Patents

Literature

321results about How to "Improve on-site construction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

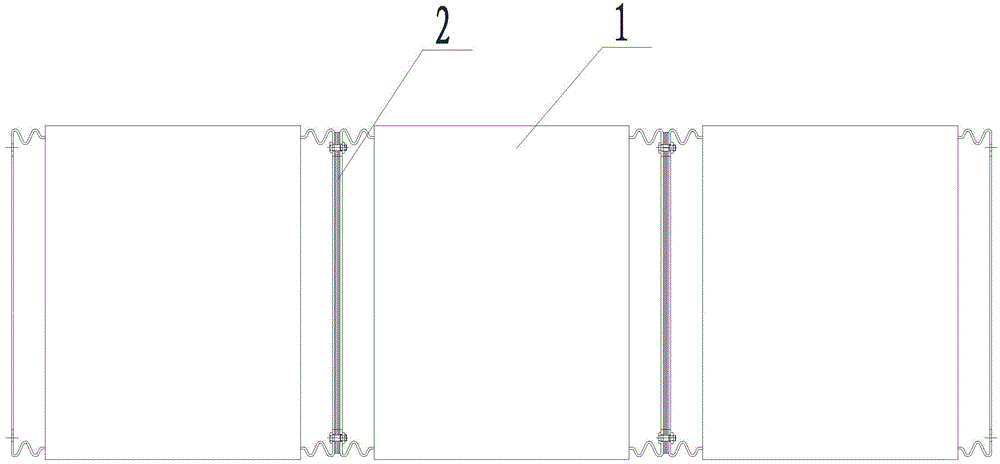

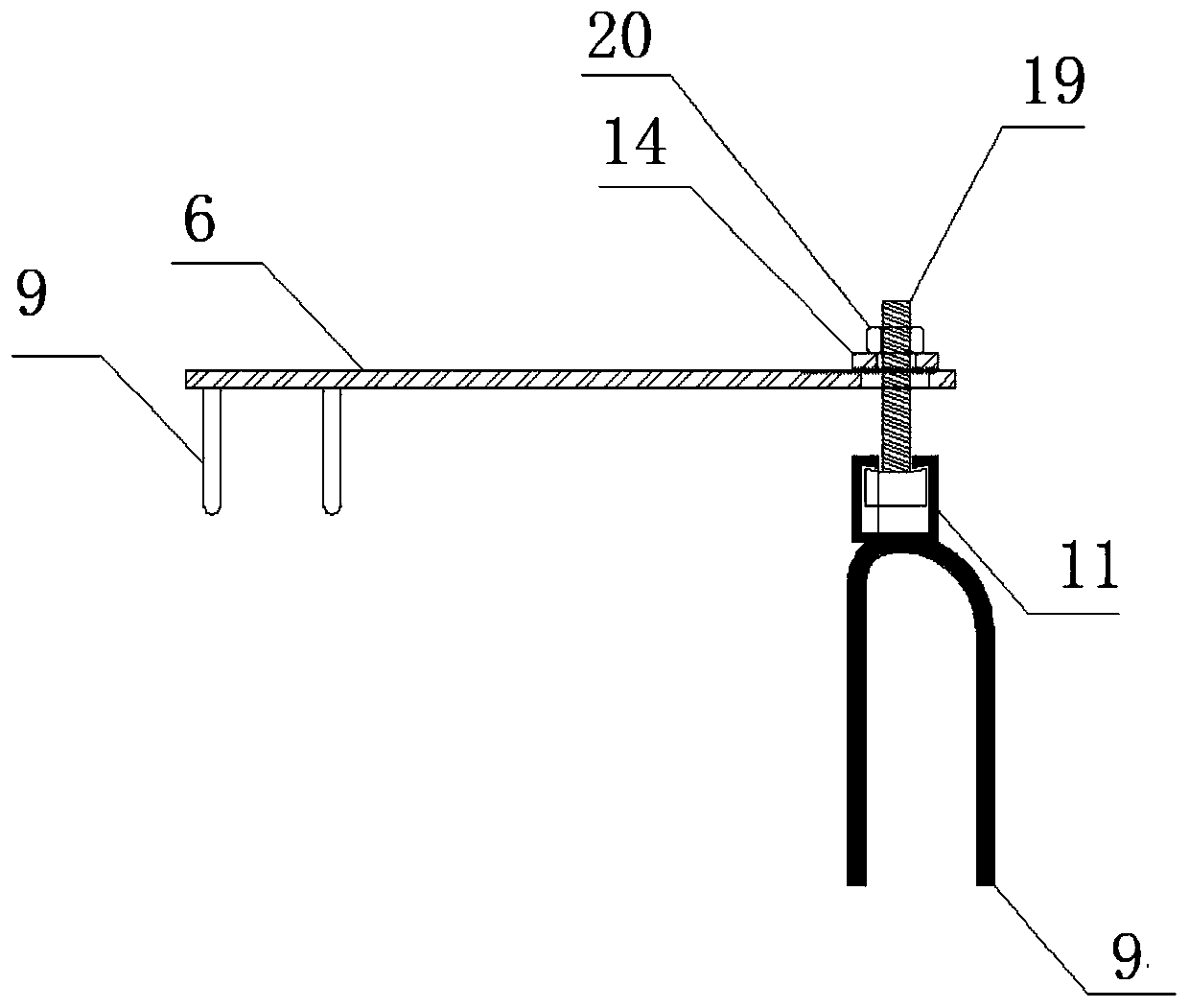

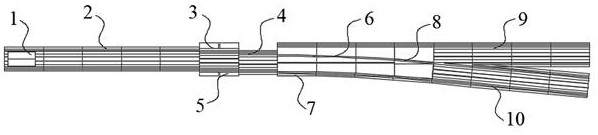

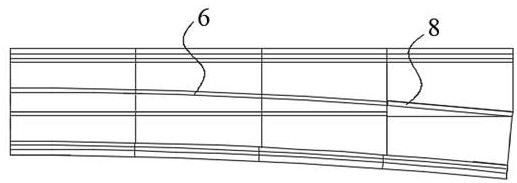

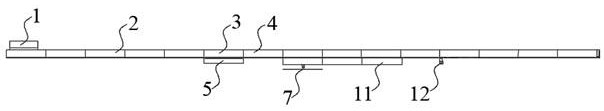

Integrated underground pipe gallery with compensation device

InactiveCN104455889AImprove carrying capacityImprove stress resistancePipeline expansion-compensationAdjustable jointsParallel pipelineFlange

The invention provides an integrated underground pipe gallery with a compensation device, and the integrated underground pipe gallery with the compensation device is high in mounting efficiency, low in cost, high in bearing capacity, long in service life and convenient to repair. The integrated underground pipe gallery with the compensation device comprises a plurality of pipe joint sealing bars and a plurality of pipe joint units connected end to end, the pipe joint sealing bars are arranged between the adjacent pipe joint units, the pipe joint units comprise pipe joints and a plurality of parallel pipelines, the pipelines are arranged on the inner bottom faces of the pipe joints through fixing seats, the two ends of each pipe joint are provided with pipe joint telescopic connecting pipes matched with the pipe joint in shape respectively, the two ends of each pipeline are provided with pipeline telescopic connecting pipes respectively, first flanges are arranged at the ends, away from the pipe joints, of the pipe joint telescopic connecting pipes, and second flanges are arranged at the ends, away from the pipelines, of the pipeline telescopic connecting pipes. According to the integrated underground pipe gallery with the compensation device, mounting efficiency is improved, construction time and cost are saved, and the capacity of resisting differential settlement of a foundation is enhanced.

Owner:杨帆

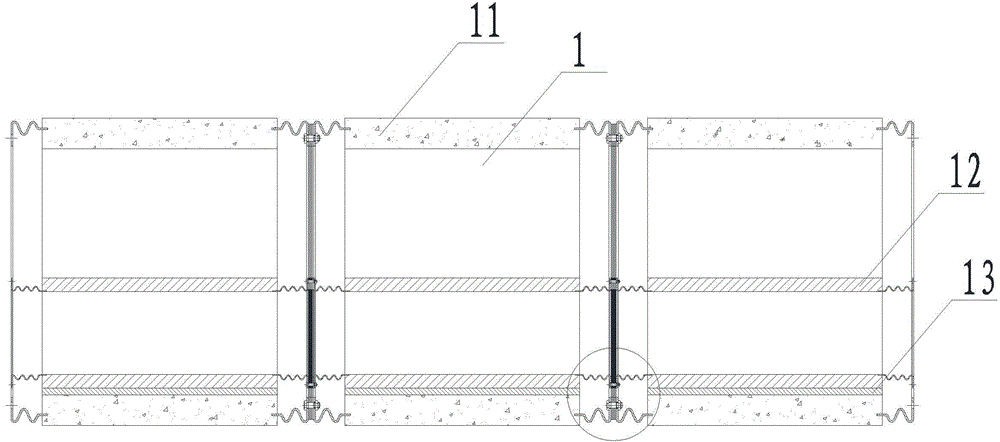

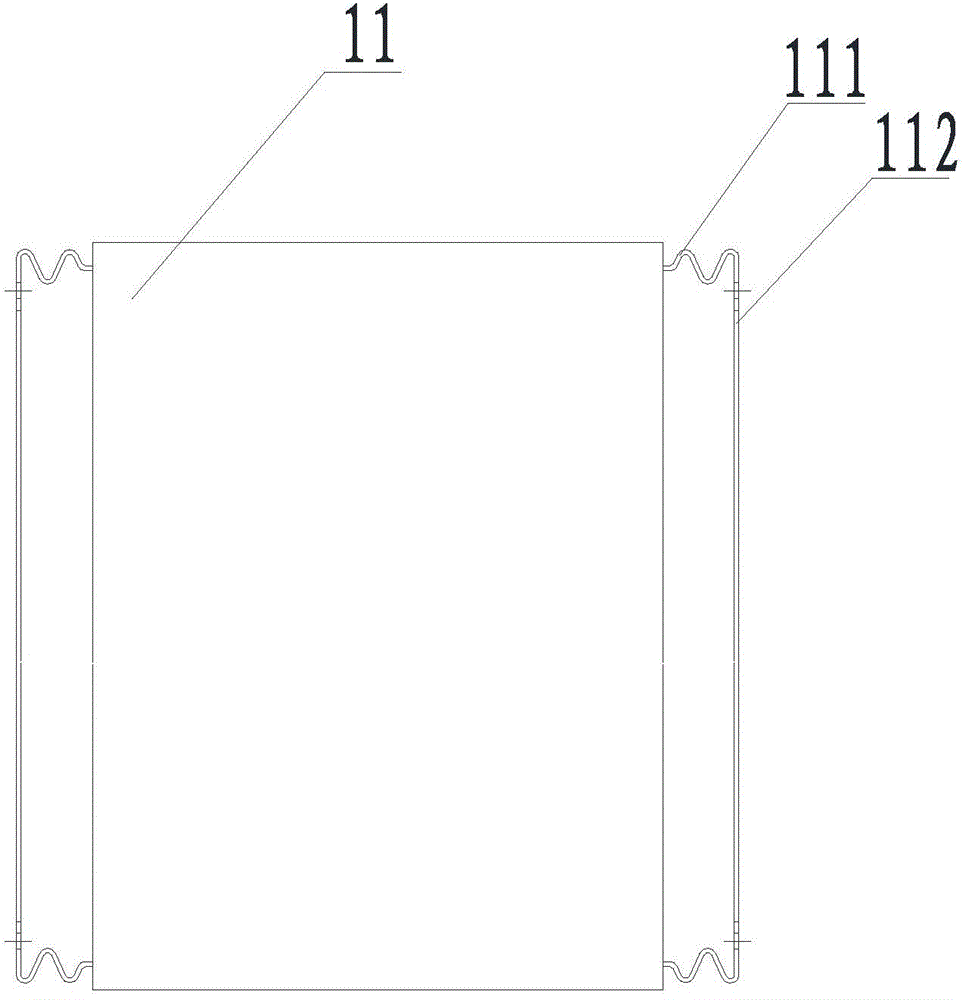

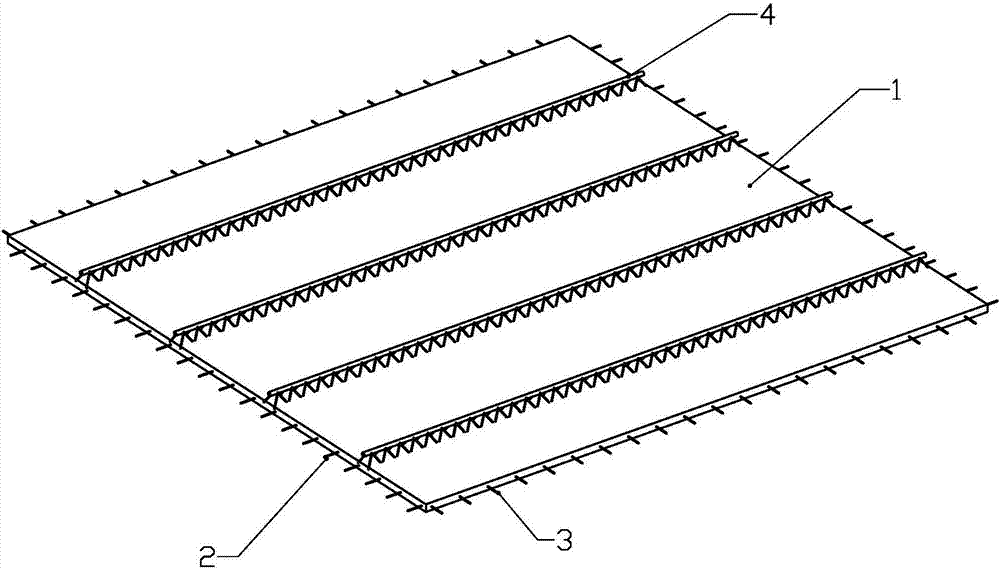

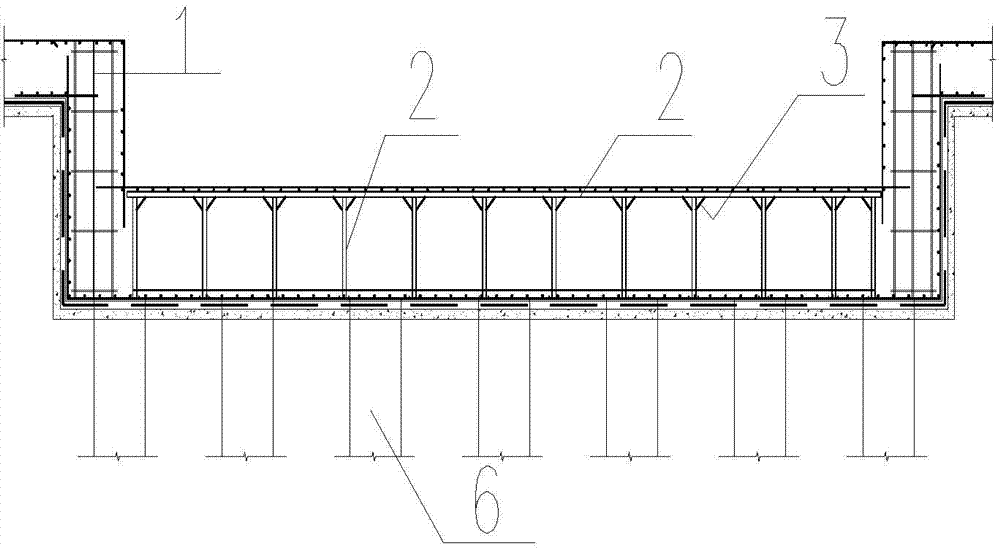

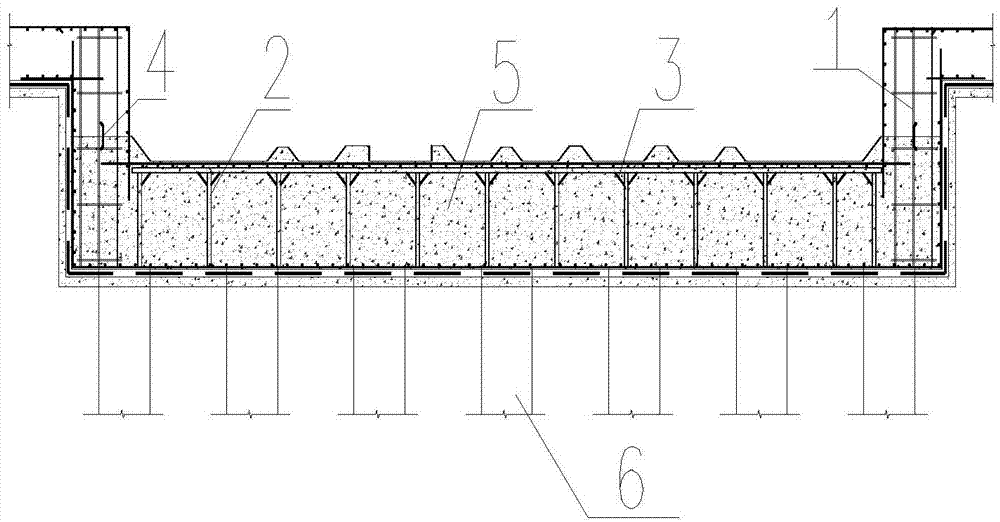

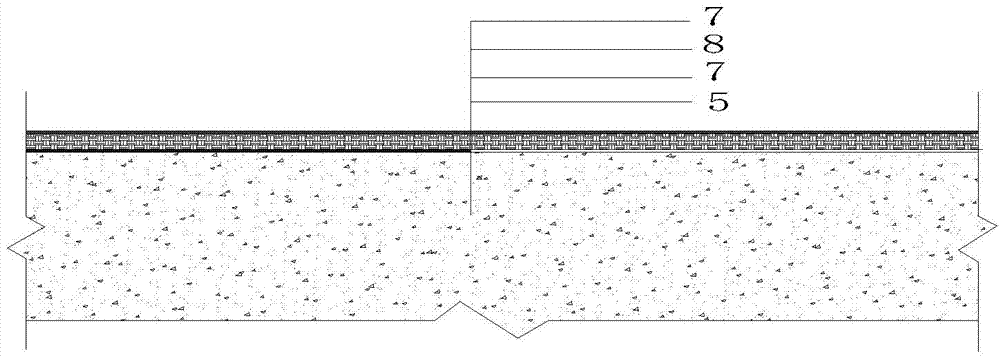

Prestressed concrete bidirectional laminated slab and manufacturing method

InactiveCN107542196AReduce support and formwork usageImprove construction efficiencyFloorsBuilding material handlingRebarPre stress

The invention discloses a prestressed concrete two-way laminated slab and a manufacturing method thereof, which belong to the technical field of construction engineering. Its structure includes a prefabricated bottom plate, a laminated layer and a steel truss. The trusses are connected, and the laminated layer transverse steel bars and laminated layer longitudinal steel bars are arranged inside the laminated layer. The laminated layer longitudinal steel bars are fixed on the upper surface of the steel truss. The transverse prestressed reinforcement is arranged at equal intervals, the longitudinal prestressed reinforcement is arranged at equal intervals along the length direction, the longitudinal prestressed reinforcement is located above the transverse prestressed reinforcement, and multiple steel trusses are arranged at equal intervals along the width direction on the upper part of the prefabricated floor. The invention also discloses a manufacturing method of the laminated board. The invention has the characteristics of high overall rigidity of the laminated slab, good force bearing performance, two-way force transmission mechanism, no joints on the prefabricated bottom plate, reduced on-site support and formwork consumption, and improved construction speed and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

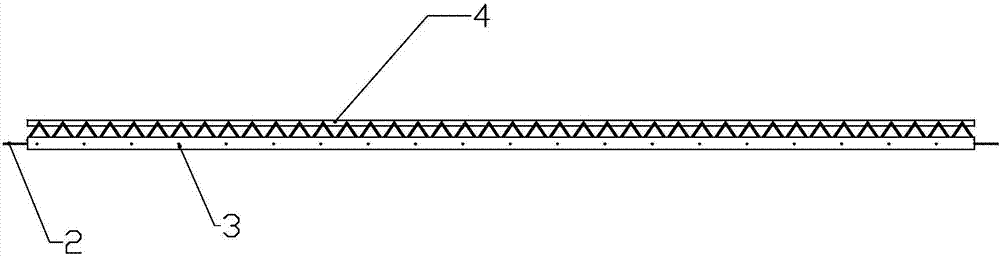

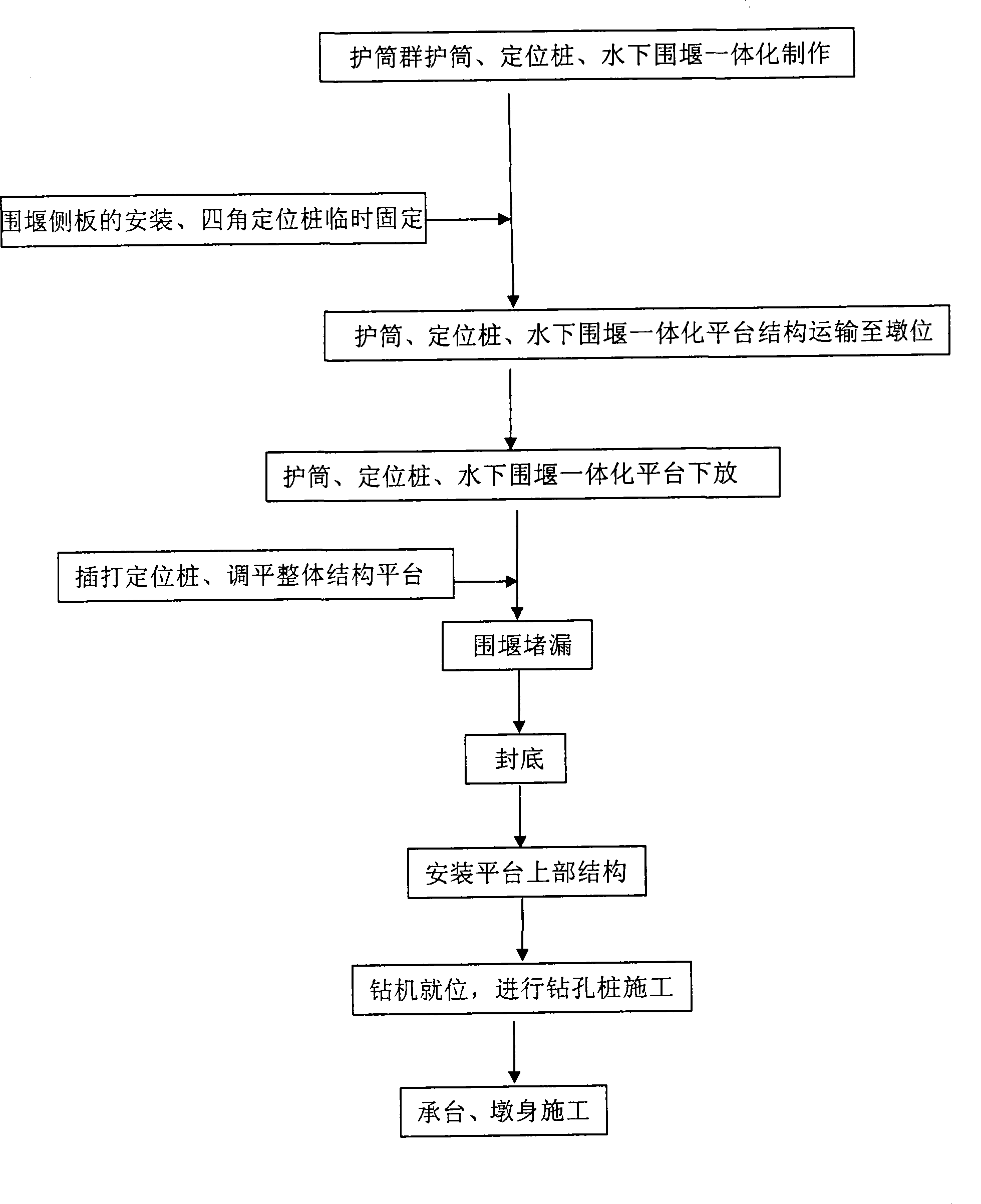

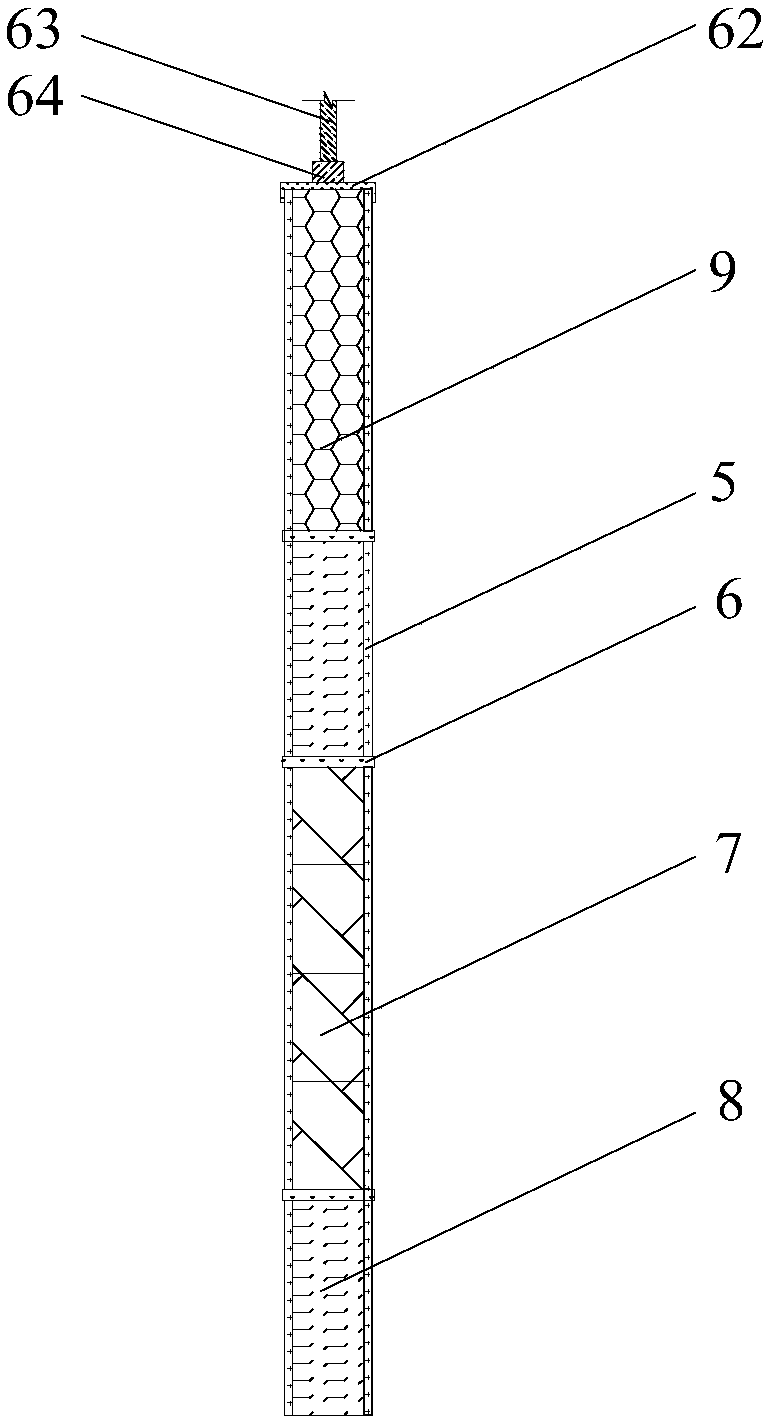

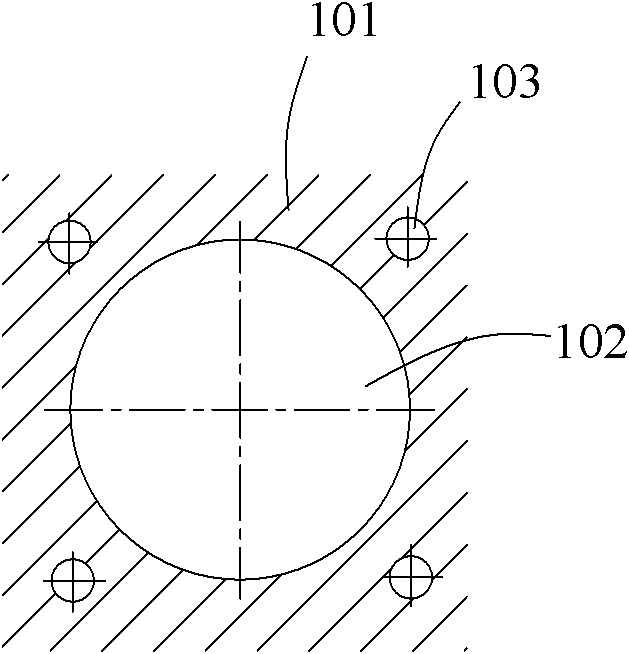

Deep sea bare rock pier protection barrel, positioning pile, underwater cofferdam integrated platform and construction method

InactiveCN101429761AImprove manufacturing precisionImprove horizontal displacementArtificial islandsUnderwater structuresRear quarterCofferdam

The invention relates to an integrated platform of a deep sea bare rock pier guard barrel, a guide pile and an underwater cofferdam and a construction method thereof. The structure of the integrated platform is as follows: the steel guard barrel and a steel sleeve are connected into a whole; the guard pile is inserted into the steel sleeve; side plates of the cofferdam are arranged along the outer ring at the bottom of the platform to form a closed bin body which is divided into a plurality of small bins; bottoming concrete is filled into each small bin; and bin baffle plates are supported on trusses of the side plates of the cofferdam. The construction method comprises the following working procedures of manufacture of the platform, lifting and conveying, descending, leak stoppage, pouring of bottoming concrete, tapped arrangement and so on. The construction method meets the requirements of construction of a bridge foundation of a bare rock pier of a bridge spanning the sea, and the requirement of the steel protective barrel and the guard pile on the pile stabilizing depth, is safe and stable to construct the prior guard pile platform, improves the construction efficiency due to overall assembly of the platform, controls the verticality and the horizontal deviation of the platform, has high construction precision, avoids overall stability of the platform and leakage stoppage of a bottom opening of the protective barrel, and provides convenient conditions and technological guarantee for bridge construction in sea areas with severe construction conditions.

