Integrated floor module and assembling method thereof

An integrated, floor technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of unable to adapt to the development direction of the construction industry, unable to realize the production of large-scale finished products, installation and production restrictions, etc., to reduce construction workers, Improve the precision and quality of processing, and enhance the effect of fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In conjunction with the accompanying drawings, the present invention is described in further detail.

[0036] The main core of the present invention is to change the construction method of on-site construction and welding, all the assembled parts are formed into finished parts, and then they can be quickly installed on site. Therefore, it is mainly to standardize the modularization of the floor system and the fixed connection nodes.

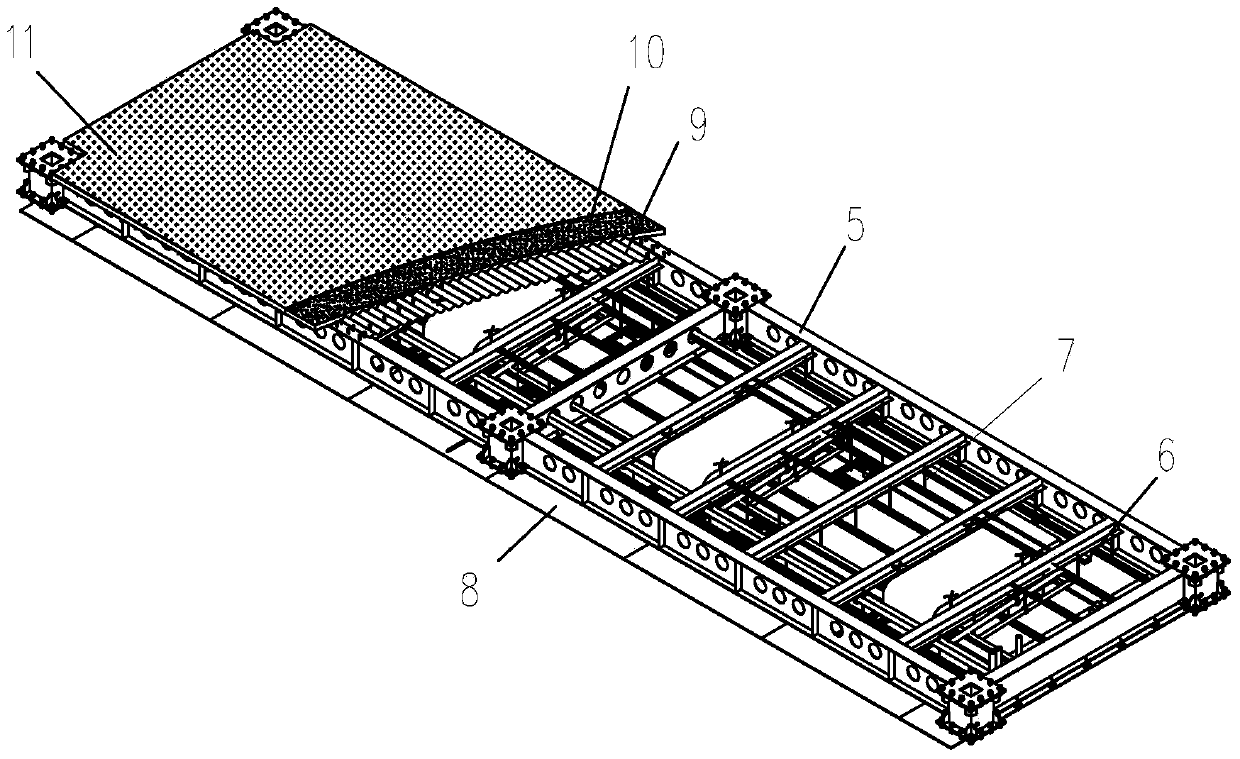

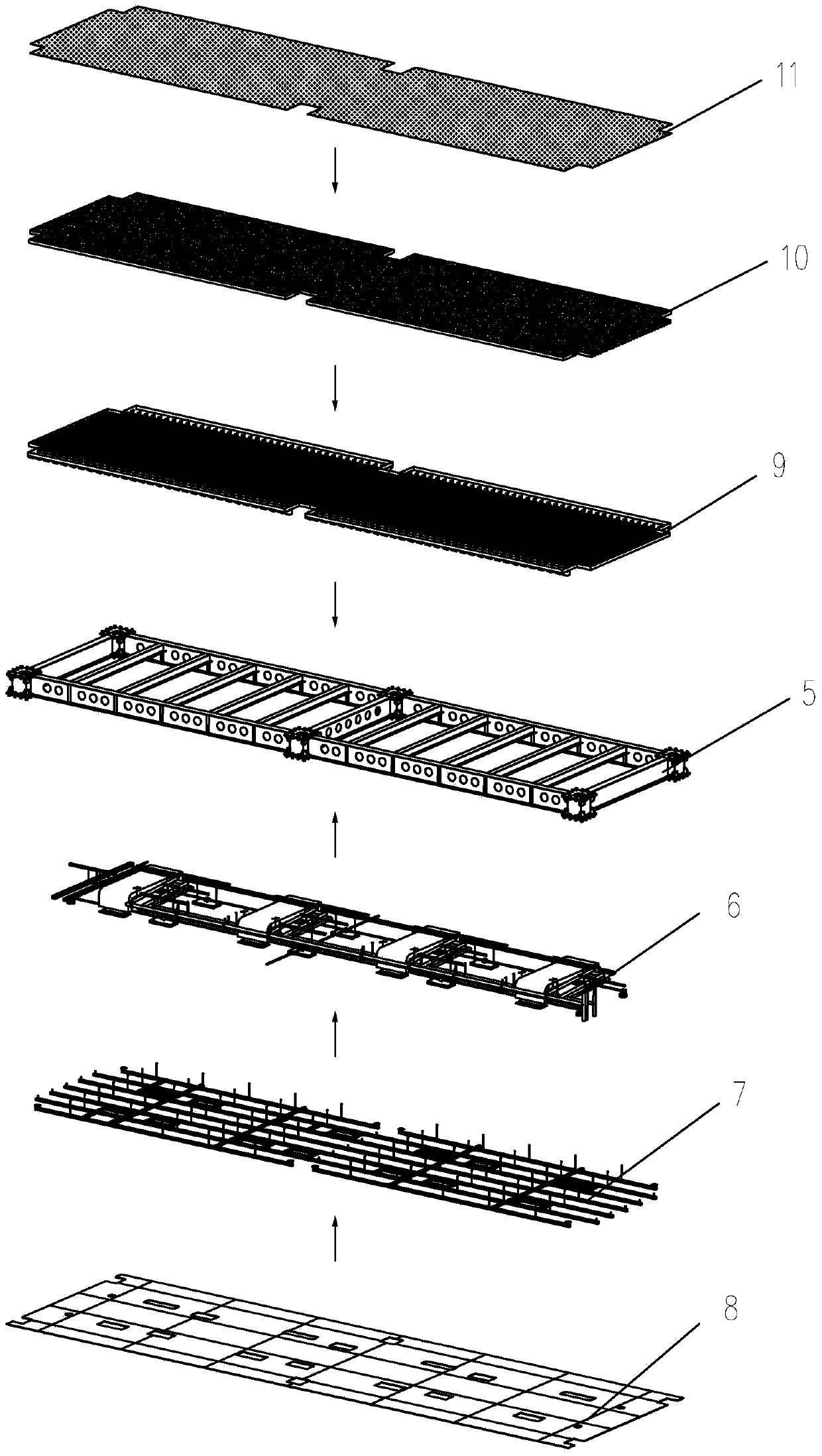

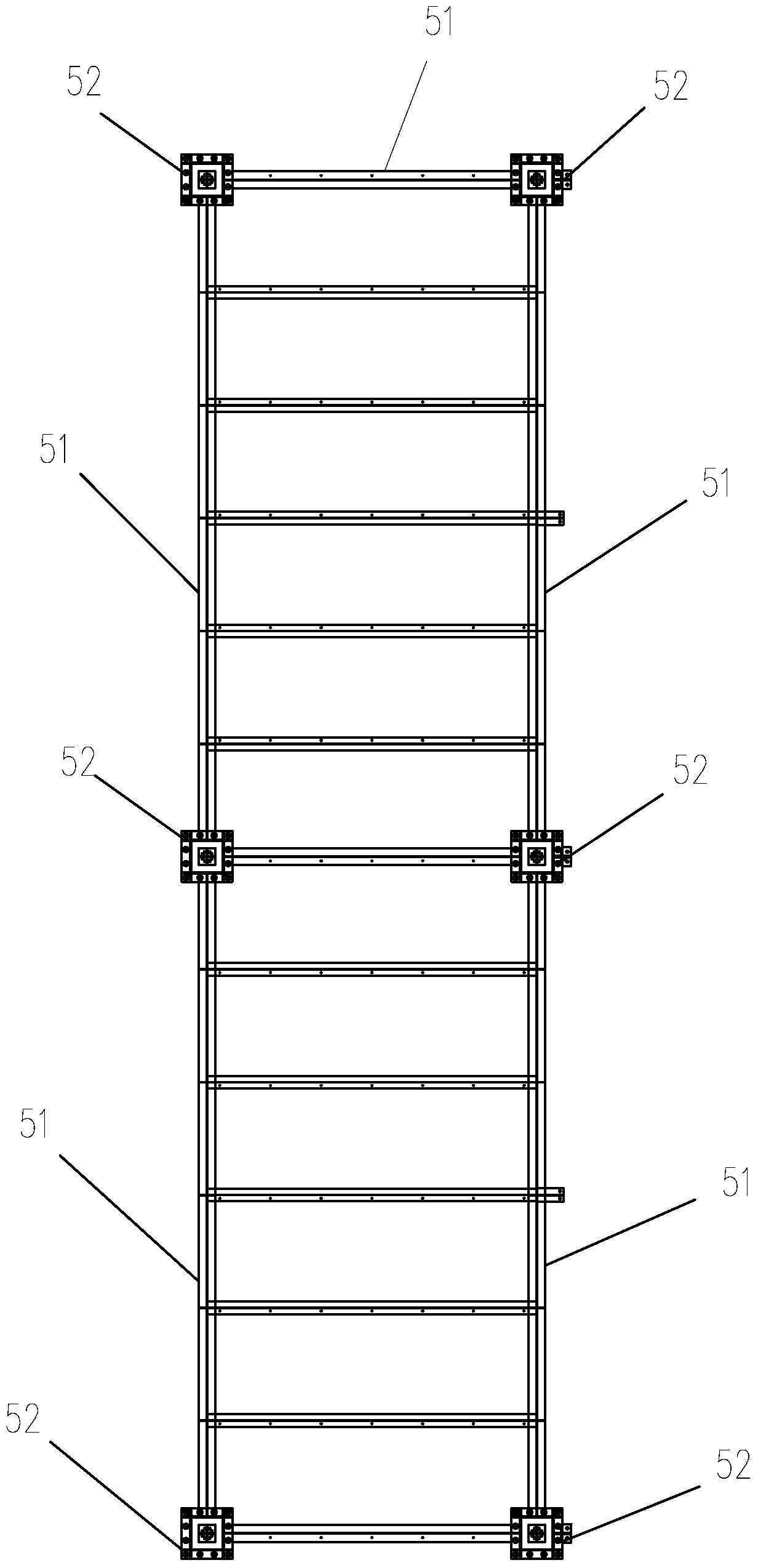

[0037] first as figure 1 , figure 2 As shown, the floor module proposed in this embodiment includes the structural module 5 of the floor, and the equipment system module 6, the ceiling joist 7, and the ceiling board 8 are sequentially assembled on the lower surface of the structural module 5 from inside to outside. A profiled steel plate 9 is installed on the upper surface of the structural module 5, the upper surface of the profiled steel plate 9 casts concrete 10, and the floor surface layer 11 is laid on the concrete surface, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com