Fabricated overhead ground installation system and method of ceramic tile concrete composite board

A technology of installation system and installation method, which is applied to floors, local raised floors, covering/lining, etc., can solve problems such as high cost, increased labor wages, and broken tiles during use, and achieve flatness and verticality. Precise, fast and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

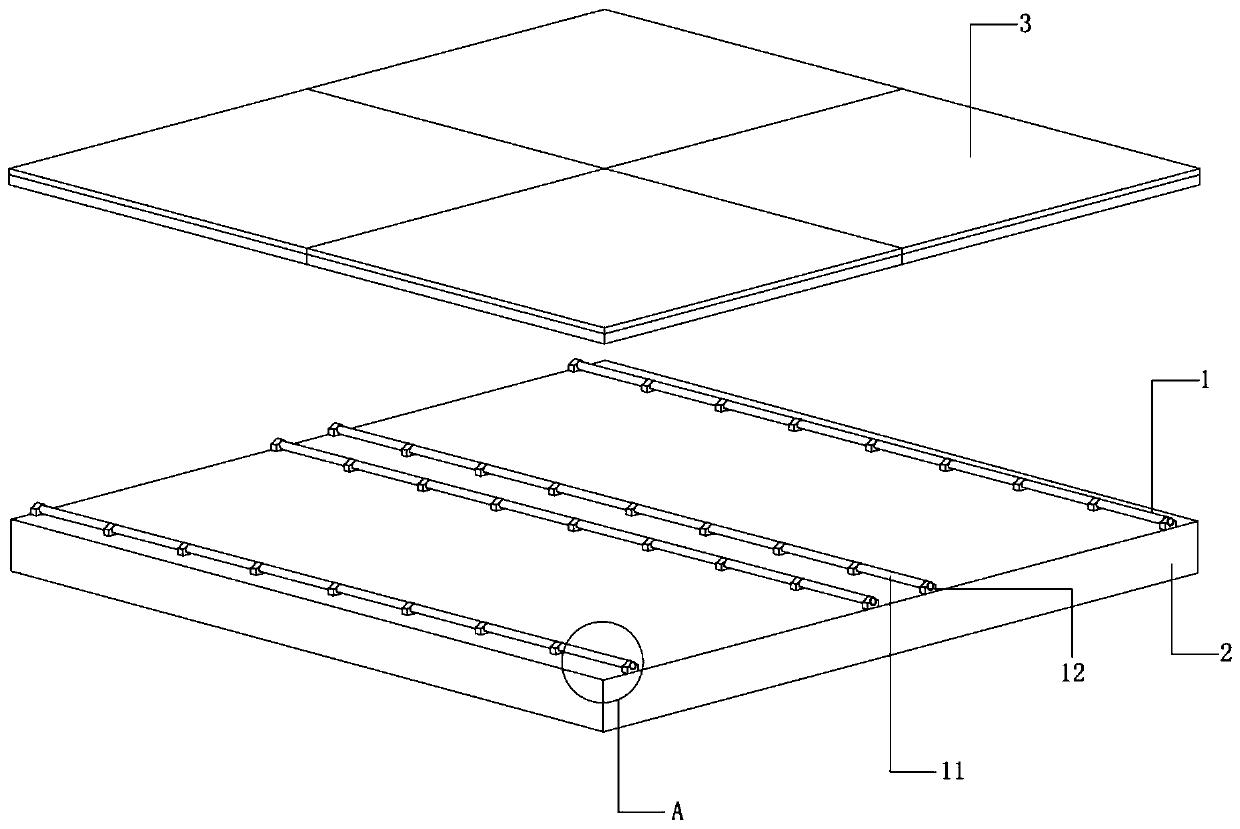

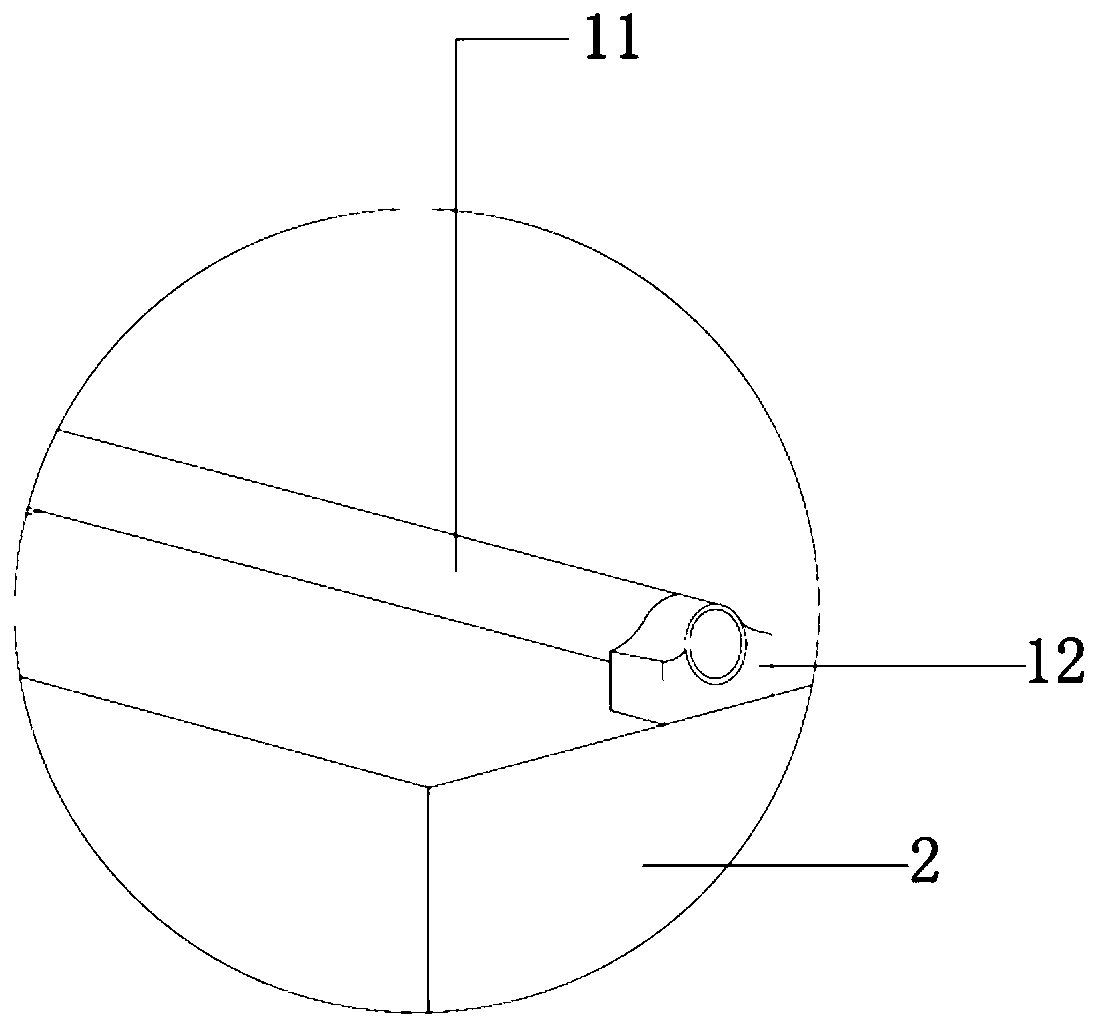

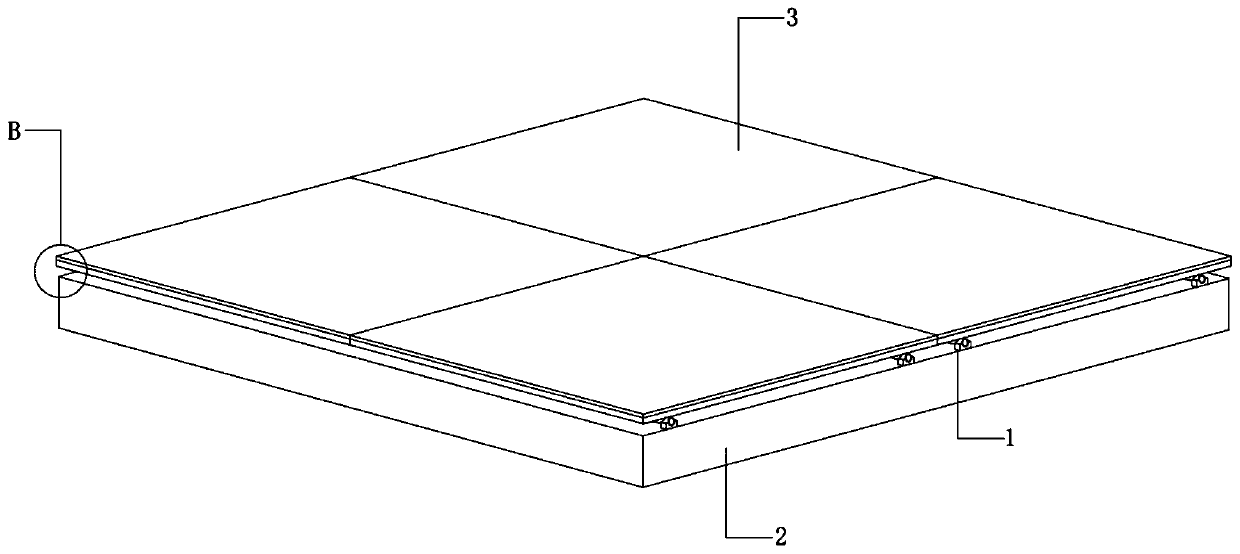

[0031] see Figure 1 to Figure 5 , the figure shows a prefabricated overhead ground installation system for a tiled concrete composite board provided by Embodiment 1 of the present invention, which includes a tiled concrete composite board 3, and a plurality of pipe clips 31 are fixedly connected to the back of the tiled concrete composite board, and the pipe clips 31 are Arc-shaped opening pipe clip, there is a cavity for laying water and electricity pipelines between the tiled concrete composite board 3 and the ground base 2: the system also includes a composite board connection