Lightweight partition wall for prefabricated building

A construction, lightweight technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of long cycle, high cost, and more dust, so as to reduce the overall cost, improve the efficiency of on-site construction, and achieve a high degree of industrialization. integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

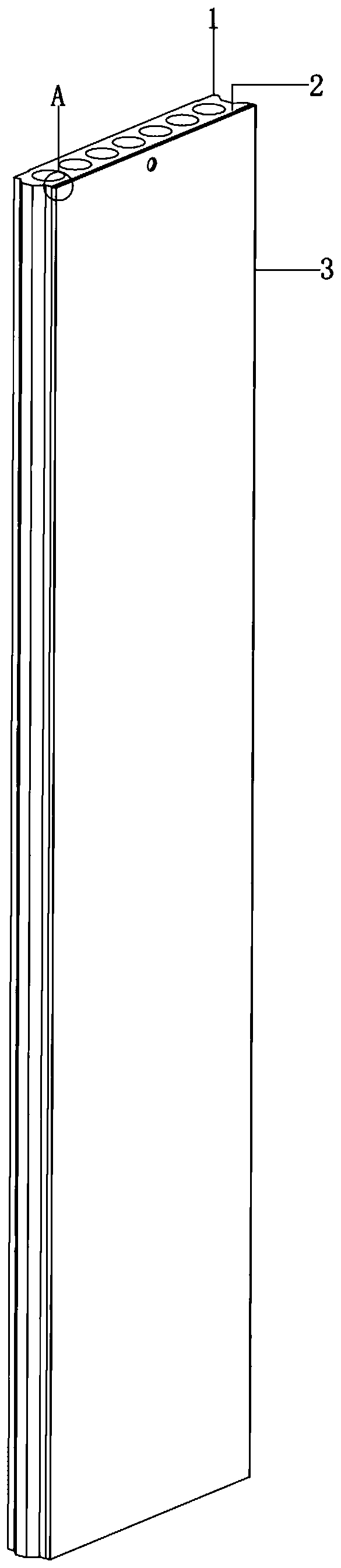

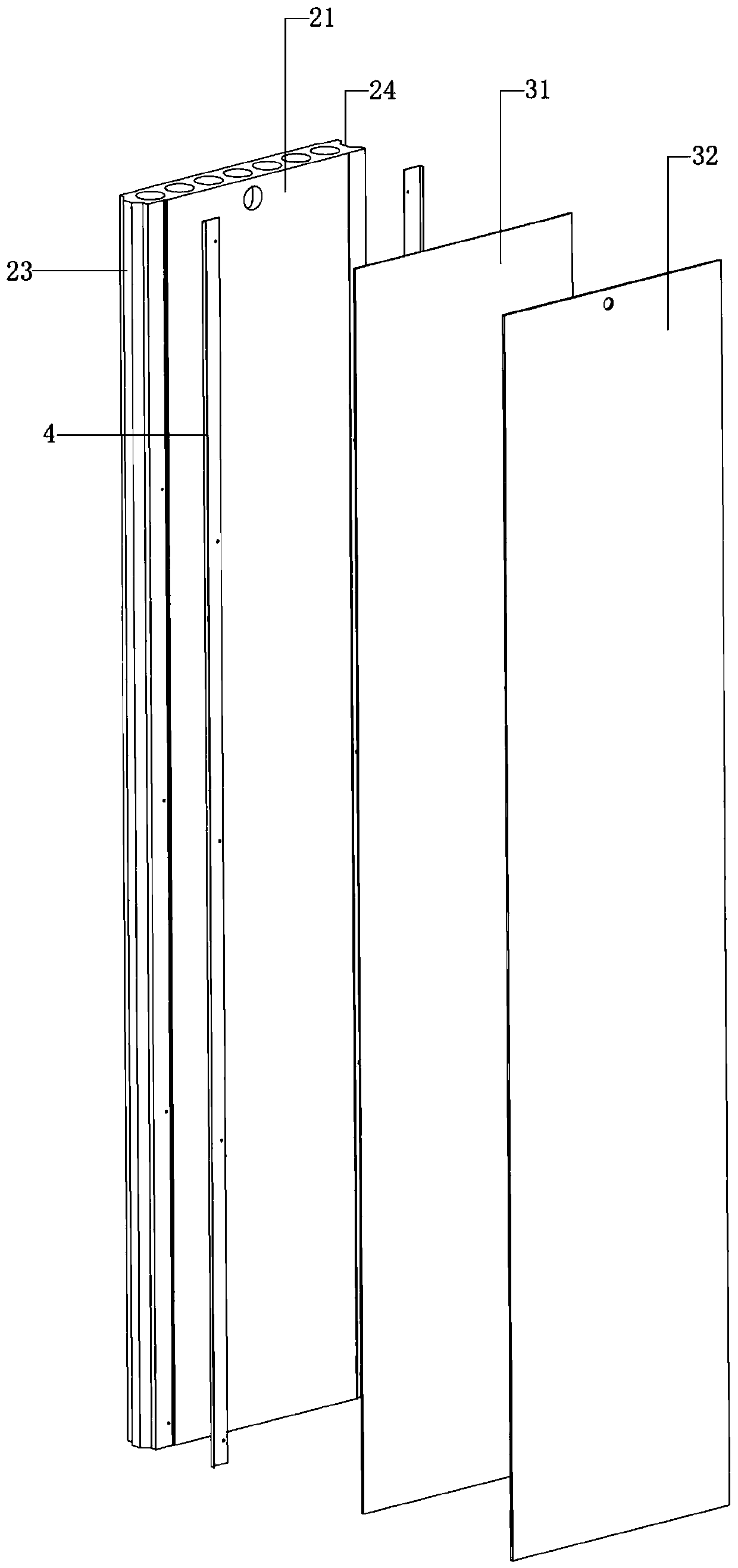

[0031] See Figure 1 to Figure 4 , The figure shows a lightweight partition wall for a prefabricated building provided by the first embodiment of the present invention, which includes a partition wall unit 1, the partition wall unit 1 is rectangular, and the partition wall unit 1 includes a lightweight wall 2 and surface layer 3. Circuit pipelines are embedded in the lightweight wall 2. The lightweight wall 2 can be a known lightweight wall such as GRC lightweight partition wall, and the surface layer 3 is fixedly laid on the front of the lightweight wall 2. 21 and / or the reverse side, the surface layer 3 includes a gypsum base layer 31 and a paint surface layer 32, the gypsum base layer 31 is fixedly laid on the front 21 and / or the reverse side of the lightweight wall 2, and the paint surface layer 32 is fixedly laid on the gypsum base layer 31.

[0032] The lightweight partition wall for prefabricated buildings provided in this embodiment adopts pre-embedded circuit cassettes a...

Embodiment 2

[0038] See Figure 1 to Figure 4 , The figure shows a lightweight partition wall for a prefabricated building provided in the second embodiment of the present invention. The rest is the same as that described in the first embodiment, except that the partition wall unit 1 is provided with multiple The partition wall units 1 are sequentially spliced along the width direction of the partition wall.

[0039] Specifically, see Figure 1 to Figure 4 A clip strip 23 or a slot 24 extending along the height direction of the lightweight wall 2 is provided on the side of the lightweight wall 2, and the clip strip 23 and the slot 24 are clamped to each other.

