Connection structure for prefabricated integral bay window, and assembling method thereof

A technology for connecting structures and bay windows, applied in building structures, buildings, etc., can solve the problems of small on-site operation tolerance and adjustable range, high production precision requirements for prefabricated components, and difficulty in grouting compactness detection. The effect of high mold turnover, high demoulding efficiency and lower construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

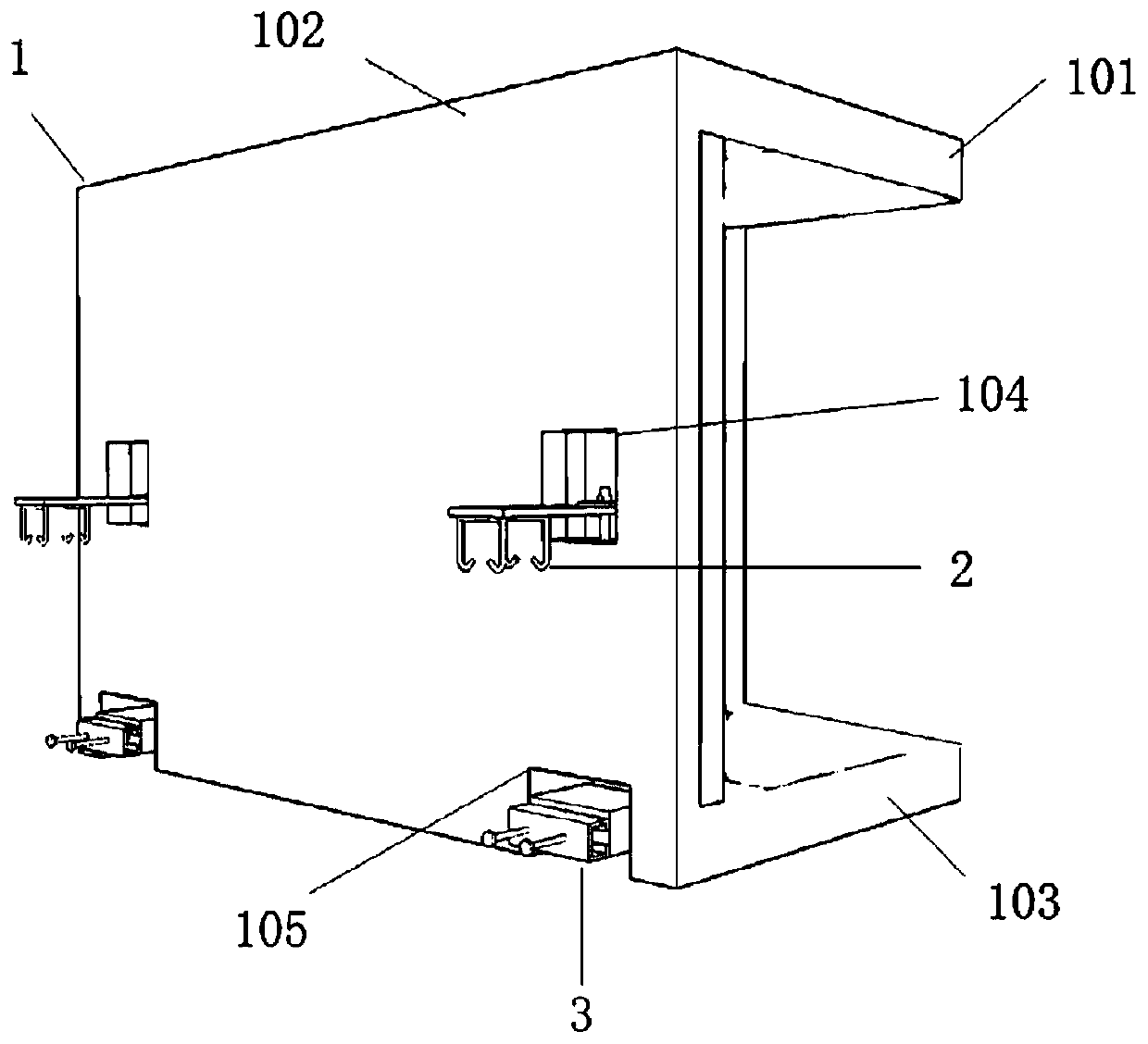

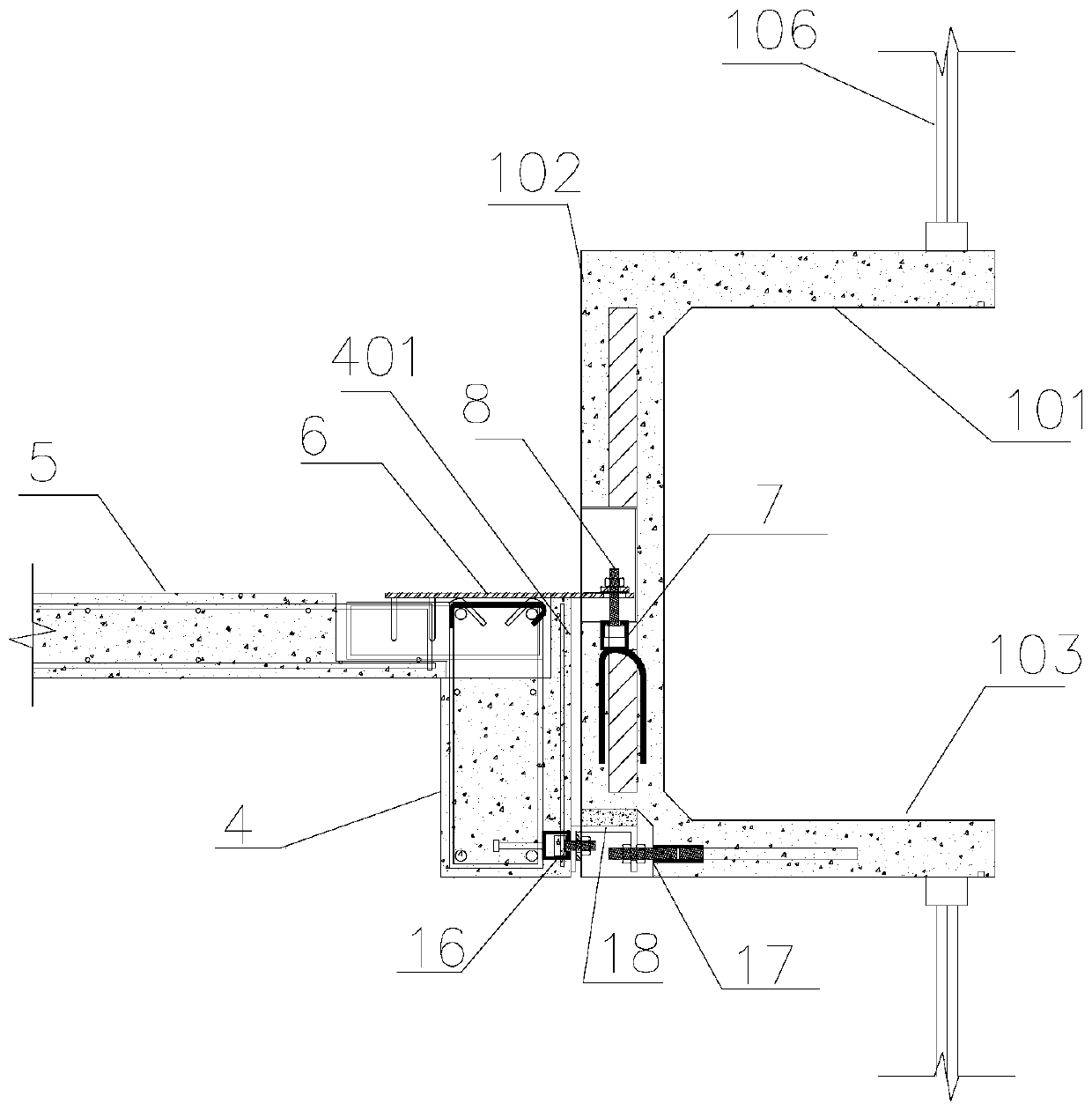

[0051] See attached figure 2 As shown, the connection structure of the prefabricated integral bay window 1 in this embodiment includes the prefabricated integral bay window 1 and the composite beam 4, wherein the composite beam 4 includes a prefabricated part and a cast-in-place part. See attached figure 1 As shown, the prefabricated integral bay window 1 is integrally cast into a C-like shape, including a top plate 101, a side wall 102 and a bottom plate 103, wherein a groove 104 is arranged on the indoor side of the side wall 102, and an upper connection assembly 2 is arranged at the groove 104; A notch 105 for accommodating the box is provided at the intersection of the side wall 102 and the bottom plate 103 , and the lower connection assembly 3 is provided at the notch 105 . See attached figure 2 As shown, the bottom surface of the bottom plate 103 of the prefabricated integral bay window 1 is located at the same level as the bottom surface of the prefabricated part. ...

Embodiment 2

[0068] The connection structure of the prefabricated integral bay window 1 in this embodiment differs from that in Embodiment 1 in that the specific structural forms of the upper connection assembly 2 and the lower connection assembly 3 are different. Wherein, the connection part 6 of the upper connection assembly 2 is the same as that in the first embodiment, and the embedded part 7 and the fixing part 8 are different.