Owner:THE 2ND ENG CO LTD MBEC

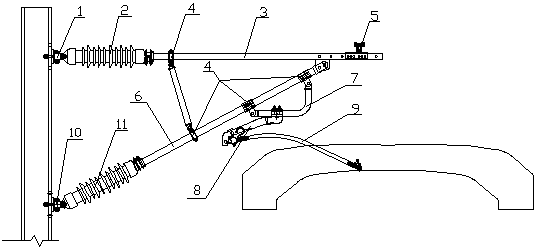

Windproof-type overall steel bracket mounting method

ActiveCN104260643ASmall sizeEfficient use ofTrolley linesSpecial data processing applicationsBuilding construction

Disclosed is a windproof-type overall steel bracket mounting method. The windproof-type overall steel bracket mounting method includes: firstly, measuring basic parameters required when a windproof-type overall steel bracket is mounted on a specified position; secondly, establishing a model of the windproof-type overall steel bracket; thirdly, respectively calculating the position of a bearing wire, the dimension of a flat inclined bracket, a support position, a positioning pipe and parameters of relevant dimensions in a coordinate frame of the model; finally taking calculating results as the design dimension of the steel bracket and performing processing and mounting according to the design dimension. Point-to-point positioning of the coordinate frame is adopted, the parameters of connecting parts are taken into consideration, the dimensions and positions of the parts are accurately calculated out, the bracket is more accurate in dimension, success rate in mounting is guaranteed, time for on-site mounting and adjusting is greatly shortened, skylight point time is effectively utilized, and on-site construction efficiency is greatly improved.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP

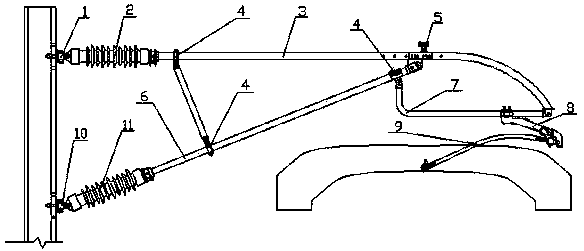

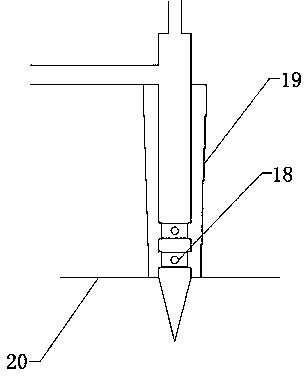

Portable intelligent high-pressure grouting system and grouting method of metamorphic concretes

ActiveCN104196030AReduce dosageEnsure construction efficiencyFoundation engineeringEngineeringHigh pressure

The invention discloses a portable intelligent high-pressure grouting system and a grouting method of metamorphic concretes. The portable intelligent high-pressure grouting system comprises a pulp feeding barrel, a pulp pump and a grouting bar which are connected though pipelines. A grouting head in a tapered shape is arranged on the grouting bar. Circular grooves are formed in the upper portion of the grouting head and internally provided with grouting holes. The tail end of the grouting bar is connected with an electric hammer. The grouting method includes the steps such as grouting and backflowing. The portable intelligent high-pressure grouting system and the grouting method are applied to automatic construction of the metamorphic concretes, construction efficiency is improved, construction workers are fewer, and grouting quantity of the metamorphic concretes is saved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

Construction method of mass concrete of high-rise building foundations

InactiveCN104264676ASimple technologyImprove construction efficiencyFoundation engineeringMass concreteCasting

The invention discloses a construction method of mass concrete of high-rise building foundations. According to the construction method, continuous construction is adopted for concrete construction, concrete is subject to segmental and layered casting and mechanical vibrating, and the temperature and the casting time are strictly controlled. The construction method is simple in technique, high in site construction efficiency, reliable in quality, short in construction period and low in labor intensity, the quality after construction reaches the design demands, and the thickness of casting layers is strictly controlled. Vibrators are arranged at multiple casting points to ensure density of the concrete. The opening temperature and the molding temperature of the concrete are strictly controlled so that shrinkage and closing of the concrete are effectively ensured. The concrete is vibrated in a fast inserting and slow stirring mode during casting so that holes caused by mixing of air during concrete casting are effectively prevented.

Owner:沈建东

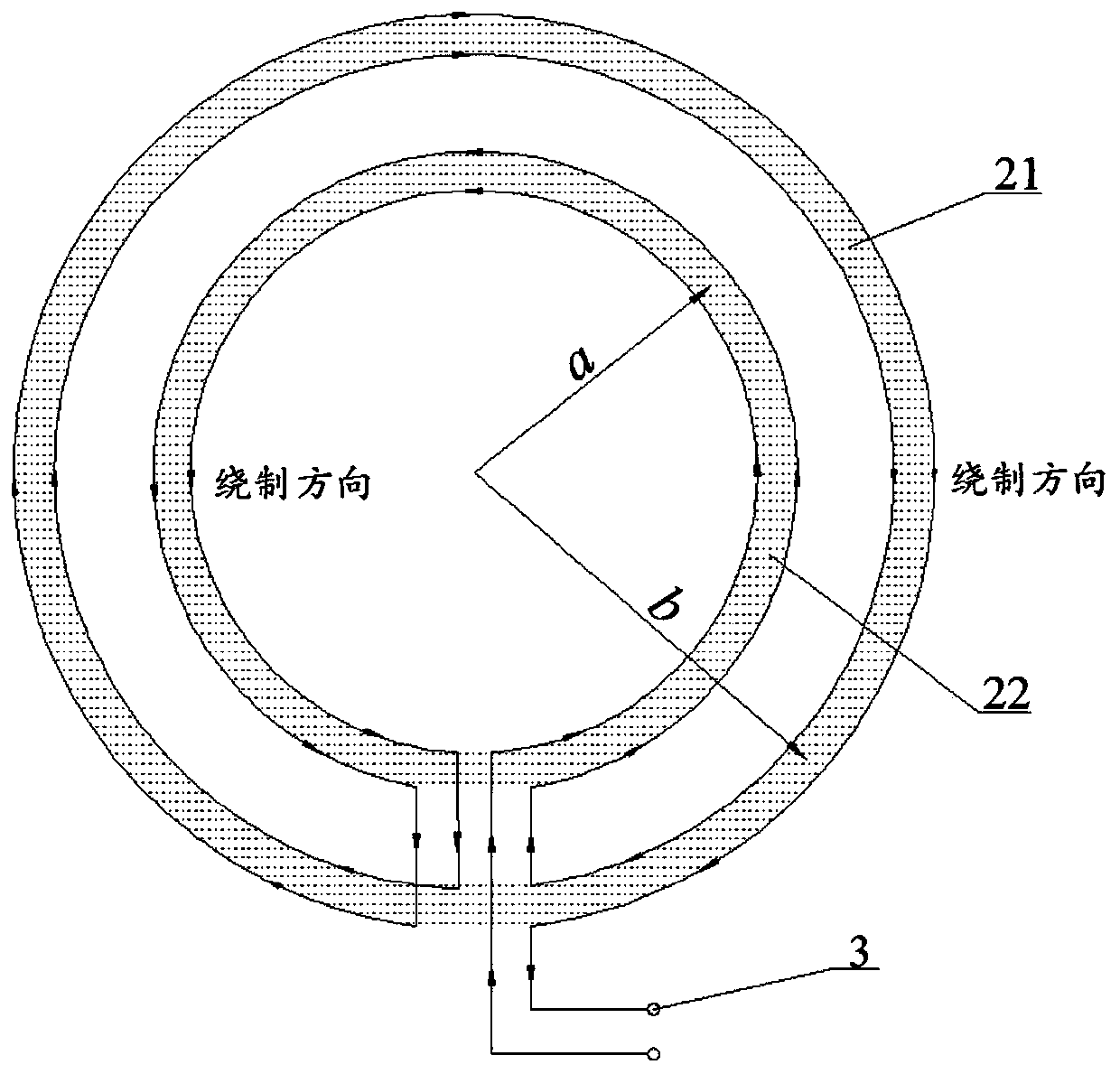

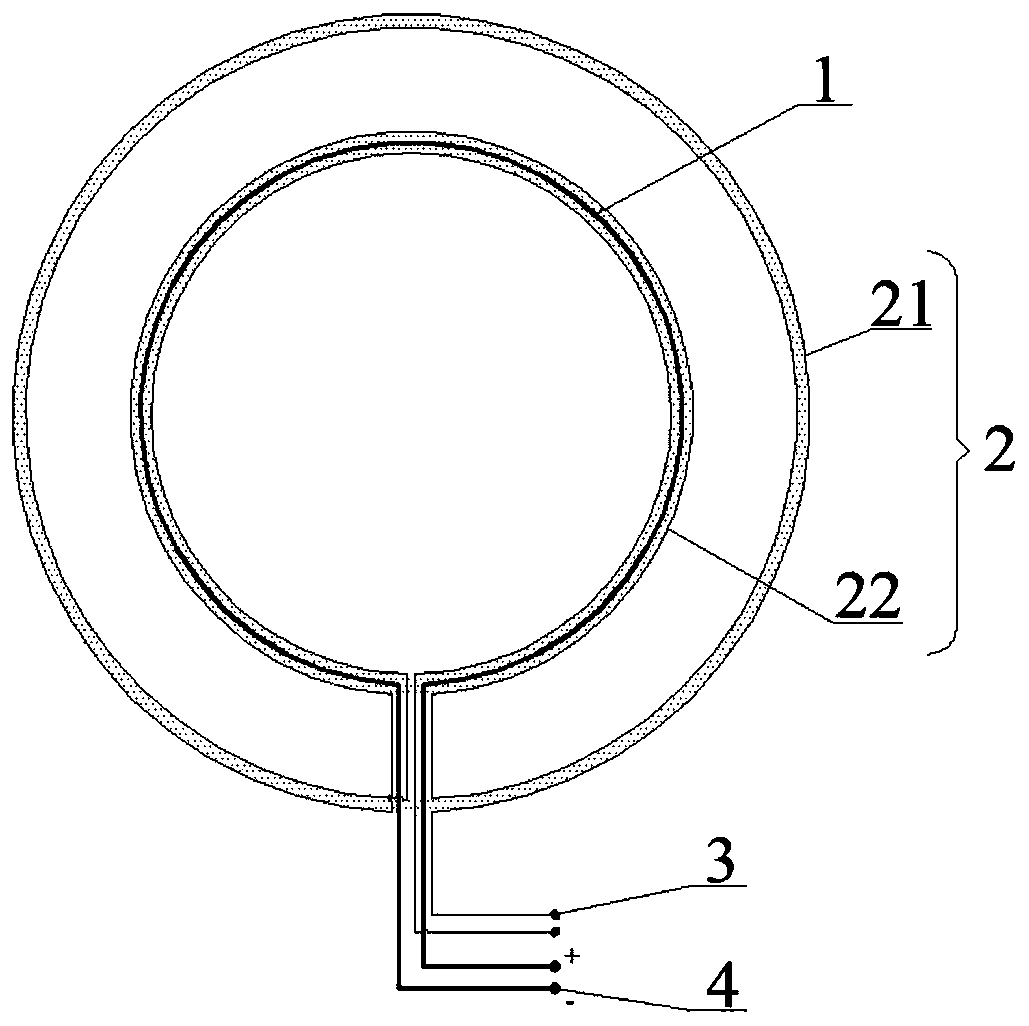

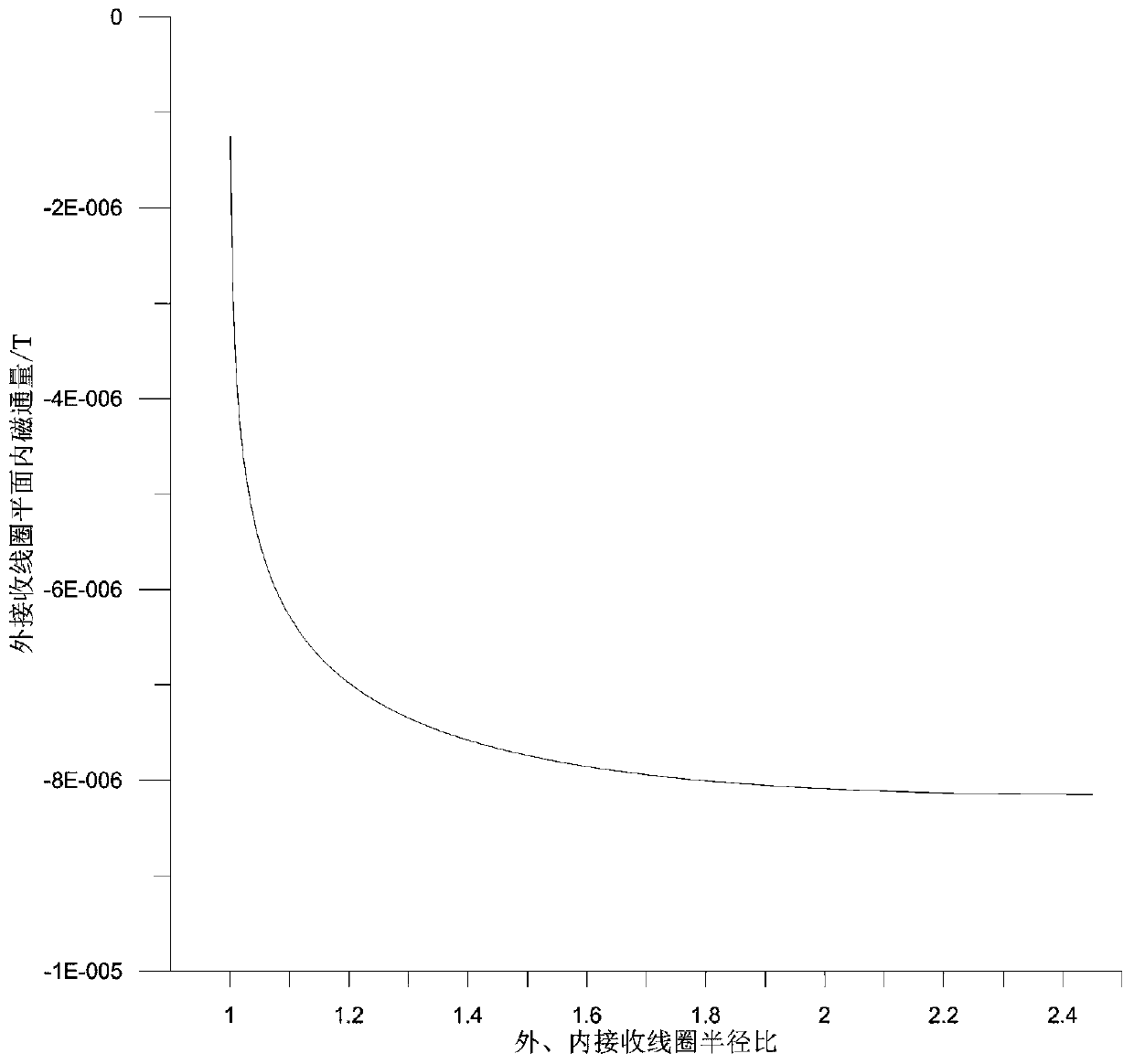

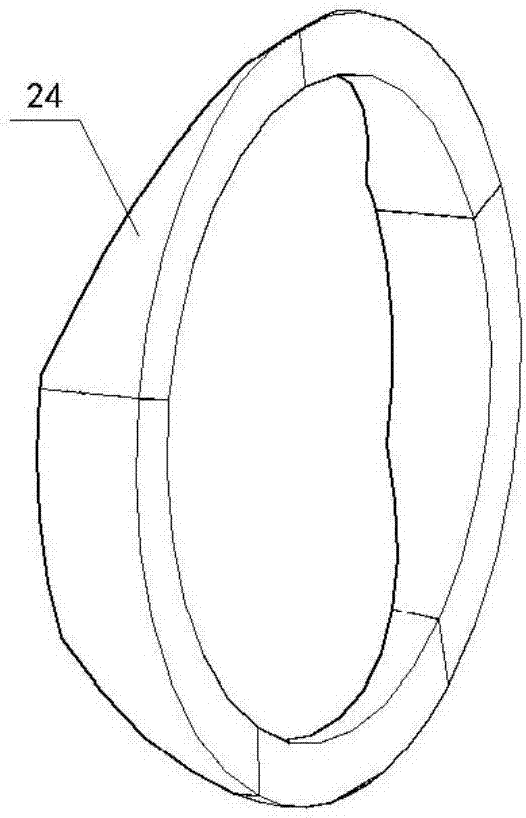

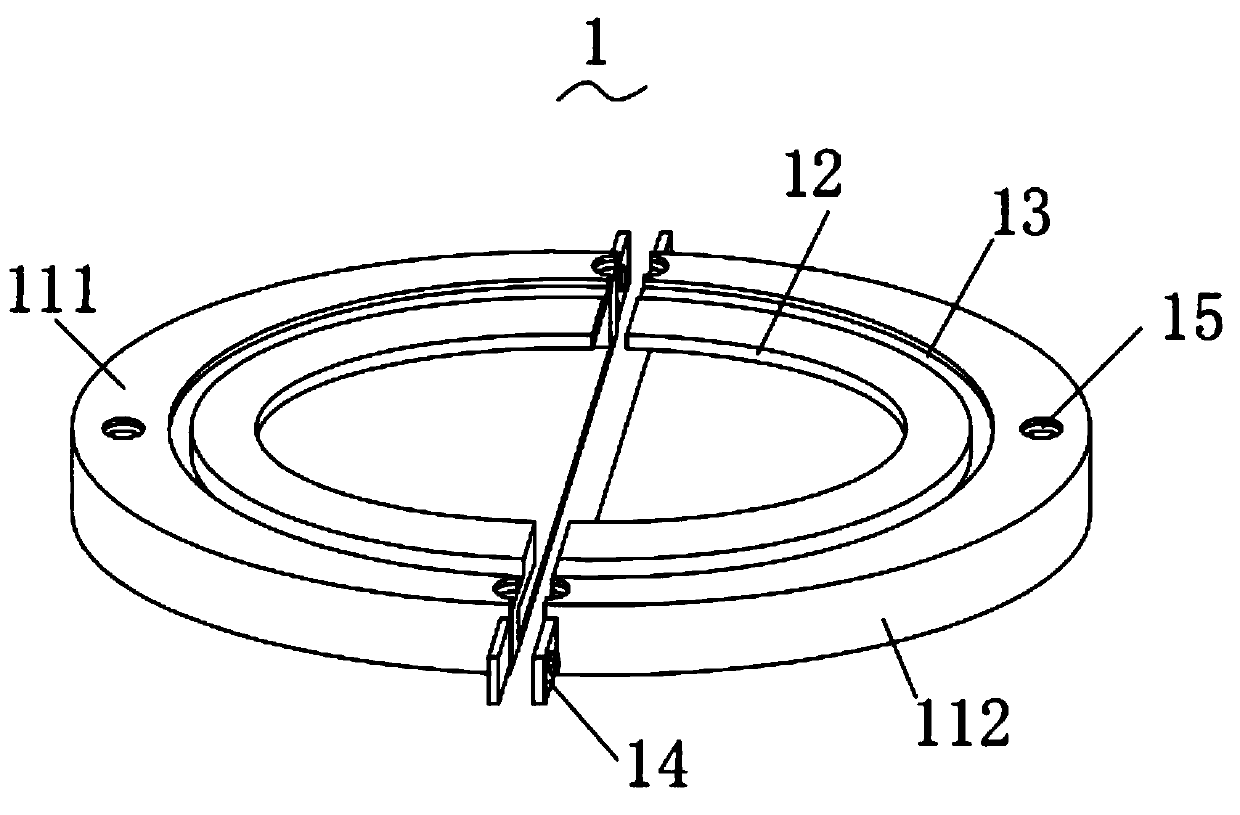

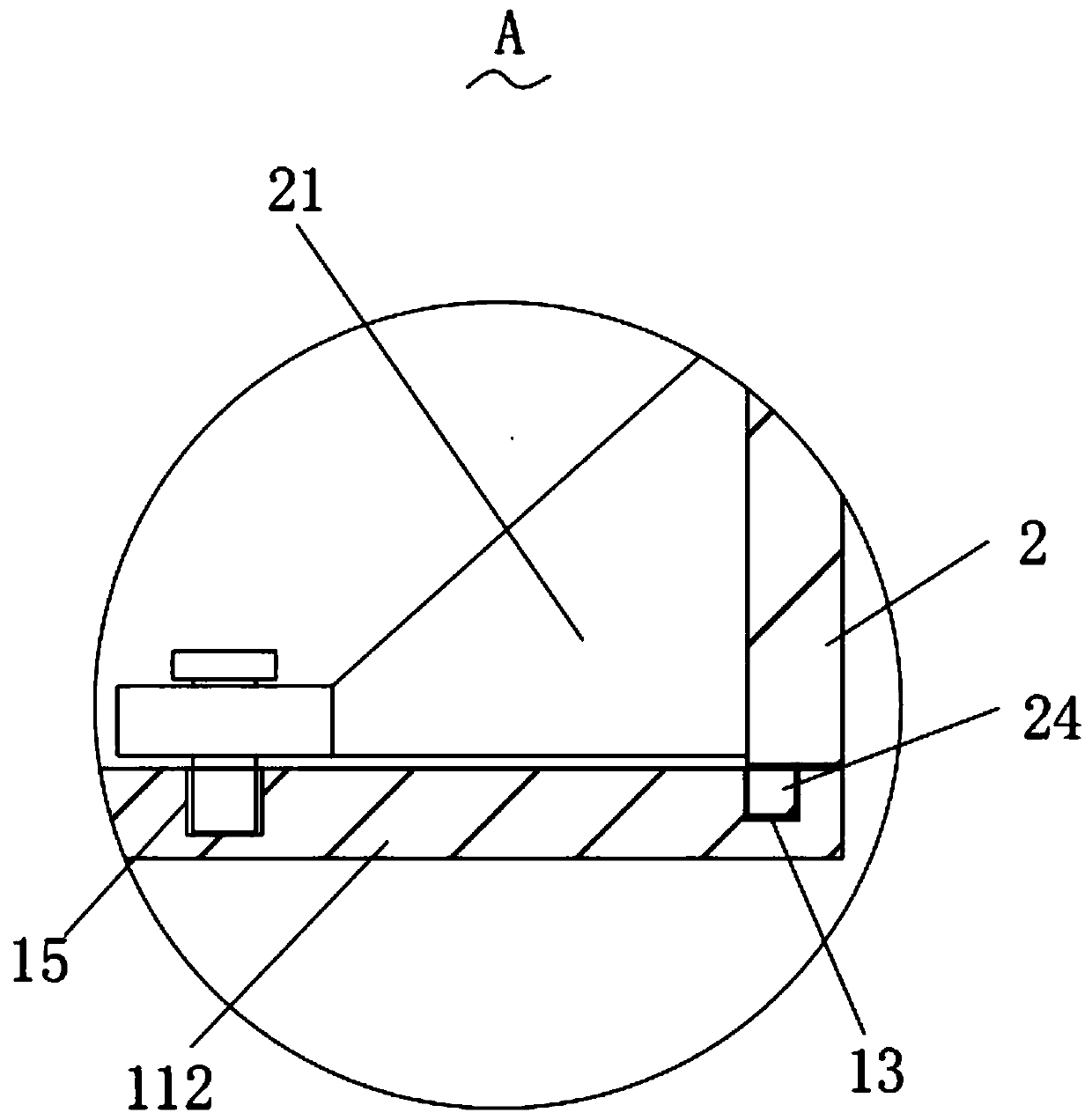

Zero-magnetic-flux shallow transient electromagnetic test coil and test method thereof

ActiveCN110187395AIncrease the areaIncrease the emission magnetic momentElectric/magnetic detectionAcoustic wave reradiationImage resolutionEngineering

The invention discloses a zero-magnetic-flux shallow transient electromagnetic test coil and a test method thereof. The test coil comprises a transmitting coil and a receiving coil, wherein the transmitting coil is embedded in the receiving coil and is arranged in a coplanar and coaxial manner; the receiving coil comprises an outer receiving coil and an inner receiving coil; the radius of the outer receiving coil is larger than that of the inner receiving coil; the radius of the inner receiving coil is equal to that of the transmitting coil; and meanwhile, the turns inside the transmitting coil and the receiving coil are connected with each other in series. By the test method provided by the invention, the primary fields in the inner receiving coil and the outer receiving coil are equal insize and opposite in direction, and mutually offset to enable the total magnetic flux in the receiving coil to be zero, so that the effective elimination of the primary fields is realized, a pure secondary field signal is obtained, the shallow detection blind area range is greatly reduced, and the transient electromagnetic shallow detection resolution is effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

