Portable intelligent high-pressure grouting system and grouting method of metamorphic concretes

A metamorphic concrete and high-pressure grouting technology, which is applied in construction and infrastructure engineering, can solve the problems of large construction randomness, low construction efficiency, and high cost, so as to ensure construction efficiency and quality, save cement slurry consumption, and improve construction efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

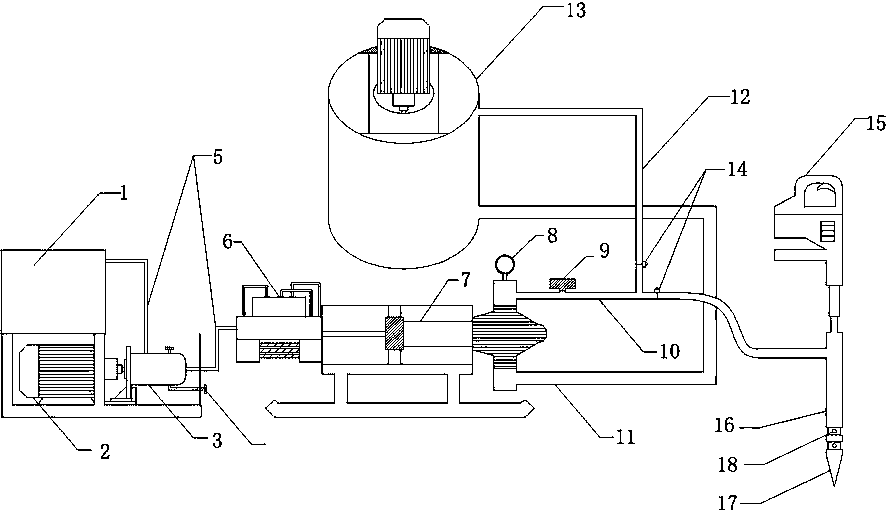

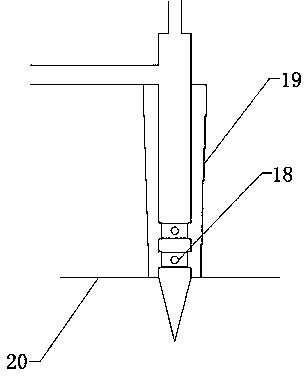

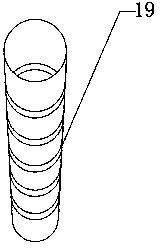

[0028] Example: such as figure 1 As shown, the portable metamorphic concrete intelligent high-pressure grouting system of this embodiment includes a fuel tank 1, a motor 2, an oil pump 3, a pressure adjustment knob 4, an oil pipeline 5, a hydraulic commutator 6, a plunger pump 7, a grout pressure gauge 8, an electromagnetic Flow meter 9, grouting pipe 10, grouting pipe 11, grouting pipe 12, grouting bucket 13, solenoid valve 14, electric hammer 15, grouting rod 16, grouting head 17 and grouting hole 18. The above-mentioned components constitute the main hydraulic oil supply system, cement slurry pumping system and grouting system of the portable metamorphic concrete intelligent high-pressure grouting system.

[0029] The hydraulic oil supply system mainly includes: oil tank 1, motor 2, oil pump 3, pressure adjustment knob 4, oil delivery pipe 5, and hydraulic commutator 6. The motor 2 is placed under the oil tank 1 to save equipment space. The motor 2 powered by three-phase A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com