Construction method for high-strength shaping combined template of plank frame of shear wall

A technology of combining formwork and shaping formwork, which is applied in construction, building structure, and building material processing, etc. It can solve the problem that the quality of engineering quality concrete is not easy to guarantee, the concrete pouring section is prone to deviation, and floor transitions are prone to misplacement, etc. It can improve the quality and appearance of concrete, make and assemble simple and convenient, and improve the efficiency of manual handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

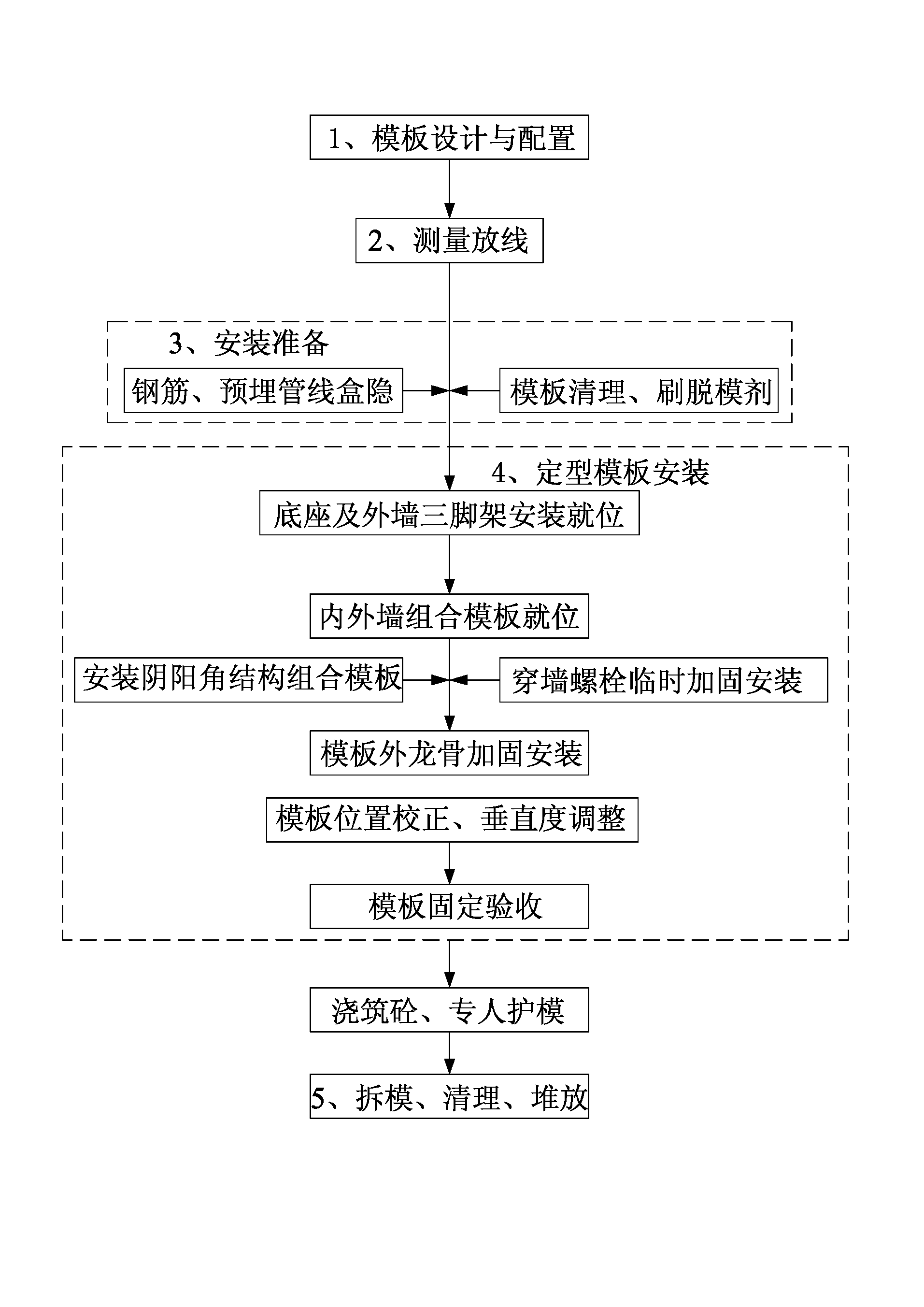

[0058] What the present invention discloses is a kind of construction method of the wooden frame stereotyped combination formwork of the shear wall, such as figure 1 shown, including the following steps:

[0059] 1. Template design and configuration

[0060] This construction method adopts shaped templates and reinforces them through keels. Therefore, it is necessary to design and configure the formwork and keel before construction.

