Deep sea bare rock pier protection barrel, positioning pile, underwater cofferdam integrated platform and construction method

A technology for positioning piles and cofferdams, which is used in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of difficulty in ensuring structural safety and stability, large inclination, and high strength, reducing the degree of freedom of the pile body and improving manufacturing. Accuracy, improve the effect of construction work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

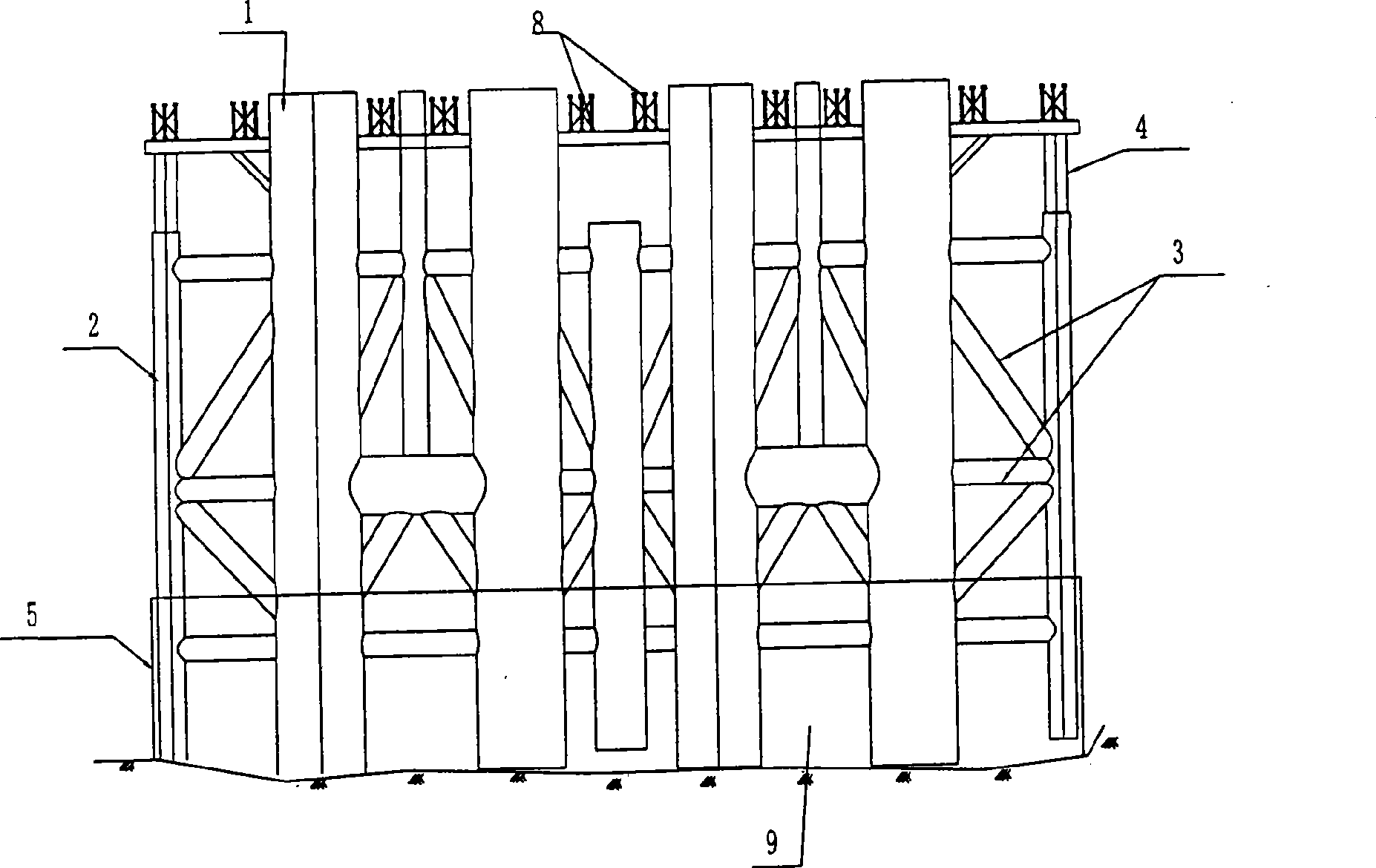

