Compact adsorption dryer

An adsorption drying and desiccant technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of on-site replacement of adsorption containers, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

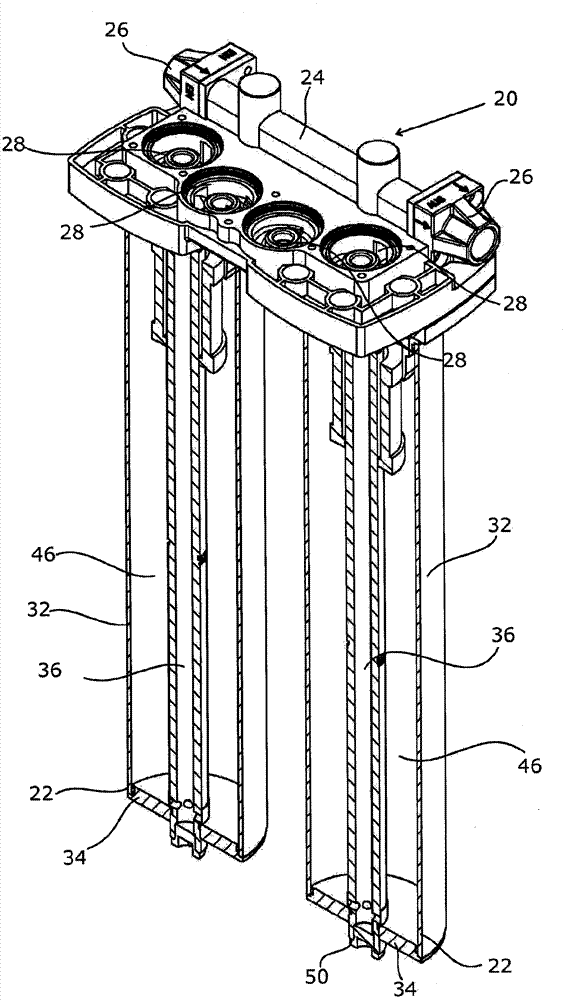

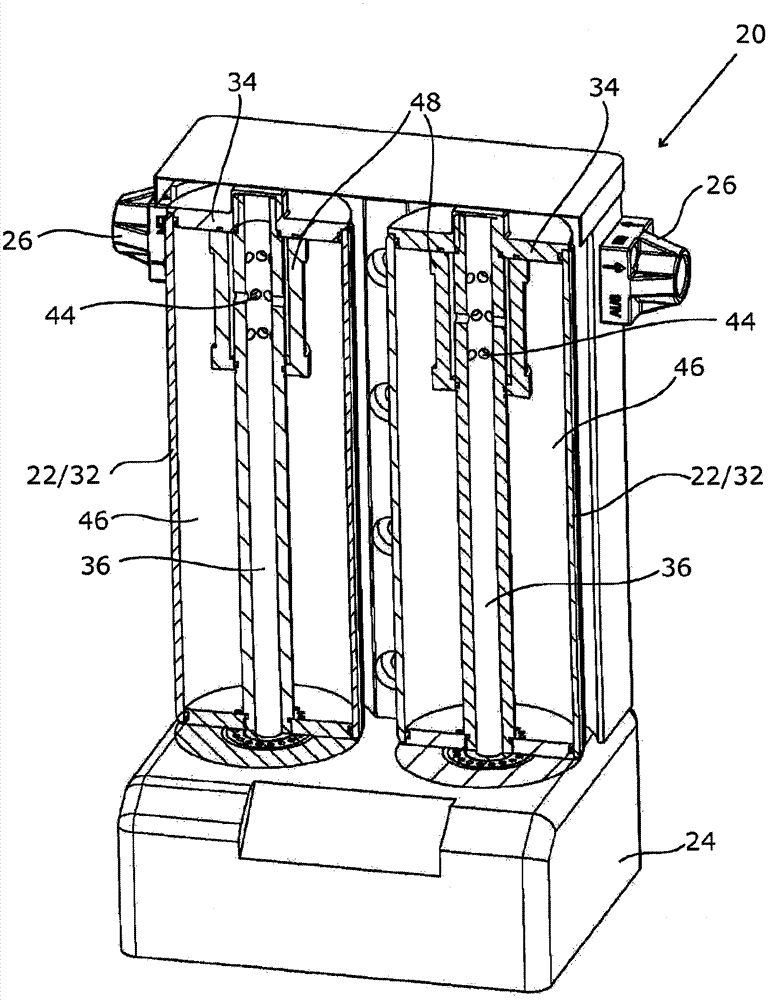

[0039] figure 1 and figure 2 Two different embodiment variants of the adsorption dryer 20 according to the invention are shown. Two adsorption containers or cartridges 22 according to figure 1 For hanging ground, according to figure 2 Then it is mounted vertically in the control head 24 . The cartridge 22 can also be arranged horizontally, and finally the cartridge 22 can be inserted into the control head 24 in various arbitrary positions and at any angle, however always depending on the embodiment of the control head 24 and the conditions on site.

[0040] The control head 24 additionally comprises a line connection 26 , a valve 28 and means, not shown, for connecting the control head 24 to the cartridge 22 . In the exemplary embodiment shown, four pilot-controlled diaphragm valves and a ball check valve are provided on the outlet side.

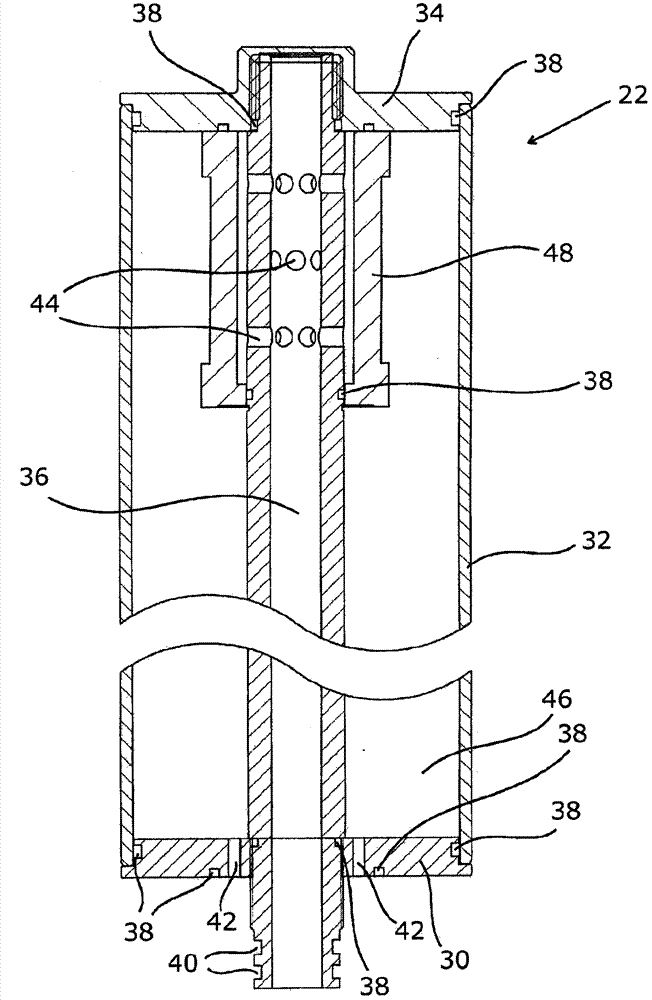

[0041] like figure 1 and Figure 4 As seen in , cartridge 22 has a cap 30 , a cartridge case 32 and a bottom 34 . A central tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com