Prefabricated thermal insulation laminated wallboard with spatial three-dimensional structure and manufacturing method of laminated wallboard

A three-dimensional structure and space technology, applied in building components, building structures, buildings, etc., can solve problems that affect building safety, thermal insulation and energy saving, large impact on wall thermal insulation performance, and increase on-site management costs, so as to prevent the occurrence of falling accidents , strong service life, and the effect of solving cracking and water leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

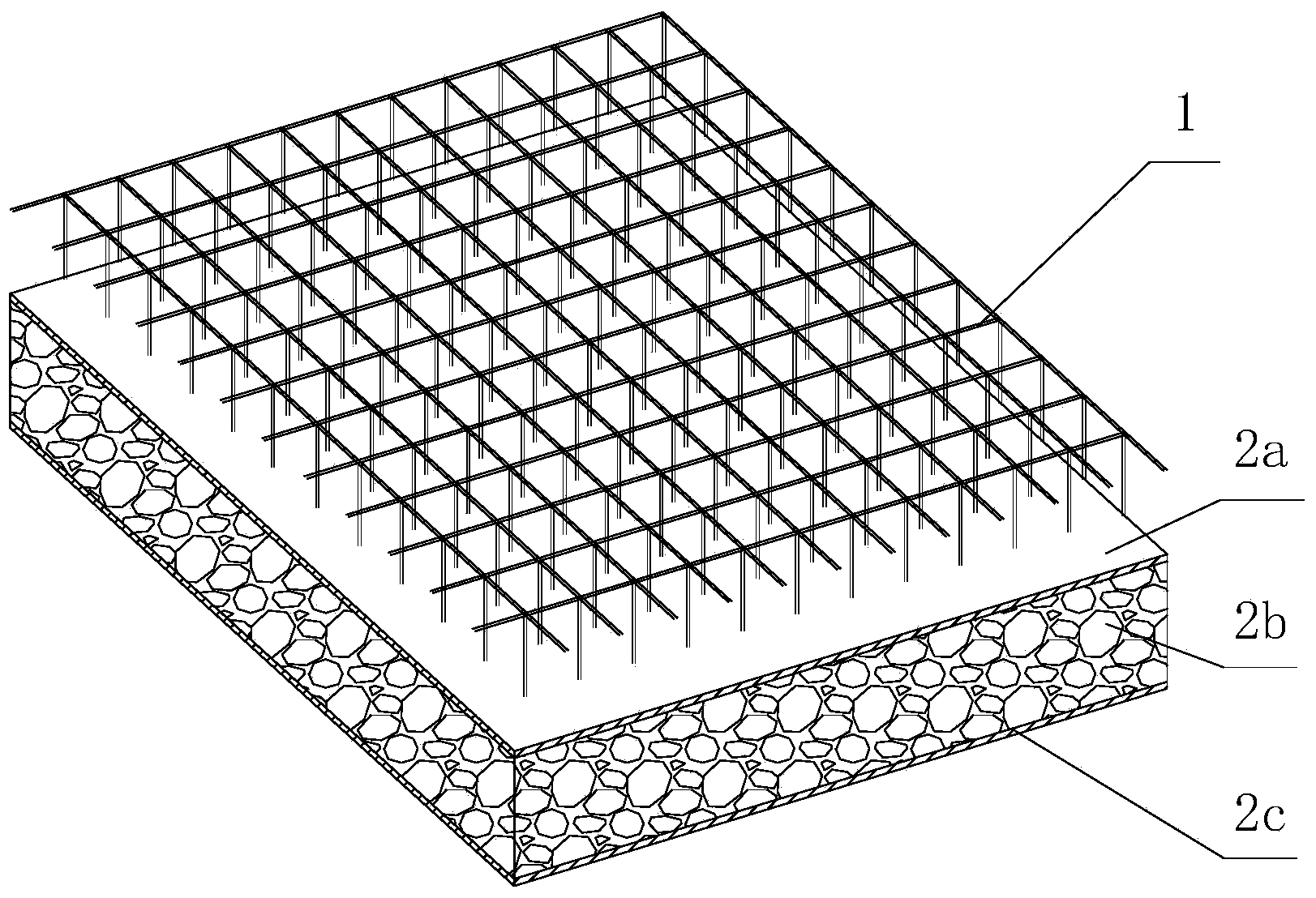

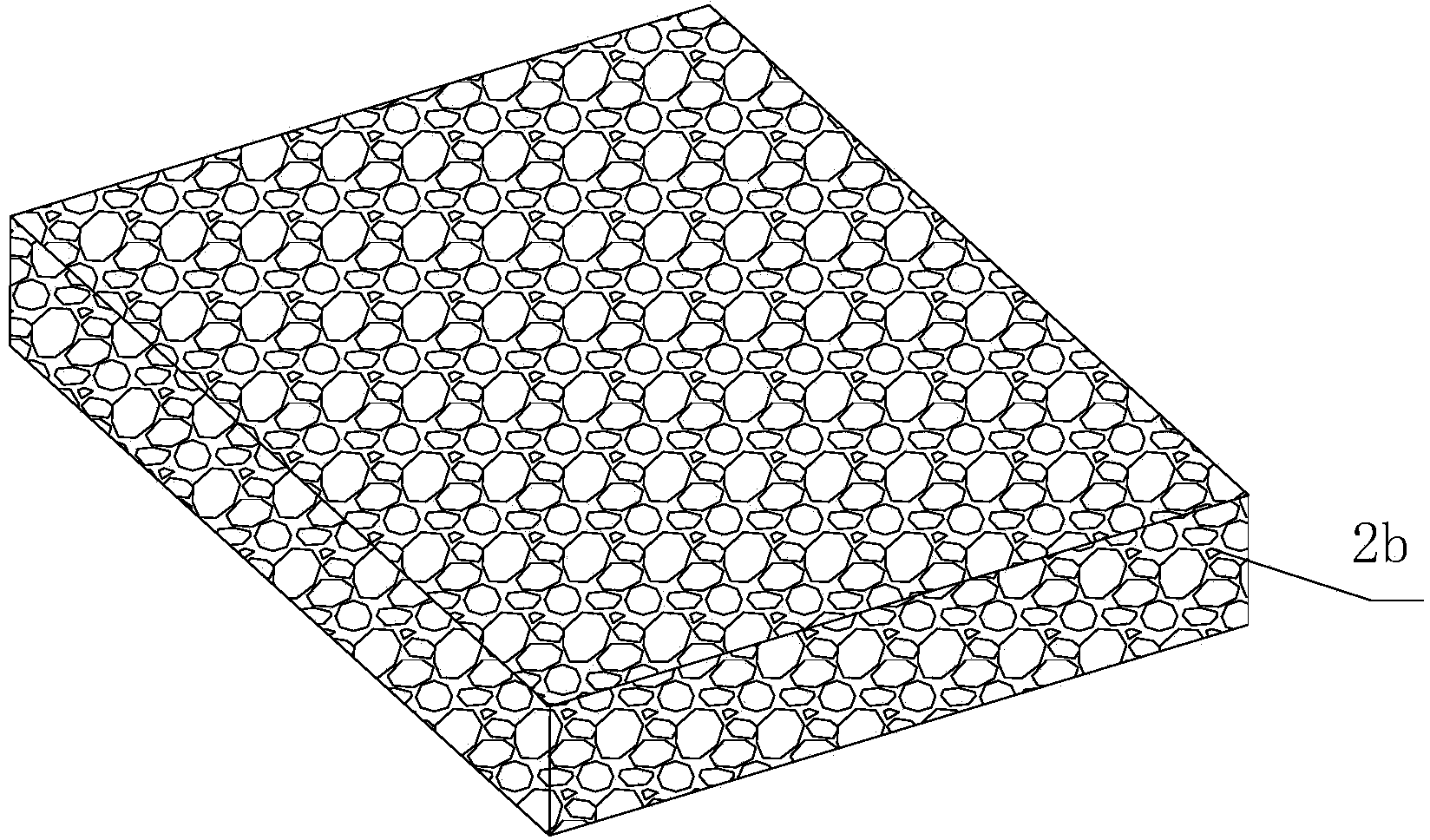

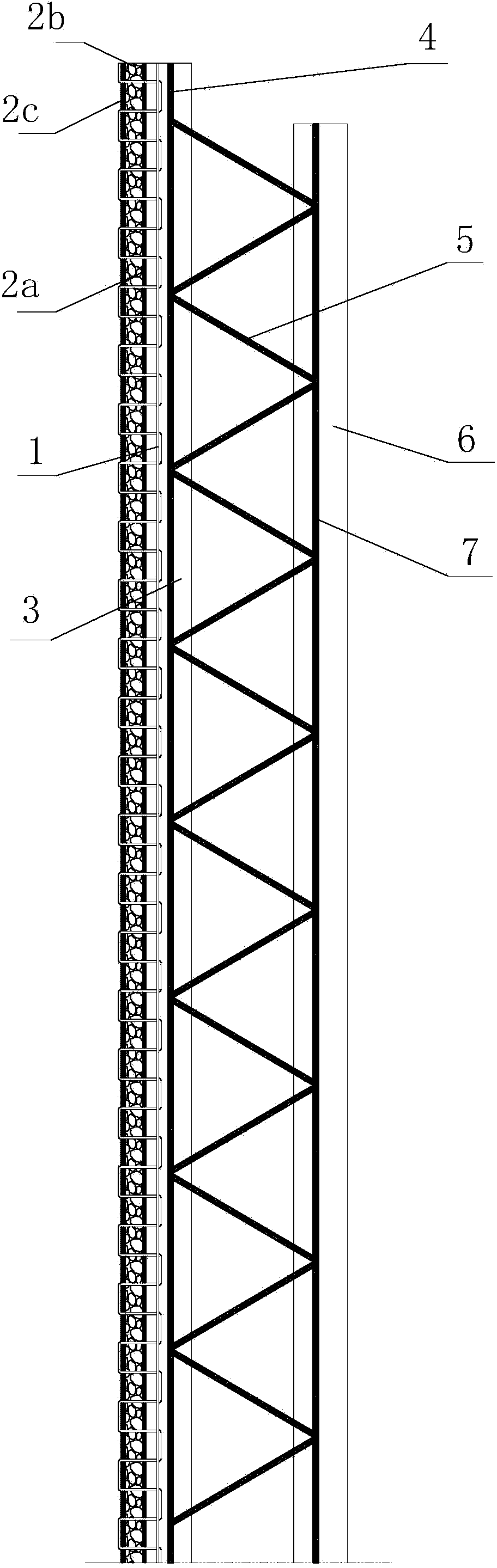

[0041] The present invention is a prefabricated thermal insulation laminated wall panel with a three-dimensional space structure, comprising an outer layer of thermal insulation body 2 and an inner layer of prefabricated laminated wall body. layer 2b and outer reinforcing plate 2c; the inner reinforcing plate 2a is provided with a three-dimensional fiber strip network frame 1 inwardly,

[0042] The three-dimensional fiber strip grid frame 1 is made of fiber strips, including a plane grid cloth 1a and a large number of net braces 1b, the plane grid cloth 1a is parallel to the internal reinforcement plate 2a and has a certain distance, the net brace 1b is connected to the plane net The grid cloth 1a is connected and extended to the inner reinforcement board 2a, penetrated and fixed on the inner reinforcement board 2a, the insulation layer 2b, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com