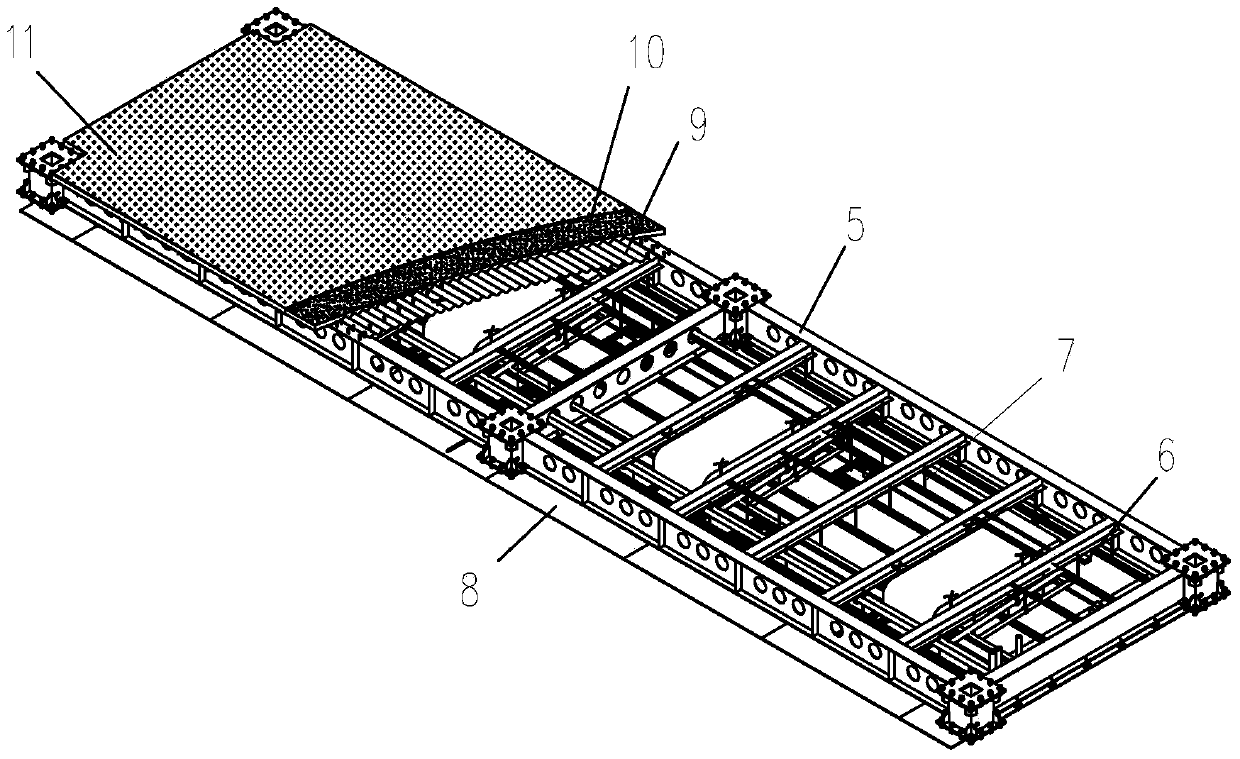

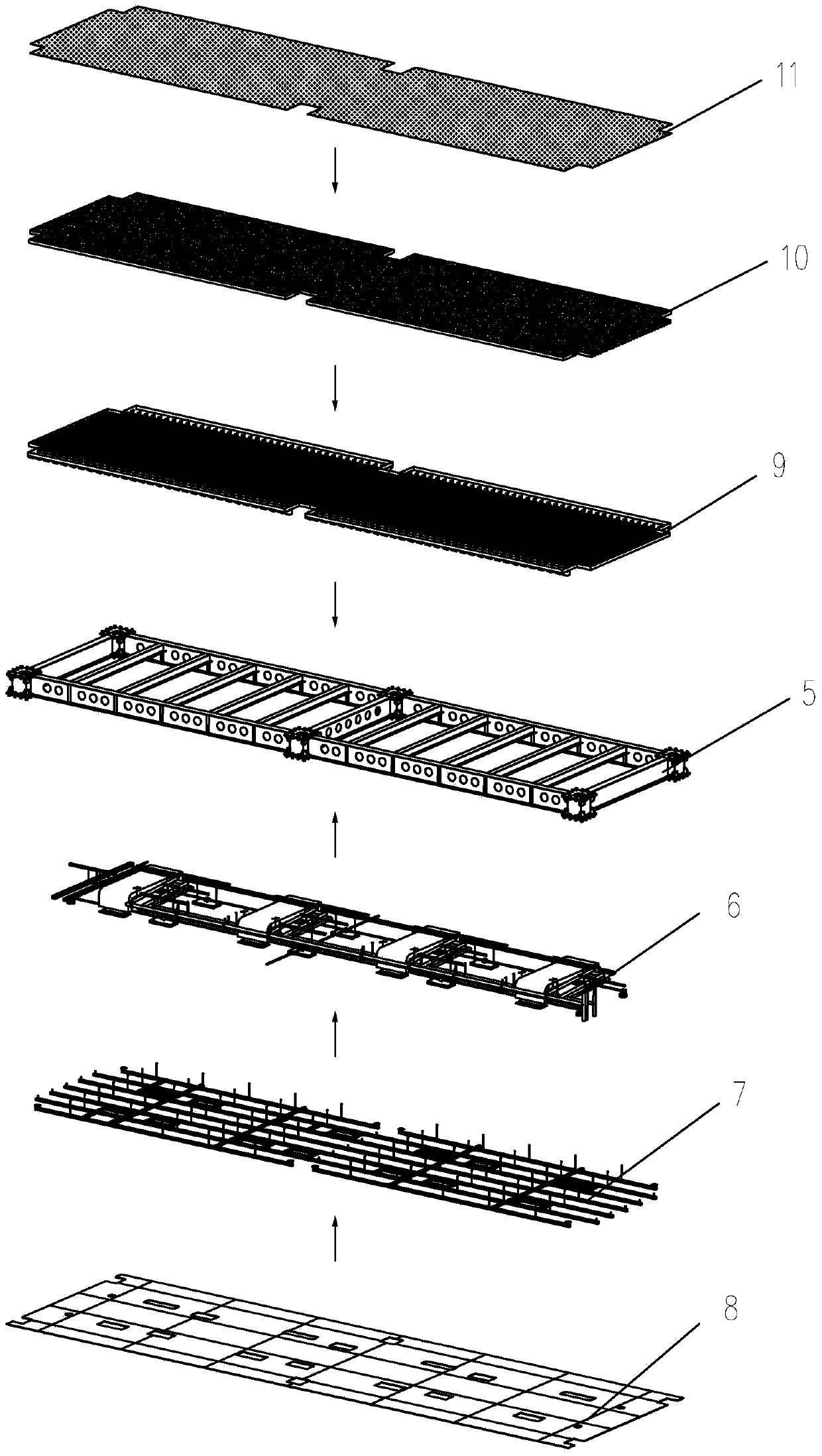

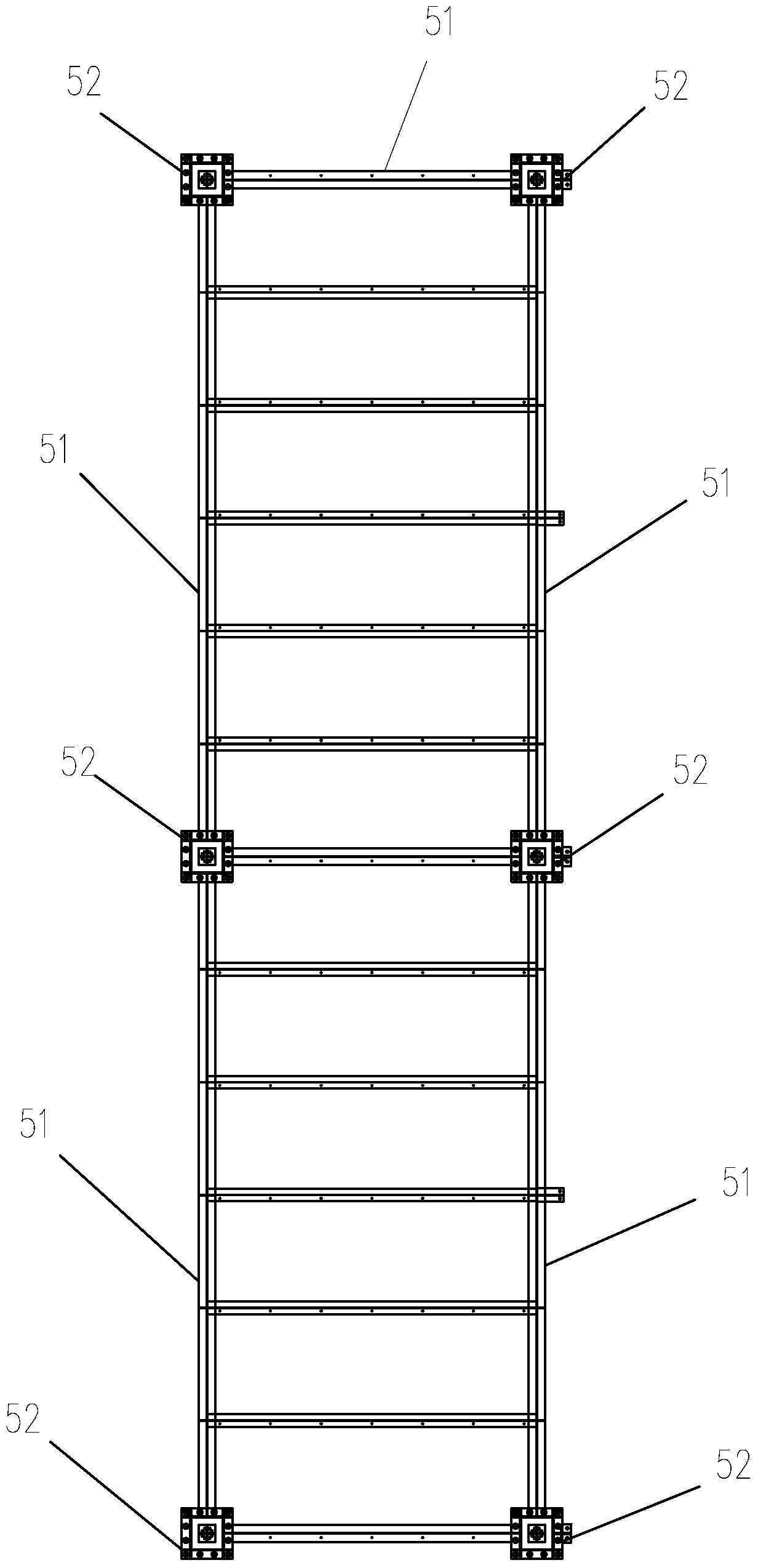

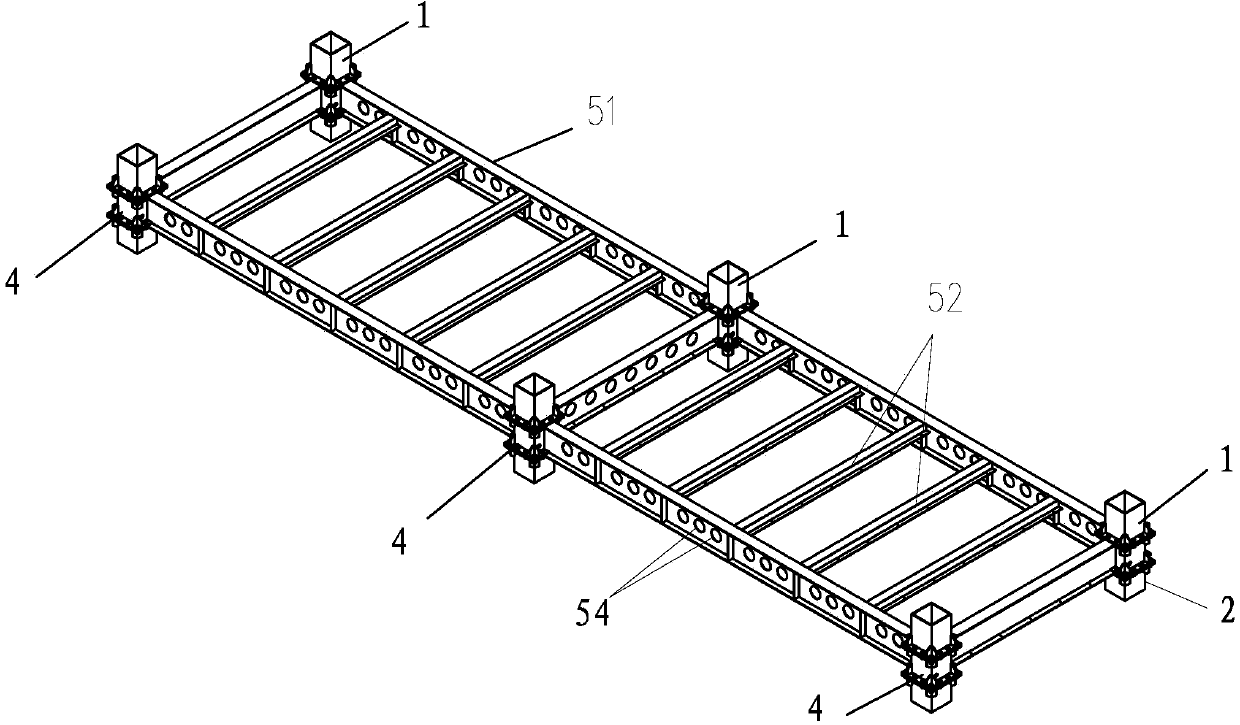

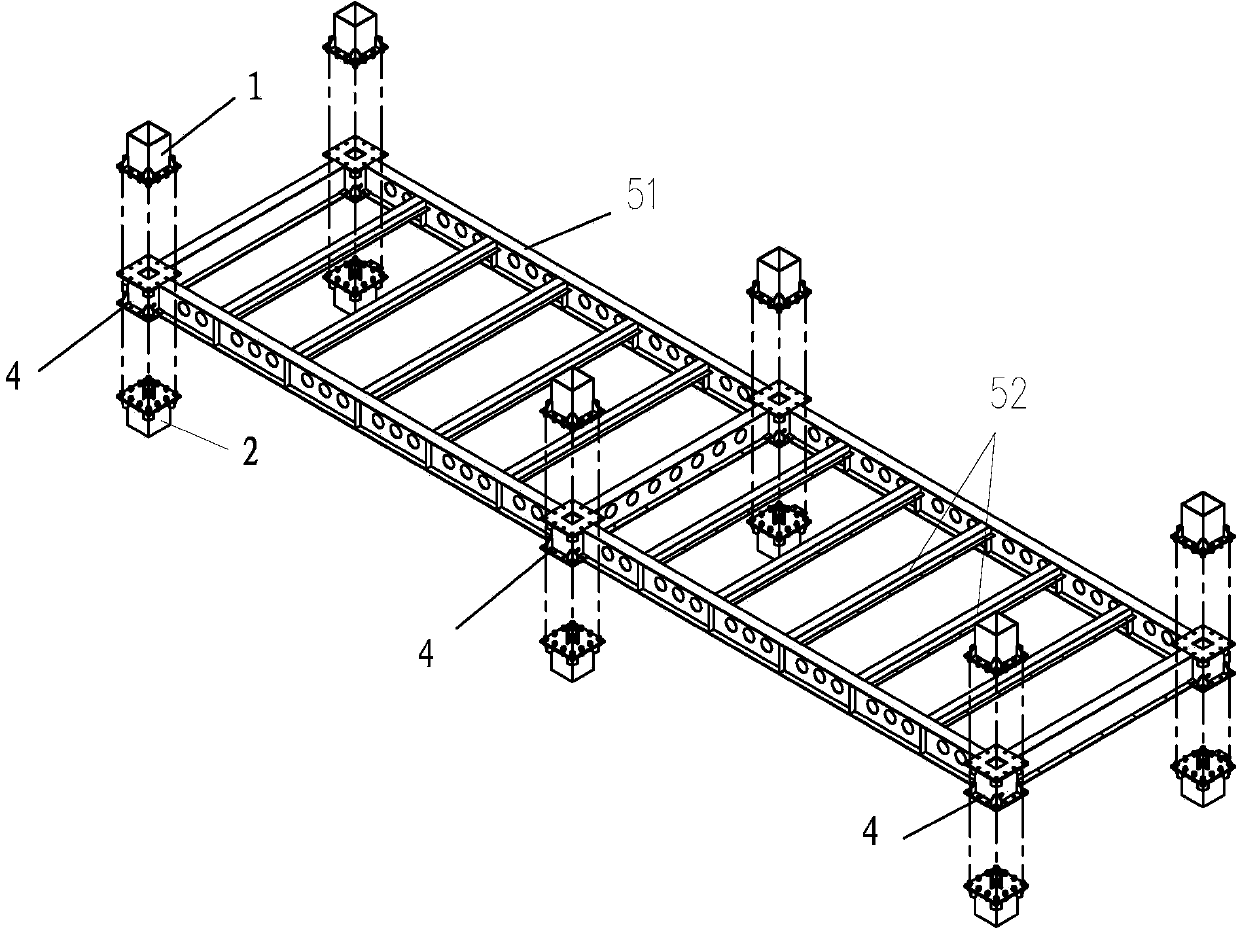

Integrated floor module and assembling method thereof

ActiveCN103993691ARealize industrial productionImprove on-site construction efficiencyFloorsSurface layerJoist

The invention mainly discloses an integrated floor module and an assembling method thereof. The integrated floor module comprises a structure module of floor. Equipment system modules, ceiling joists and suspended ceiling boards are sequentially assembled on the lower surface of the structure module from inside to outside; a profiled steel sheet is installed on the upper surface of the structure module, concrete is poured to the upper surface of the profiled steel sheet on site, a floor surface layer is laid on the surface of the concrete, and a finished product of whole floor system is formed. The assembling method includes the steps that the floor system is prefabricated in a factory firstly, then the finished product of the floor system is carried to a construction site, and the floor system is quickly connected with on-site square columns. According to the integrated floor module and the assembling method, modular production of the floor system is achieved, convenience is brought to quick assembly, and industrialization, assembly and standardization of building industry are propelled.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

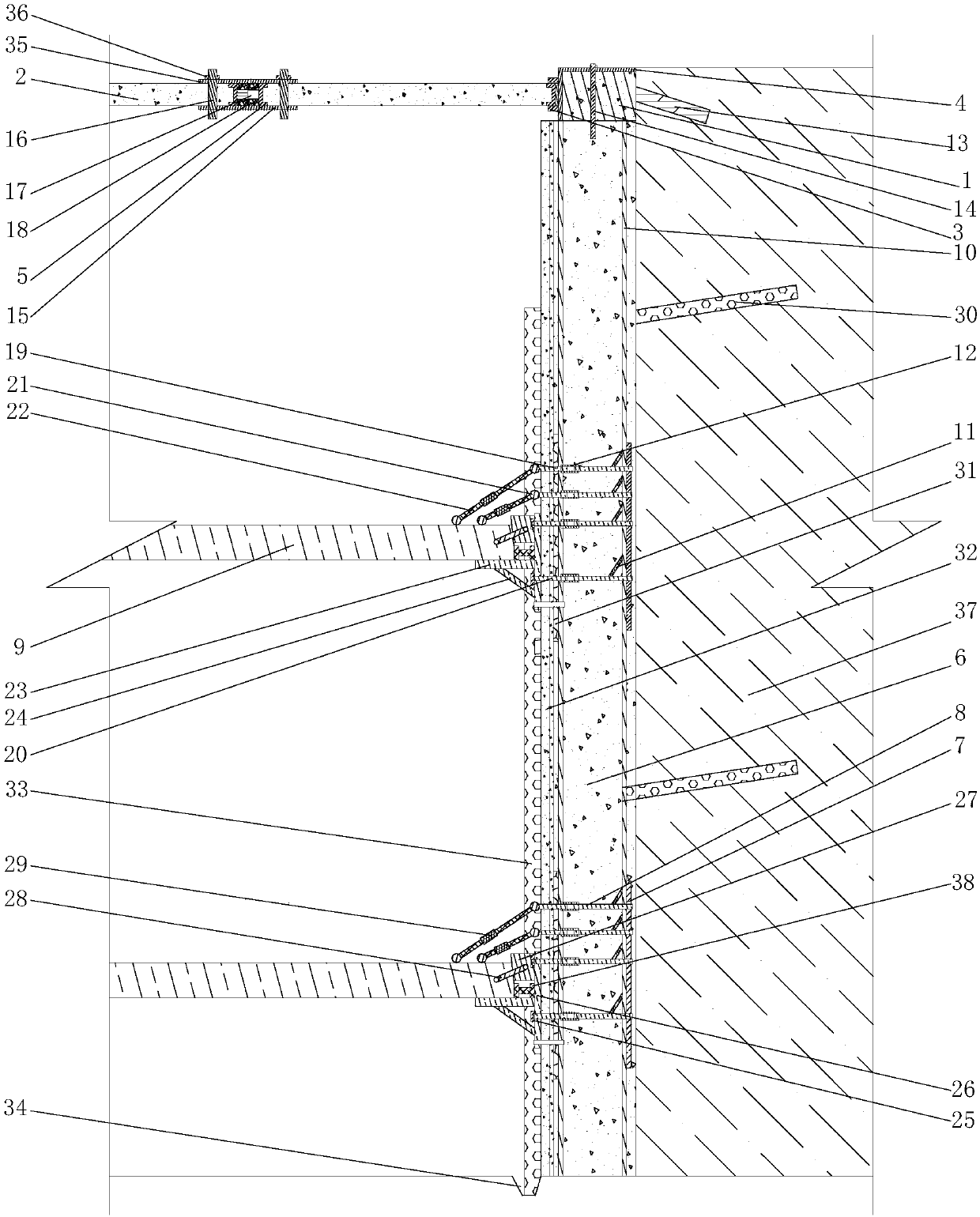

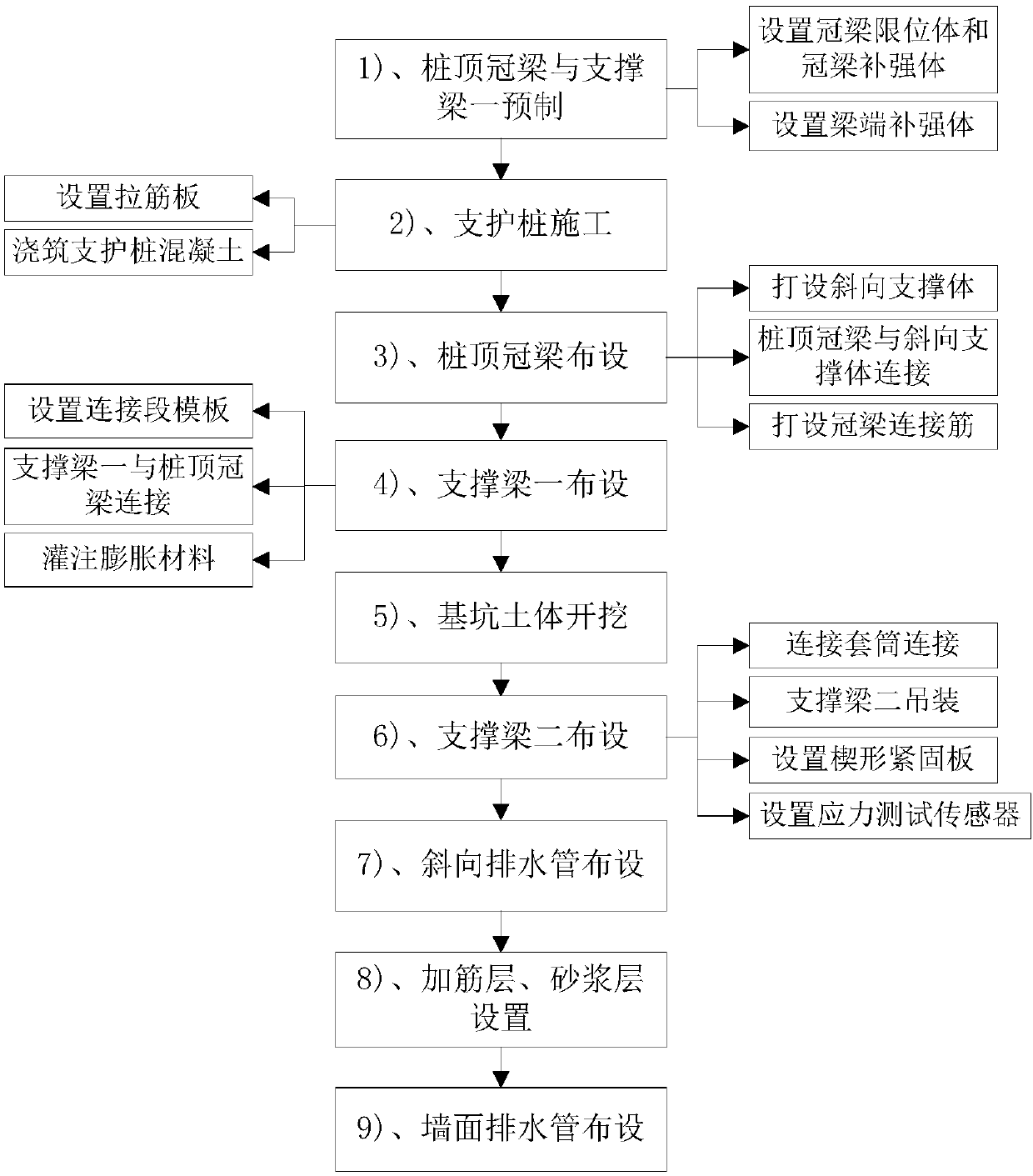

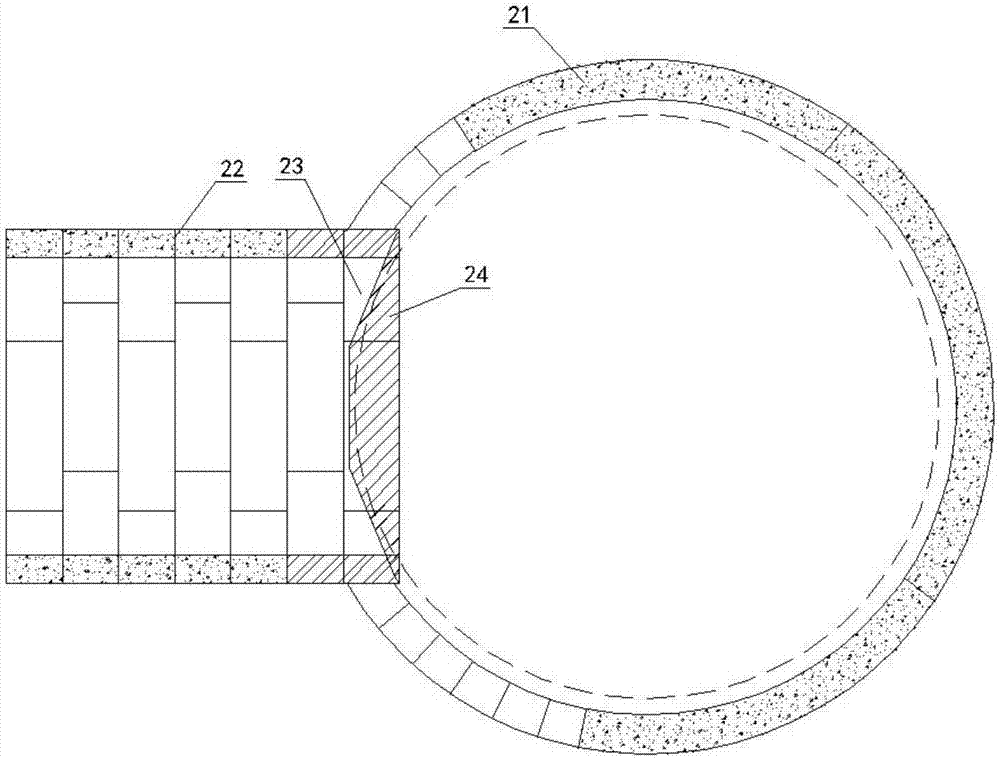

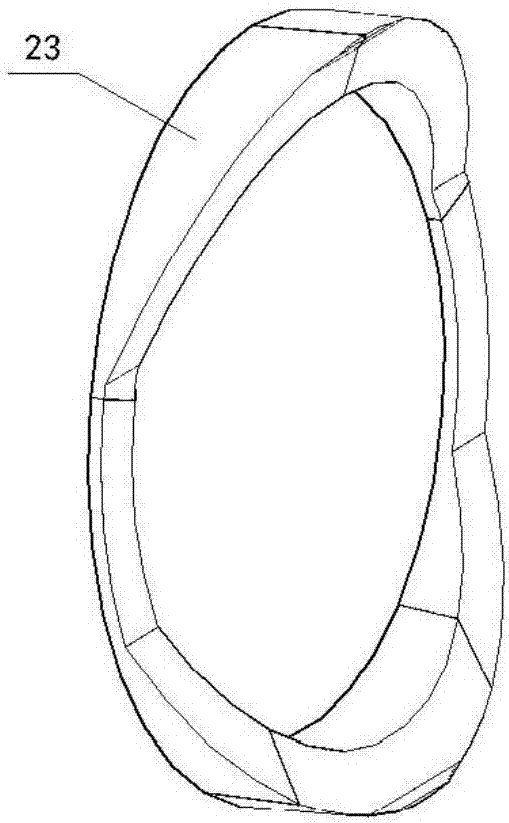

Metro station deep foundation pit combined type support construction method

ActiveCN108612110AReduce deflectionImprove on-site construction efficiencyExcavationsMetro stationDisplacement control

