Double-rod well drilling machine

A frame and drill pipe technology, applied in the field of double-rod drilling rigs, can solve problems such as landslides, inconvenient disassembly and assembly, hidden safety hazards, etc., and achieve the effect of correcting verticality, convenient disassembly and assembly, and ensuring production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

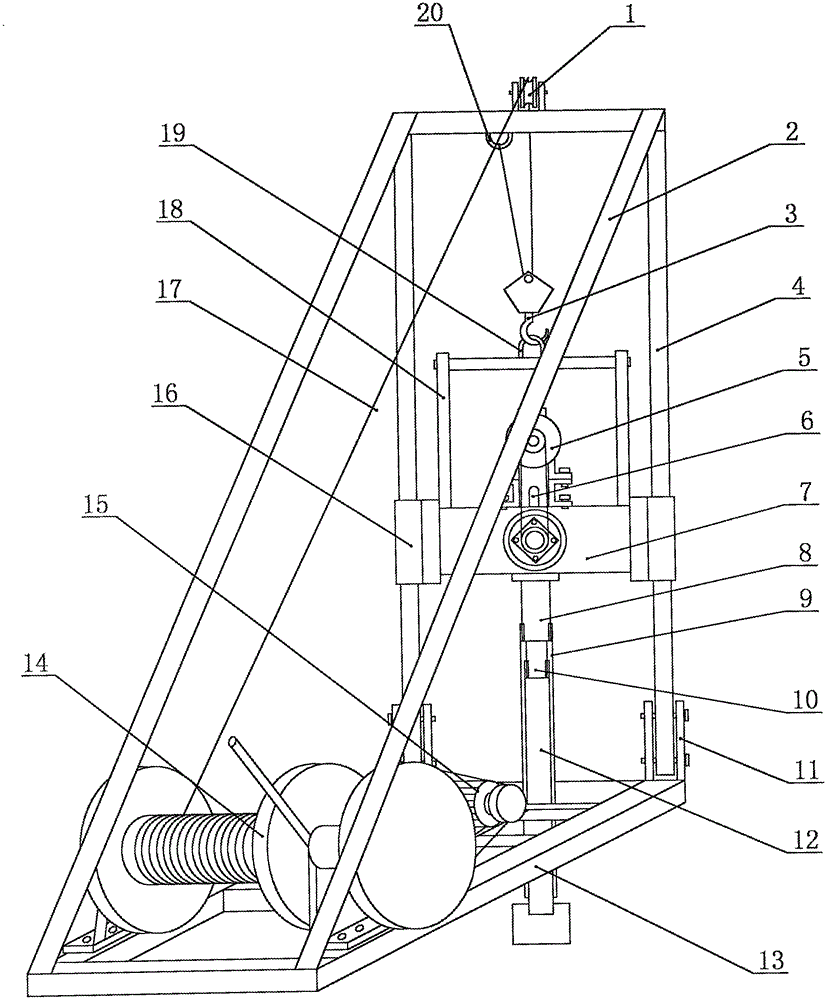

[0015] The utility model relates to a double-rod well drilling machine, which comprises a frame, a traction device arranged on the frame, a power head movably installed on the frame, and a drill pipe fixedly installed at the bottom of the power head.

[0016] As shown in the drawings, the power head includes a drilling head 7, movable sleeves 16 fixed on both sides of the drilling head 7, a motor 5 fixed on the top of the drilling head 7, a hitch 18 and a grouting pipe 6, and The drill rod seat at the bottom of the head 7, the motor 5 provides power for the drill head 7. Described drill rod base comprises outer drill rod base 8 and is located at the inner drill rod base 10 in outer drill rod base 8, and described drill rod comprises outer drill rod 9 and the inner drill rod 12 that is located in outer drill rod 9, and inner drill rod The outer diameter of the rod 12 is smaller than the inner diameter of the outer drill rod 9 . The inner drill rod 12 is threaded on the inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com