Control system and method for printing paper or coating film

A control system and control method technology, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of not using environmental protection and personal safety, environmental and human hazards, and products that are prone to wrinkling, so as to improve the process Processing efficiency, uniform gluing, and enhanced product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings.

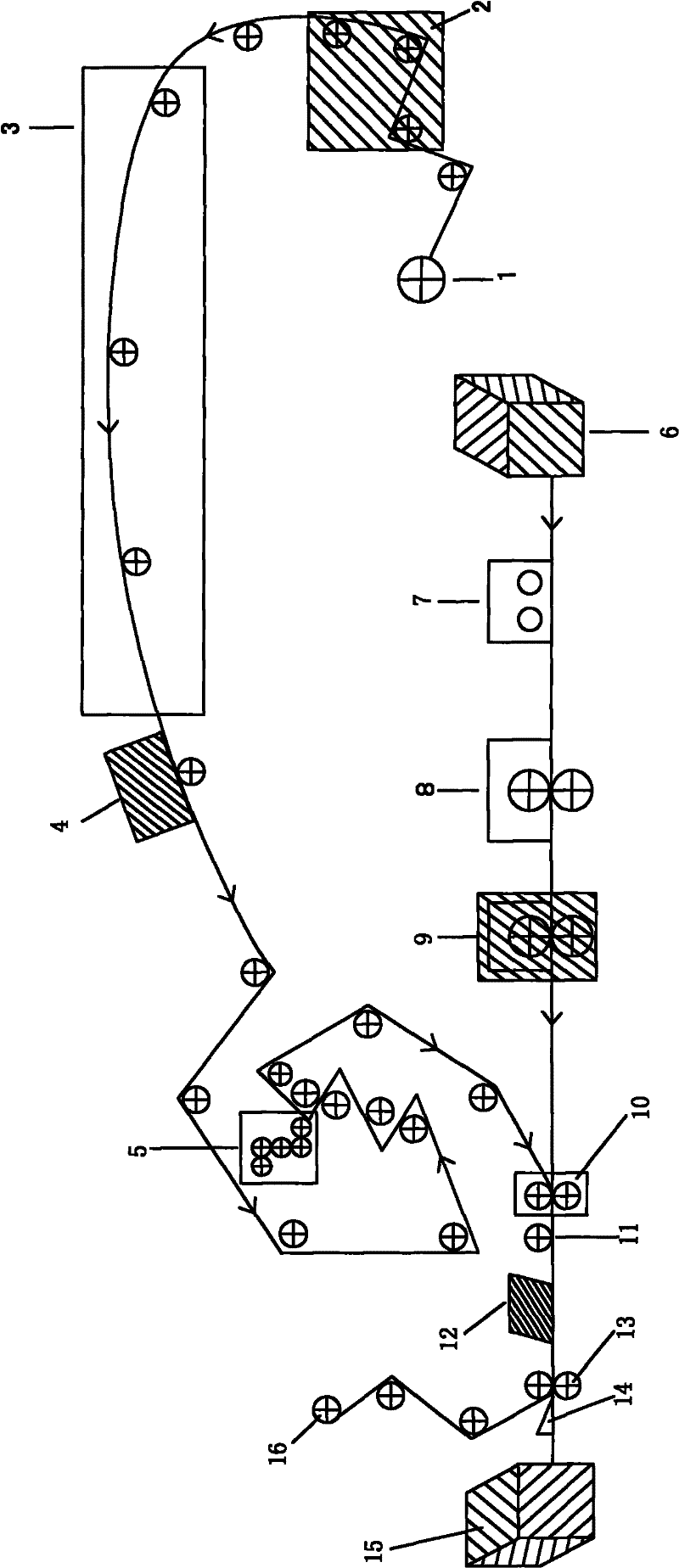

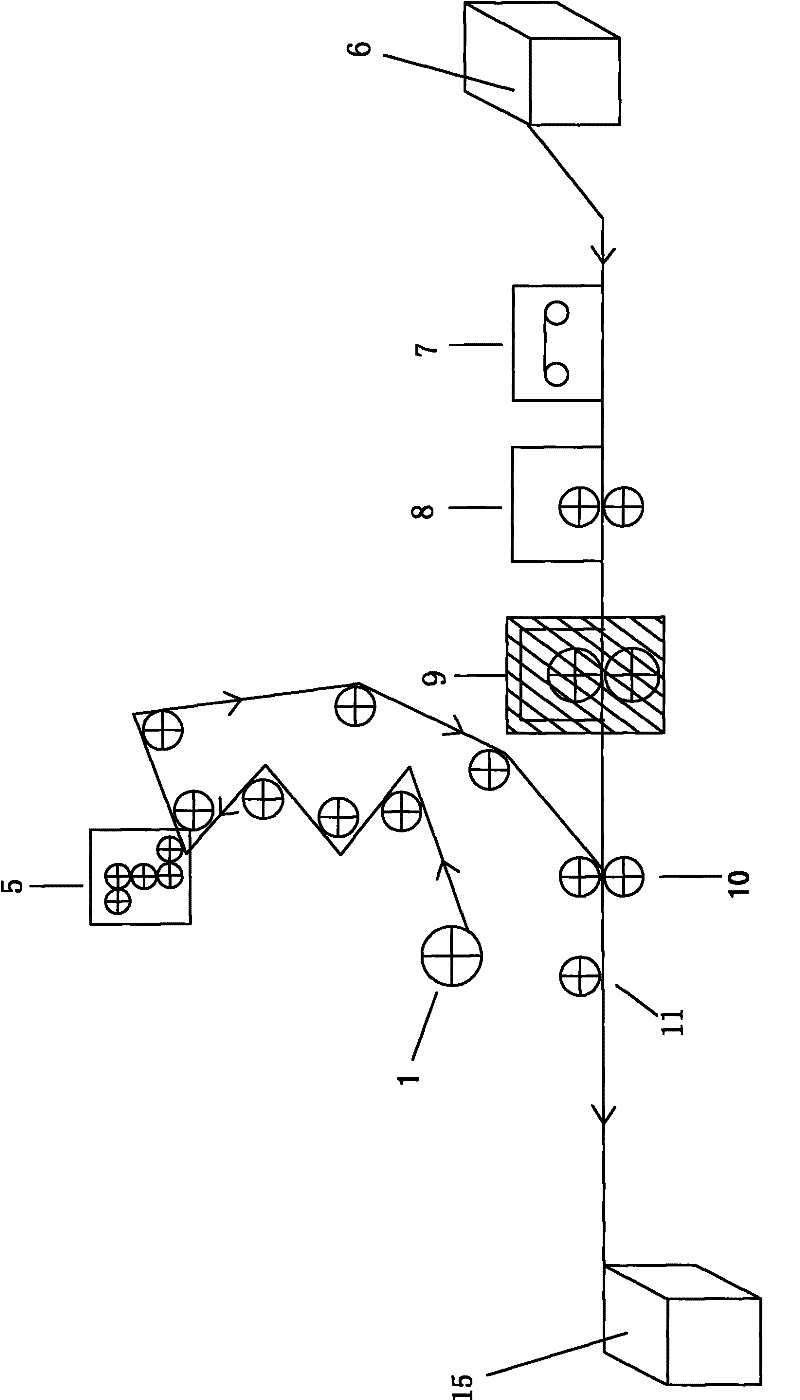

[0047] figure 2 As shown, the system implemented by the present invention includes a film unwinding device 1, a varnish unit 2, a drying channel 3, a corona device 4, a film gluing unit 5, a sheet unwinding device 6, a dust removal unit 7, a calender Unit 8, single sheet gluing unit 9, composite unit 10, thermal fuse knife 11, curing unit 12, film peeling device 13, film winding device 16 and single sheet receiving device 15.

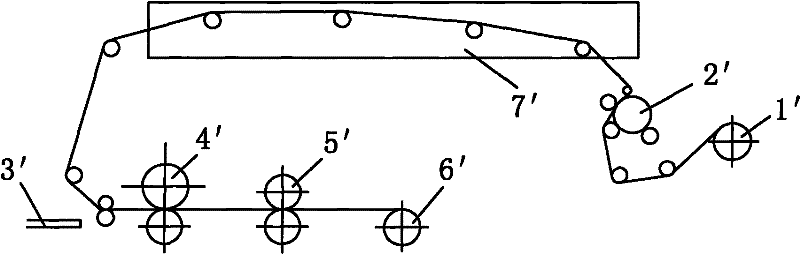

[0048] The system includes three parts: varnish, lamination, cold stamping or laser transfer, which can be used independently as a process or combined. Among them, the pre-treatment of the film is the varnish part. The varnish part is mainly composed of a varnish unit. The film is released through the film unwinding device, varnished through the varnish unit, and then dried through the drying channel. The fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com