[0061] 1) design

[0062] a. According to the construction drawings, design templates of different specifications, determine the use position and size of non-standard templates, and draw template assembly diagrams and large-scale drawings.

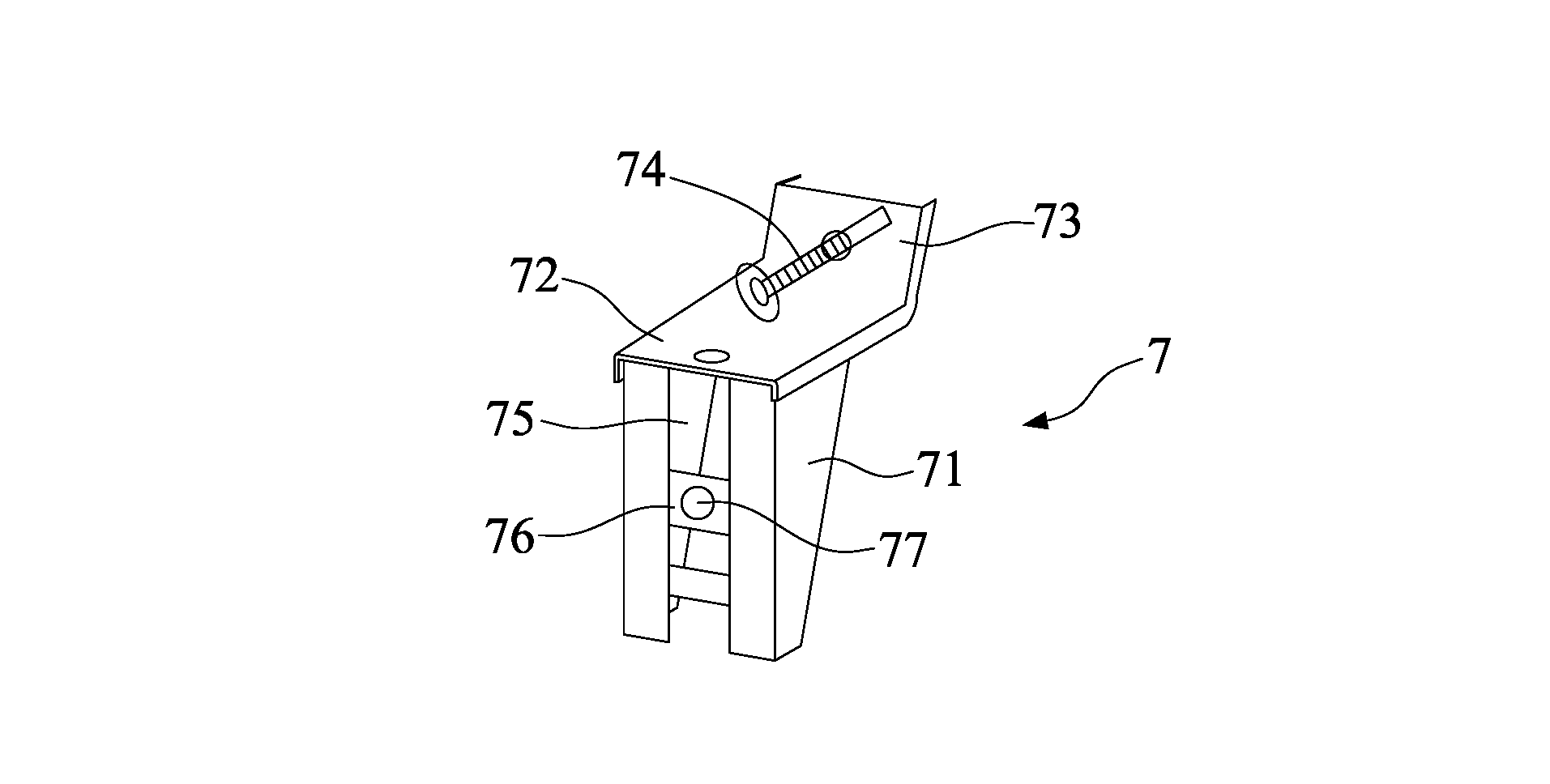

