Accumulative sliding installation structure of grid roof and construction method

A technology for accumulating slip and installing structures, applied in truss structures, roofs, building components, etc., can solve the problems of not considering the improvement of the seismic performance of the structure, the difficulty of realizing large-span synchronous movement, and the structure being easily disturbed, so as to avoid construction. The effect of quality problems, improving application efficiency, and reducing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the technical requirements for the construction of the assembled platform, the technical requirements for the design and installation of the shock absorber, the technical requirements for the construction of the sliding track laying, the technical requirements for the on-site welding construction, etc. will not be described in detail in this embodiment, and the focus will be on the structure and construction of the present invention. Implementation of the construction method.

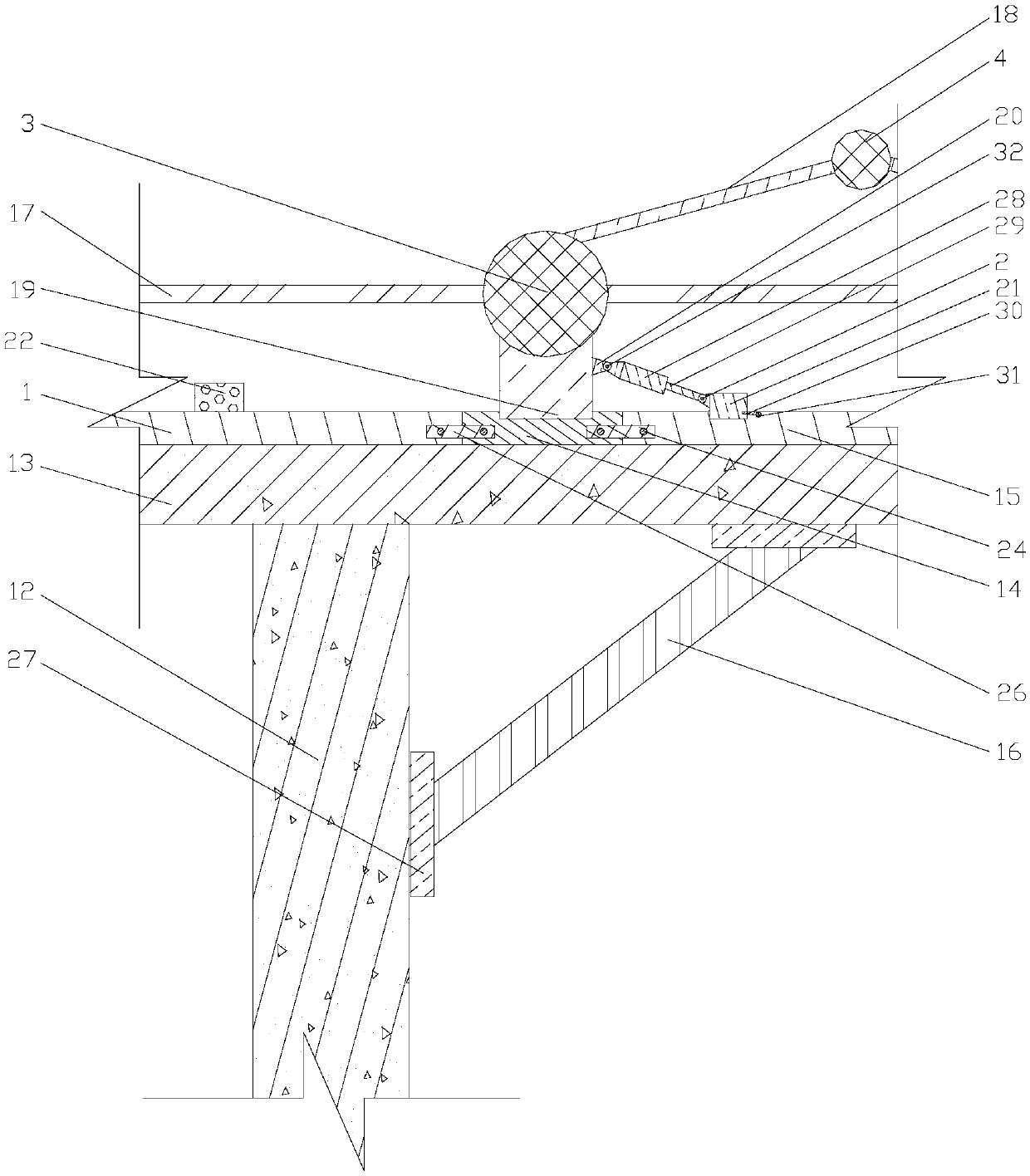

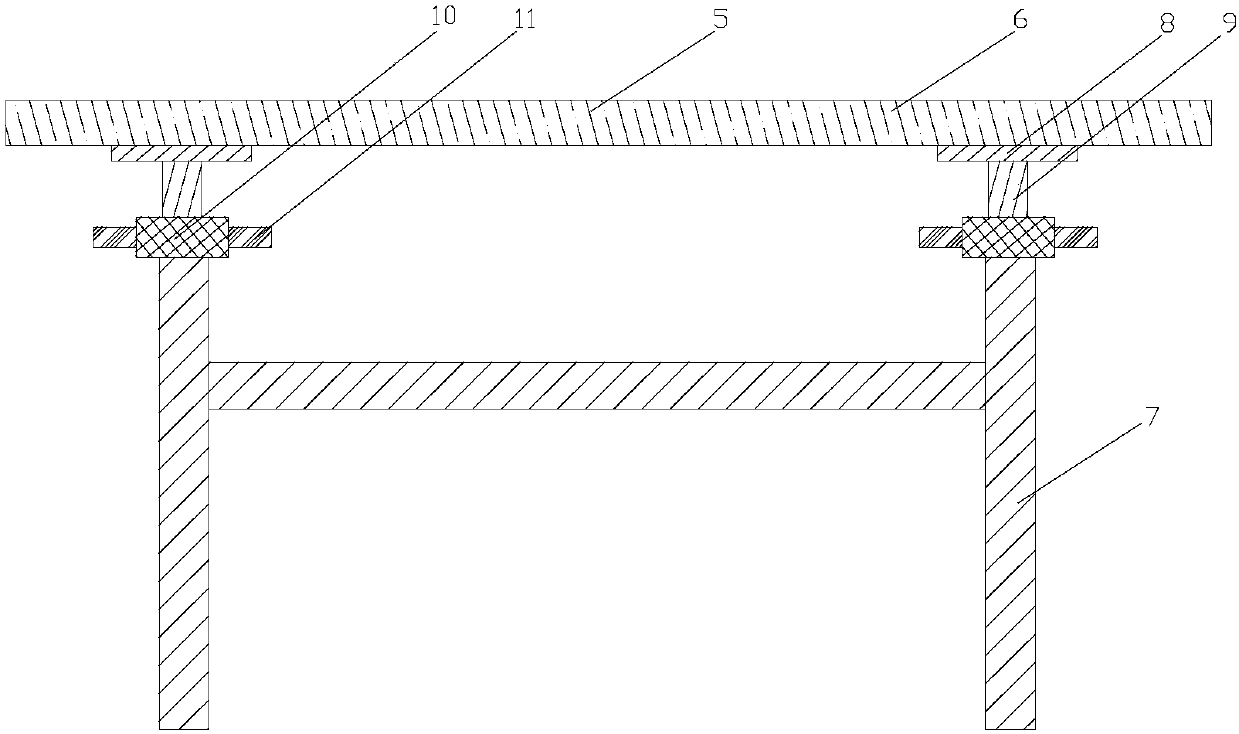

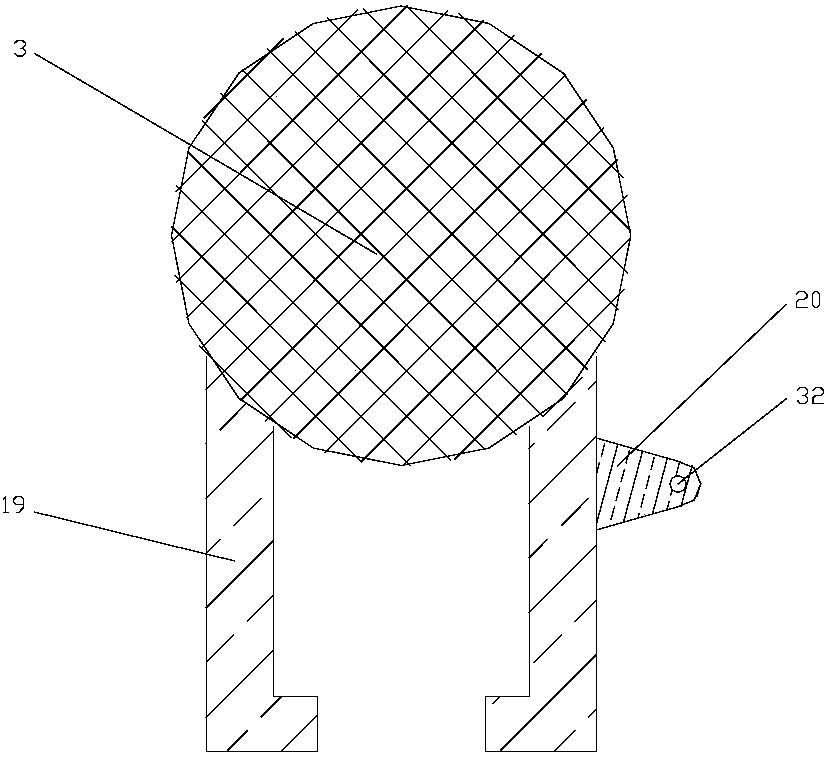

[0037] figure 1 It is a structural schematic diagram of grid roof accumulative sliding installation of the present invention, figure 2 yes figure 1 Schematic diagram of the structural section of the assembled platform, image 3 yes figure 1 cross-section of the shoe, Figure 4 Schematic diagram of the structure after the grid roof is installed. refer to Figure 1 ~ Figure 4 As shown in the figure, a cumulative sliding installation structure of the grid roof, the assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com