The invention relates to a metro station deep foundation pit combined type support construction method which comprises the following steps: 1, prefabricating a pile top beam and a support beams I; 2 carrying out support pile construction; 3, laying the pile top beam; 4, laying the support beam I; 5, excavating foundation pit soil mass; 6, laying a support beam II; 7, laying a slant water drain pipe; 8, adding a rib layer and a mortar layer; and 9, laying a wall surface water drain pipe. The metro station deep foundation pit combined type support construction method has the following benefits:the pile top beam and the support beams I are prefabricated according to the design requirements, so that the site construction efficiency is improved, and the project construction period is shortened; in addition, a displacement control body and an expansion filling body are arranged between the connected support beams I to apply jacking pressure to the support beams I and to reduce flexural deflection of the support beams I; and a rib plate and a connecting screw rod I are pre-arranged on the outer side of a support pile reinforcement cage, so that the pulling resistance of the connecting screw rod I is effectively promoted, the construction difficulty of a rear connecting piece is lowered, and the site construction efficiency is improved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Pile foundation hole forming construction process under large-particle-size cobble sandy soil and severe water seepage geological condition

InactiveCN105970918AReduce porosityImprove on-site construction efficiencyBulkheads/pilesSlagSteel bar

The invention discloses a pile foundation hole forming construction process under the large-particle-size cobble sandy soil and severe water seepage geological condition. Holes are formed through a follow-up process that rotary drilling rig drilling is matched with a steel casing. The pile foundation hole forming construction process comprises the specific construction steps that 1, site formation is conducted, specifically, site formation of a pioneer road and site formation within a construction area range are conducted; 2, pile position lofting is conducted, specifically, on the basis of technical disclosure data, surveying and setting out are conducted through a total station, the specific position of a pile is determined, and a marker is made in the center of the pile in the mode of coating a short steel bar with paint; and 3, outer-side steel casing inserting and beating are conducted, specifically, an outer-side steel casing is inserted and beat to the position 4-6 m under the river bed ground with a crawler crane being matched with a hydraulic vibration hammer, the wall thickness of the outer-side steel casing is not less than 10 mm, and the diameter of the outer-side steel casing is 40 cm larger than that of the actual drilled pile. According to the pile foundation hole forming construction process under the large-particle-size cobble sandy soil and severe water seepage geological condition, the problem that drilling is difficult due to the fact that a rotary drilling rig encounters large-particle-size cobbles during construction is solved, the amount of drill slag after the holes are formed is decreased, the problem that the holes are not cleaned thoroughly is solved, accordingly, the drilling time is shortened, and the formed hole quality is improved.

Owner:STEEL STRUCTURE CONSTR CO LTD OF CHINA TIESUU CIVIL ENG GRP

Combined type steel pipe sheet of connection channel at position of joint with main tunnel and construction method

PendingCN108005686AImprove on-site construction efficiencyGuarantee the quality of the projectUnderground chambersTunnel liningBuilding constructionEngineering

The invention discloses a combined type steel pipe sheet of a connection channel at the position of a joint with a main tunnel and a construction method. The connection channel at the position of thejoint with the main tunnel adopts a combined steel pipe sheet, the combined type steel pipe sheet is that each steel pipe sheet is arranged to be two parts according to radian split bodies of the maintunnel at the corresponding circumferential positions, one part is a fixing pipe segment located in the connection channel, and the other part is a temporary pipe segment needing to be dismounted. Dismounting and mounting of the fixing pipe segment and the temporary pipe segment are achieved by utilizing direct bolts. The combined steel pipe sheet is adopted, dismounting and mounting are achievedthrough the direct bolts, cutting at a site is not needed any longer, the on-situ construction efficiency is improved greatly, and it is greatly beneficial for ensuring the project quality.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

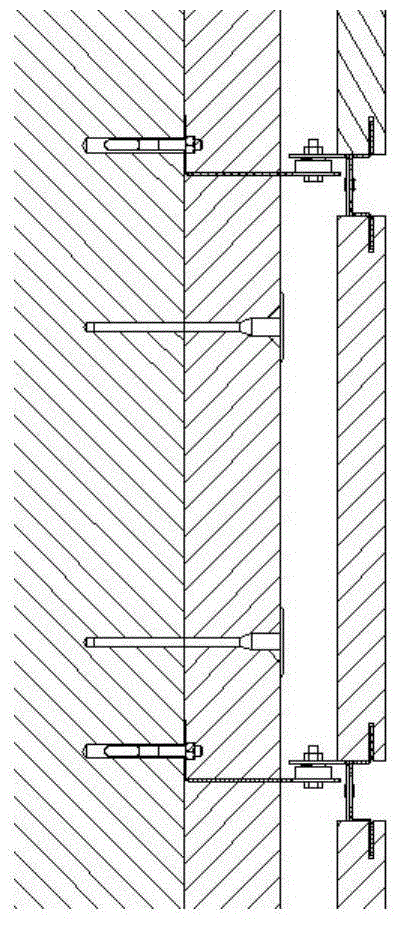

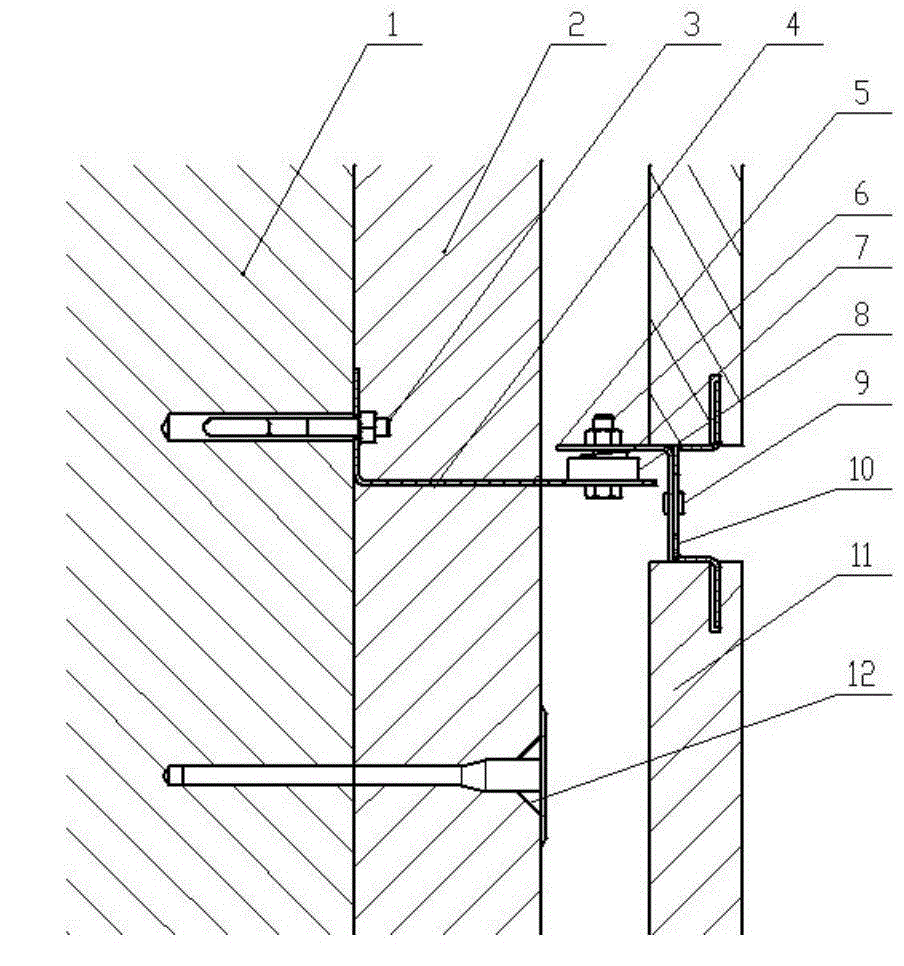

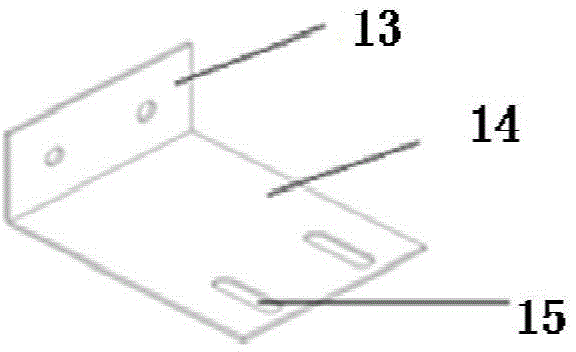

Assembly external wall heat insulation system and assembly method of assembly external wall heat insulation system

ActiveCN104358325AUse lightweightGuaranteed installation locationClimate change adaptationHeat proofingKeelArchitectural engineering

The invention relates to an assembly external wall heat insulation system and an assembly method of the assembly external wall heat insulation system, and belongs to the field of building external wall heat insulation. The assembly external wall heat insulation system mainly comprises a heat insulation material, a support seat, a keel, a wedge-shaped gasket, a heat insulation pad, a panel clamp element and an external wall panel, wherein the heat insulation material is connected to a wall body, the support seat is fixedly arranged on the wall body and is connected with the keel, and the panel clamp element is used for supporting the external wall panel and is connected with the keel. The assembly method comprises the following main steps that the support seat is fixedly arranged on the wall body, then, the heat insulation material is fixedly arranged on the wall body, the keel is fixedly arranged on the support seat, the panel clamp element and the external wall panel are installed, and then, gaps are sealed. The heat insulation material filling mode in the external wall heat insulation system can avoid the negative air pressure effect, the external wall heat insulation system can realize the horizontal, transverse and vertical three-dimensional adjustment in all angles, the panel installation position and the flatness are ensured, the field installation mode is adopted, the field construction efficiency can be improved, and the construction period is shortened.

Owner:BEIJING UNIV OF TECH +1

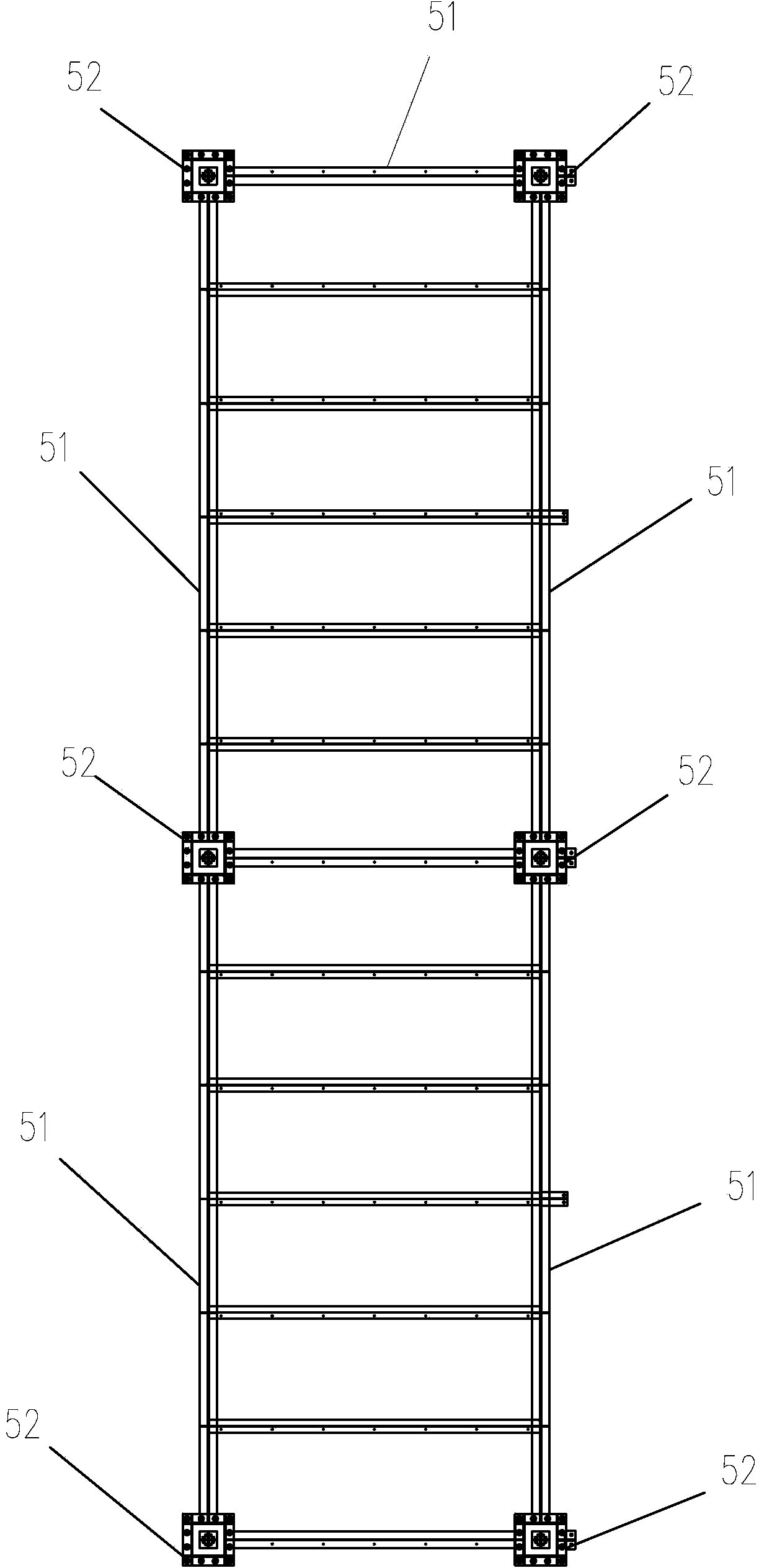

Floor structural modules and assembling method thereof

ActiveCN103993659ARealize industrial productionImprove on-site construction efficiencyBuilding constructionsStructural unitBuilding construction

The invention mainly discloses an assembling method of floor structural modules. Each floor structural module comprises a plurality of main beams, secondary beams and a plurality of box-type components, the main beams are connected to form an outer frame with the box-type components as unit connecting points, and the secondary beams are arranged in the outer frame defined by the main beams. The assembling method includes the steps that first, the structural modules are prefabricated in a factory; second, the finished structural modules are carried to a construction site, and the structural modules and on-site square columns are fast assembled and connected. According to the method, structural units for the floor modules are formed in the factory, welding is reduced, the quality of machining in the factory is improved, and the industrial degree of steel components is improved.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Method for constructing cavity foundation of super high-rise building

ActiveCN103938649ASolve the problem of high heat of hydration and difficult crack controlSimple technologyFoundation engineeringRebarHigh rise

The invention discloses a method for constructing a cavity foundation of an elevator shaft foundation pit of a super high-rise building. According to the method for constructing the cavity foundation of the super high-rise building, slope arrangement and ejector anchor supporting are conducted on the periphery of mass concrete, so that a formwork is formed, a steel channel is arranged on a bed course to serve as a stirrup for supporting, so that it is guaranteed that a steel reinforcement framework does not deform, the size is accurate, concrete pouring construction is conducted twice, a bottom solid base plate is poured when the concrete pouring is conducted for the first time, and a cavity structure is poured when the concrete pouring is conducted for the second time. Heat preservation and maintenance are conducted after the concrete pouring is completed, so that the surface temperature is prevented from falling too quickly, and concrete cracks are prevented. Due to the adoption of the cavity design, the effective section of the concrete can be well reduced, temperature cracks are prevented from being generated, the self weight of the structure is low, the construction period is shortened, and materials are saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

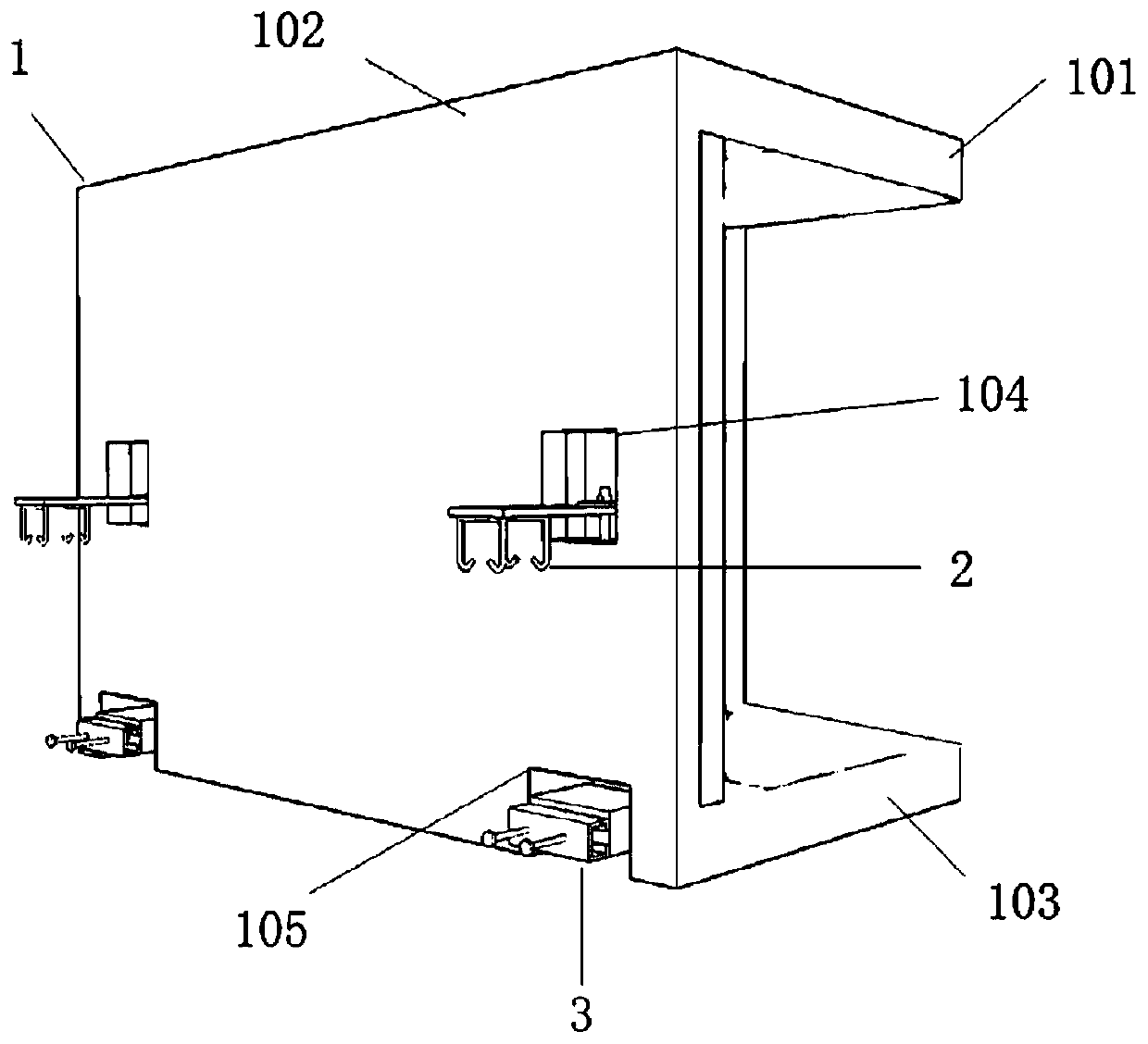

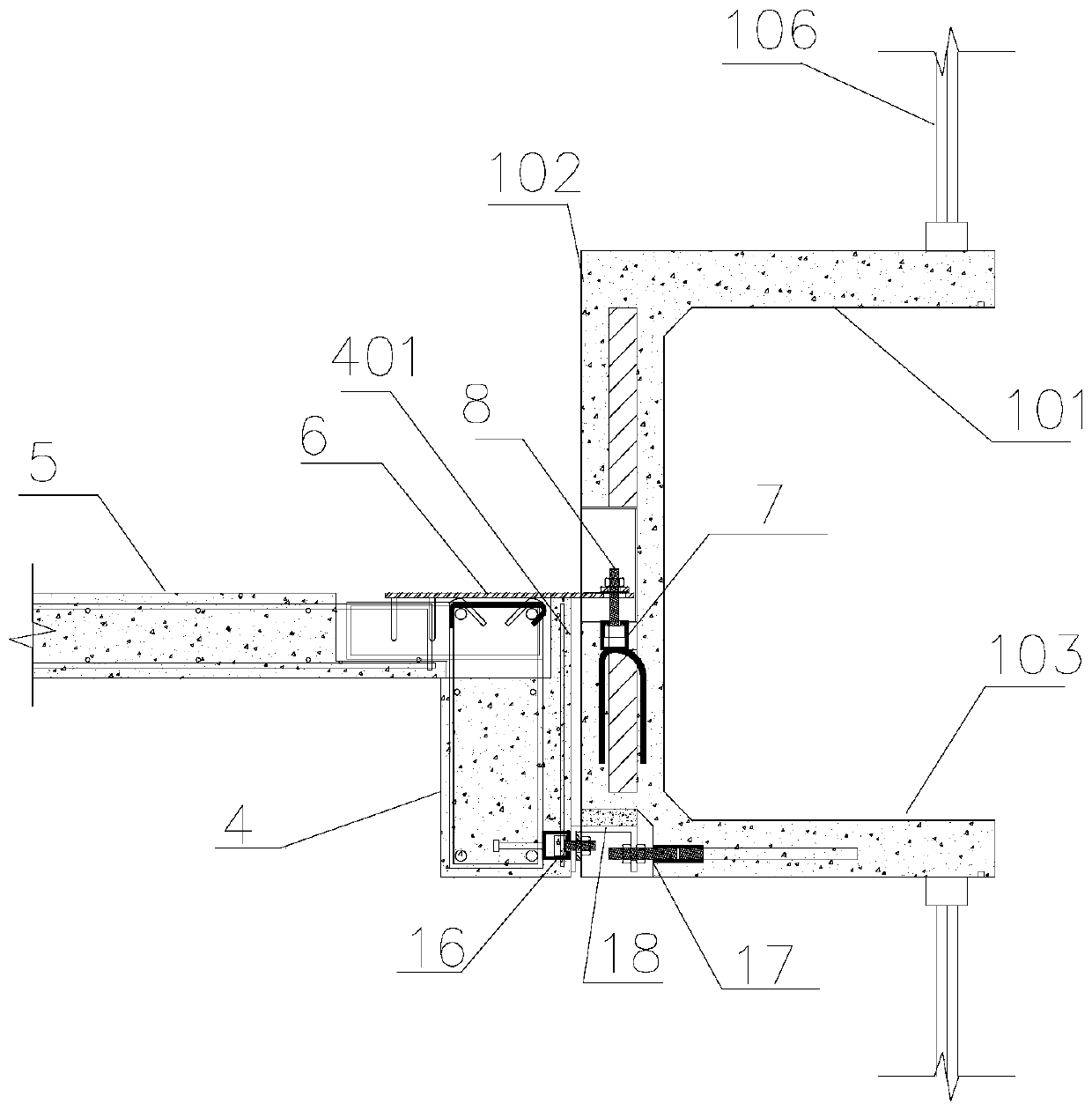

Connection structure for prefabricated integral bay window, and assembling method thereof

The invention provides a connection structure for a prefabricated integral bay window. The connection structure comprises a prefabricated integral bay window and a superposed beam and is characterizedin that the prefabricated integral bay window is integrally poured into a C-similar shape and comprises a top plate, a side wall and a bottom plate; the superposed beam comprises a prefabricated partand a cast-in-place part; the bottom surface of the bottom plate and the bottom surface of the prefabricated part are positioned on the same horizontal plane; the indoor side of the side wall is fixedly connected with the cast-in-place part through an upper connecting component; and the bottom plate is fixedly connected with the prefabricated part through a lower connecting component. When the connection structure for the prefabricated integral bay window in the scheme is produced and manufactured, no reinforcing steel bars extend out of the edge part of the prefabricated integral bay window,a production module is simple, demoulding efficiency is high, and a mould turnover frequency is improved. In a transportation stage, a loading rate can be improved; wet operations in an assembling field are few, form erection is avoided, field construction efficiency is improved, and construction cost is lowered; an error-tolerant rate of field assembling is high, the position of the prefabricated integral bay window can be regulated in field through ways, including gaskets, bolts, mortar, bed mortar and the like, and the connection structure disclosed by the invention is convenient for fieldinstallation and regulation.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