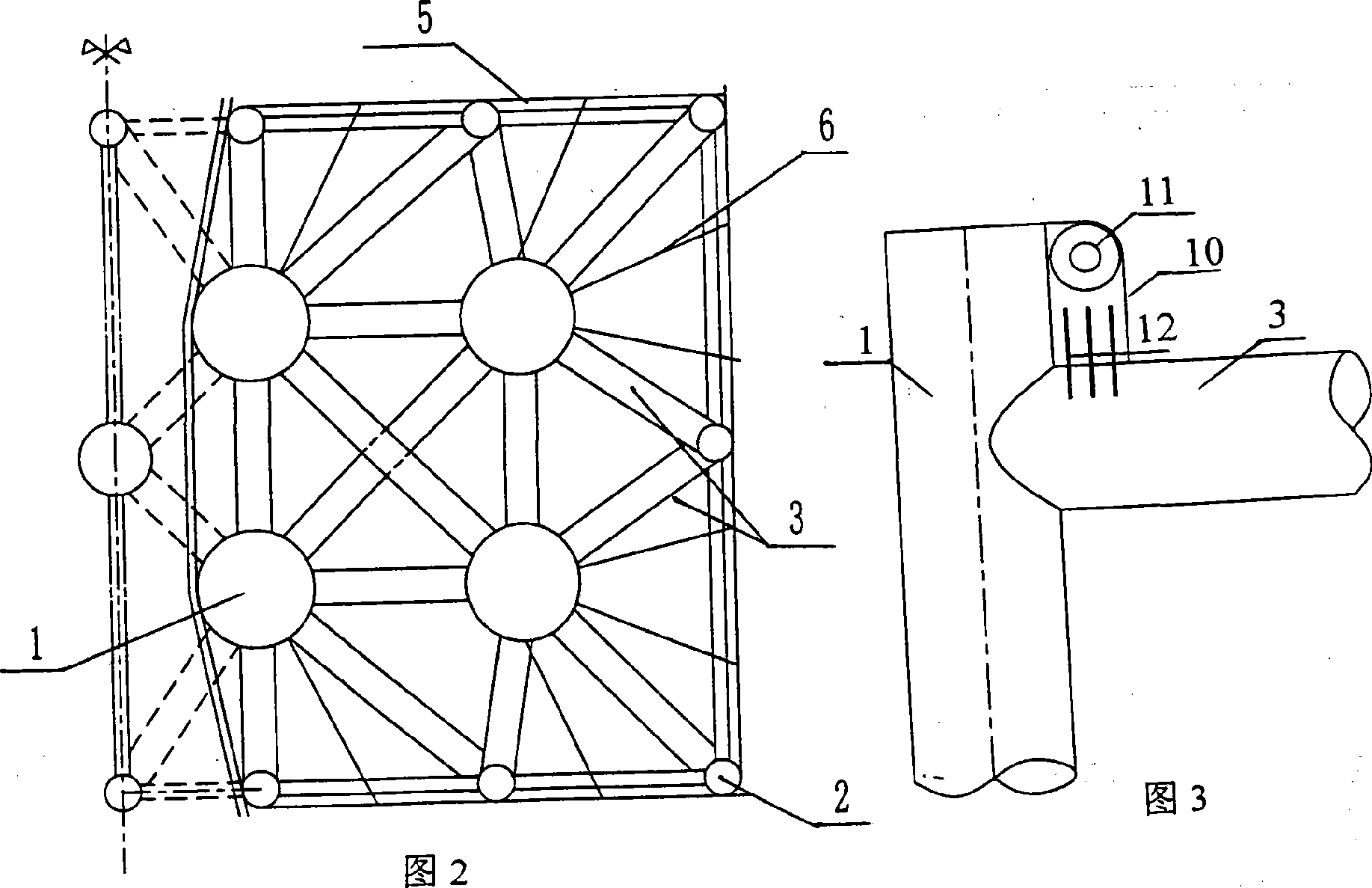

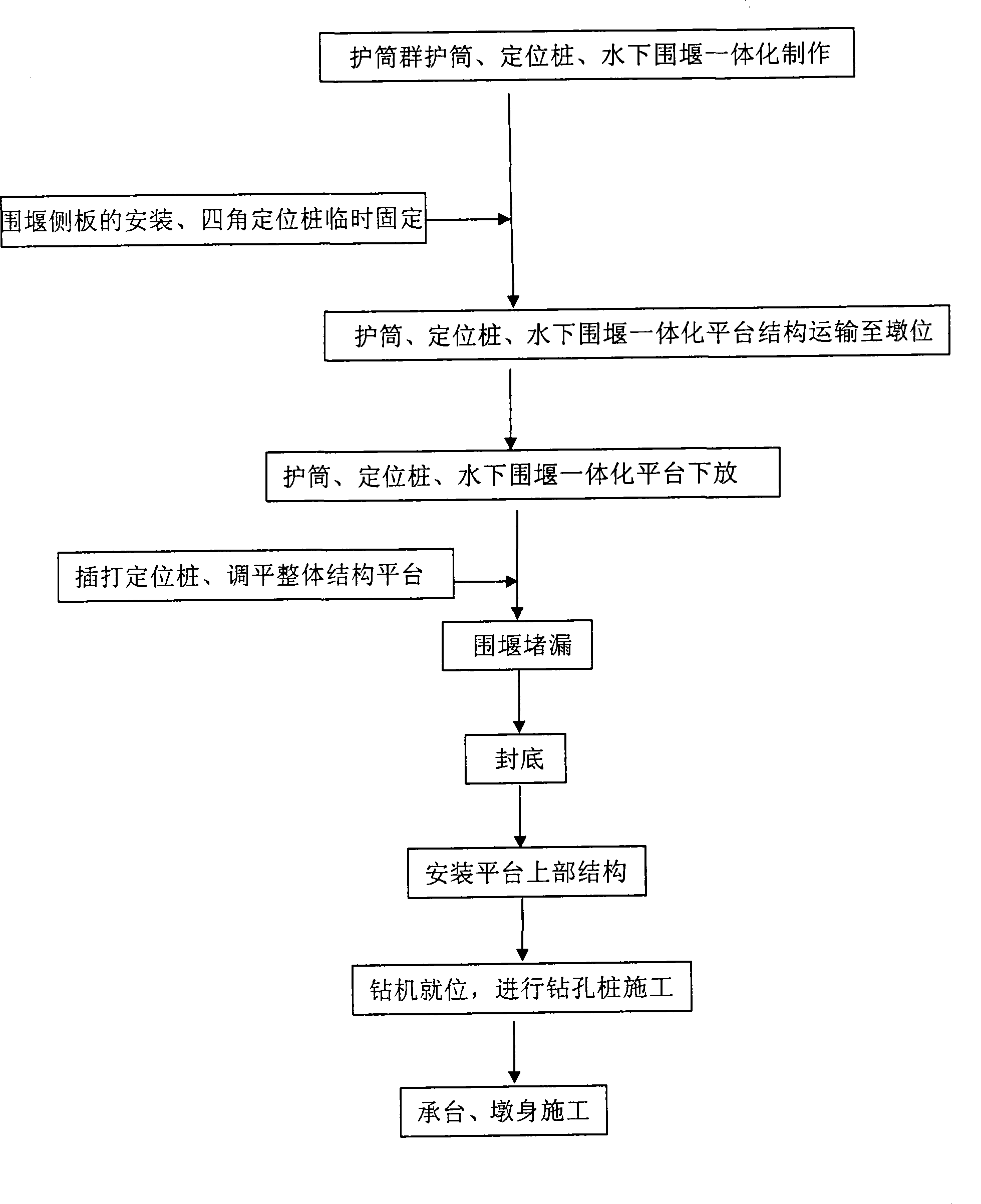

[0018] Control attached figure 1 , 2, its structure is that the steel casing 1 and the steel casing 2 are connected into a whole through the coupling system 3, the positioning pile 4 is inserted into the steel casing 2 to locate the construction platform, and bears the horizontal and vertical loads during the construction process, the surrounding The weir side plate 5 is arranged along the outer ring of the bottom of the integrated structure of the casing, the positioning pile, and the underwater cofferdam to form a closed warehouse body. The warehouse body is divided into multiple small chambers, and each small chamber is arranged in sequence , filling the bottom concrete 9 inside each small warehouse, and the partition board 7 is supported on the side plate truss 6 of the cofferdam.

[0019] Referring to accompanying drawing 3, lifting lug 10, a lifting lug stiffening plate 11, b lifting lug stiffening plate 12 connect the steel casing 2 and the coupling system 3 into a whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com