Embodiment 3

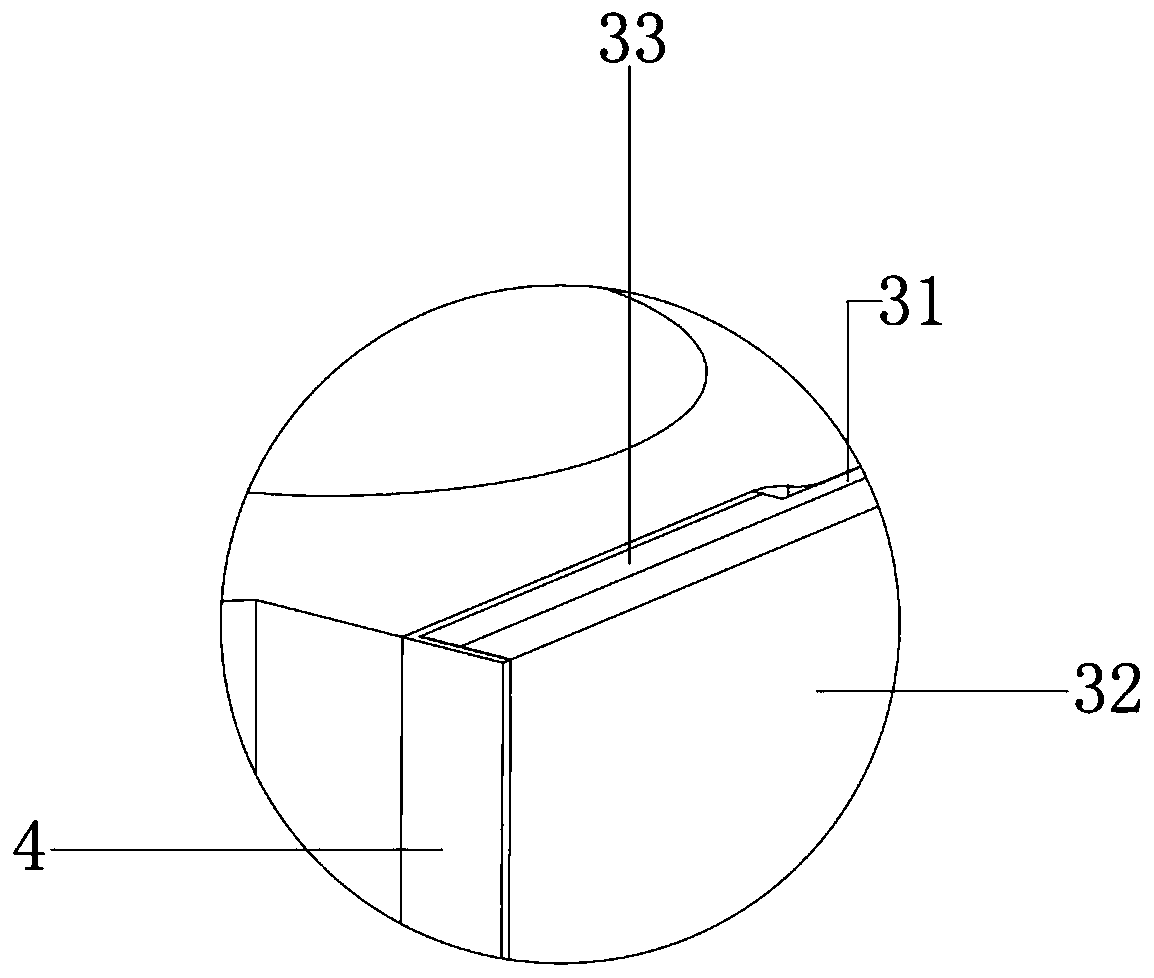

[0041] See Figure 1 to Figure 4 , The figure shows a lightweight partition wall for prefabricated buildings provided by the third embodiment of the present invention. This embodiment further makes the following as an improved technical solution on the basis of the foregoing embodiments: The side edges of the wall unit 1 are fixedly provided with aluminum corner protection strips 4. The cross section of the corner protection strips 4 is L-shaped, and the sides of the surface layer 3 are located inside the corner protection strips 4. At the same time, the back surface of the gypsum base layer 31 is provided with a convex strip 33 located inside the corner bead 4, and the convex strip 33 is parallel to the corner bead 4. Through the optimized arrangement of the above structure, it is possible to form a protective effect on the side of the partition wall unit, and prevent the side of the partition wall unit from being damaged during transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com