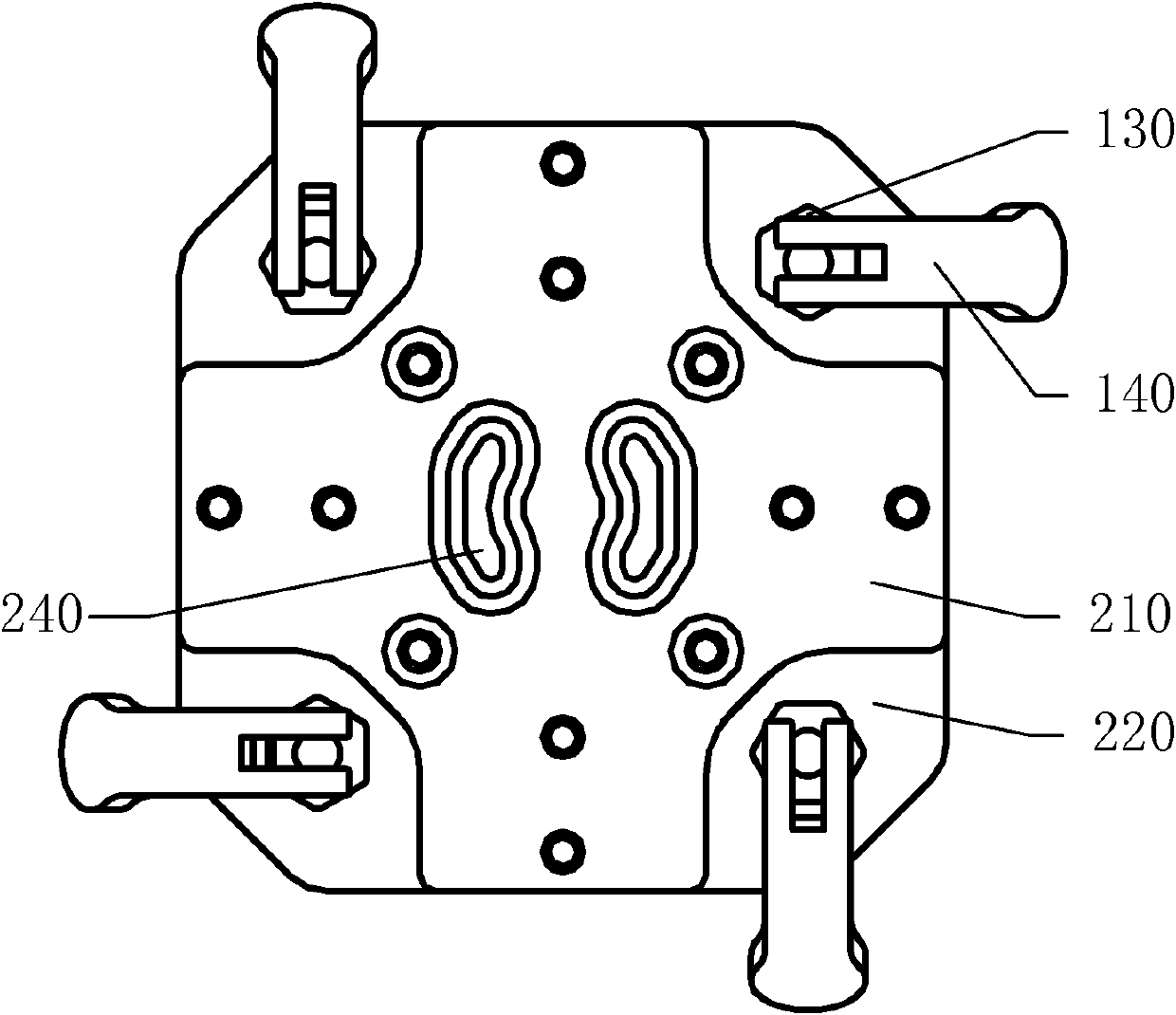

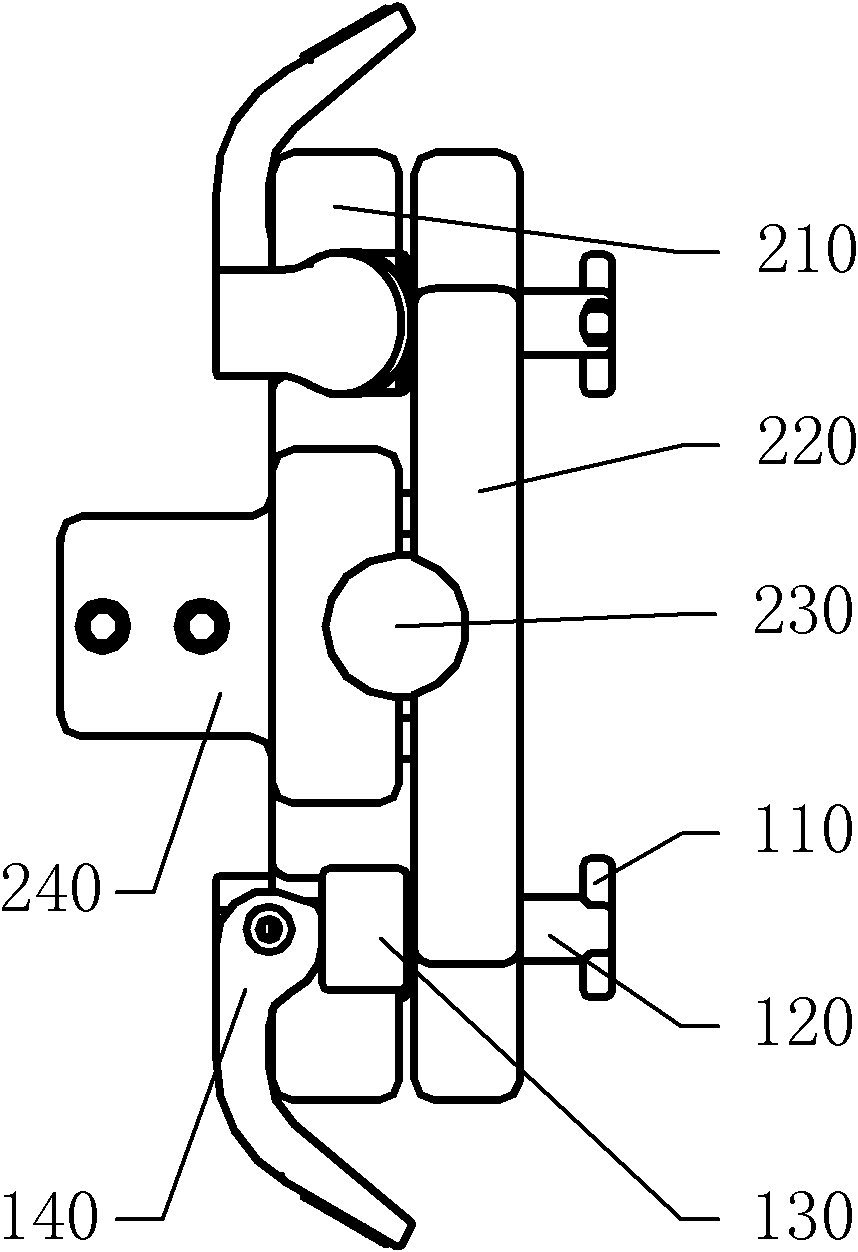

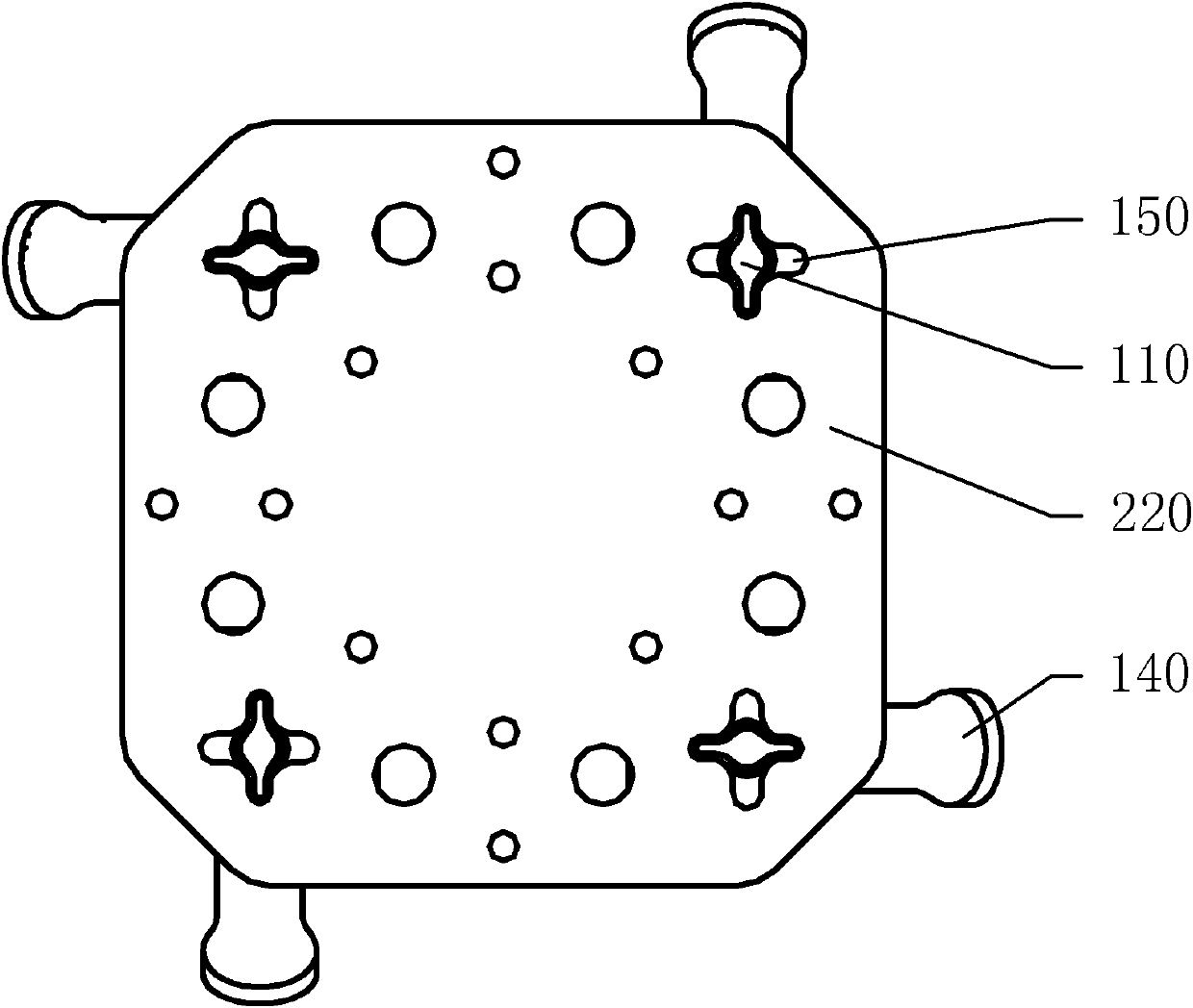

Connecting device

Owner:SHENZHEN APEXLS OPTOELECTRONICS

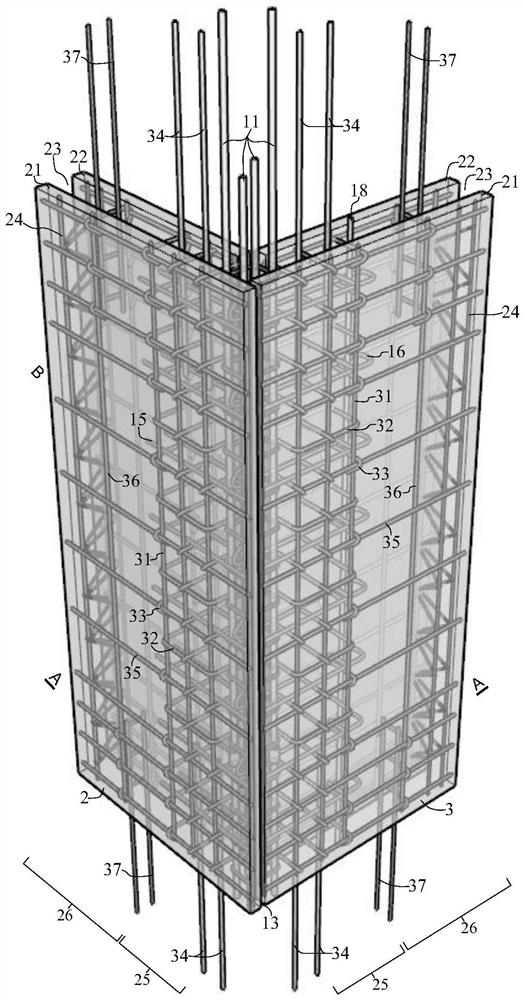

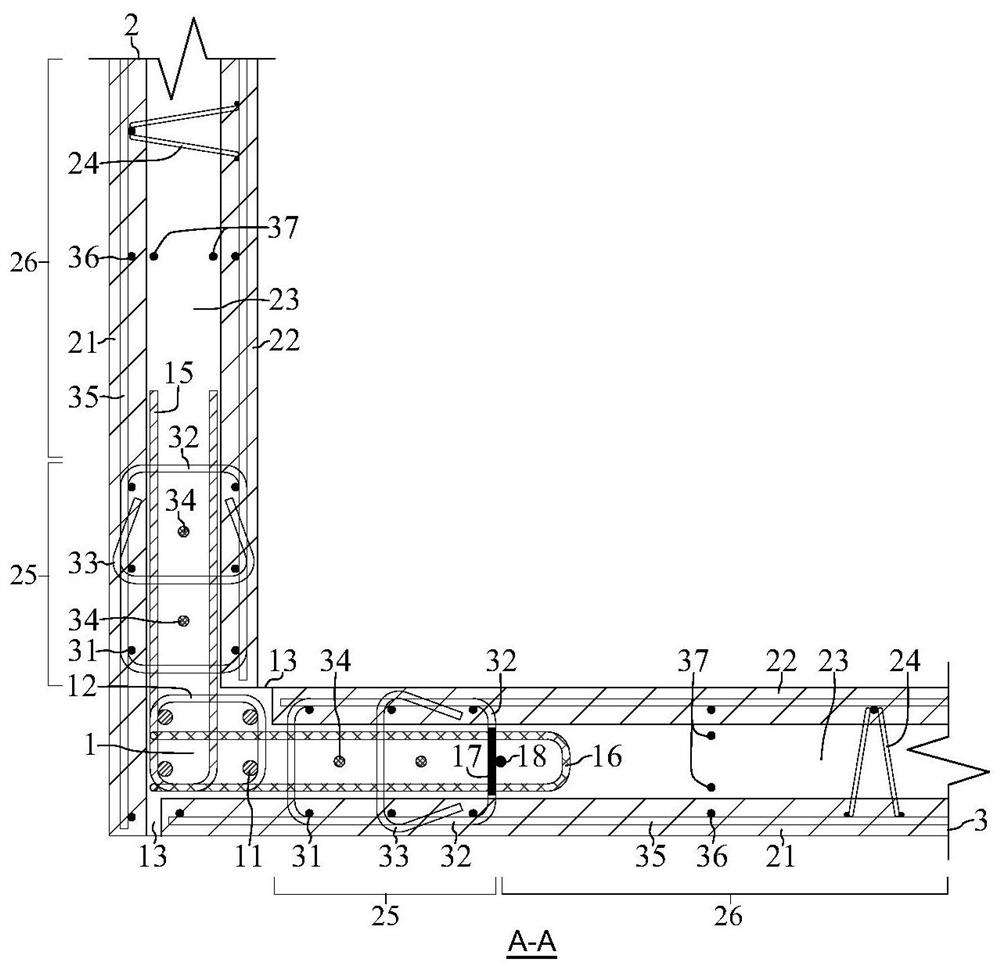

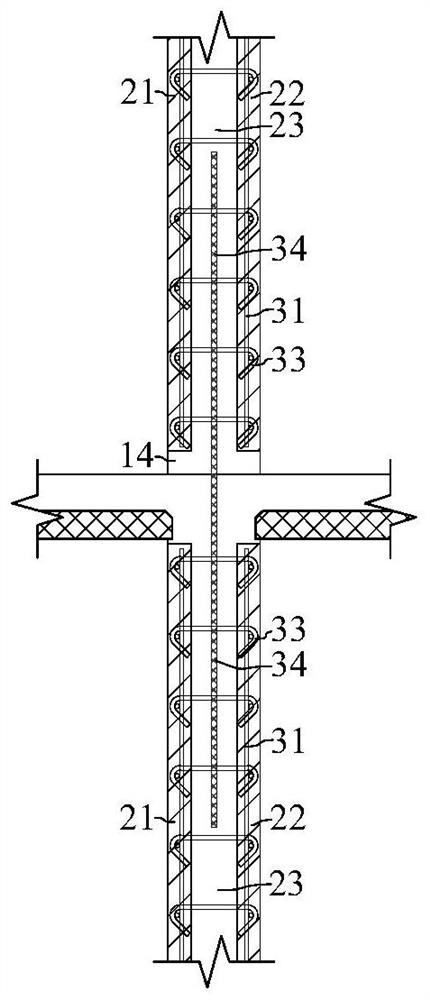

On-site formwork-erecting-free longitudinal and transverse wall connecting structure for superposed shear wall and construction process

PendingCN111691581AImprove on-site construction efficiencySatisfy the requirements of lap force transmissionWallsBuilding reinforcementsArchitectural engineeringLap joint

The invention discloses an on-site formwork-erecting-free longitudinal and transverse wall connecting structure for superposed shear walls and a construction process. Prefabricated concrete wall plates of prefabricated walls extend towards a joint position to form a closed cavity, a vertical post-pouring section is arranged in the closed cavity, horizontal connecting steel bars are arranged in a penetrating mode in advance, the horizontal connecting steel bars in the cavity are integrally moved to a designed position by means of a special shifting rod, and post-pouring concrete is poured to realize connection of the longitudinal and transverse prefabricated walls. According to the on-site formwork-erecting-free longitudinal and transverse wall connecting structure, the construction on-siteformwork-erecting-free of the longitudinal and transverse prefabricated wall connecting joint position vertical post-pouring section of the composite shear wall structure can be achieved, the site construction efficiency can be obviously improved, meanwhile, an edge component area with the stirrup restraining effect basically equal to that of the cast-in-place shear wall can be formed at the connecting joint position, the length of the horizontal connecting steel bars stretching into the cavity of the prefabricated walls can meet the lap joint force transmission requirement, the connecting integrity is high, and the structure is suitable for a high-layer superposed shear wall structure with the high seismic fortification requirement.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

