Windproof-type overall steel bracket mounting method

An installation method and windproof technology, applied in the field of steel wrist arm, can solve the problems of inapplicability and installation requirements that cannot meet the installation requirements of the overall windproof steel wrist arm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0254] The present invention will be further described below in conjunction with specific examples, but they are not used to limit the scope of the present invention.

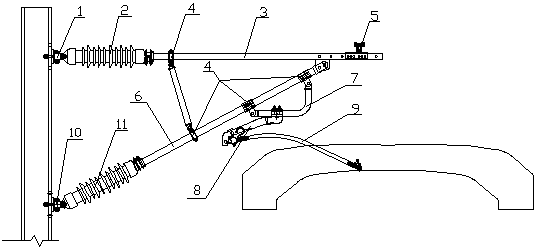

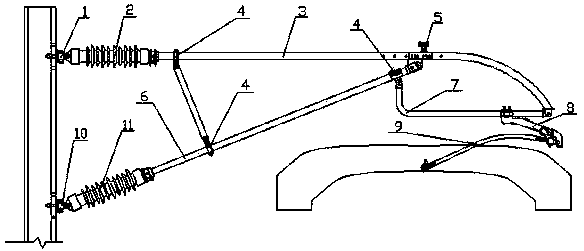

[0255] A method for installing a windproof integral steel wrist arm, comprising the following steps:

[0256] 1) First measure the basic parameters required when the windproof integral steel wrist arm is installed in a specific position, including the height measurement of the wrist arm base, the measurement of the slope of the pillar and the limit measurement;

[0257] 2) Establish a windproof integral steel wrist arm model

[0258] Establish a coordinate system. The origin of the coordinates is the intersection point of the horizontal plane where the midpoint of the rail surface connection line at the steel wrist-arm pillar is to the longitudinal centerline of the inner surface of the pillar. Line, the Y-axis selects the vertical line of the horizontal plane where the middle point of the rail-surface connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com