Floor structural modules and assembling method thereof

A technology of structural modules and components, applied in the direction of building structure, construction, etc., can solve the problems of inability to realize the production of large-scale finished products, inability to adapt to the development direction of the construction industry, installation and production restrictions, etc., to ensure stability and accurate guidance. , the effect of enhancing the fixed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In conjunction with the accompanying drawings, the present invention is described in further detail.

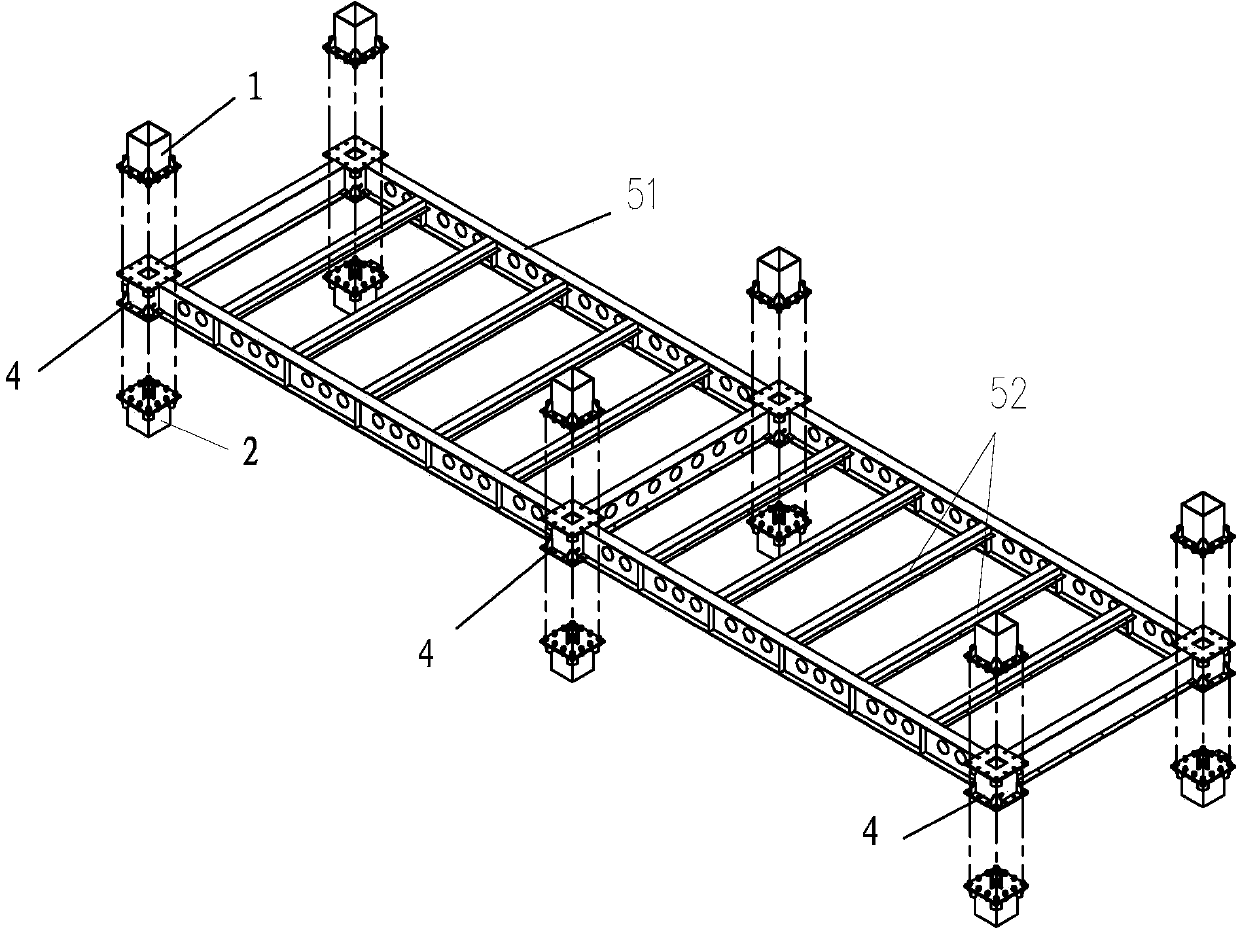

[0033] The main core of the present invention is to change the construction method of on-site construction and welding. All the assembled parts are formed into finished parts, and then they can be quickly installed on site, so that the structural modules are modularized and standardized.