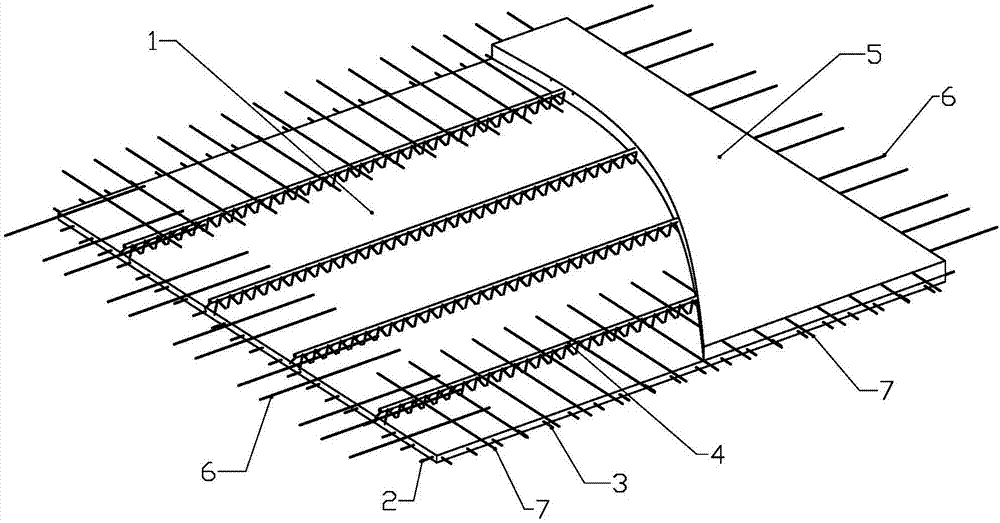

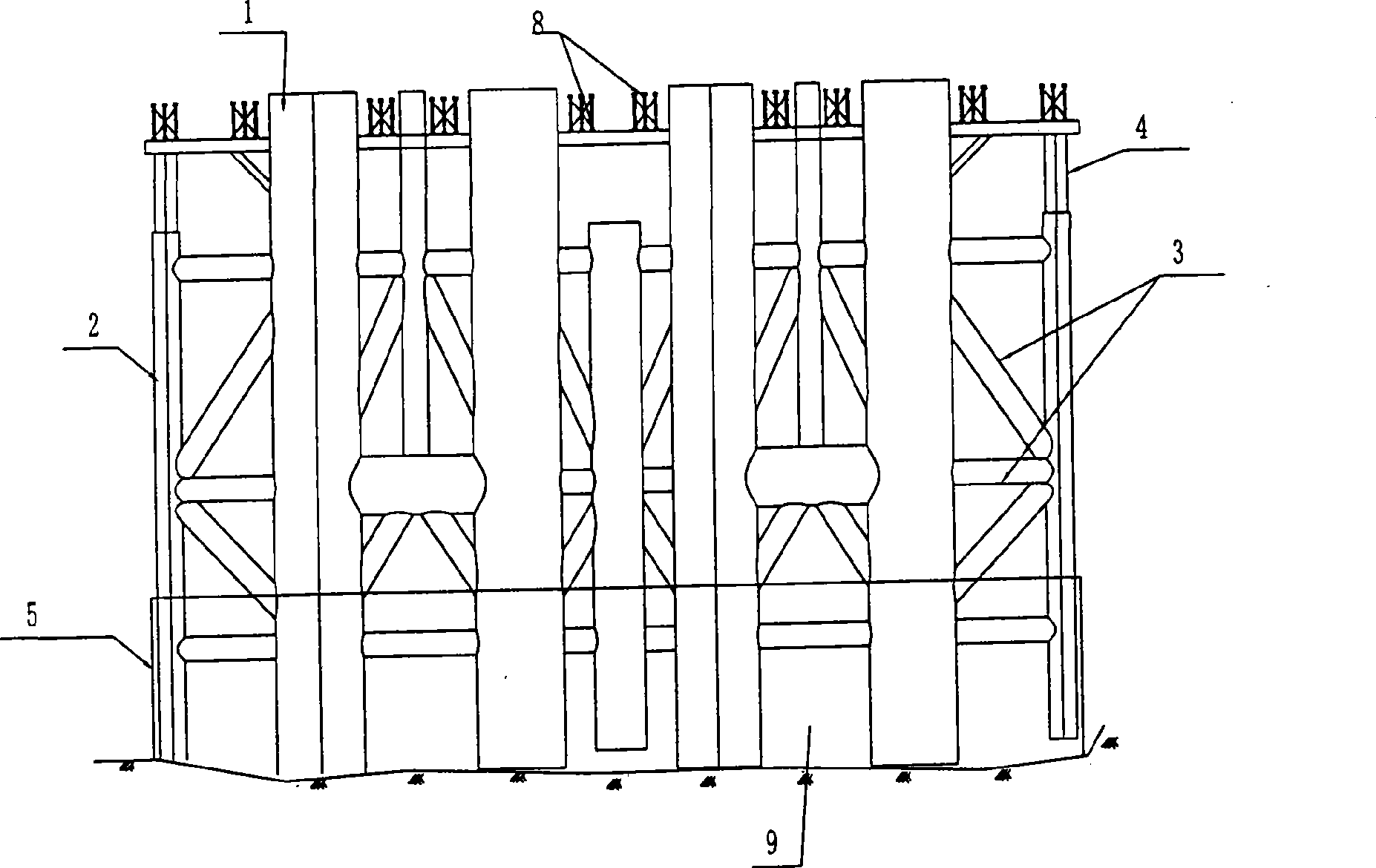

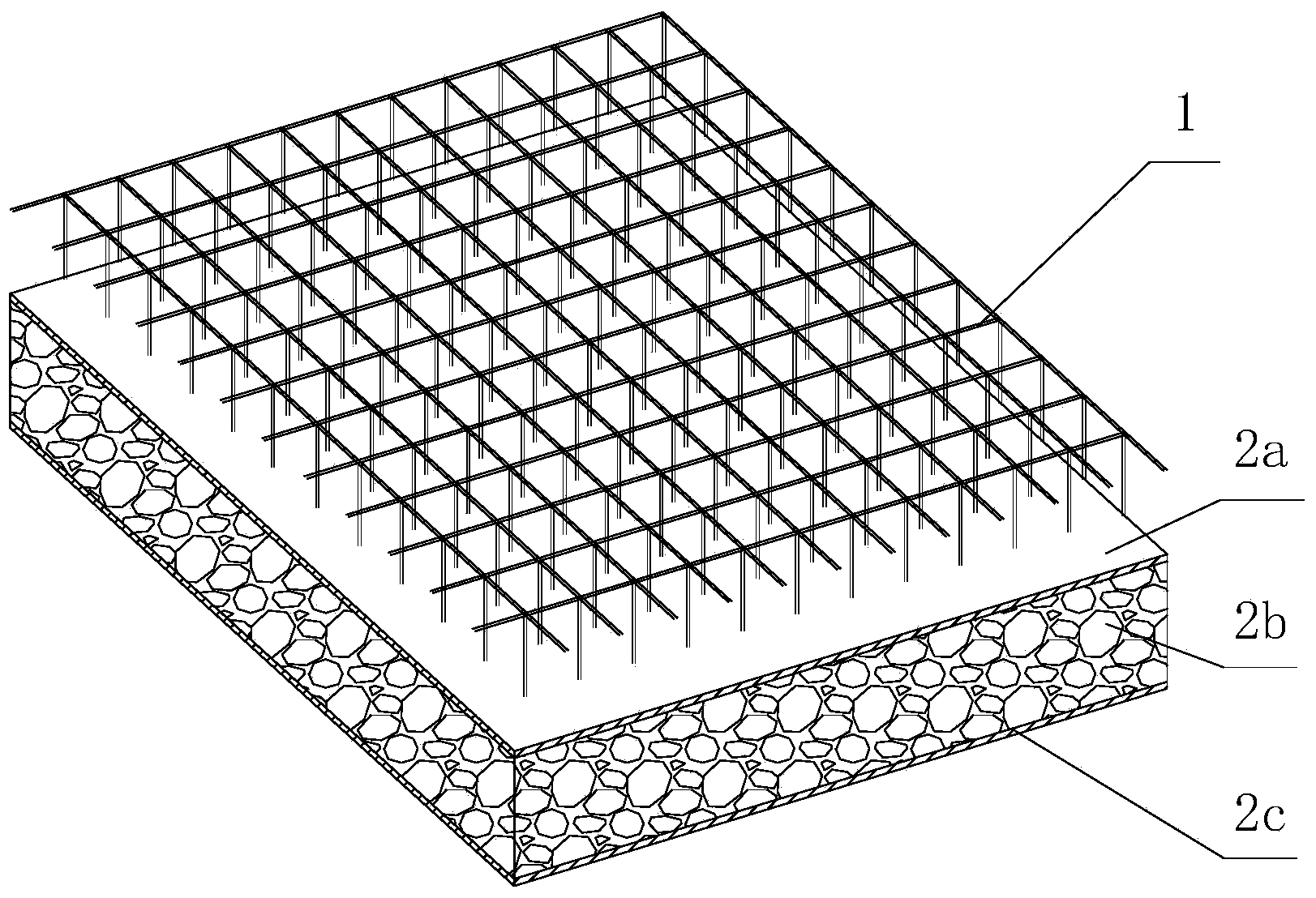

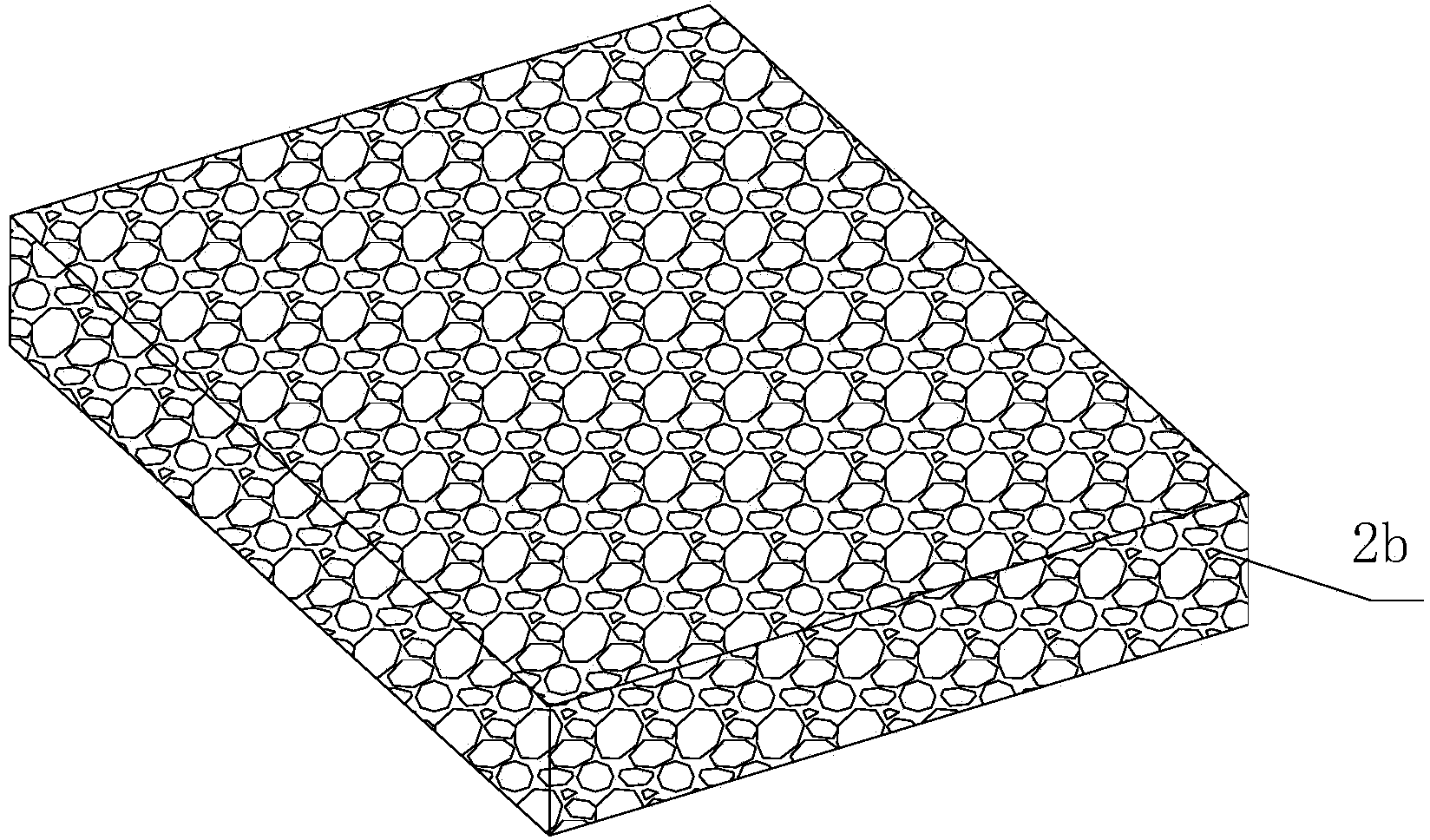

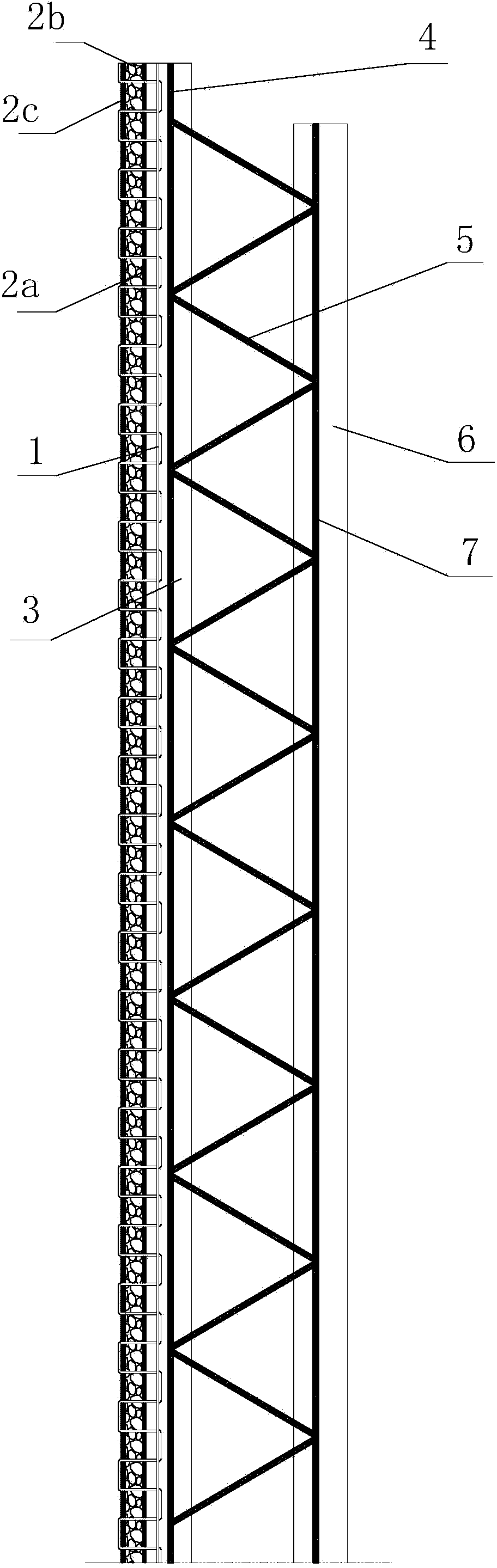

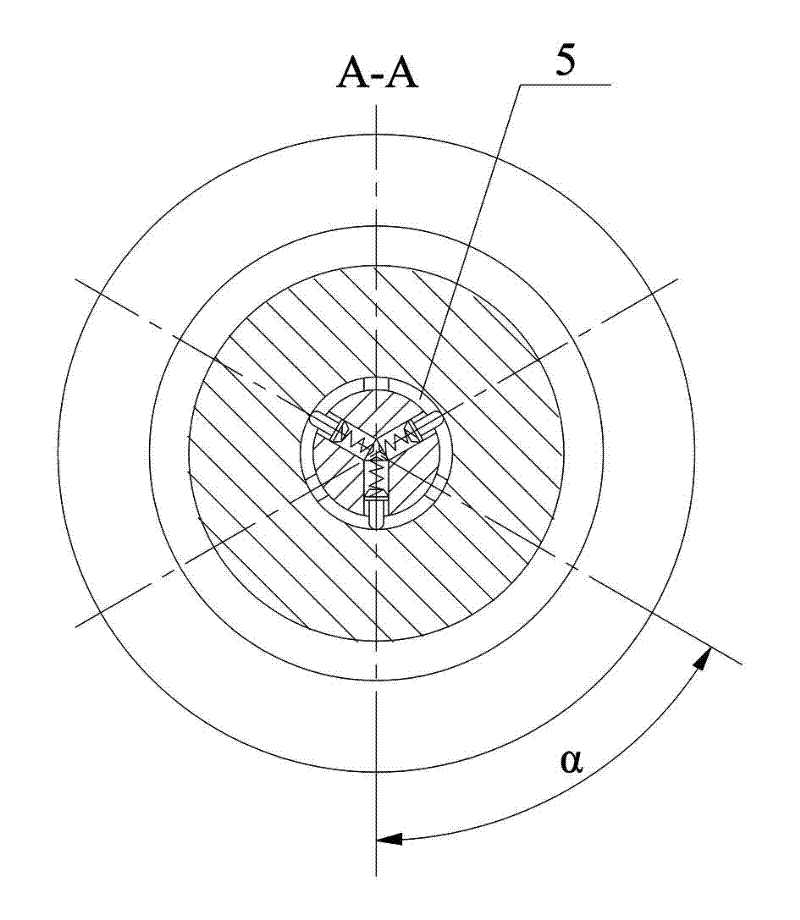

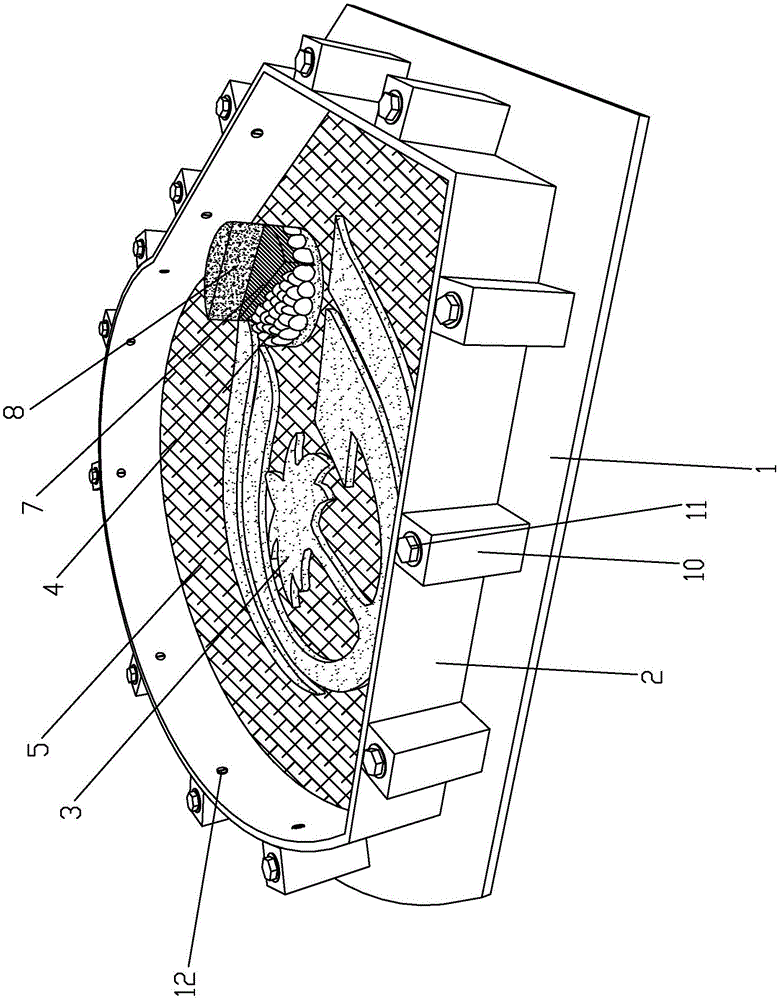

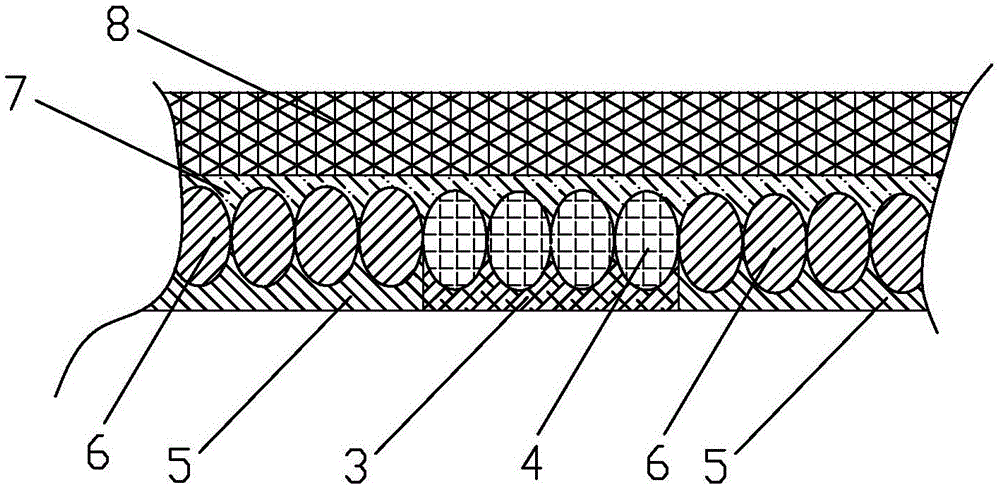

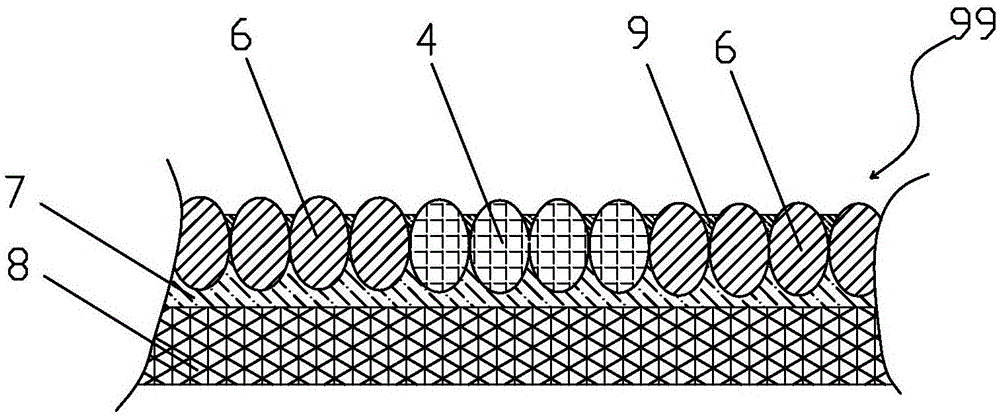

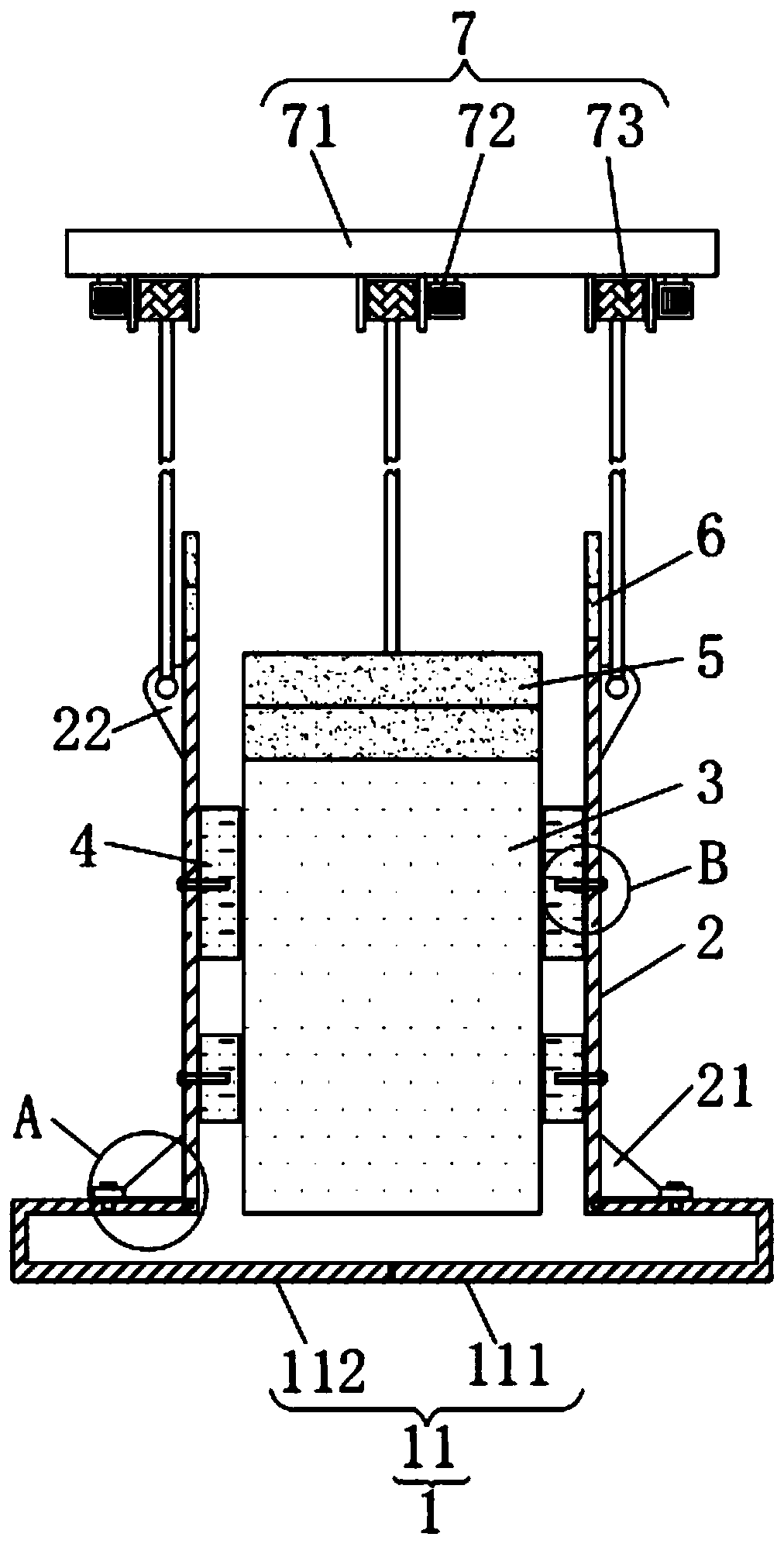

Prefabricated thermal insulation laminated wallboard with spatial three-dimensional structure and manufacturing method of laminated wallboard

ActiveCN104278794AImprove the quality of heat preservation and energy savingSimplify operating proceduresBuilding componentsFiberWater leakage

The invention relates to construction prefabricated members and manufacturing methods thereof and in particular relates to a prefabricated thermal insulation laminated wallboard with a spatial three-dimensional structure. The prefabricated thermal insulation laminated wallboard comprises a thermal insulation body (2) on the outer layer and a prefabricated laminated wall on the inner layer, wherein the thermal insulation body (2) sequentially comprises an inner reinforcing plate (2a), a thermal insulation layer (2b) and an outer reinforcing plate (2c) from interior to exterior; the inner reinforcing plate (2a) is inwards provided with a three-dimensional fiber rod net rack (1) and is embedded into an outer prefabricated layer (3); the prefabricated laminated wallboard consists of the outer prefabricated layer (3), an outer longitudinally and transversely stressed steel bar plane rack (4), lattice reinforcements (5), an inner prefabricated layer (6) and an inner longitudinally and transversely stressed steel bar plane rack (7); a meshed bracing bar (1b) and a planar mesh fabric (1a) are connected to stretch into the inner reinforcing plate (2a) and are repeatedly inserted into the inner reinforcing plate (2a), the thermal insulation layer (2b) and the outer reinforcing plate (2c) in a large scale; and the thermal insulation layer and the structural layer are connected together through a three-dimensional space structure. The problems of cracks and water leakage of the thermal insulation system are solved, the energy-saving effect is good, the service life of the insulation board is prolonged, and the problem that the outer thermal insulation layer of the outer wall needs to be frequently maintained and replaced is solved.

Owner:BAOYE GROUP CO LTD +1

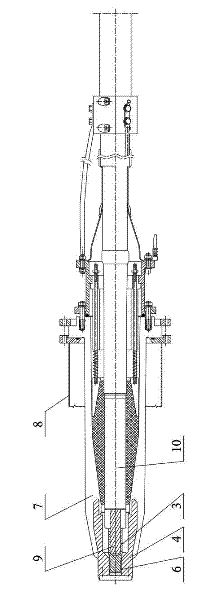

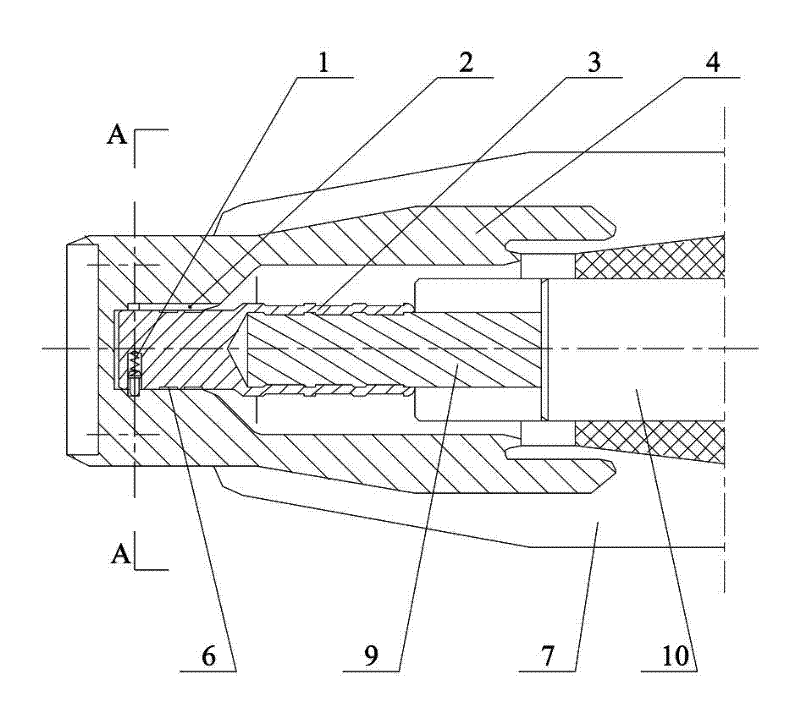

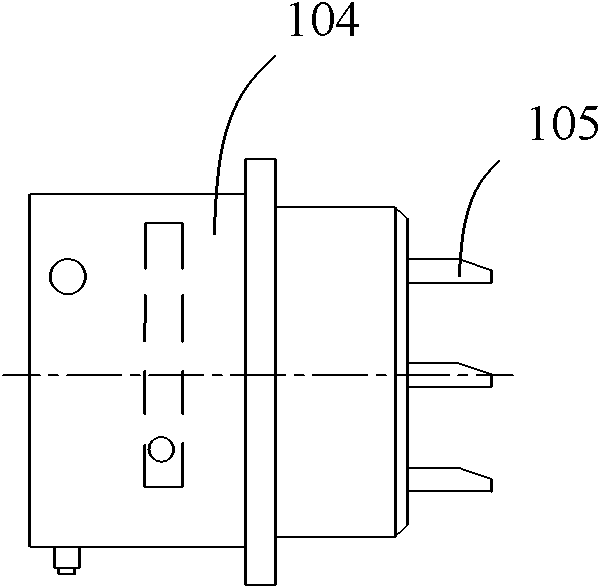

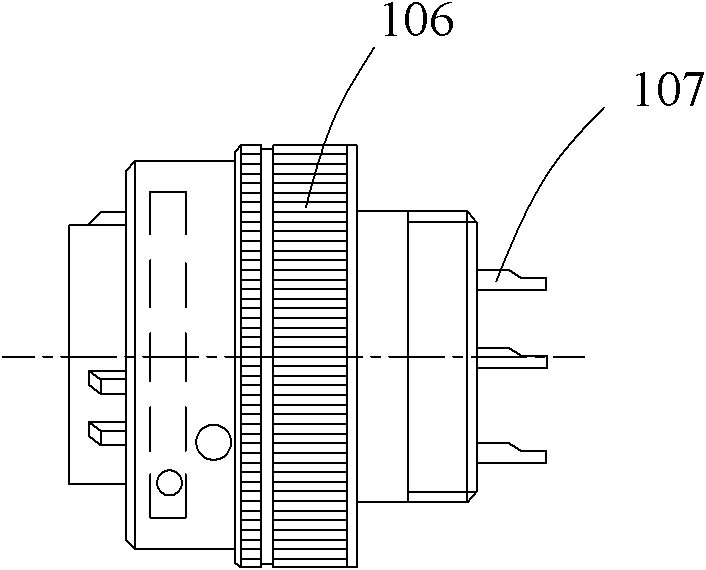

High-voltage gas immersed termination mounting and positioning structure

ActiveCN102231488ARealize the plug-in functionPrecise positioningSwitchgear arrangementsEpoxyEngineering

The invention discloses a high-voltage gas immersed termination mounting and positioning structure. A pluggable high-voltage gas immersed termination (GIS) comprises a high-voltage cable, an epoxy sleeve, an inner insulator and a plugging and unplugging mechanism. The structure is characterized in that: three groups of sliding pins and springs are radially uniformly distributed on the end part of a moving contact in the plugging and unplugging mechanism; three sliding chutes are axially formed on the inner hole sidewall of an upper electrode of the epoxy sleeve; the roots of the three sliding chutes are radially provided with a positioning groove respectively; and the three groups of sliding pins and springs of the end part of the moving contact are assembled, disassembled, moved and positioned by the three corresponding sliding chutes and the corresponding positioning grooves. The structure realizes the function of plugging and unplugging the cable relative to the epoxy sleeve, improves the positioning accuracy of the cable, simplifies a mounting process and improves the construction efficiency.

Owner:上海三原电缆附件有限公司

Prefabricating and mounting method for pebble-pattern prefabricated slab

ActiveCN105088914APavement quality is stableGuaranteed accurate textureSingle unit pavingsSidewalk pavingsEngineeringCement paste

The invention discloses a prefabricating and mounting method for a pebble-pattern prefabricated slab. The method comprises the steps that a bottom plate and a prefabricated frame with the area not larger than 1m<2> are made; graph paper is printed and is fixed to the bottom plate; the prefabricated frame is mounted on the bottom plate and surrounds the graph paper; a figure river sand layer is laid on graph paper figures; figure pebbles are laid on the figure river sand layer; a bottom river sand layer is laid on the non-figure position of the graph paper; bottom pebbles are laid on the bottom river sand layer; unqualified pebbles are replaced; a cement paste sticking layer is laid on the pebble layer; a concrete cushion is laid on the cement paste sticking layer; after the concrete cushion is cured, the prefabricated frame is removed, and 180-degree turning is carried out; the figure river sand layer and the bottom river sand layer are swept out; a cement mortar layer is brushed on the pebble layer; the pebble layer protrudes out of the cement mortar layer by 8mm to 10mm; a concrete base layer is laid; the cement mortar layer is laid on the concrete base layer; and multiple pebble-pattern prefabricated slabs are put on the cement mortar layer; and the pebble-pattern prefabricated slabs are jointed. The site operation efficiency is high, and the quality is stable.

