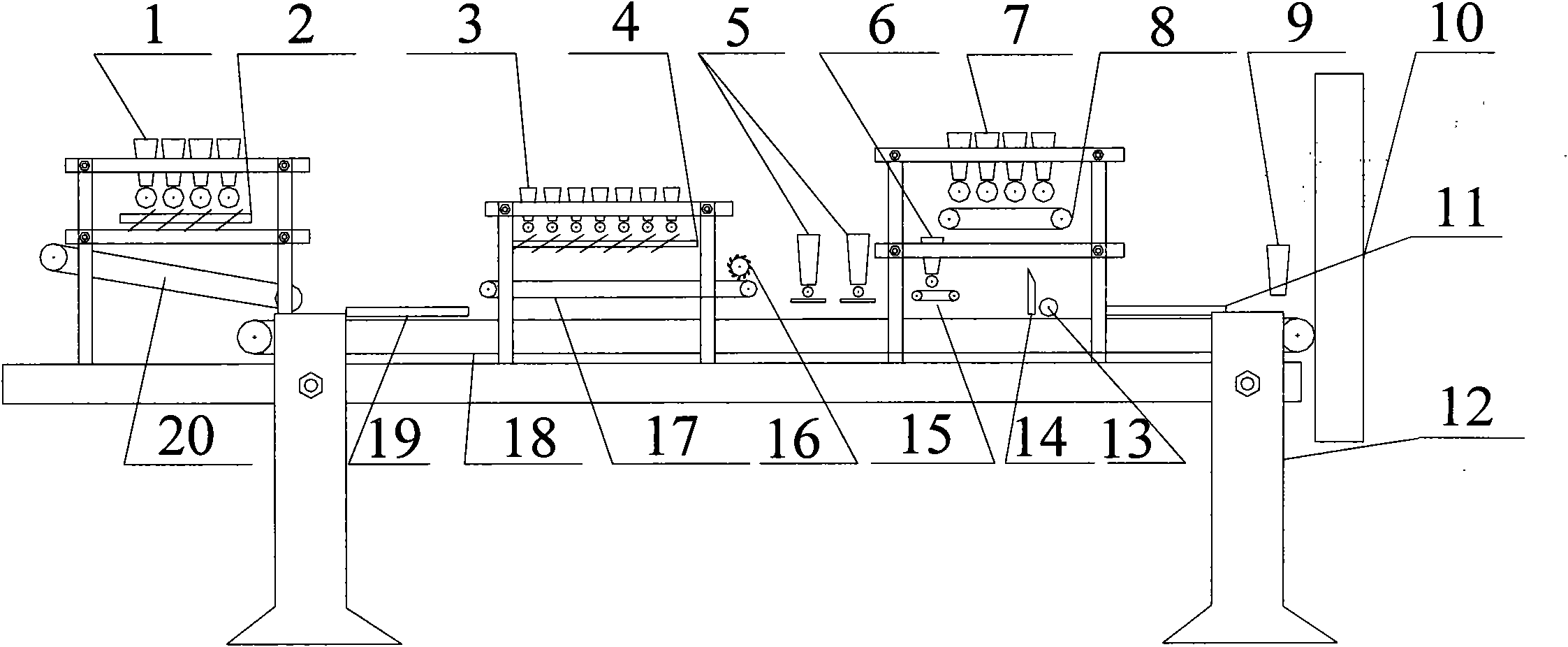

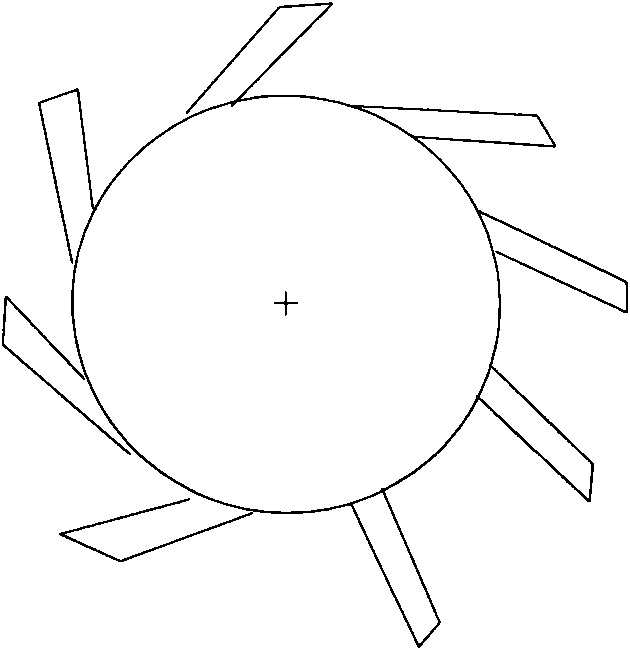

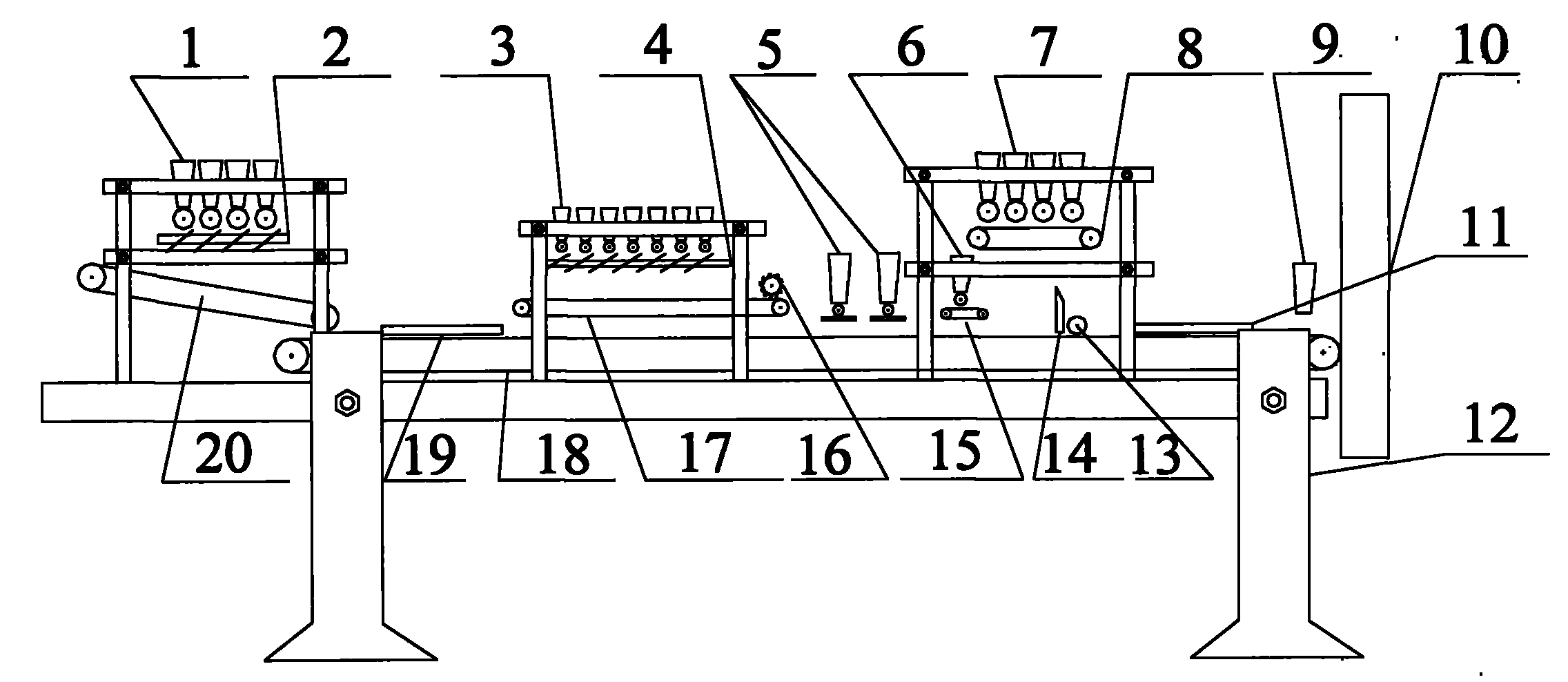

[0022] See figure 1 , figure 2 , figure 1 It is a structural schematic diagram of porcelain micropowder distributing equipment in the present invention; figure 2 for figure 1 Schematic diagram of the structure of the middle blade type cutting roller.

[0023] The distributing process of the porcelain micropowder brick provided in this embodiment comprises the following steps:

[0024] (1) The No. 1 station includes 4 hoppers 1. Various fabrics in the No. 1 station fall into the No. 1 vibrating screen 2, and the No. 1 vibrating screen 2 lays multiple layers of various fabrics on the No. 1 inclined belt 20 Then turn over from the No. 1 oblique belt 20 to the large circulation belt 18, and form a multi-layer extruded and folded material layer on the large circulation belt 18;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com