mechanism, which includes a horizontal metal pipe body 11 and a pipe code 12, and the pipe clip 31 will The tile-concrete composite board 3 is connected to a horizontal metal pipe body 11, which is a round pipe;

[0032] Among them, see Figure 1 to Figure 2 and Figure 5 Specifically, the horizontal metal pipe body 11 is a round pipe, and the pipe clamp 31 is an arc-shaped clamping plate, which ca...

Embodiment 2

[0042] see Figure 1 to Figure 2 , the figure shows a prefabricated overhead ground installation system for tile-concrete composite panels provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements : the back side of the cardboard is provided with a plurality of ribs 311 extending along the width direction of the cardboard. When the cardboard is an arc-shaped cardboard, the ribs are arc-shaped ribs. Form the strengthening effect of the clamping plate to prevent the deformation of the clamping plate and affect the firmness of the clamping connection; on the other hand, when removing the floor veneer, use the ribs on the back to make one end of the clamping plate in the length direction first detach When the metal pipe body is horizontal, the ribs can prevent the one end from being broken when it is pulled up, so that the ground veneer can be easily removed wh...

Embodiment 3

[0044] see Figure 1 to Figure 2 , the figure shows a prefabricated overhead ground installation system for ceramic tile concrete composite panels provided by Embodiment 3 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments Technical solution: the thickness of the tiled concrete composite board 3 is 15-25mm, and the height of the cavity between the tiled concrete composite board 3 and the ground base 2 is 15-25mm, which can not only ensure the strength of the composite board, but also ensure the bottom of the composite board Sufficient space for piping installation.

[0045] The prefabricated overhead ground installation system of a tile-concrete composite panel described in the above embodiment is mainly realized by the following construction methods:

[0046] 1. Through the aluminum alloy pipe code 12 (16mm in height) through the galvanized horizontal metal pipe body 11 (diameter 20mm, set 6 pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com