Owner:PALM ECO TOWN DEV CO LTD

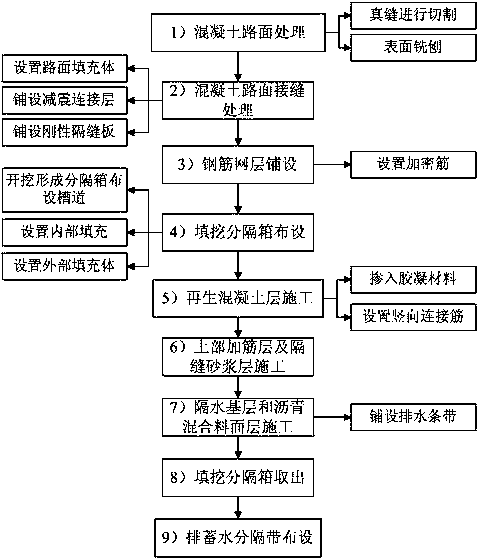

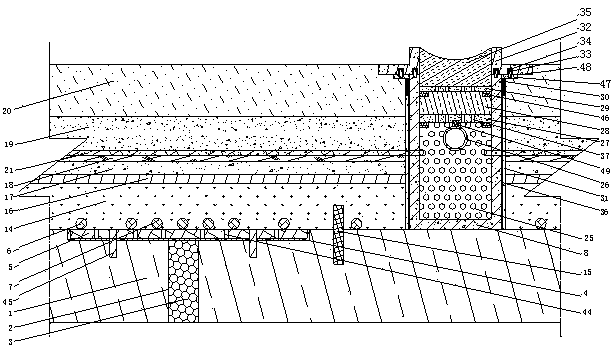

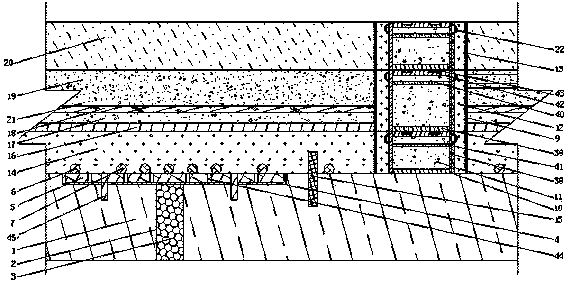

Green upgrading structure of concrete pavement and a reconstruction method thereof

ActiveCN109024135ATake advantage ofSave construction resourcesIn situ pavingsSurface layerReconstruction method

The invention provides a green upgrading structure of concrete pavement and a reconstruction method thereof. The A reconstruction method comprises the following steps: concrete pavement treatment, concrete pavement joint treatment, reinforcing bar mesh layer laying, filling and excavating partition box laying, recycling concrete layer construction, upper reinforcement layer and partition mortar layer construction, water-proof base layer and asphalt mixture surface layer construction, filling and excavating partition box taking out and draining and storing water partition belt laying. The method provided by the invention realizes the full utilization of the milling material of the concrete pavement and saves the building resources. At the same time, in order to prevent the crack from reflecting, the upper reinforced layer and the spacer mortar layer can effectively prevent the crack from blocking the reflection channel and enhance the integrity of the pavement structure. It reduces thedifficulty of setting up the water drainage and storage partition belt in the later period and improves the compaction effect of the pavement structure. The utility model meets the needs of storing and utilizing rainwater, greening construction of partition belt and assembling installation of curb stone, and effectively improves the construction efficiency on site.

Owner:JIANGXI BOHUI ENG TECH SERVICE CO LTD

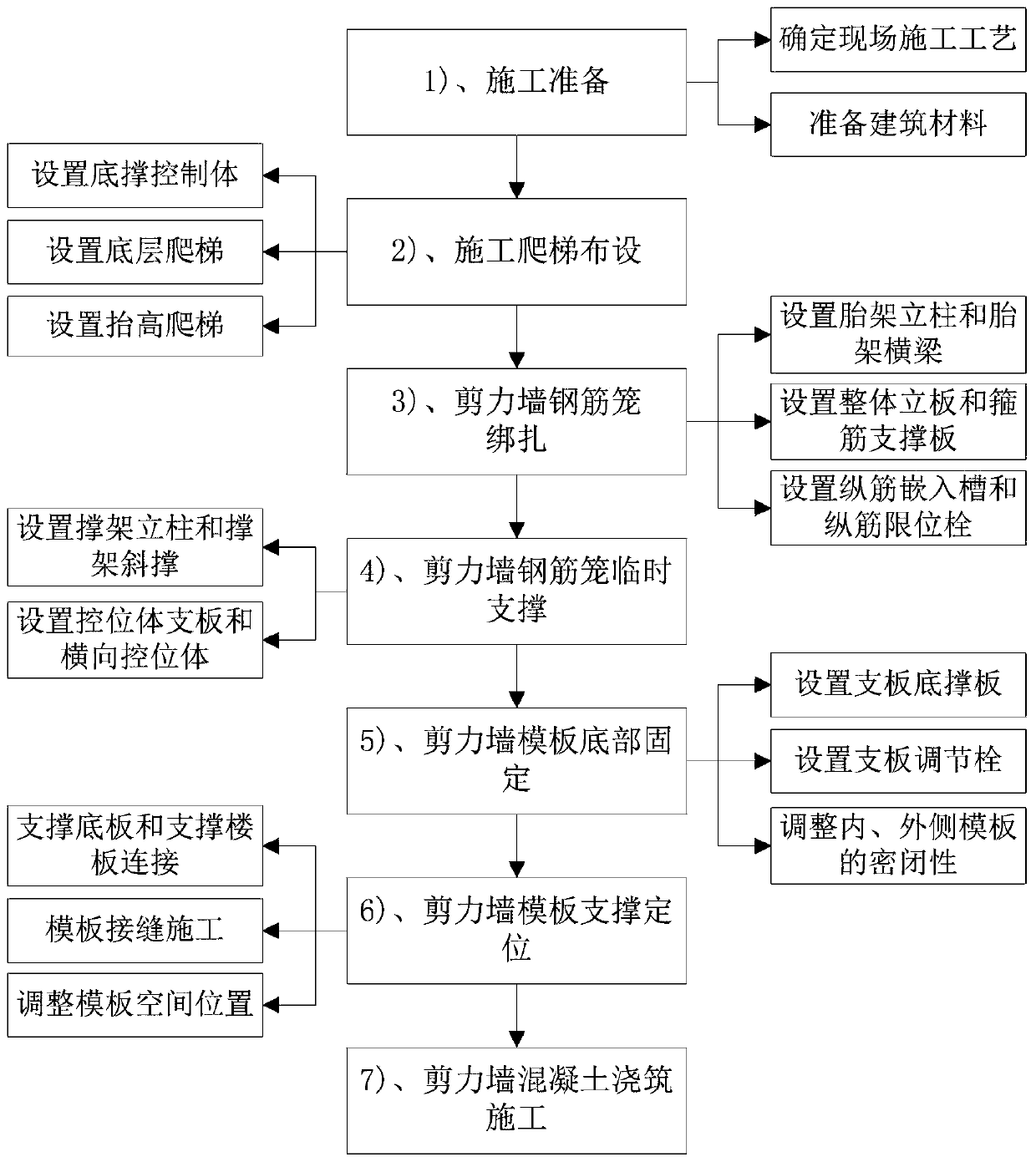

One-piece large template shear wall and construction method

ActiveCN110409670AImprove stabilityExpand the scope of application of the projectWallsForms/shuttering/falseworksShear wall

The invention relates to a one-piece large template shear wall and a construction method. A bottom support adjusting body is arranged between a bottom support baffle and a bottom support control body;an elevated bottom plate is arranged on an elevated support beam, and an elevated ladder and an elevated supporting column are arranged on the elevated bottom plate; the vertical position of a stirrup supporting plate is controlled through a vertical plate limiting plate, and vertical longitudinal ribs are tightly connected to a longitudinal rib limiting plate through a longitudinal rib baffle; the stiffness of the vertical longitudinal ribs is improved through a control body supporting plate; the verticality of inner and outer templates is corrected by supporting plate adjusting bolts, and the tightness between the inner and outer templates and a supporting slab is adjusted by pressing rod squeezing bolts; template corner beads are arranged at the bottom ends of the inner and outer templates, and connecting square strips are arranged at vertical joints; and the vertical position of a support frame column is controlled by a unit support body, and the spatial position of the inner template is controlled by a frame plate positioning rod and a support frame plate. The one-piece large template shear wall and the construction method can improve the binding quality of a reinforcing cageand reduce the supporting and positioning difficulty of the templates.

Owner:华神建设集团有限公司

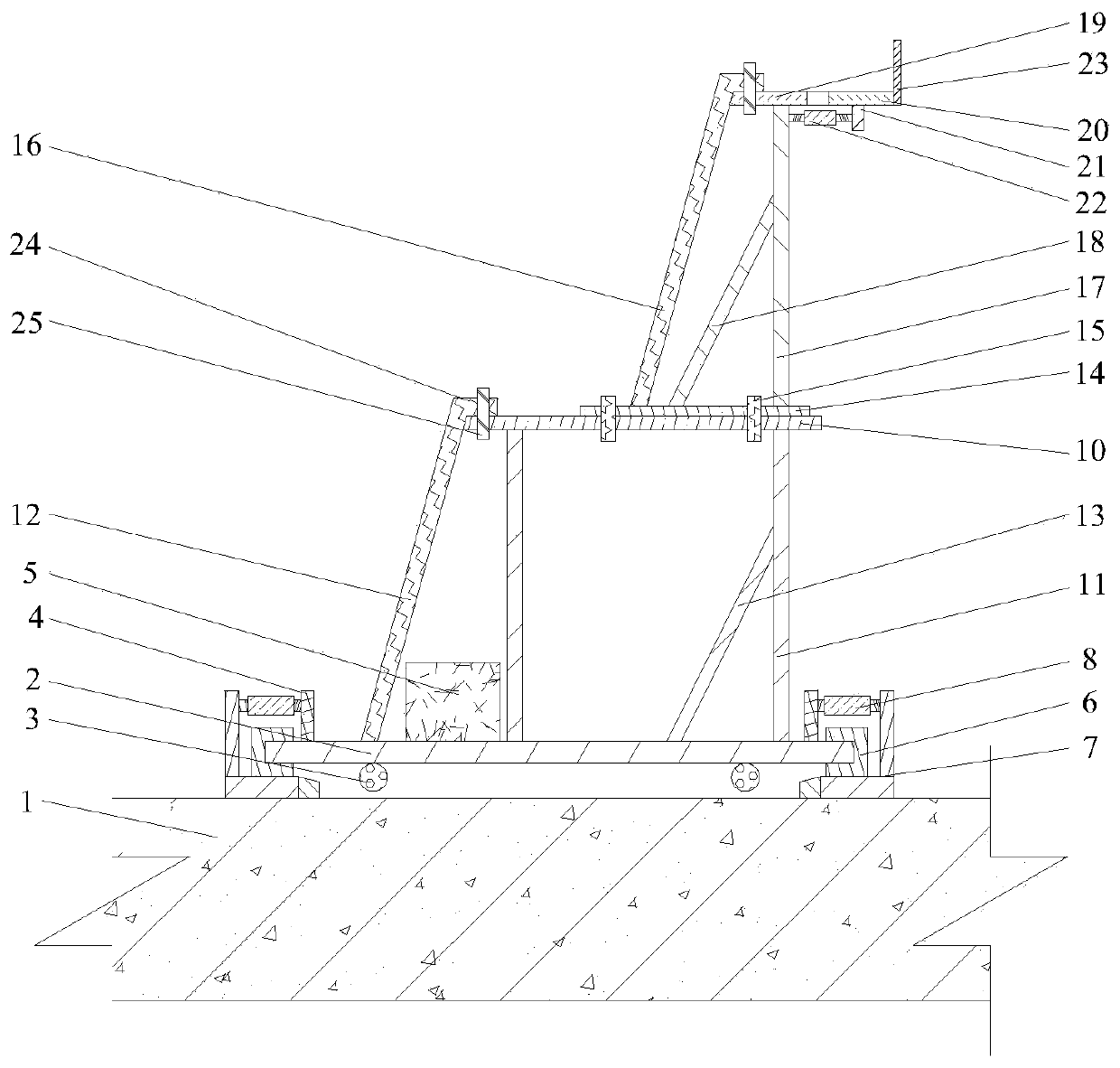

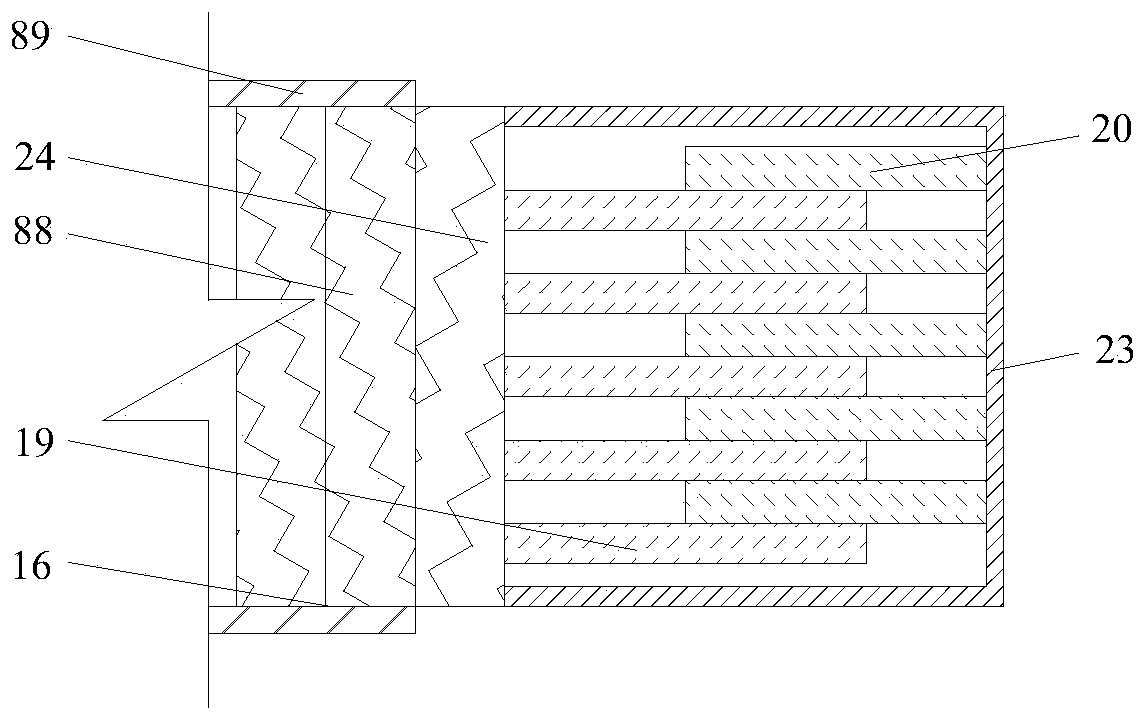

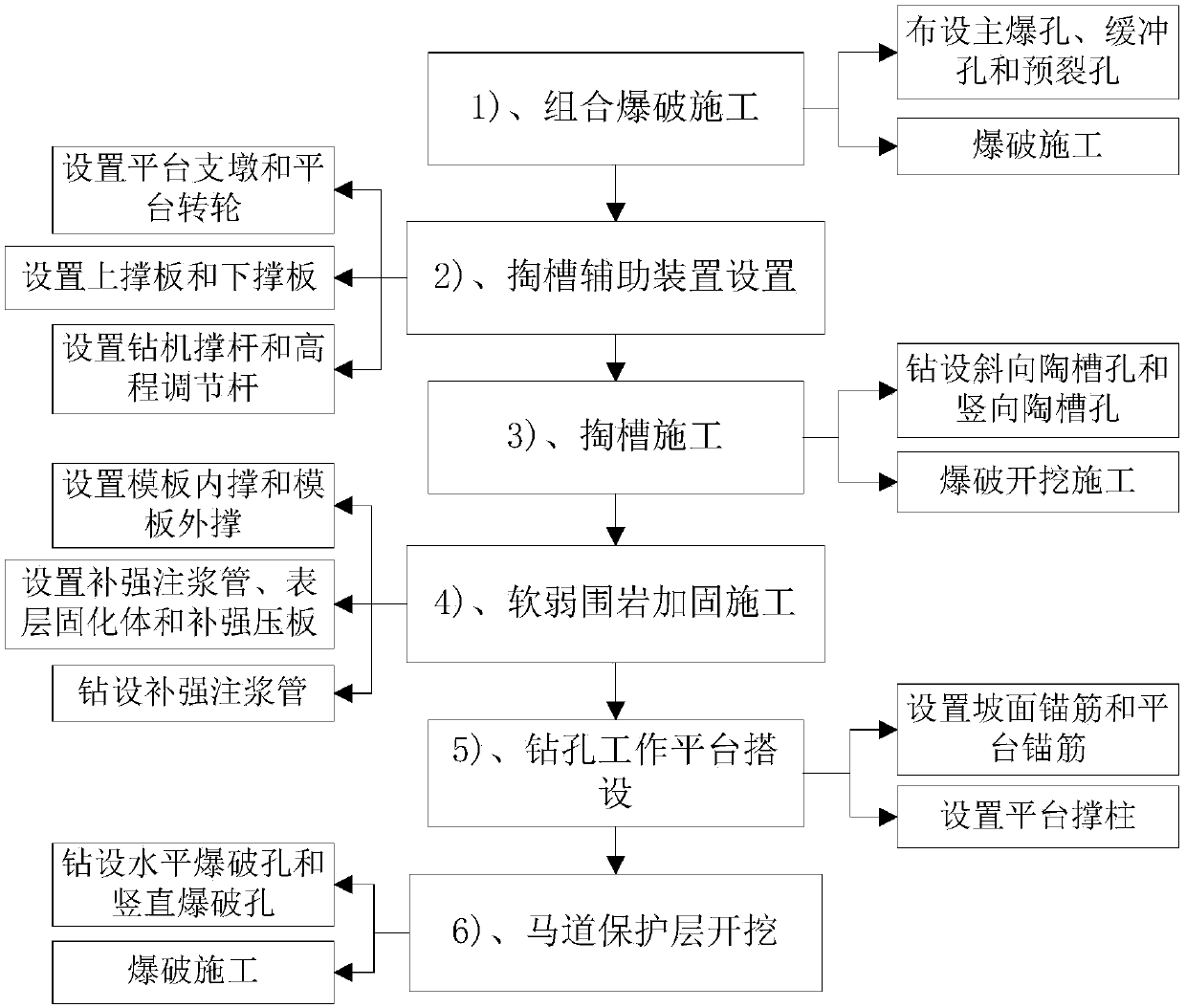

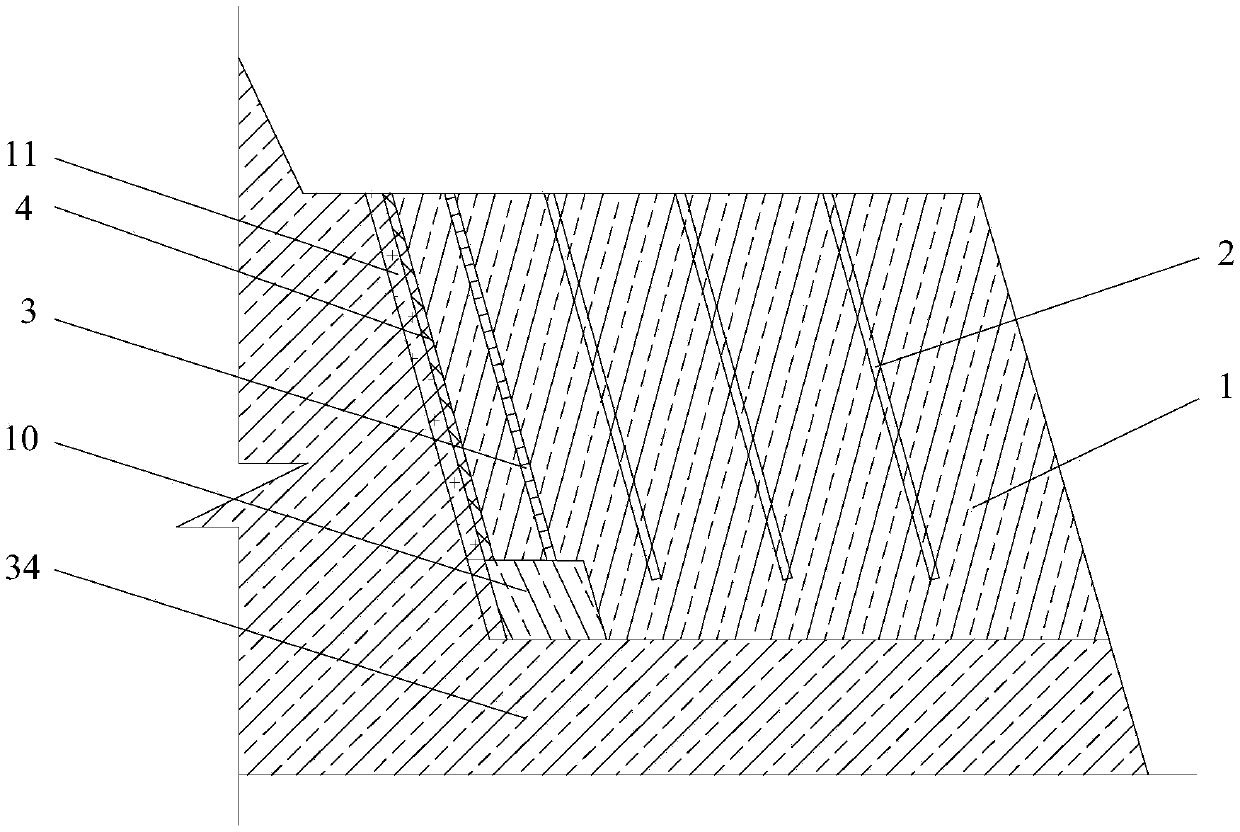

Construction method of foundation pit digging system

ActiveCN109577338AAccurately control the scope of constructionImprove construction qualityBlastingExcavationsStress conditionsProtection layer

The invention relates to a construction method of a foundation pit digging system. The method includes the steps: 1) combined blasting construction; 2) cutting auxiliary device arrangement; 3) cuttingconstruction; 4) weak surrounding rock reinforcement construction; 5) drilling platform erecting; 6) riding track protection layer digging. The construction method has the advantages that inclined cutting holes are radially formed, cutting construction ranges can be accurately controlled, cutting construction quality is improved, positioning strip plates enclose storage cavities of water bags, explosive and stemming, horizontal dividing plates and positioning hoop plates are arranged at boundaries of different materials, blasting material positioning and arranging difficulty can be reduced,onsite construction efficiency is improved, reinforcement grouting pipes, surface curing bodies and reinforcement pressing plates are arranged at weak surrounding rocks, the integrality of the weak surrounding rocks can be enhanced from multiple angles, and stress conditions of a slope structure are improved.

Owner:中建八局华南建设有限公司

Power station generating set oil groove signal extension apparatus

InactiveCN102255419AAchieving pressure resistanceAchieve impact resistanceSupports/enclosures/casingsInterior spacePower station

The invention relates to a power station generating set oil groove signal extension apparatus which comprises a pedestal and a panel. The pedestal and the panel are in sealed connection to form internal space. A central section of the pedestal extends a conduit which communicates with the internal space. An end of the conduit is in threaded connection with a first cable jacket. The panel is provided with a plurality of second cable jackets. A plurality of signal cables fixed by the first cable jacket go through the conduit and the internal space, and go out from the second cable jackets. The signal lead out apparatus of the present invention has the advantages of novel design, vibration proof, impact resistance, high grade of sealing pressure, high reliability, reduction of interference to an oil groove sensor signal by electromagnetic field, reduction of site construction difficulty, improvement of site construction efficiency and cost saving. Thereby, the signal extension apparatus of the present invention is especially suitable for extension of a power station generating set large bearing oil groove sensor signal.