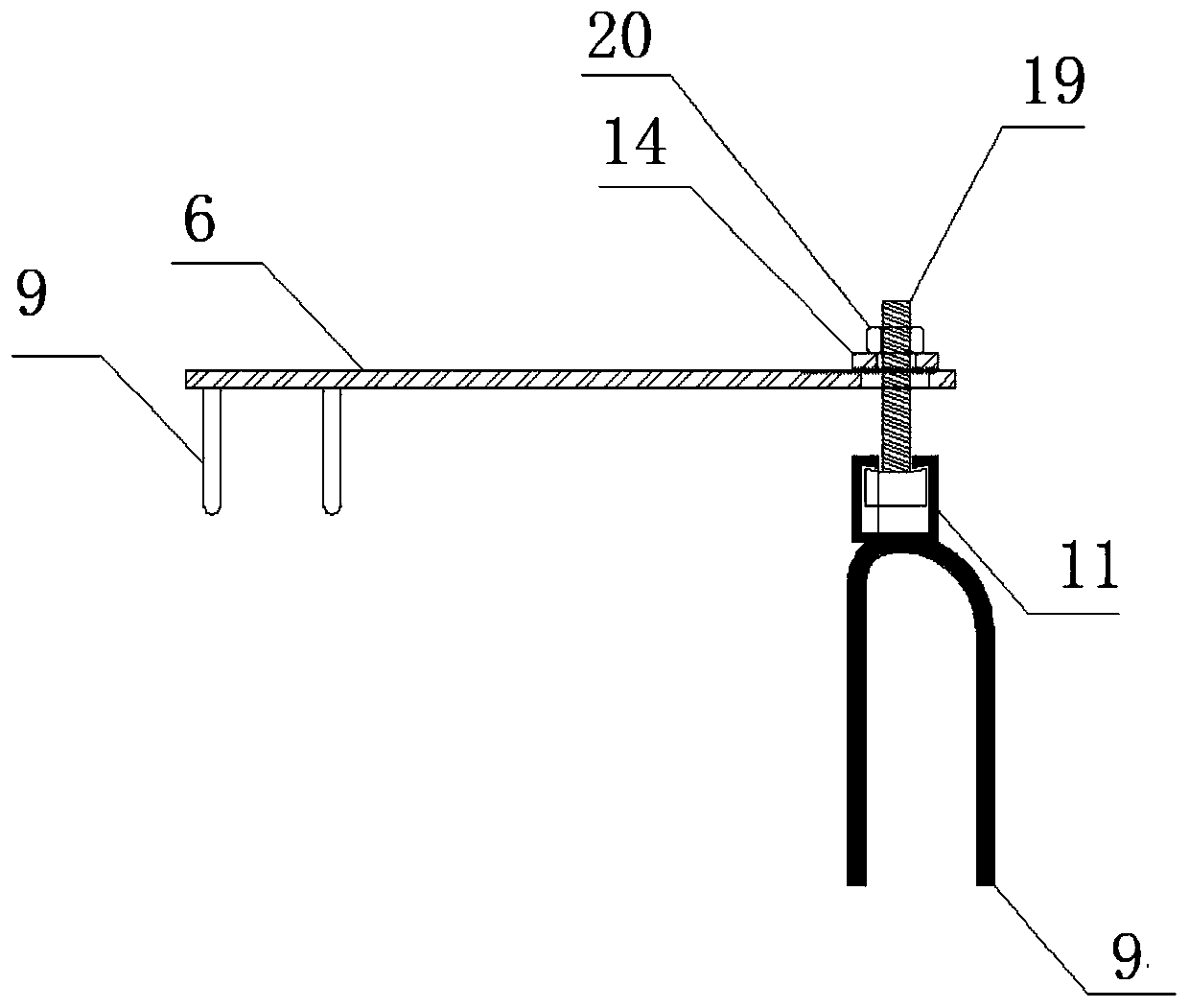

[0069] See attached Figure 7As shown, the embedded part 7 of the upper connection assembly in this embodiment includes the first sleeve 11 and the anchoring leg 9 embedded in the concrete of the side wall 102 of the bay window. In this embodiment, the first sleeve 11 is a hollow sleeve with openings at both ends and internal threads. The fixing part 8 includes a screw, a nut 20 and a washer 14 , the bottom of the screw is inserted into the top of the first hollow sleeve 11 and threaded, and the top of the screw is connected with the connecting part 6 throug...

Embodiment 3

[0072] The connection structure of the prefabricated integral bay window 1 in this embodiment differs from that in Embodiment 1 in that the specific structural form of the upper connection assembly 2 is different. See attached Figure 8 As shown, in this embodiment, the upper connection assembly 2 includes a connection part 6 , a pre-embedded part 7 and a fixing part 8 . Wherein, the connecting part 6 includes a second sliding groove 12 and a sliding rod 2525. The opening end of the second sliding groove 12 faces upward and is flush with the upper surface of the prefabricated part. The first end of the sliding rod 2525 is clamped on the second sliding In the groove 12 , the second end is connected with the fixing part 8 . The embedded part 7 is a positioning box 22 with an open top side, and the opening end surface of the positioning box 22 is flush with the lower surface of the groove 104 of the bay window. The fixed part 8 is an L-shaped plate 24, and the L-shaped plate 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com