Power station generating set oil groove signal extension apparatus

A signal extraction and cable clamp technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of affecting signal transmission, difficult construction, long-term sealing, etc., to achieve good reliability, novel design, high sealing pressure level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

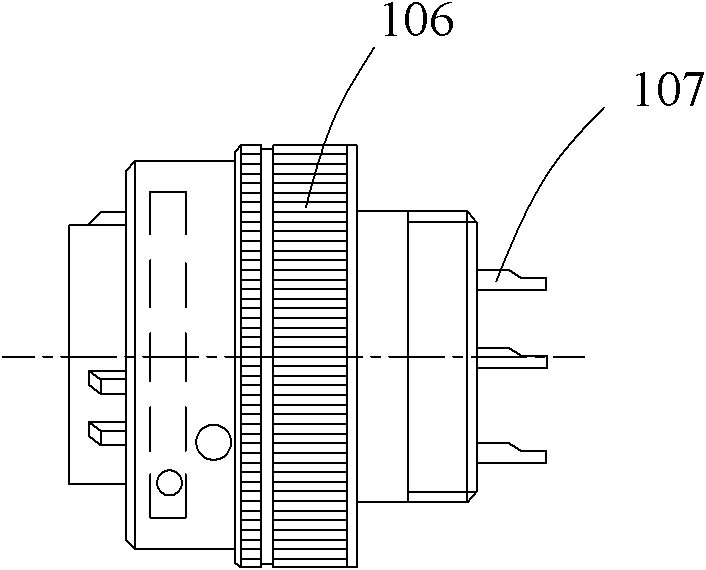

[0034] Figure 4 is a schematic structural diagram of a signal extraction device according to an embodiment of the present invention. Such as Figure 4 As shown, the signal extraction device 200 includes a base 210 and a panel 220 , and the base 210 and the panel 220 are sealed and connected to form an inner space 214 . Specifically, the base 210 is barrel-shaped and includes a circular bottom plate 211 and a side wall 212 extending along the periphery of the bottom plate 211 , and a flange 213 extends from an outer end surface of the side wall 212 . The panel 220 is installed in the step formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com