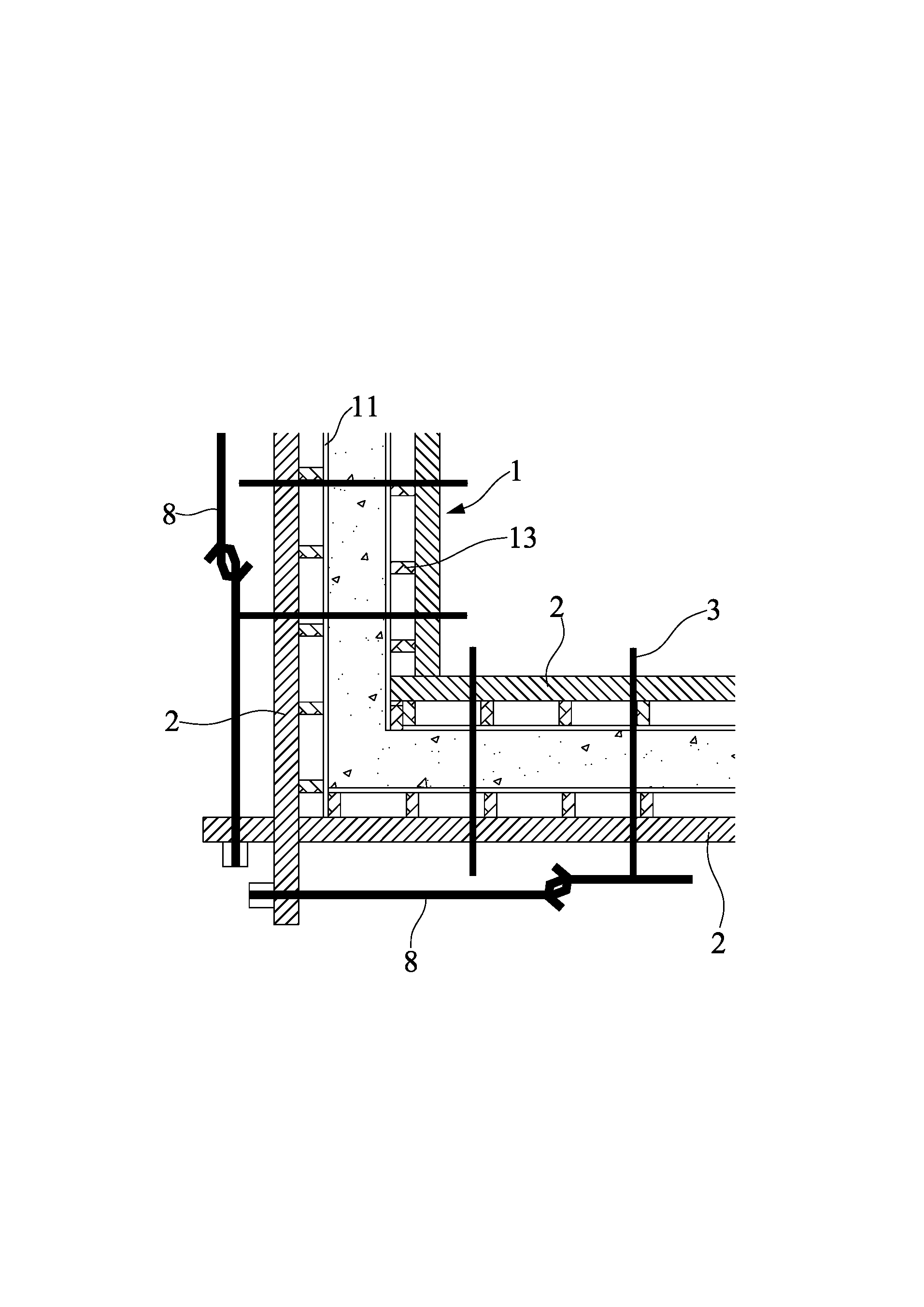

[0063] The structure of the stereotyped formwork 1 that this construction method adopts is as Figure 2A and Figure 2B As shown, it includes a panel 11, two tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com