Owner:SHENZHEN TESTECK TECH

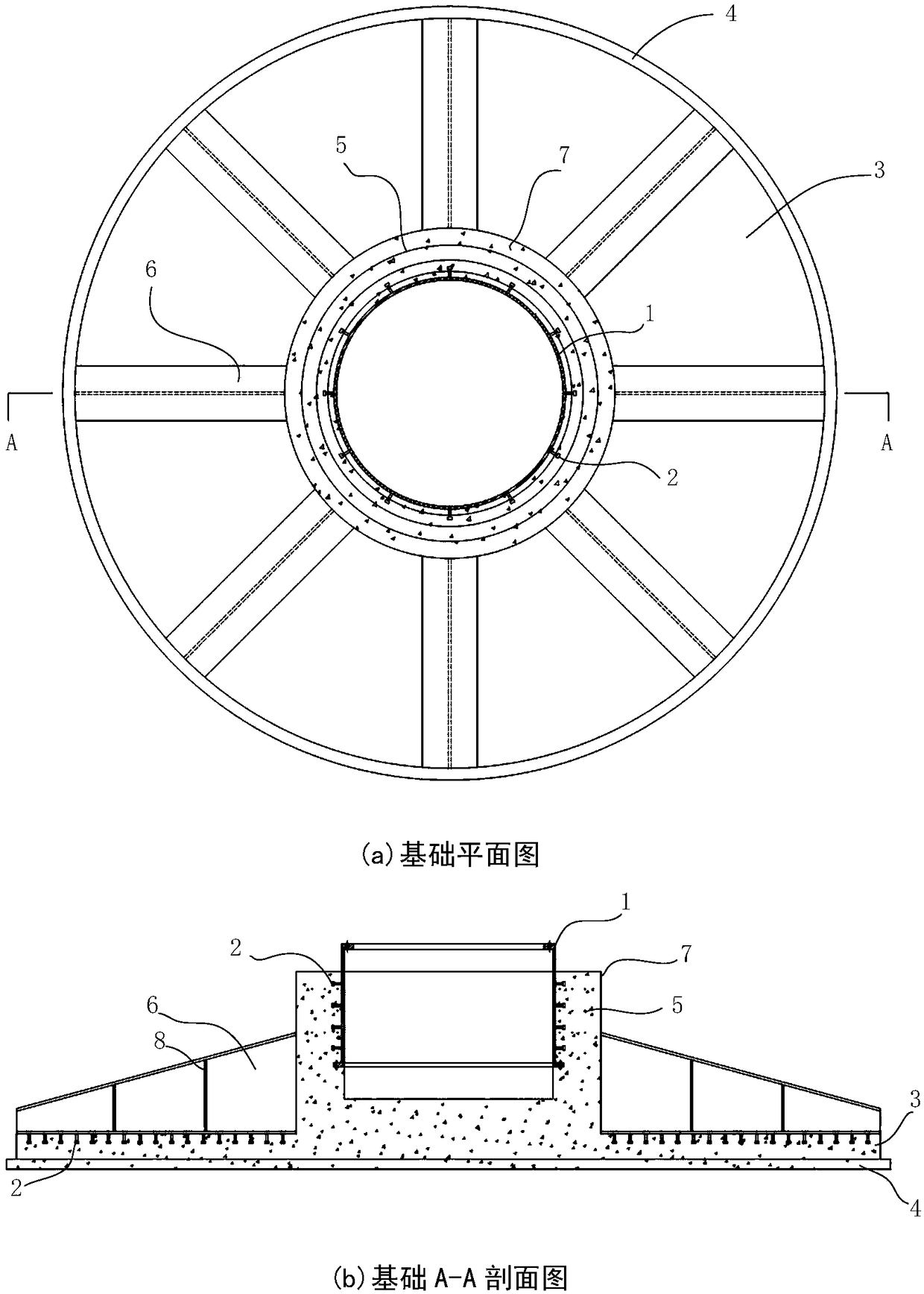

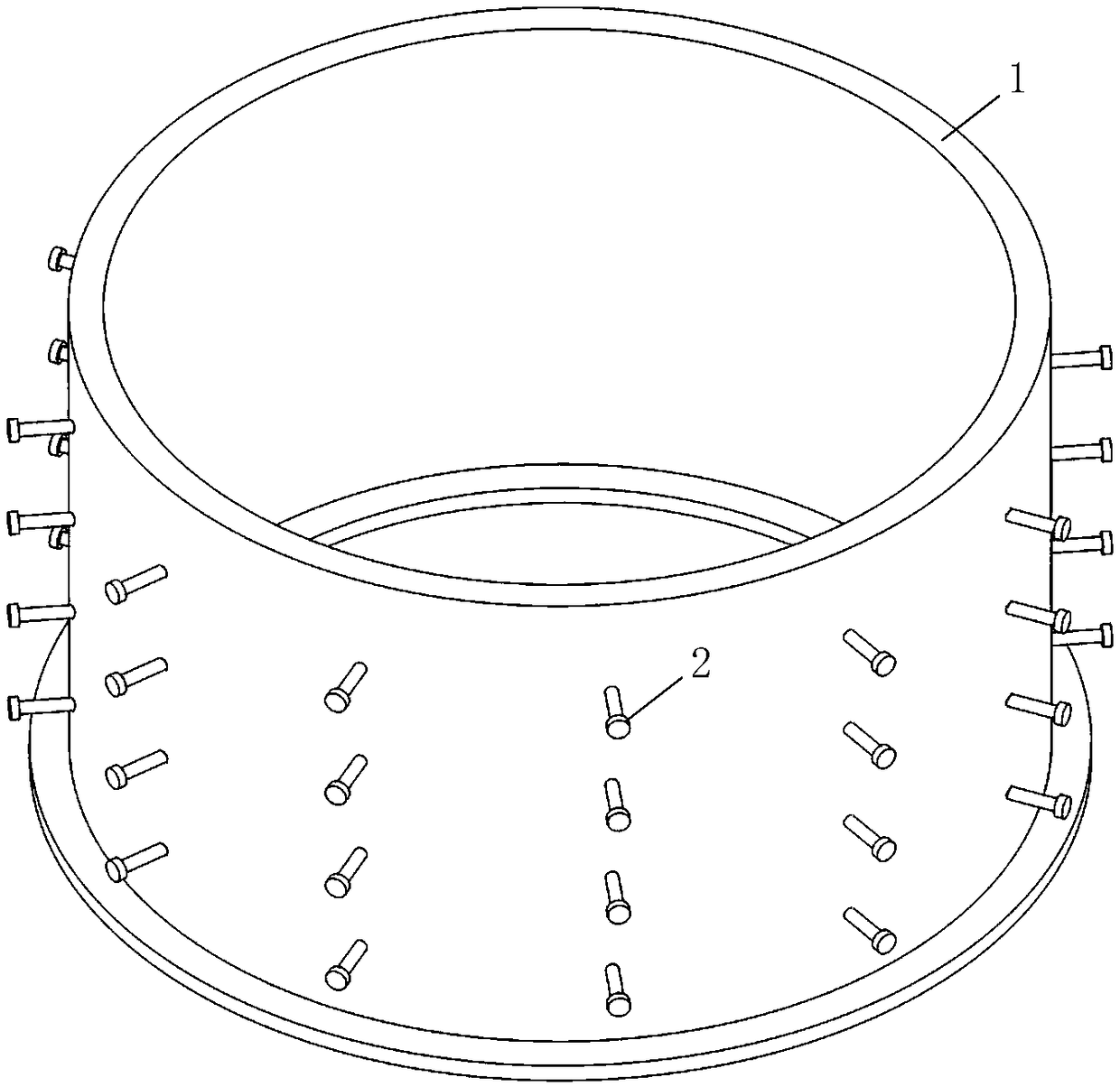

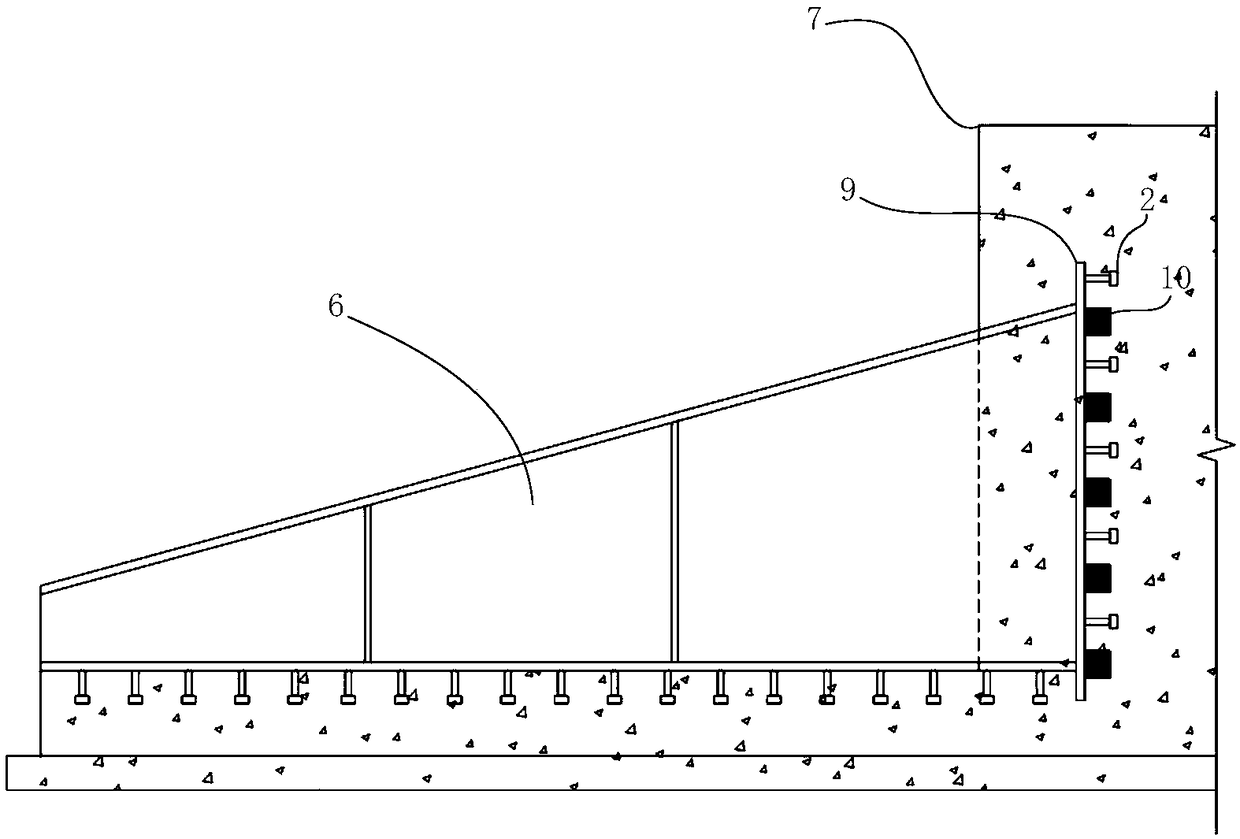

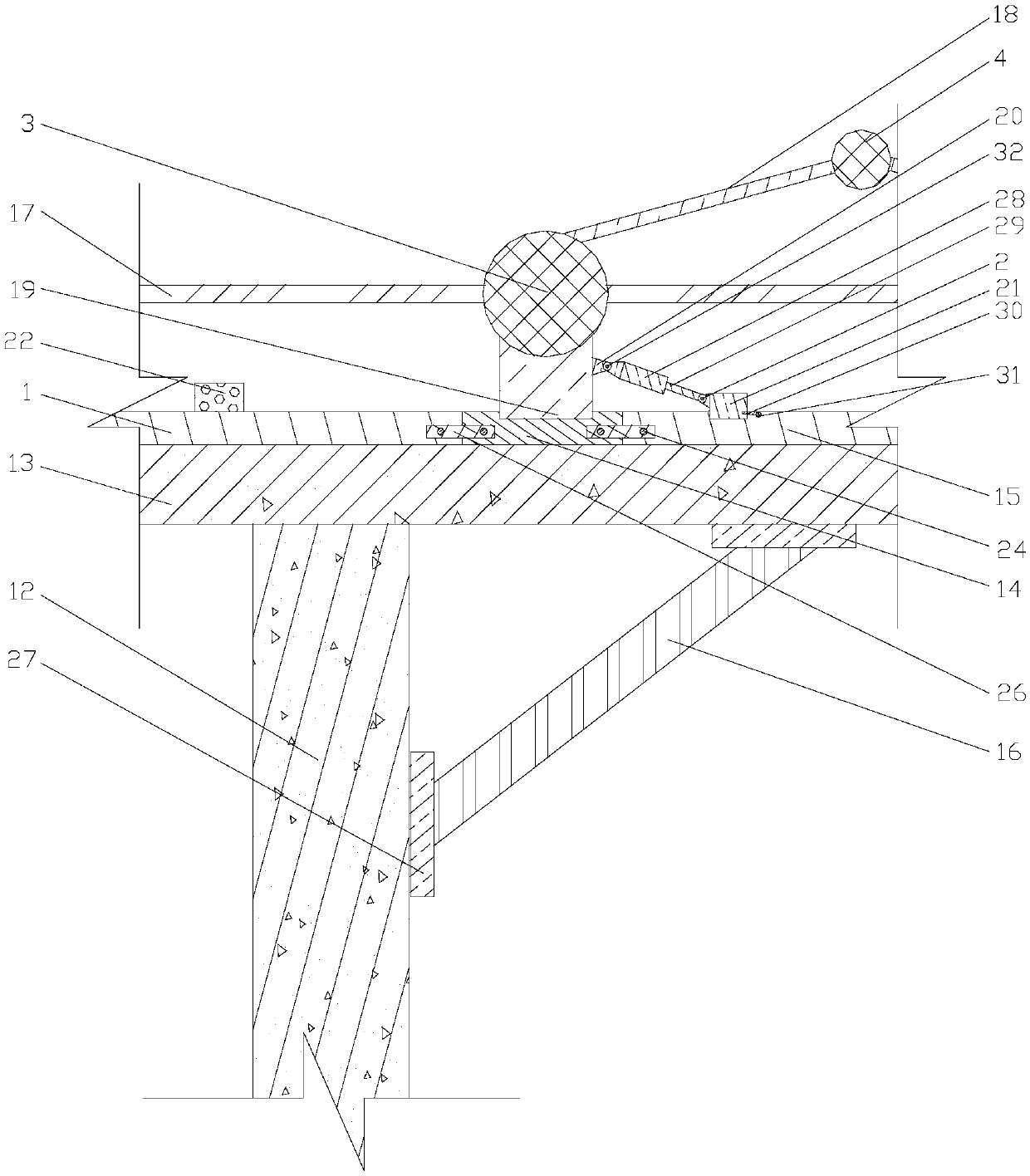

Wind power tower drum foundation ring ribbed beam type foundation based on combined structure

The invention discloses a wind power tower drum foundation ring ribbed beam type foundation based on a combined structure, and relates to the technical field of onshore wind power generation. The system comprises a foundation ring, a circular concrete floor, a variable-cross-section H-shaped steel rib beam, a hollow concrete pillar, a toggle pin and a square steel shear connector. The foundation ring is connected with a wind power tower drum on the upper part, and a perforation reinforcing steel bar required by a traditional basic ring is removed and replaced with the prefabricated welding toggle pin, so that the basic ring and a foundation concrete form effective connection by utilizing favorable shearing resistance and pulling resistance of the toggle pin, and the construction difficultyin reinforcing steel bar perforating on site is remarkably reduced. The variable-cross-section H-shaped steel rib beam is connected with a foundation slab and the pillar through the shear connector so as to form a combined structure stress system, so that the mechanical characteristics of two materials are fully played, and larger internal force produced by the upper load can be resisted. The foundation system can be applied to a circular bearing platform of a circular spread foundation or a pile foundation, and is high in on-site construction efficiency and material-saving so as to have a good engineering application prospect.

Owner:CHONGQING UNIV

Accumulative sliding installation structure of grid roof and construction method

The invention relates to an accumulative sliding installation structure of a grid roof. The accumulative sliding installation structure is characterized in that an assembly platform is built between two axes of the middle of the grid roof through a full hall scaffold, and upper bearing plates, jacking screws and lower connecting bolts are arranged at the joints of a platform steel plate and scaffold steel tubes; a sliding track comprises a support sliding track body and a middle sliding track body which are arranged at the tops of a frame column and a frame beam respectively, and an oblique supporting rod is arranged between the frame beam and the frame column on the lower side of the sliding track; after grid assembly sections are assembled on the assembly platform, the grid assembly sections are synchronously pushed to a designed position through a pushing device, and the expansion and contraction quantity of a hydraulic cylinder is controlled through a displacement sensor in the pushing process; after the grid assembly sections are jacked through a jack, a lower chord ball connecting body and damping supports are installed. By means of the structure, the grid roof sliding difficulty can be lowered, the construction efficiency can be improved, and the construction safety can be improved. The invention further discloses a construction method of the accumulative sliding installation structure of the grid roof.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY

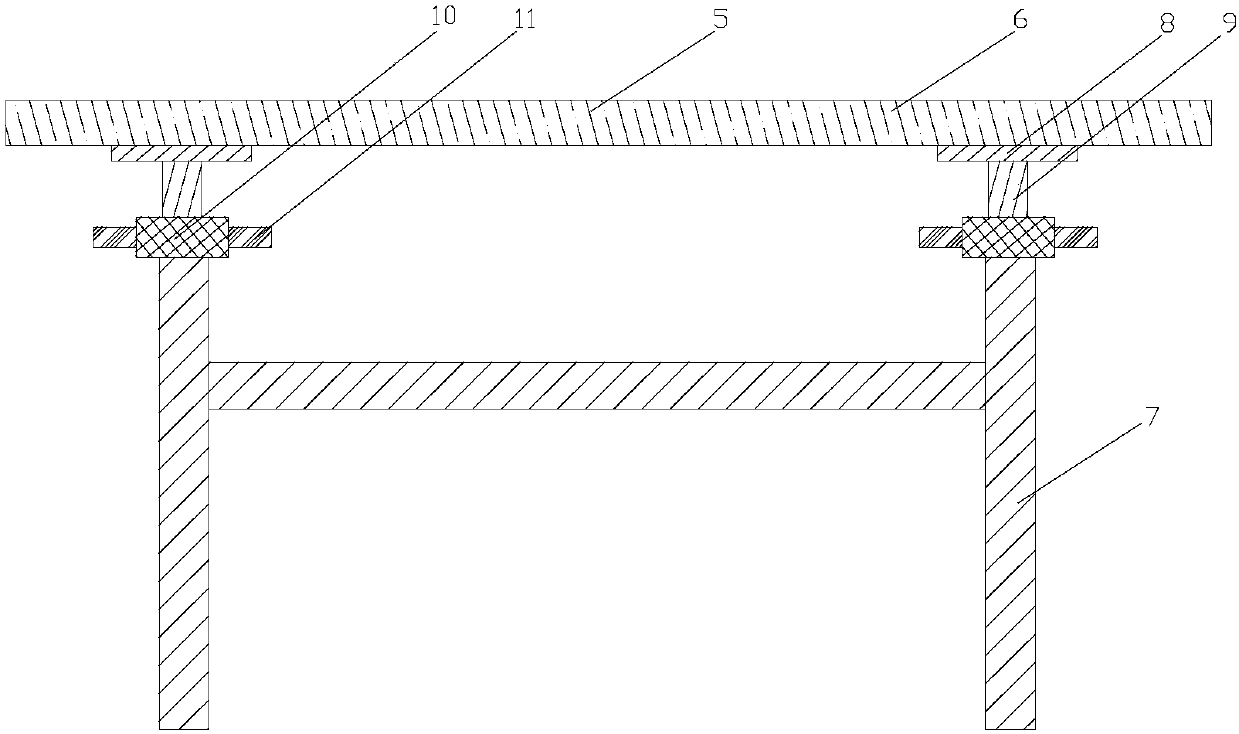

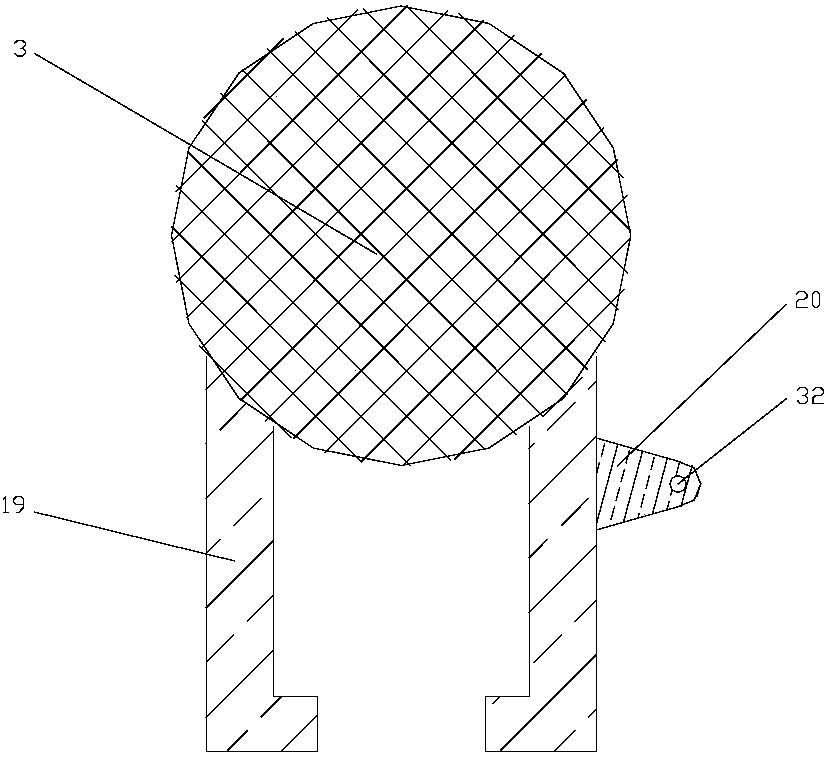

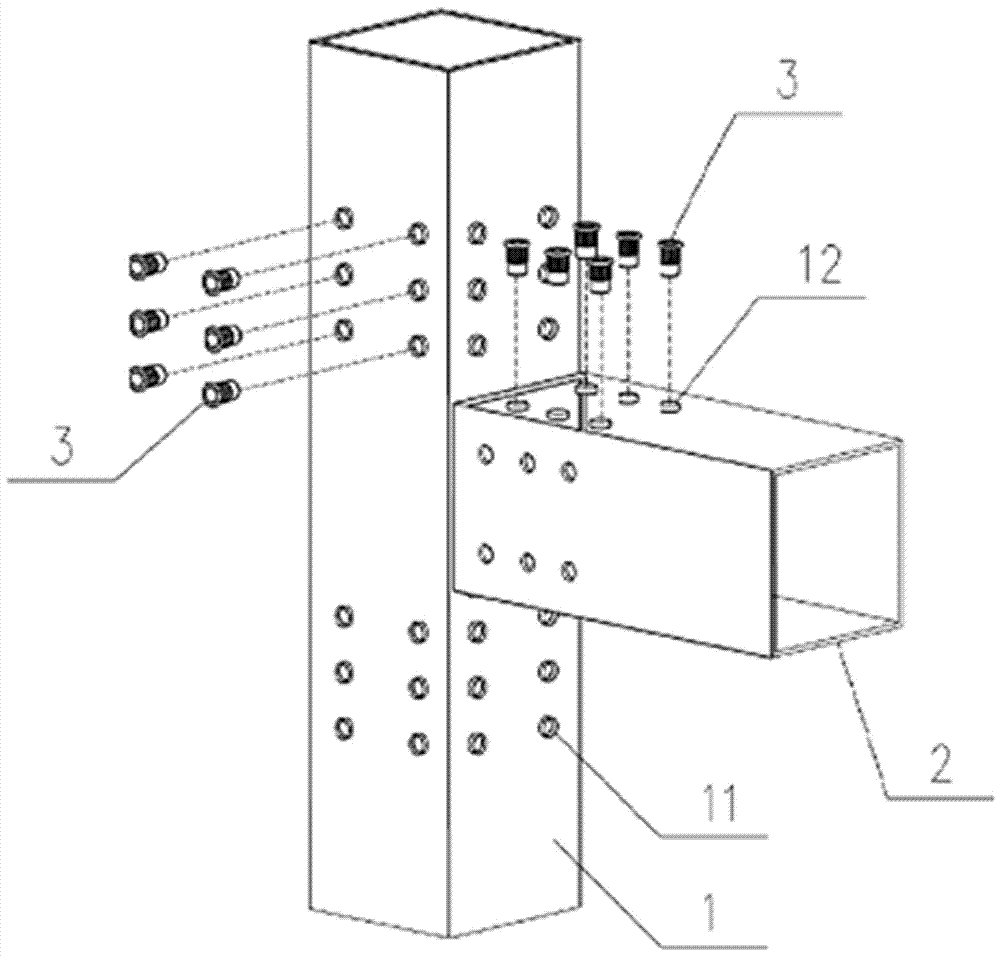

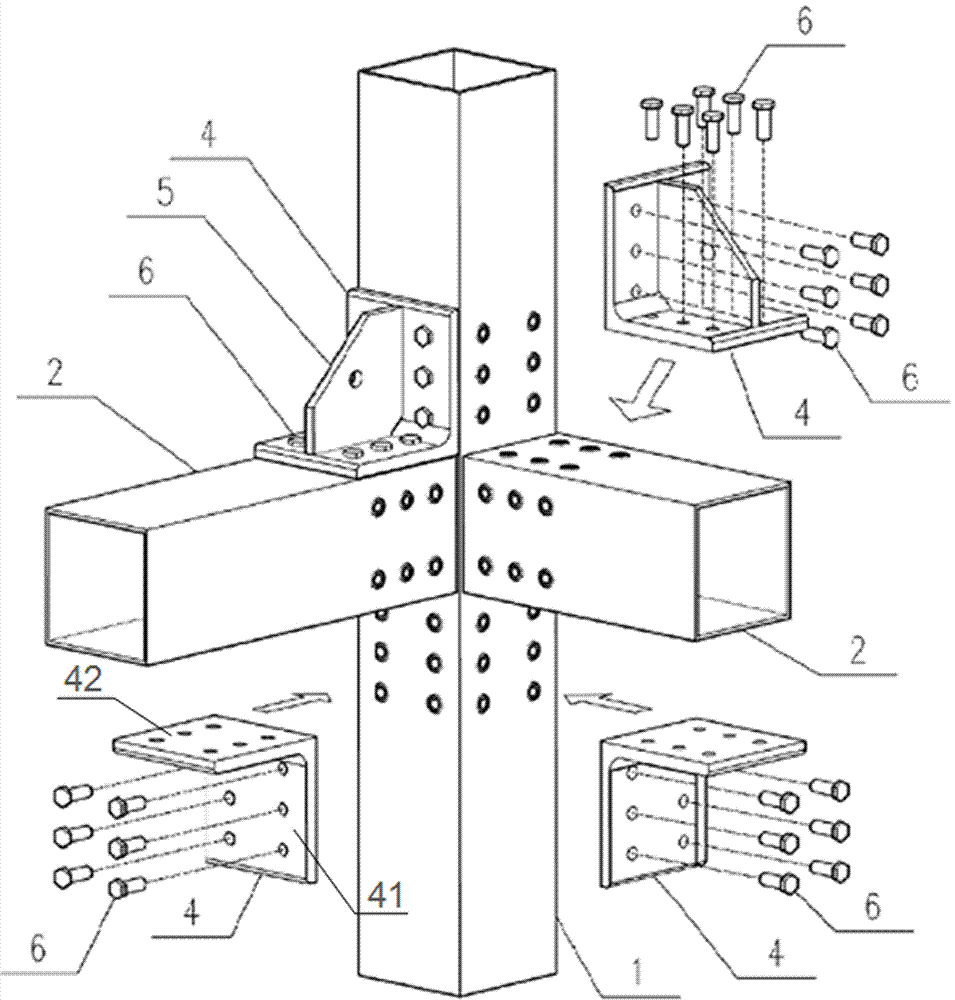

Modular building connection structure

PendingCN107503437AFor later reuseSimple construction methodBuilding constructionsConstruction engineeringSteel columns

A modular building connecting structure comprises a plurality of steel columns, a plurality of steel beams and a plurality of connecting steel angles; a plurality of fastening components are arranged in steel column connection holes and steel angle connection holes respectively and in steam beam connection holes and steel angle connection holes respectively and used for fixing the steel columns and steel beams through the cooperation of the connecting steel angles. Workers on site have no need to use rulers for measurement, the structure is not affected by the structural system installation accuracy, no welding is needed, no special installation tools are needed, the construction method is simple, the installation quality in the installation process is controllable, the connection strength is high, the installation accuracy is high, late maintenance and dismantling are convenient to conduct, later use of column and beam components is easily achieved, meanwhile the structure comprehensively exceeds existing connection modes in the market in the aspects that the installation cost is saved and the site construction efficiency is improved, and the structure has unique superiority.

Owner:USAS BUILDING SYST SHANGHAI

Side wall lifting translation type high-speed magnetic levitation turnout structure and control system thereof

ActiveCN114438832AImprove operational efficiencyImprove operational safetyRailway tracksMultiple dynamo-electric motors speed regulationShaped beamControl system

The invention discloses a side wall lifting translation type high-speed magnetic levitation turnout structure. A magnetic levitation turnout beam comprises a translation section, a lifting section and a rotating section which are arranged in sequence; the translation section at least comprises a first translation beam and a second translation beam; the lifting section comprises a turnout main beam and fixed side walls arranged on the two sides of the main beam, a first lifting side wall and a second lifting side wall are arranged in the middle of the main beam, and the two lifting side walls alternately ascend and descend to form a straight strand U-shaped beam and a side strand U-shaped beam when the maglev train runs; the rotating section comprises a main beam, fixed side walls arranged on the two sides of the main beam and a rotating type side wall arranged in the middle of the main beam, and the rotating type side wall can rotate to be in butt joint with the first lifting side wall or the second lifting side wall. The invention further discloses a high-speed magnetic levitation turnout control system. By the adoption of the split type design, the manufacturing difficulty of the beam body is effectively reduced, the structure is compact, operation and maintenance are convenient, the partition turnout modules and the turnout machine are integrally designed, and the field construction and debugging efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Prefabricated concrete inspection well pouring template

PendingCN109930629AImprove integrityIncrease stiffnessArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention relates to a prefabricated concrete inspection well pouring template. The prefabricated concrete inspection well pouring template comprises a supporting mechanism; the supporting mechanism comprises a base, an outer model tube, an inner model tube and a plugging plate; the plugging plate is installed in a position at a gap between the outer model tube and the inner model tube; the plugging plate is in assembly connection with the inner wall of the outer model tube; the base, the outer model tube, the inner model tube and the plugging plate jointly form a mould main body; the mould main body is used for integrated forming of a bottom plate and a well chamber; the base is used for pouring and forming the bottom plate; the outer model tube and the inner model tube are used for pouring and forming the well chamber; and the plugging plate is used for opening a water passing hole of the well chamber. According to the prefabricated concrete inspection well pouring template, thebottom plate and the well chamber is integrally prefabricated by one step; and not only can a leakage problem be effectively solved, but also the integrality and rigidity of the well chamber can be greatly improved.

Owner:宣城市政建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com