High-strength plywood for building shutter panel

A technology for building formwork and plywood, which is used in construction, building structure, formwork/formwork components, etc., can solve the problems of less turnover, large one-time investment, inconvenient disassembly and assembly, etc., and achieves more turnover and low amortization cost. , Easy to cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

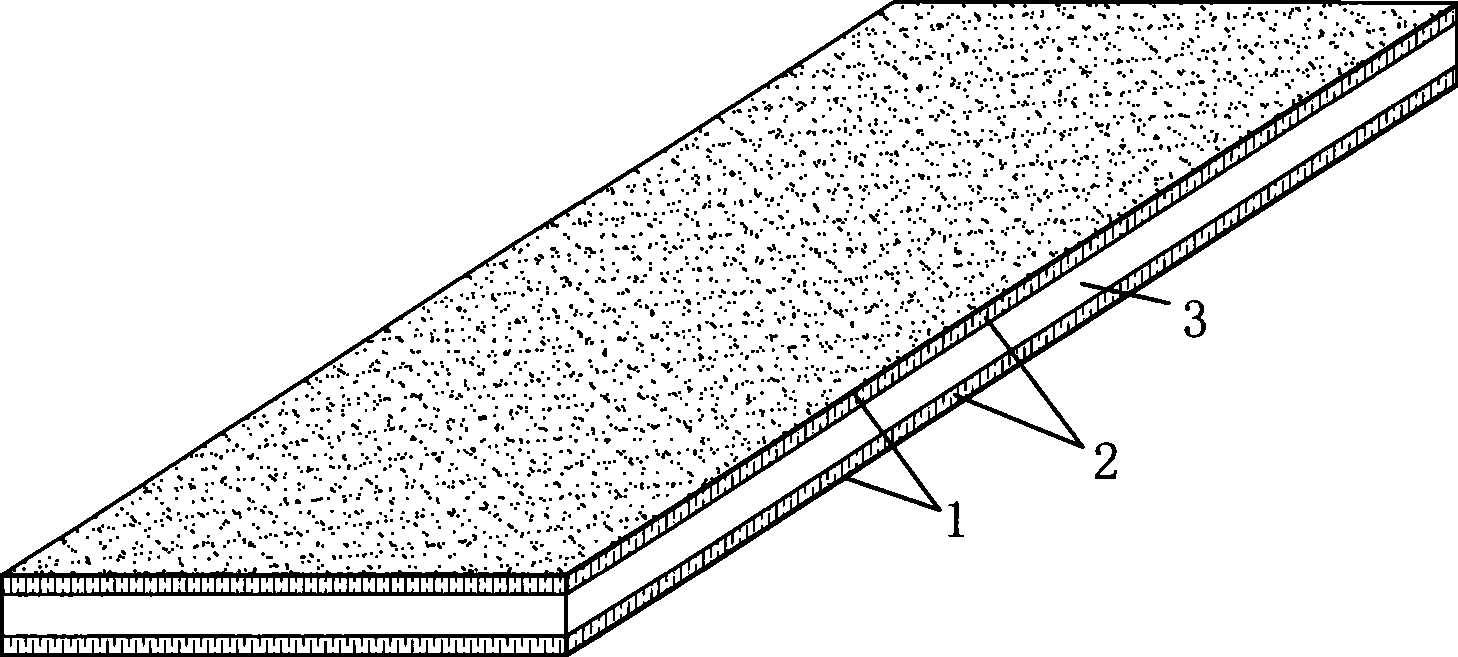

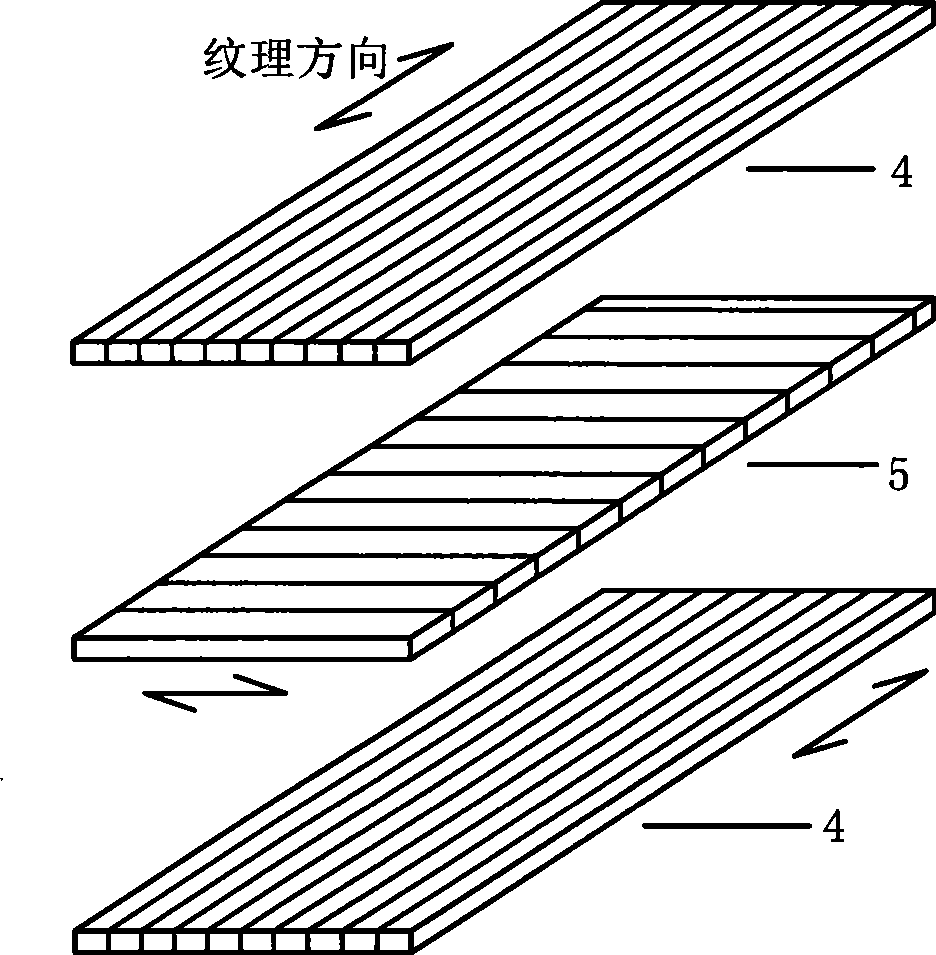

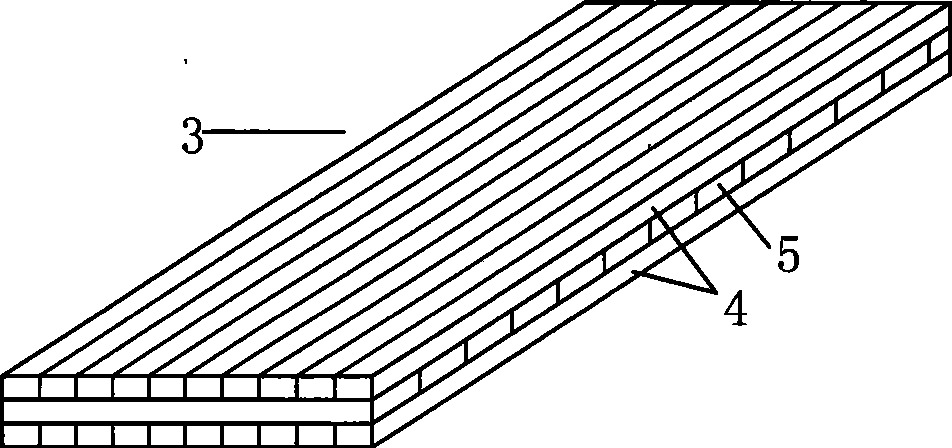

[0018] In the accompanying drawings, 1 is the covering film, 2 is the panel, 3 is the core board, 4 is the outer layer board in the core board, and 5 is the inner layer board in the core board.

[0019] Such as figure 1 , 2 , and shown in 3, a high-strength plywood for building formwork panels, including a film 1, a panel 2 and a core board 3, the thickness of the plywood is 21mm. The covering film 1 is a phenolic resin laminated film. According to requirements such as wear resistance, the laminated film amount is 80-200g / m2 on the front side of the plywood, and about 80g / m2 on the reverse side; the thickness of the panel 2 is about 1-200g / m2. 3mm, the panel 2 is glued together by dipped glass fiber mat, and the adjacent layers are perpendicular to each other; the core board is a three-layer structural board, each layer is a laminated board, the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com