Automatic foundation pit support monitoring system

A monitoring system and foundation pit support technology, which is applied in foundation structure engineering, foundation structure testing, sheet pile walls, etc., can solve problems such as threats to foundation pit construction safety, collapse, deformation, displacement, etc., and reduce construction safety hazards. , reduce the measurement error, improve the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-6 The application is described in further detail.

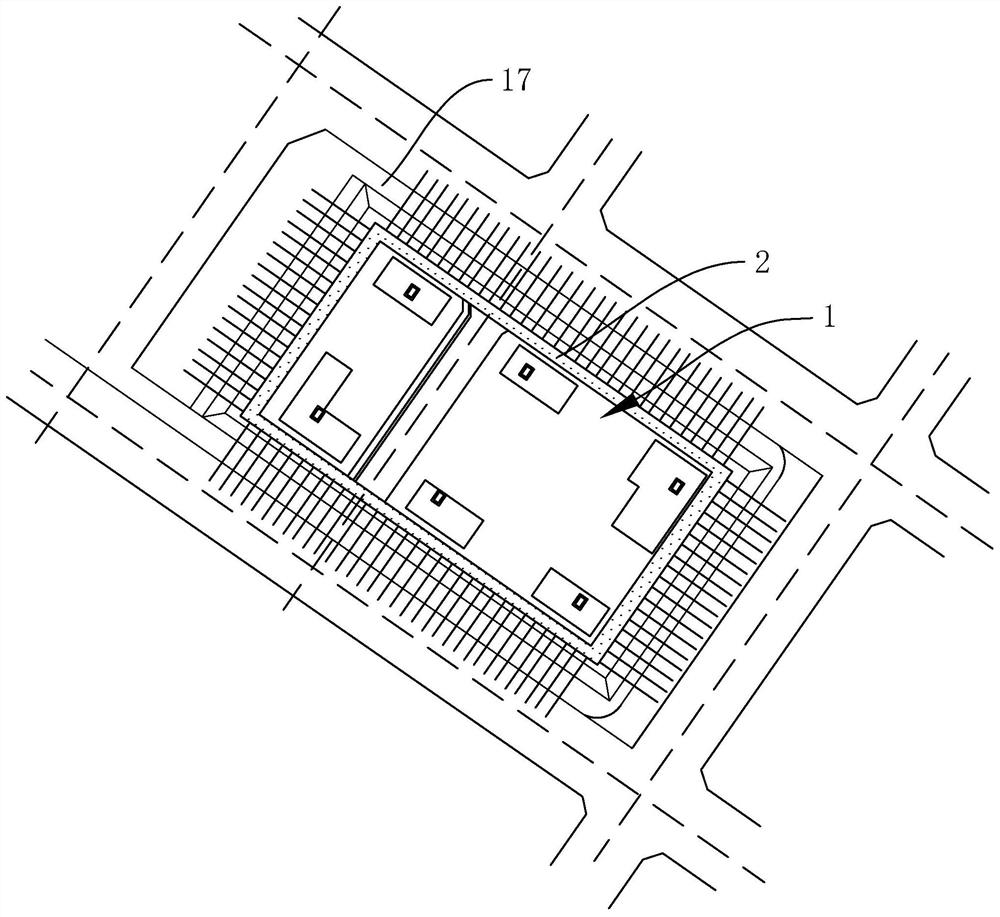

[0038] An automatic monitoring system for foundation pit support, referring to figure 1 , including an enclosure 2 for enclosing the pit wall of the foundation pit 1, wherein the enclosure 2 is formed by pouring reinforced concrete. An anchor cable axial force monitoring device is installed on the enclosure 2, and the anchor cable axial force monitoring device is used to monitor the stress variation of the slope body 17 around the foundation pit 1.

