Design of hoisting slag hopper by utilizing shaft gantry

A technology of gantry cranes and slag buckets, which is applied in the design field of shaft gantry crane lifting slag buckets. It can solve the problems that the grabbing slag grabbing head is not dense, affects the progress of tunnel excavation, and has dangerous factors, so as to reduce the number of construction workers and reduce Potential safety hazards in construction and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

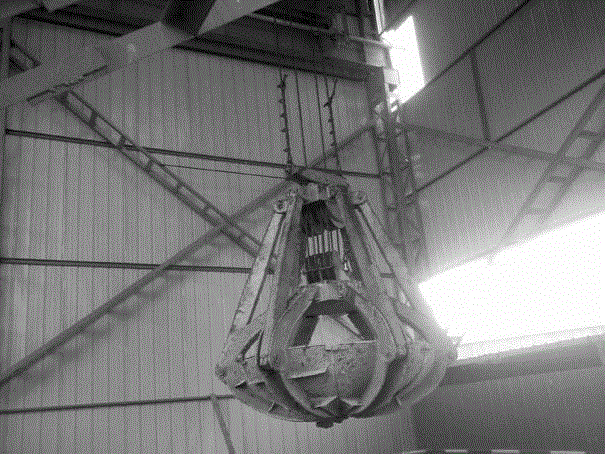

[0007] Shaft gantry crane lifting slag bucket design, such as figure 1 As shown, a 3m*2.5m*2m slag hopper is welded with a steel plate over 2cm in size, and the bottom of the slag hopper is designed with double doors that can be opened. For the steel wire rope of the hopper door, after the hopper door is closed, the primary and secondary hooks are hoisted at the same time, and after being lifted out of the shaft and transported to the slag yard, the secondary hook is lowered to open the hopper door, and the slag is unloaded to the slag yard, and the secondary hook is lifted to close the hopper door. After improving the design of the shaft slag hopper, the work efficiency of the shaft gantry derrick is improved during slag discharge, the number of construction workers is reduced, construction costs are saved, construction safety hazards are reduced, and the construction progress is also strongly guaranteed. The invention also has the advantages of simple and compact structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com