High-voltage gas immersed termination mounting and positioning structure

A high-pressure gas, installation and positioning technology, applied in the direction of switchgear, electrical components, switchgear, etc., can solve problems such as unreliable fixation, inaccurate positioning of cables, and mechanical fixation of cables and epoxy bushings. To achieve the effect of ensuring long-term reliability, improving construction efficiency, and making the product simple and beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

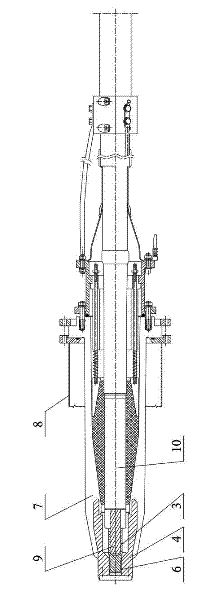

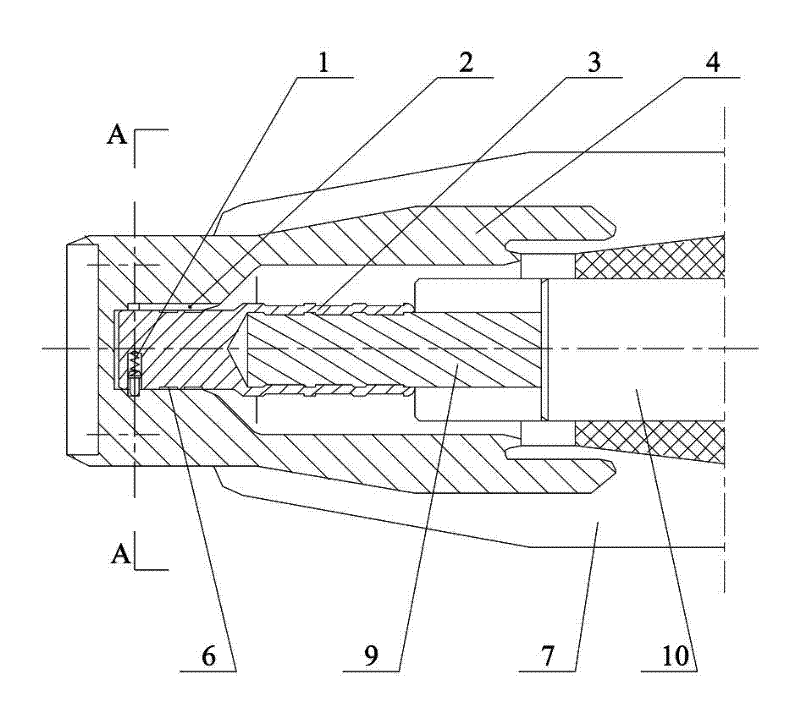

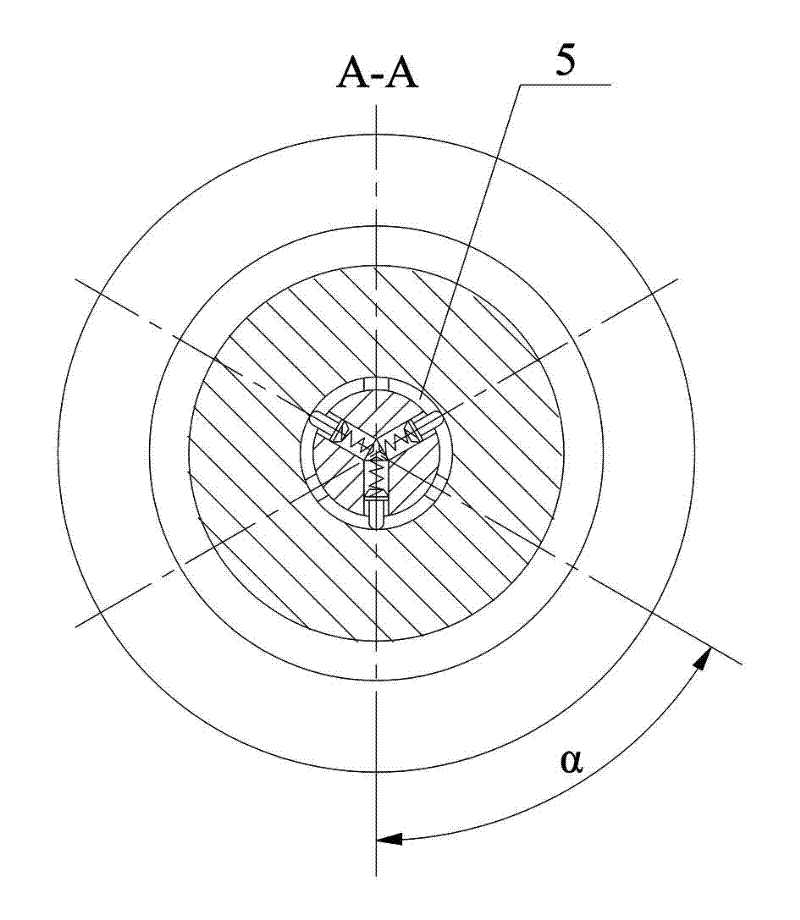

[0012] According to attached figure 1 , 2 And 3, an installation and positioning structure of a high-voltage gas-insulated terminal, a plug-in high-voltage gas-insulated terminal (GIS terminal) includes a high-voltage cable 10, a GIS cylinder 8, an epoxy sleeve 7, an inner insulation and a plug-in mechanism. The upper electrode 4 of the epoxy bushing 7 is provided with an inner hole, the inner hole of the upper electrode 4 is a blind hole, the movable contact 6 is matched in the inner hole of the upper electrode 4, and the movable contact 6 is connected with the outlet rod 3 as a whole, The outlet rod 3 and the high-voltage cable core 9 are connected by mechanical crimping, and the structure of this part of the outlet rod 3 is a shell structure. The plug-in mechanism is pre-installed with 3 sets of sliding pins and springs 1 evenly distributed radially at the end of the moving contact 6, and 3 sliding grooves 2 are axially processed on the side wall of the inner hole of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com