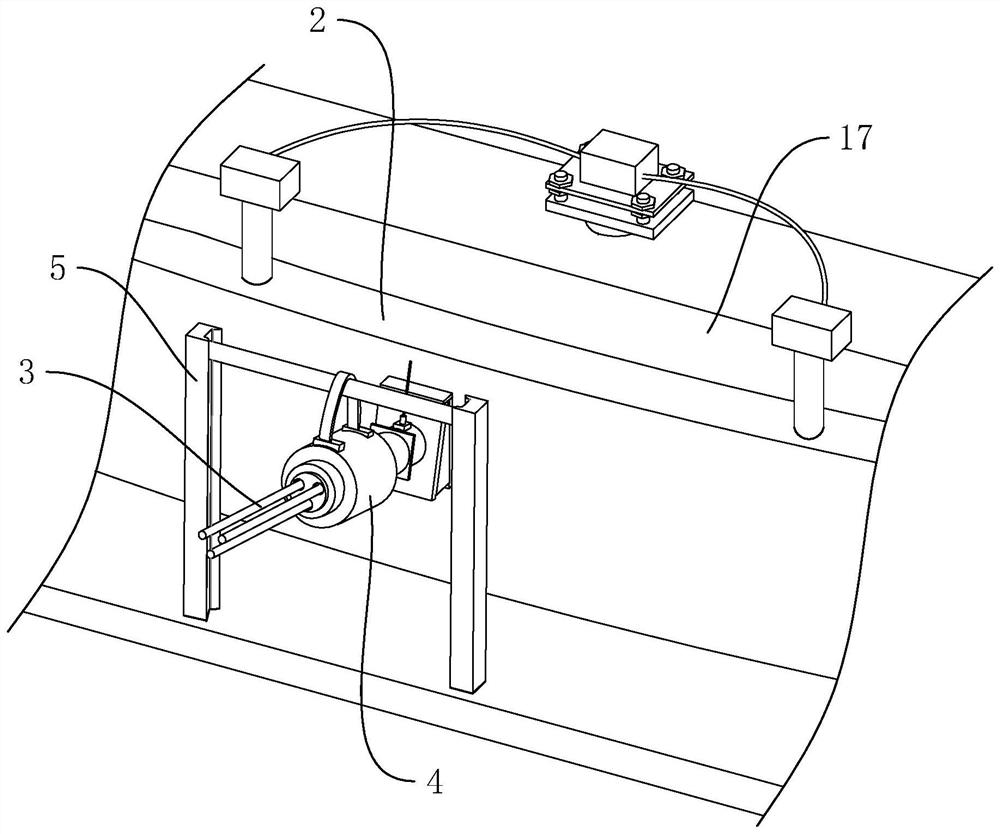

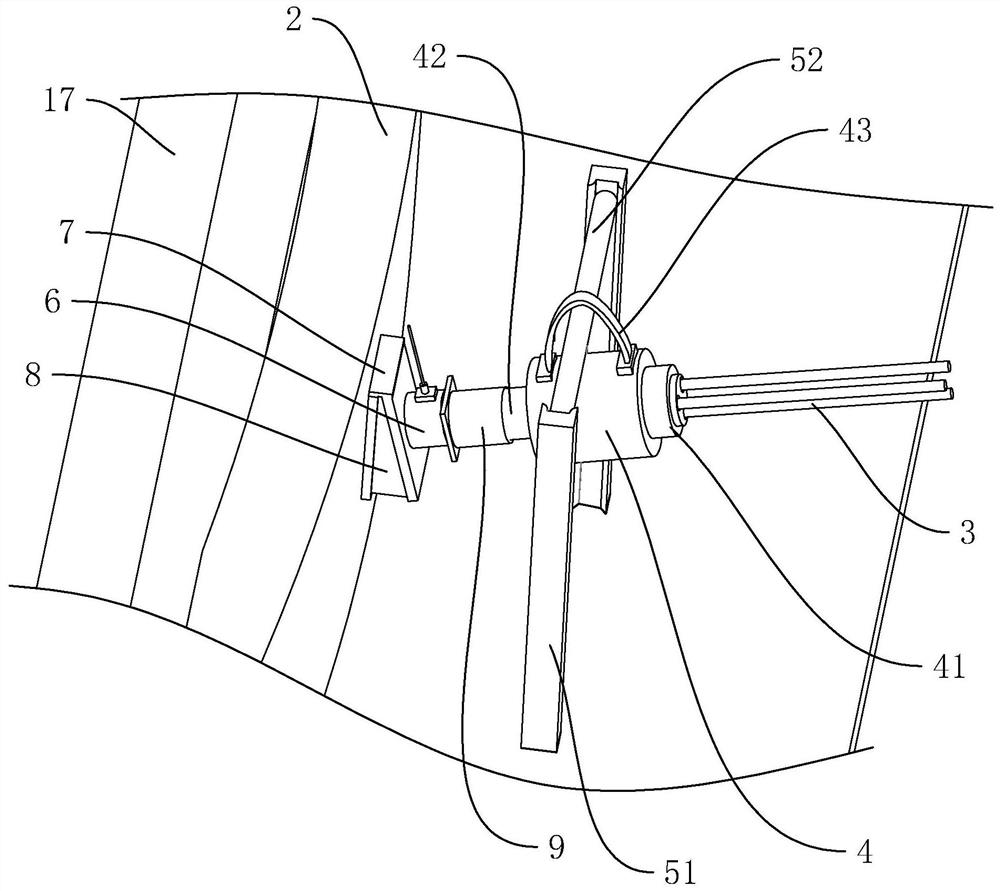

[0039]Specifically, refer to figure 2 and image 3 The anchor cable axial force monitoring device includes an anchor cable 3 inserted into the slope body 17 at one end and a tension mechanism for providing tension to the anchor cable 3. In this embodiment, the anchor cable 3 passes through the enclosure 2, and the tension mechanism is located at An end of the anchor cable 3 away from the slope body 17 . When the anchor cable 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com