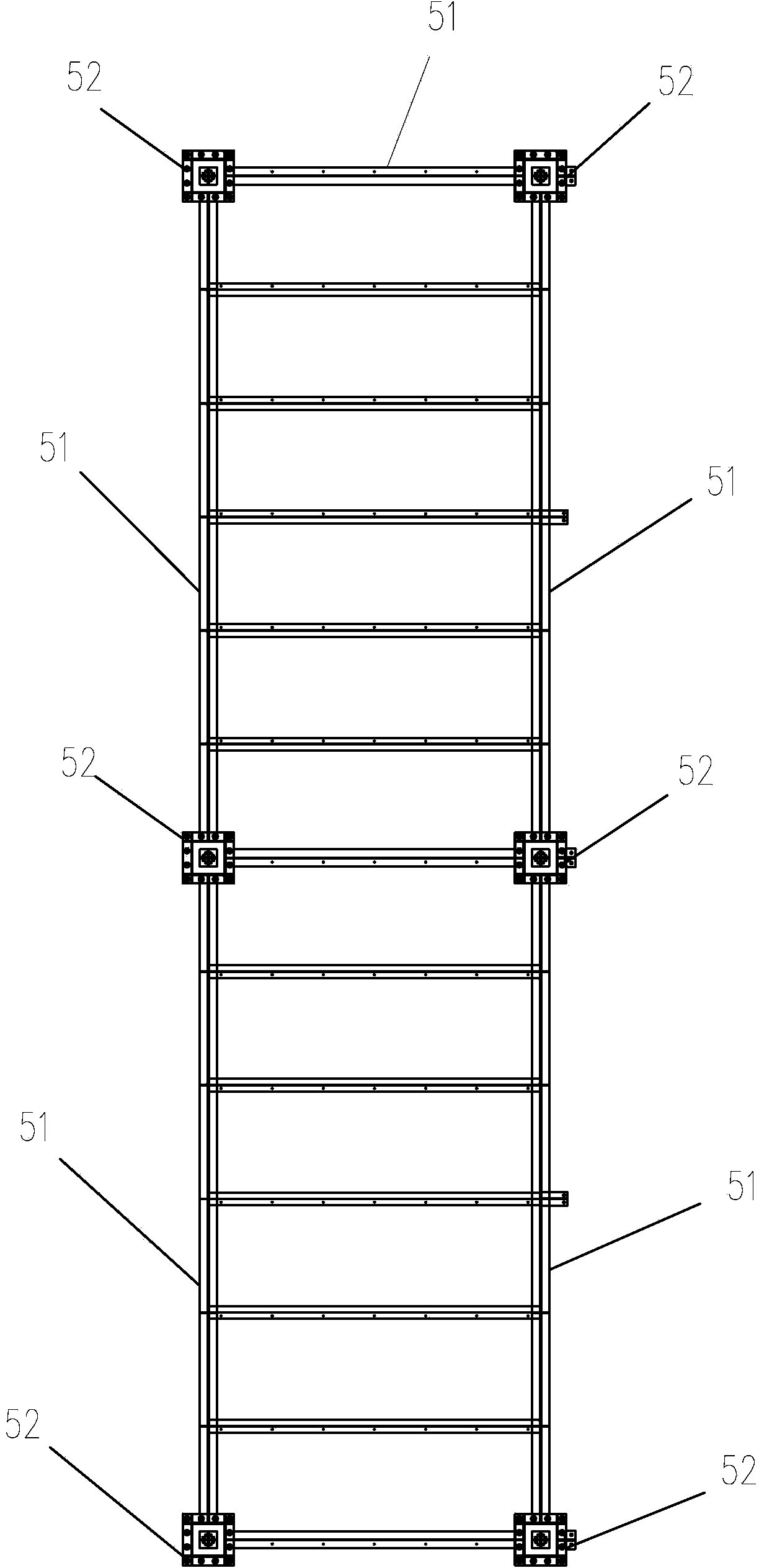

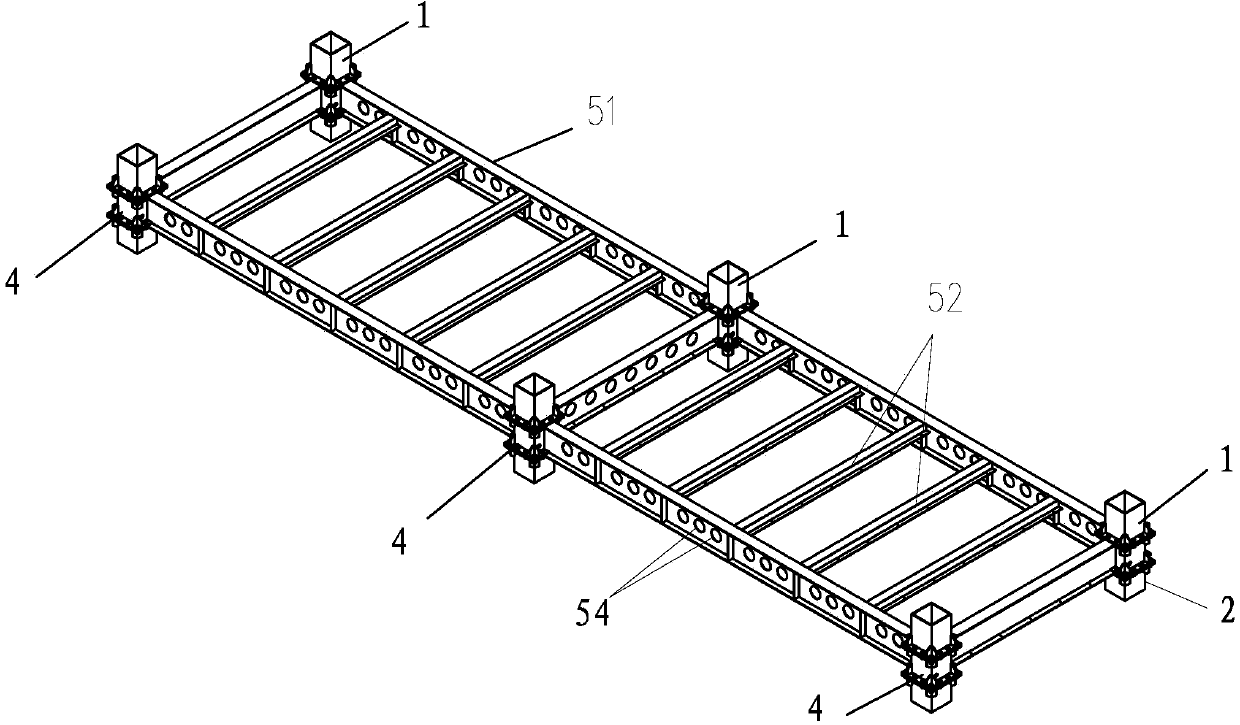

[0034] to combine Figure 1 to Figure 3 , the structural module 5 in the present invention is the key unit of the load-carrying building system, and mainly includes several main beams 51 , secondary beams 52 and a plurality of box-shaped components 4 . The main girders 51 are connected in four directions to form an outer frame, and box-shaped members 4 are used as connection points at each connection point. Each floor unit can be assembled by splicing the outer frame formed by a plurality of main girders 51 according to the actual area and shape. Then several secondary beams 52 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com